Weird partial layer shift

-

Hello together,

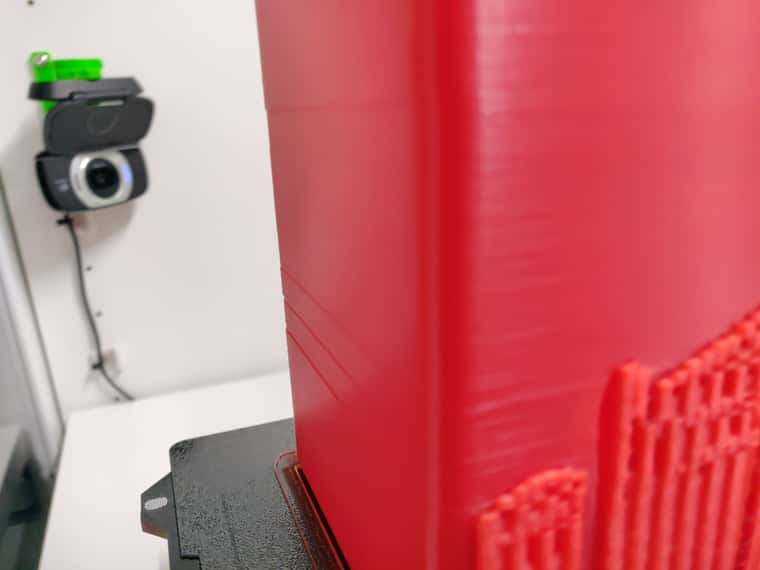

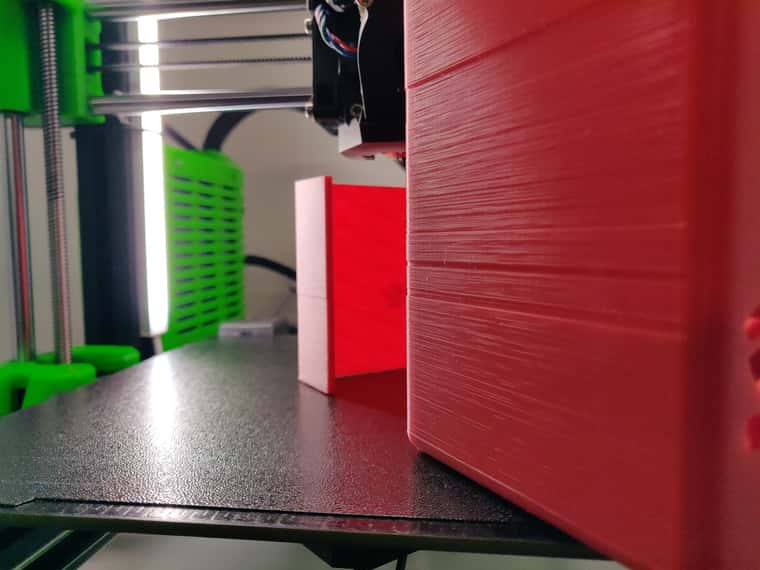

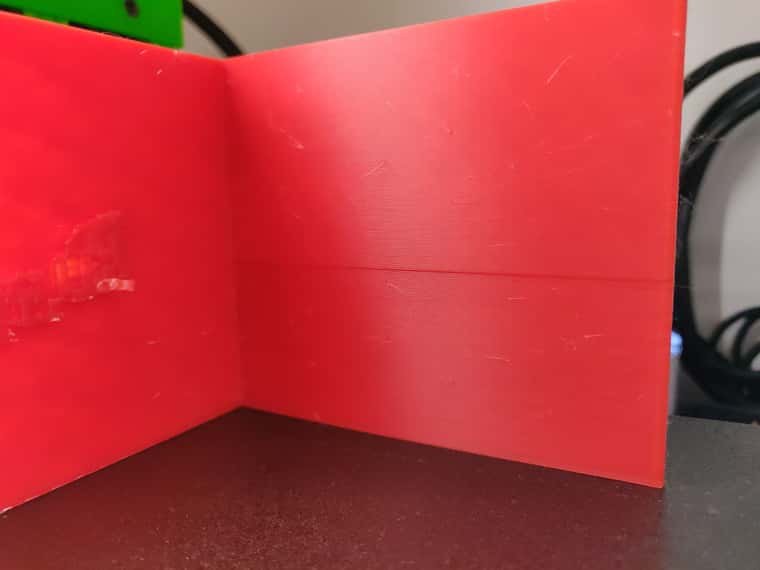

I have a little bit of a weird problem with layer shift only in Y-Direction.

First of all the 3D-Printers details:

Model: Caribou Duet 320

Board: Duet2 Wifi

Firmware Version: 3.5.3

Filament: Sunlu PLA (Hotend @195°C, Bed @55°C)

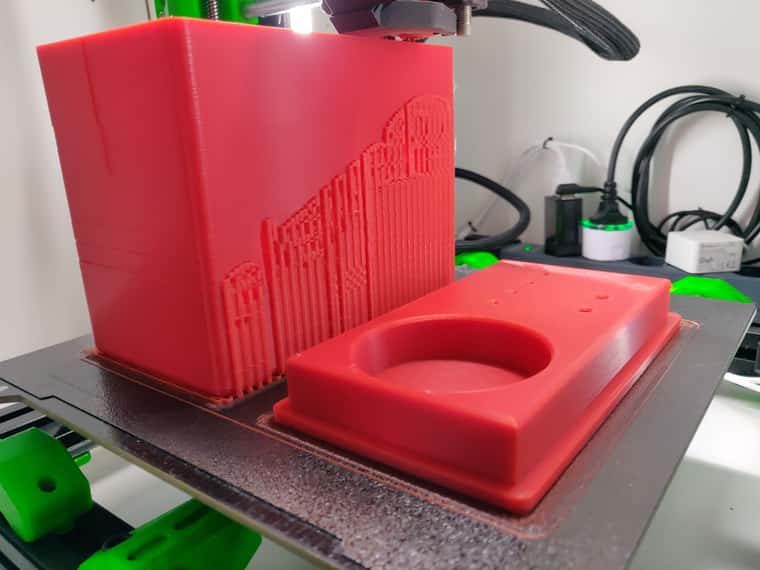

Slicer: Caribour Slicer 2.8.0 (based on PrusaSlicer)This is my first 24h+ print job.

The part is also so far my biggest and heaviest one.

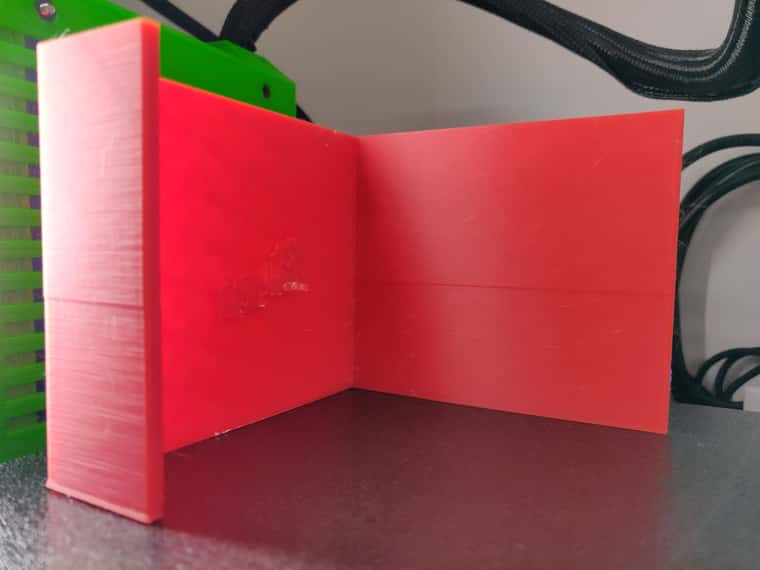

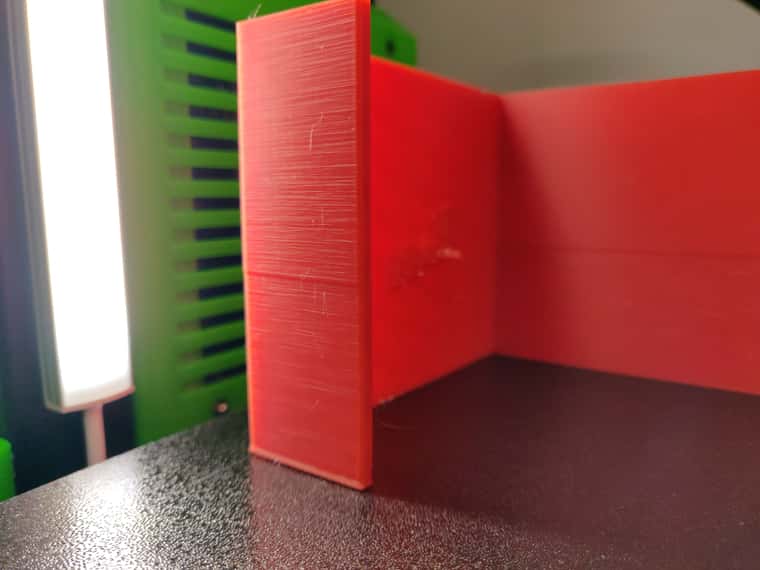

With all print jobs before I do not have a issue like this.Some layers are shifted toward the back side, but comming back after a couple of layers to the original value.

I do not see this shifts when checking the g-code with g-code viewer.So far I have checked belt tension recently, it is within tolerance.

On the Y-Axis I use a MT-1704HSM168RE (also known as MT-1704HSM168A) stepper with the following values in config.g:

; ========================================================================================================= ; drives ; ========================================================================================================= ; M569 P0 S1 F11 ; physical drive 0 goes forwards - x-axis M569 P1 S0 F8 Y3:2 ; physical drive 1 goes backwards - y-axis ; M569 P2 S1 F10 ; physical drive 2 goes forwards - z - left M569 P3 S1 F14 ; physical drive 3 goes forwards - Extruder M569 P4 S1 F10 ; physical drive 4 goes forwards - z right ; ; motor configuration ; M584 X0 Y1 Z2:4 E3 ; set drive mapping M671 X-43.5:293.5 Y0:0 S2.00 ; leadscrews at left (connected to Z/drive 2) and right (connected to E1/drive 4) of x axis ; ; set microsteps and steps / mm ; ========================================================================================================= ; M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z400.00 ; set steps per mm M98 P"0:/settings/Set-E-Steps.g" ; set esteps ; ; set motor currents ; ========================================================================================================= ; M906 X1250 Y1250 Z650 E650 I40 ; set motor currents (mA) and motor idle factor in percent ; M84 S60 ; set idle timeout ; ; set speeds ; ========================================================================================================= ; M201 X3000.00 Y3000.00 Z100.00 E500.00 ; set accelerations (mm/s^2) M203 X18000.00 Y18000.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M204 P500.0 T500.0 ; set print and travel accelerations (mm/s^2) M566 X480.00 Y480.00 Z48.00 E300.00 ; set maximum instantaneous speed changes (mm/min) ; set global.x_accel = move.axes[0].acceleration ; save accelerations (mm/s^2) set global.x_jerk = move.axes[0].jerk ; save maximum instantaneous speed changes (mm/min) ; set global.y_accel = move.axes[1].acceleration ; save accelerations (mm/s^2) set global.y_jerk = move.axes[1].jerk ; save maximum instantaneous speed changes (mm/min) ; M564 H0 ; allow unhomed movement!

Should I raise the motor current a little bit or what might be the solution here?

Thanks a lot,

Regards Kubunter -

@Kubunter I think, the motor current isn't the problem as the layer shift is coming back.

Are these shifts also visible on the other side of the part? Or only at one side? -

@cosmowave Thanks for your reply.

The shifts are visible through the complete layer. -

@Kubunter Could it be a mechanical problem? When you print another model with that height, do you also have layer shifts?

-

@cosmowave Thats what I need to test today.

I have printed parts who were higher, but all of them where mainly orientated in X-Axis.

Maybe this influences also the layer shift.

I believe I do not see the shifts on these parts.I will leave a reply once test is done.

-

@Kubunter It's interesting that it goes back to the original position after the shift. Skipped steps don't usually do that. I'd think this is more indicative of a very slightly loose belt pulley on the Y motor, though I'd expect more shifts than just a couple.

Ian

-

@droftarts Thats what I also think about after my test print yesterday.

But so far I was able to reproduce the shift.

The test print was shorter on the Y-Axis (that is maybe why the shift is not that noticeable than on the print before).

Additional the Z-Axis position when it appears was lower.

This time it looks like the shift remained.

But so far I do not understand why it needs a couple of mm (on the last print 32.2mm) to appear.

Maybe it depends on the weight of the printed part, leading to the conclusion that pulley might be slightly loose.I will check belt tension and pulley assembly on the stepper motor shaft, then I will repeat the last testprint.

Thanks a lot,

Regards Kubunter -

Good morning,

so yesterday I checked the pulley, both worm screws were absolutely tight, no movement of the pulley on the motor shaft at all.

I reduced the Y-Axis belt tension a little bit from 115 to 90Hz.

I printed a test part, the same layer shift in 2 layers appears.But then I recognized, that the layer shift happens in a layer where some letters are extruded through the part and at exactly the layer where I see the shift, the extruded letters have a damage.

After this i started up Fusion and removed the letters from the test part.

The next test part without the letters comes out absolutely smooth without any layer shift.So is it possible that the nozzle collides with small printing errors, leading to a shift of the Y-Axis?

Thanks a lot,

Regards Tobias -

@Kubunter said in Weird partial layer shift:

So is it possible that the nozzle collides with small printing errors, leading to a shift of the Y-Axis?

That can be. But normally when that happens, the shift isn't "comming back" and remains for the rest of the print.

But nice, that you've found the problem!

-

@Kubunter said in Weird partial layer shift:

But then I recognized, that the layer shift happens in a layer where some letters are extruded through the part and at exactly the layer where I see the shift, the extruded letters have a damage.

If that's the case, I would think that it is an extrusion issue, possibly with the nozzle slowing down when it prints the letters, and when it speeds back up there's a lag in extrusion. If that's the case, try tuning pressure advance.

It could also be a slicing problem. Maybe there's hole in the mesh so the Gcode is generated incorrectly, or the text is messing up the Gcode generation in another way. Can you see the shift in the Gcode preview?

Ian

-

@droftarts I do not see a hole or an error when checking the letters with a G-Code Viewer.

I will take a look at my pressure advance settings.

Thanks a lot!

-

@Kubunter Are there many retracts when printing the letters?