Measuring the heating rate (M307 R parameter)

-

@oliof its a dry box for filament so a small chamber

-

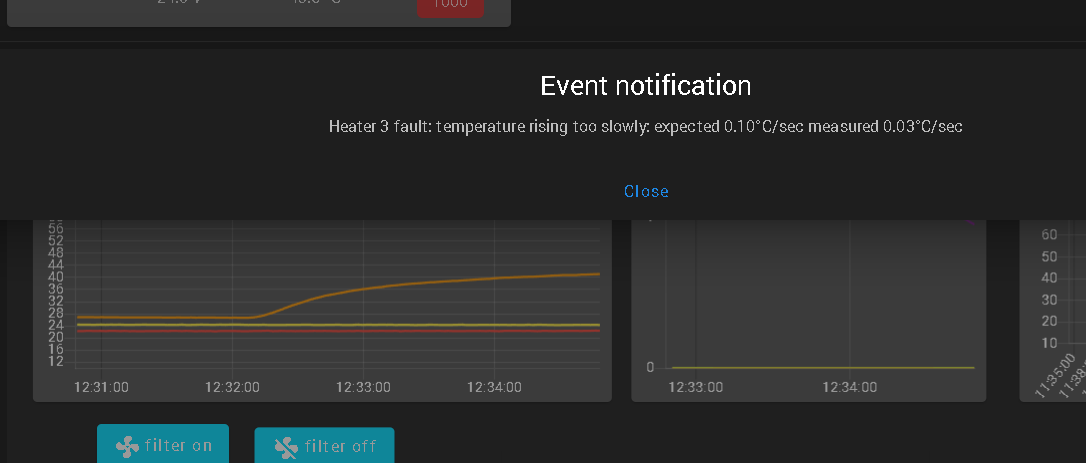

@moth4017 here is a better graph with a larger time scale, the PWM on the heater is still at 100%

-

@moth4017 Do you even need PID control over that heater? Maybe bang-bang mode would provide good enough control? But having said that I'm not sure if the heating rate etc. is still needed for the protection features or not when bang-bang is used?

-

@gloomyandy said in Measuring the heating rate (M307 R parameter):

@moth4017 Do you even need PID control over that heater? Maybe bang-bang mode would provide good enough control? But having said that I'm not sure if the heating rate etc. is still needed for the protection features or not when bang-bang is used?

But would it matter if protection features were disabled? It's struggling to reach 40 Deg C so if a MOSFET failed fully on, nothing bad is going to happen.

-

@deckingman it will get to 70C if i keep resetting it, i do have a thermal fuse on the heater at 80C , and its all made of poly carbonate

-

@moth4017 from what I understand, PTC heaters can be hard to characterise, as their heater profile is more non-linear compared to normal heaters. I’ve asked @dc42 if any improvements have been made following his comment here https://forum.duet3d.com/post/241598, but I’m not aware of any.

Ian

-

@droftarts cheers i see dc42 is doing some support in v3.4 :).

it needs a bang bang with a cooling check for saftey,

eg demand heat 70C

heat to 30C ,then cool check if cooling, heat to 40c then cool , check if cooling etc etcthis way if the heater is in runaway can alarm or switch off

-

@moth4017 said in Measuring the heating rate (M307 R parameter):

@deckingman it will get to 70C if i keep resetting it, i do have a thermal fuse on the heater at 80C , and its all made of poly carbonate

Sure - so the maximum it could get to is about 10 to 15 degrees above what domestic hot water or heating runs at and well below the Tg of polycarbonate or any filament that you might have inside the box. My point is that even in a thermal runaway situation, it isn't going to be a fire hazard so it won't be the end of the world if you don't have that additional protection.

-

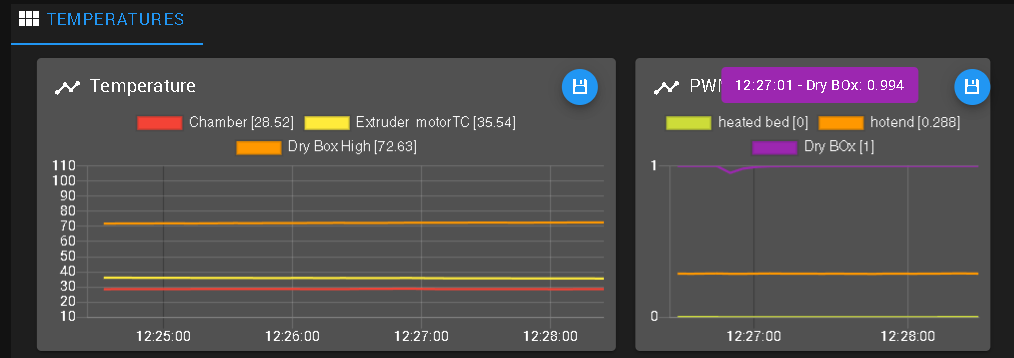

@deckingman i ran the chamber up to the max it could maintain which was 46C above ambient today ambient 25C max the dry box could get too was 72.69 C with a 100W heater , going to upgrade to a 300W heater maybe the PID will work better with this.

-

@moth4017 I'm confused. You said in your OP that the heater was 350 Watts. Now you say it's 100 Watts and that you are going to try 300 Watts.

-

@deckingman i thought it was , i checked the part number today , it was quite surprised, ive just ordered a 300W .

-

@moth4017 So it seems that your woes were all due to the fact that you had an under powered heater. For sure, changing it should give a steeper rate if heating and alow PID tuning to work.