Issues with integrated closed loop steppers

-

Hi all,

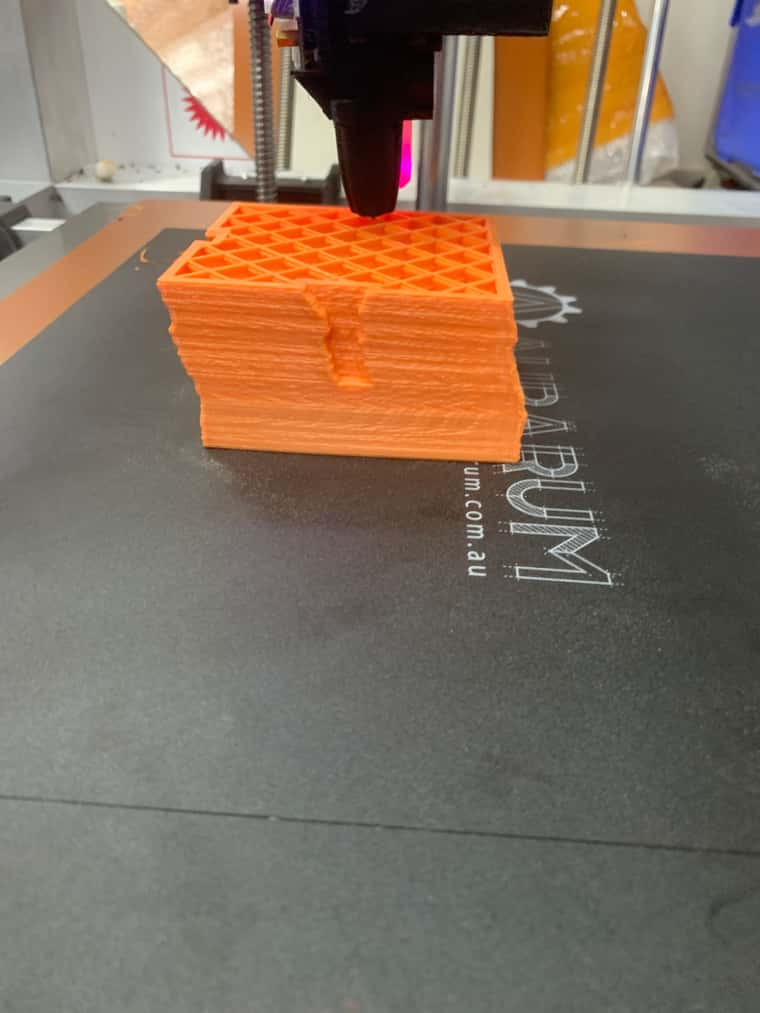

having issues big time with the drigting of the closed loop integrated steppers.

6XD + 1XD + 1LC

2 motors on the Y and 1 on the X

4 on Z

tried different timing and the result is still the same

Tried 3.4.6 and 3.5.0RC2 firmware - no difference.

Mechanically there is no play in the system - all looks nice and tight

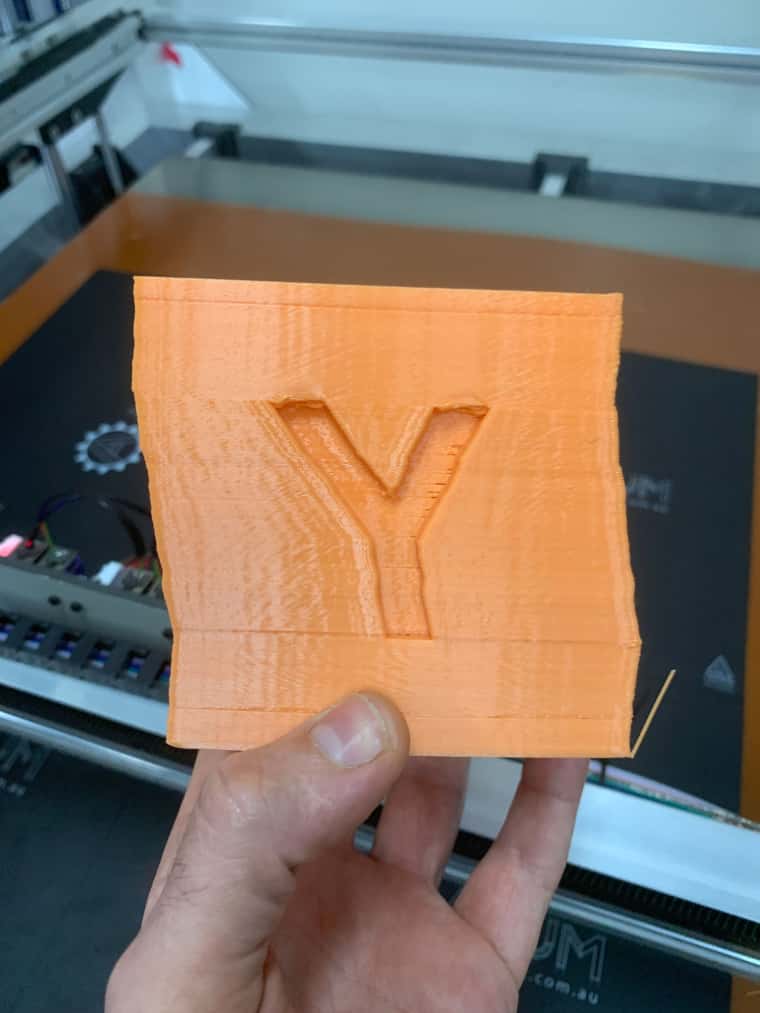

It is not too bad on X, but Y is just out of this world.

Any ideas?

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Giga Vega" ; set printer name ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet M575 P1 S0 B57600 ; Drives M569 P43.0 S0 T8:8:8:8 ; physical drive 121.0 goes forwards M569 P20.0 S1 T8:8:8:8 M569 P122.0 S0 T8:8:8:8 ; physical drive 0.1 goes forwards M569 P0.0 S1 T8:8:8:8 ; physical drive 0.2 goes forwards M569 P0.1 S1 T8:8:8:8 M569 P0.2 S1 T8:8:8:8 M569 P0.3 S1 T8:8:8:8 M569 P121.0 S0 D3 V40 ; physical drive 0.3 goes forwards M584 X20.0 Y122.0:43.0 Z0.0:0.1:0.2:0.3 E121.0 ; set drive mapping M671 X-180:-180:1100:1100 Y40:1100:1100:40 S14 M350 X16 Y16:16 Z16 E16 I1 ; configure microstepping with interpolation M92 X60.25 Y15.06 Z3000 E400.00 ; set steps per mm M566 X1000.00 Y1000.00 Z5 E10000.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z250 E10800.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z25 E2000.00 ; set accelerations (mm/s^2) M906 Z2000 E600 ; Axis Limits M208 X0 Y0 Z-1 S1 ; set axis minima M208 X1000 Y1000 Z1000 S0 ; set axis maxima M564 H0 ; Endstops M574 X1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin M574 Y1 S1 P"!io4.in" M574 Z1 S2 ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"121.^io0.in" H5 F5200 T5000 S0.25 ; set Z probe type to bltouch and the dive height + speeds G31 P300 X-30 Y5 Z3 ; set Z probe trigger value, offset and trigger height Increase Z number if the nozzle is too far M557 X50:500 Y25:500 S150 ; Heaters ;M140 H-1 ; disable heated bed (overrides default heater mapping) M308 S1 P"121.temp0" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S350 ; Fans M950 F1 C"out6" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 S1 ; set fan 1 value. Thermostatic control is turned off M950 F1 C"out5" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 S1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"121.out2" Q500 M106 P2 T45 H1 M950 F3 C"121.out1" Q500 ; create fan 0 on pin out3 and set its frequency M106 P3 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M376 H2 ; Tools ; Tools ; Tools M563 P0 S"Left Extruder" D0 H1 F3 ; define tool 1 M568 P0 S0 R0 A0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined T0 M376 H2