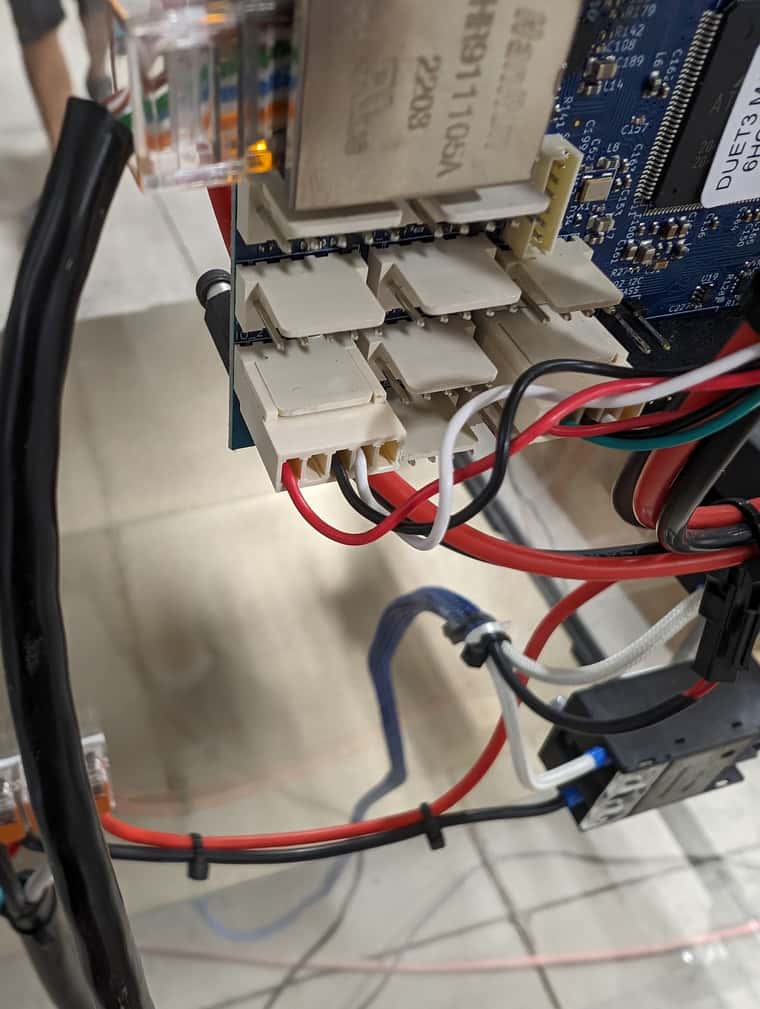

Z motor on expansion board not moving

-

@wdenker so a couple of things. You need to have something like

G4 S2in your config before any CAN boards are referenced to give them time to connect. So put it before the M584.

You have M584 twice in your config. -

@jay_s_uk G4 S2 is at the very first of the config.g M584 is called twice as we were having some issues and testing a theory. I can remove those no problem. Doesn't explain why it says driver 1.2 doesn't exist even though it is definitely there.

-

@wdenker G4 S2 isn't in the config you posted in the first post. In which case repost your config please ideally as code like your M122 outputs so I don't have to download it to look at it

-

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.4.5 on Thu Jun 18 2020 20:04:02 GMT-0600 (Mountain Daylight Time) ; General preferences G4 S2 G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Fabricator by IOFX" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 P192.168.1.14 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives M584 X0.1 Y0.2 Z0.3:0.4:0.5:1.2 E0.0 ; set drive mapping M569 P0.0 S1 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes backwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.3 goes forwards M569 P0.5 S1 ; physical drive 0.3 goes forwards M569 P1.0 S1 ; physical drive 1.0 goes backwards M569 P1.1 S1 ; physical drive 1.1 goes backwards M569 P1.2 S1 ; physical drive 1.2 goes backwards M584 X0.1 Y0.2 Z0.3:0.4:0.5:1.2 E0.0 ; set drive mapping M915 P0.1:0.2 F0 S2 M350 X16 Y16 Z8 E8 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z160.00 E420.00 ; set steps per mm M205 X20.00 Y20.00 Z3.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z300.00 E6000.00 ; set maximum speeds (mm/min) M201 X2500.00 Y2500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1800 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M584 X0.1 Y0.2 Z0.3:0.4:0.5:1.2 E0.0 ; set drive mapping M671 X-125:-125:1125:1125 Y100:900:900:100 S7 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1000 Y1000 Z1100 S0 ; set axis maxima ; Endstops M574 X1 S3 F0 R0 ; configure sensorless endstop for low end on X M574 Y1 S3 F0 R0 ; configure sensorless endstop for low end on Y M574 X1 Y1 S3 ; Set endstops controlled by motor load detection M574 Z1 S2 ; configure Z-probe endstop for low end on Z M915 X Y S2 R0 F0 ; set X and Y to sensitivity 7, do nothing when stall, unfiltered ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"^io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.65 ; set Z probe trigger value, offset and trigger height M557 X25:955 Y25:955 S150 ; define mesh grid ; Heaters M308 S0 P"temp1" Y"thermistor" T100000 B4725 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp2" Y"pt1000" ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"out2+out3" T1 ; create nozzle heater output on out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out6 and set its frequency M106 P0 S0 H-1 C"Part Cooling" ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out9" Q500 ; create fan 0 on pin out6 and set its frequency M106 P1 S0 H-1 C"Part Cooling" ; set fan 0 value. Thermostatic control is turned off M950 F2 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency M106 P2 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F5 C"1.out6" Q500 ; create fan 1 on pin out7 and set its frequency M106 P5 S1 H100 T15 ; set fan 1 value. Thermostatic control is turned on M950 F3 C"1.out7" Q500 ; create fan 1 on pin out7 and set its frequency M106 P3 S1 H100 T15 ; set fan 1 value. Thermostatic control is turned on M950 F4 C"1.out8" Q500 ; create fan 1 on pin out7 and set its frequency M106 P4 S1 H100 T15 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0:1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M591 D0 P2 C"io1.out" S1 ; filament monitor connected to E0 endstop M911 S22 R23.5 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss M570 H1 P10 T15 S999 M501; -

@wdenker I guess it doesn't like the Z drivers being spread across the mainboard and CAN board. Best move all Z drivers on to one and move Z or Y onto the 3HC

-

@jay_s_uk any ideas on the filament error I get literally every 30 seconds no matter no filament movement?

-

@wdenker can't even get it to report 3 out of 4 times.

12/20/2023, 4:25:15 PM M591 D0 12/20/2023, 4:25:12 PM M591 D0 Simple filament sensor on pin (io1.out,serial1.tx), enabled, output high when no filament, filament present: no 12/20/2023, 4:25:00 PM M591 D0 12/20/2023, 4:24:59 PM M591 D0 12/20/2023, 4:24:41 PM M591 D0 -

@wdenker it probably needs connecting to a .in rather than a .out

-

@jay_s_uk we've tried both in and out.

-

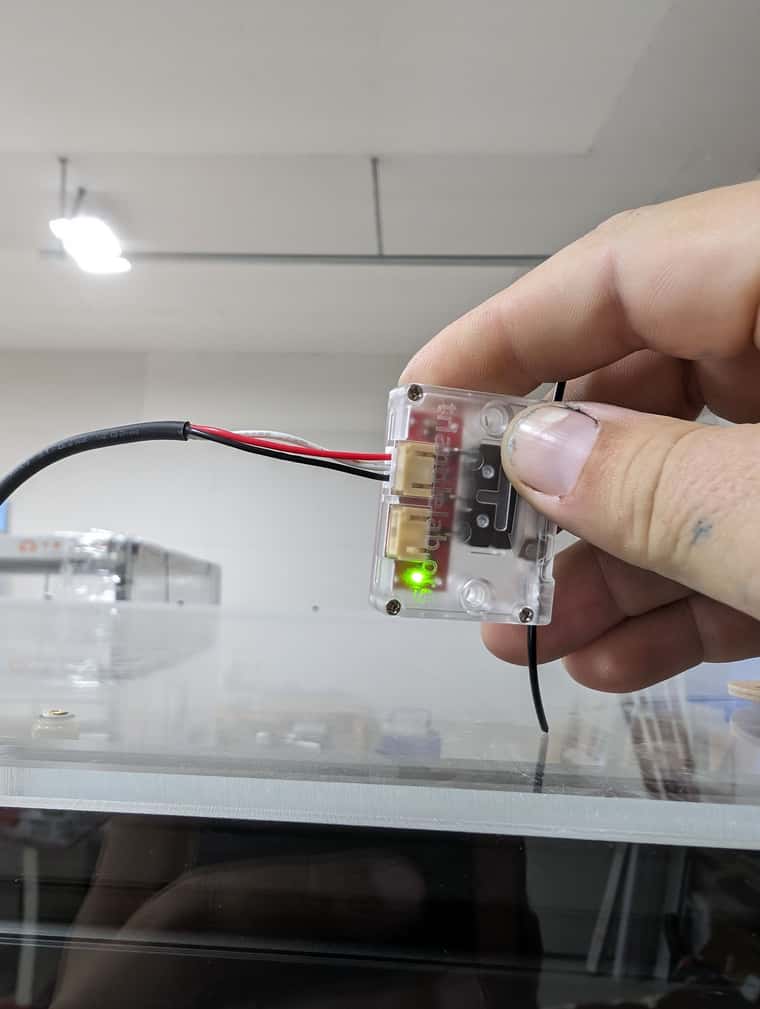

@wdenker can you confirm your wiring, ideally with pictures , and what type of filament sensor it is?

-

@jay_s_uk ah you were right. We had to switch it to 5v vs 3.3 and didn't have it on in after we swapped to the 5v. So all of my issues are resolved at this point.

-

@wdenker Well I got ahead of myself still getting the error just not as often.

-

-

@Phaedrux any ideas?

-

@wdenker on Duet 3 boards, io.out pins can be used as inputs, but have no series resistor to offer voltage protection, so are only 3.3V tolerant. It is possible you have damaged the 3HC connecting a 5V endstop to an io.out pin.

Have you tried a different filament sensor? It is quite possible that the microswitch or wiring is faulty, or could be picking up interference from motor or heater wiring.

Ian

-

@wdenker are you powering the 5v_ext? have you tried using it with 3.3v as according to the trianglelab docs it also works with that

-

@jay_s_uk we have tried the 3.3 on the duet and it does not work so we figured we have to use the 5 volt.

-

@wdenker if it doesn't work with 3.3v, which the manufacturer indicates it should, then i guess theres an issue with it

-

@droftarts I would think that I would have only damaged that one port if that was the case. I have tried multiple ports to validate that.

-

@jay_s_uk no none of them work with the 3.3 manufacturer claims they are 3.5 from everything I've seen and I have five working ones that I tried on the 3.3 and moved over to the duex 5 And they all work with the 5 volt.