Duet3 Mini5+ Ethernet Nozzle Distance to PEI sheet is too large

-

@Wobi neopixels aren't supported on the 1LC currently. You would have to run a control wire from the main board

-

@jay_s_uk

Okay, that's a shame, thanks.

I have now calibrated the Z axis and everything worked. Only after a restart do I still have this large distance between the nozzle and the PEI and I cannot change this without the command 'M564 S0'.

I entered and saved the change to Z in all files containing the G31 command.

But after a restart everything is back to normal.

What did I miss?Thank you for your valuable help and support.

-

@Wobi

Sorry, I forgot the file 'homez.g'! Now the setting is retained even after a restart.

Thank you for your support. -

@Wobi LEDs on toolboards and expansion boards are supported from RRF 3.5, which is in ‘release candidate’ state, ie not yet final release, but not beta. They are not supported in 3.4. See https://docs.duet3d.com/en/User_manual/Connecting_hardware/IO_Neopixel_DotStar (which I need to tidy up a bit).

If you want to use 3.5.0rc2, you can connect the LEDs to an io[x].out pin, so long as it has digital output. As these output 3.3V, you may need to level shift this to 5V, unless you have LEDs that support 3.3V signalling. You can take 5V power from the toolboard so long as it doesn’t draw too much current.

Ian

-

@droftarts Hello, thank you, I have already found this document.

But a new firmware would mean that I would also have to update it on the 1LC. I don't know how that works. Then I have to leave it behind with the Stealthburner LEDs, which is a shame.

I'm thinking about converting to Bigtreetech Octopus, everything is possible there. -

@Wobi Updating the firmware on the expansion board is simple, much simpler than rewiring your whole machine for a new mainboard, and go through the pain of setting it all up with a different firmware (though the Octopus does support RepRapFirmware as well).

I assume you are running in standalone mode (you haven't posted your M115 or M122 output, so I don't know what firmware version you are running now), not with a connected Raspberry Pi in SBC mode? If you are using an SBC, see the notes here to update the firmware and/or change to the unstable package feed.

For standalone, to update your expansion board to 3.5.0-rc1, download the following files from https://github.com/Duet3D/RepRapFirmware/releases/tag/3.5.0-rc.1

Duet3Firmware_TOOL1LC.bin

Duet3Firmware_Mini5plus.uf2

DuetWebControl-SD.zip

DuetWiFiServer.binUpload Duet3Firmware_TOOL1LC.bin to the Duet via DWC: in Files > System, click the 'Upload System Files' button. DWC should ask if you want to install the firmware, click yes. If not, send

M997 B#where # is the CAN address of your 1LC board.Once that has flashed, then upload Duet3Firmware_Mini5plus.uf2 to the Duet, and allow it to install when asked. The Duet should reboot.

Finally, upload DuetWebControl-SD.zip to the Duet. Once it has uploaded, refresh your DWC page, and check the firmware versions of all connected boards and DWC.

If you're on an old version of the WiFi firmware (which should still work fine with 3.5.0), you can also update this by uploading DuetWiFiServer.bin. However, you will need to setup your WiFi connection again via USB, as covered here: https://docs.duet3d.com/en/How_to_guides/Getting_connected/Getting_connected_to_your_Duet

Then see the wiki page here https://docs.duet3d.com/en/User_manual/Connecting_hardware/IO_Neopixel_DotStar for connecting the LEDs to the 1LC.

Ian

-

@droftarts Wow thanks

I was amazed myself!

This was really very easy with just one click of the mouse.

The Duet Mini, the 1LC and the DWC are now displayed in a list in the interface for the first time and all have the same version: 3.5.0-rc.1; Thank you. Horror fairy tales were then told on the Internet.

Now I'll test it first and then finally connect the LEDs.

I'll get back. -

@Wobi well done! Updating to regular release firmware is generally even easier, as there is a zip file with all the firmware components, and you just upload that.

Ian

-

@droftarts

Hello Jan, the tests were a bit extensive and initially not successful and have not yet been completed but now the printing is finally working, not yet perfect but usable, I have attached a photo testdruck.jpg of the first successful test print with PETG, again thank you for your competent help.

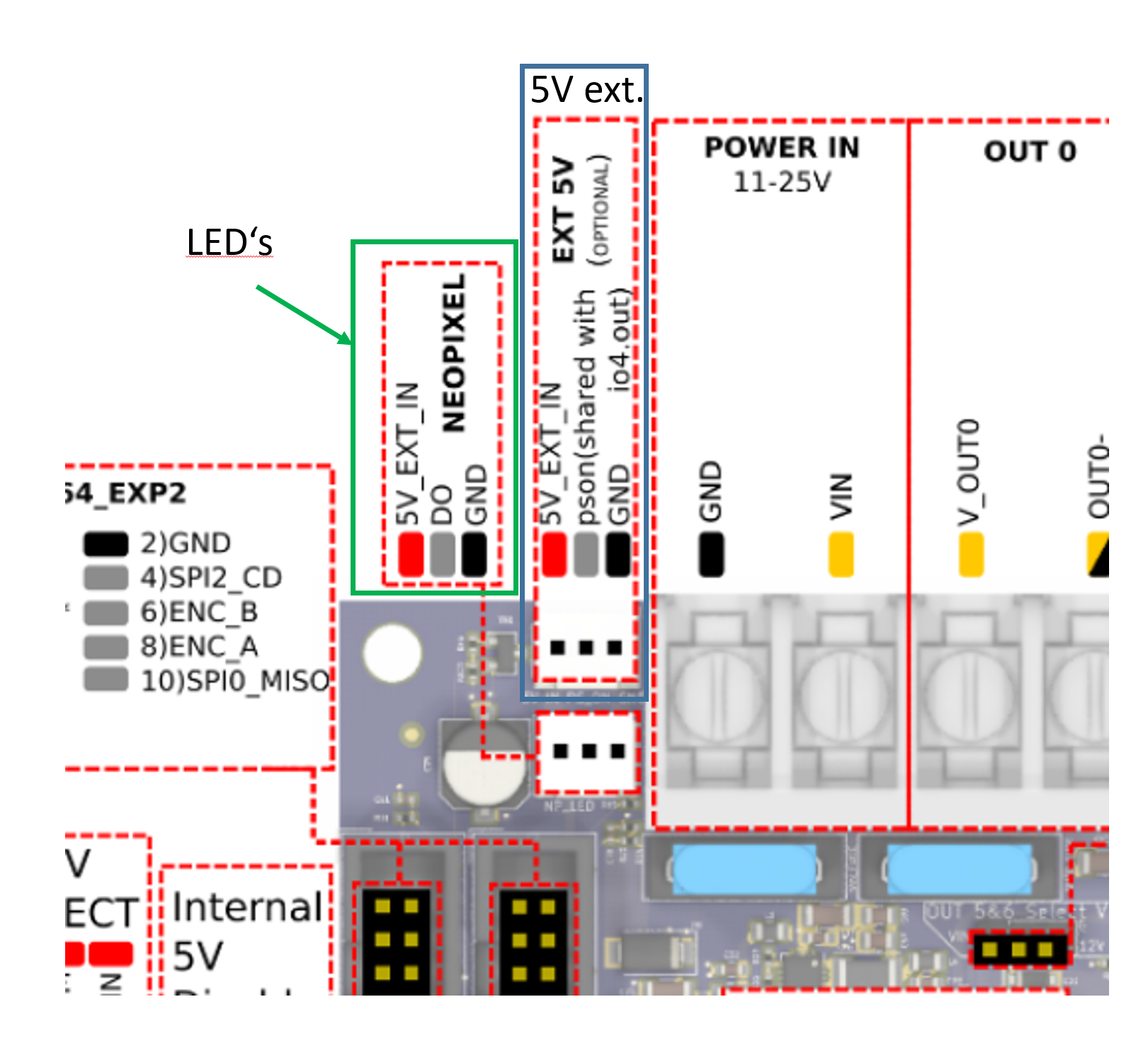

Unfortunately the LEDs still don't work. I also don't know which PIN name I have to use in the command. 'NEOPIXEL' or 'DO' or something completely different, see photo leds.png? I connected the external 5 volt 5 amp voltage source right next to it, I hope that's correct or do I still have to set/remove a jumper?

In 'config.g' I added these lines at the very end:

M950 E0 C"led" T1 Q3000000

M150 E0 U255 B255 P255 S1 F1

M501 ;was already there

Can you please tell me the correct command lines?

And another question about the DWC interface, in the previous version I could call up and view the mesh grid, this option is now completely missing, how can I display the mesh now?

Thanks for your help

Wobi

-

@Wobi I had a look at this guide: https://docs.vorondesign.com/community/howto/drachenkatze/neopixel_guide.html

And also I looked at https://www.dhm-online.com/en/voron-2-4/10529-kit-voron-24-300-mm-pitch-step-7-stealthburner-hot-end-revo-voron.html that seems to supply this set of LEDs https://www.dhm-online.com/en/led/12720-neopixel-rgbw-led-kit-wired-for-stealthburner-printer-voron.html which is perhaps like the Stealthburner kit you got? If it's only 3 LEDs, you should be able okay supply 5V via the board, as these LEDs can draw up to 80mA (peak) per LED, and usually about half of that if you're using colour. But first, check:- check you get 5V between 5V_EXT_IN and GND, on the EXT 5V connector, and then on the NEOPIXEL header.

- check whether you have RGB or RGBW LEDs (the kit says RGBW):

RGBW LEDs will have a visible yellow-ish phosphor section to the chip. If your LEDs do not havethis yellow portion, you have RGB LEDs.

- The Voron guide says "The data is sent with a signal rate of 800kHz", so 3MHz may be too fast. This datasheet from Adafruit also says 800KHz.

- the pin name for the Neopixel D0 pin is 'led'.

With the above information, I think a better M950 command may be:

M950 E0 C"led" T2 Q800000Send that and then test with your M150 command.

Note the use of the M150 S and F parameters:Snnn Number of individual LEDs to set to these colours, default 1

Fn Following command action. F0 (default) means this is the last command for the LED strip, so the next M150 command starts at the beginning of the strip. F1 means further M150 commands for the remainder of the strip follow this one.So

M150 E0 ... S1 F1will set the first LED, then wait for another command. You need to send an M150 command that ends with F0 to set the LEDs. Try:M150 E0 U255 B255 P255 S3 F0This should set the first three LEDs to full brightness on green and blue.

Hopefully that gets you going. Once it is working on the mainboard, are you going to try them on the toolboard? I think there is only one pin you can use for the LEDs, and that is io0.out. This is a 3.3V pin, but it may still work with a short LED strip without level shifting the 3.3V to 5V.

Let me know if that works.

Ian

-

@droftarts

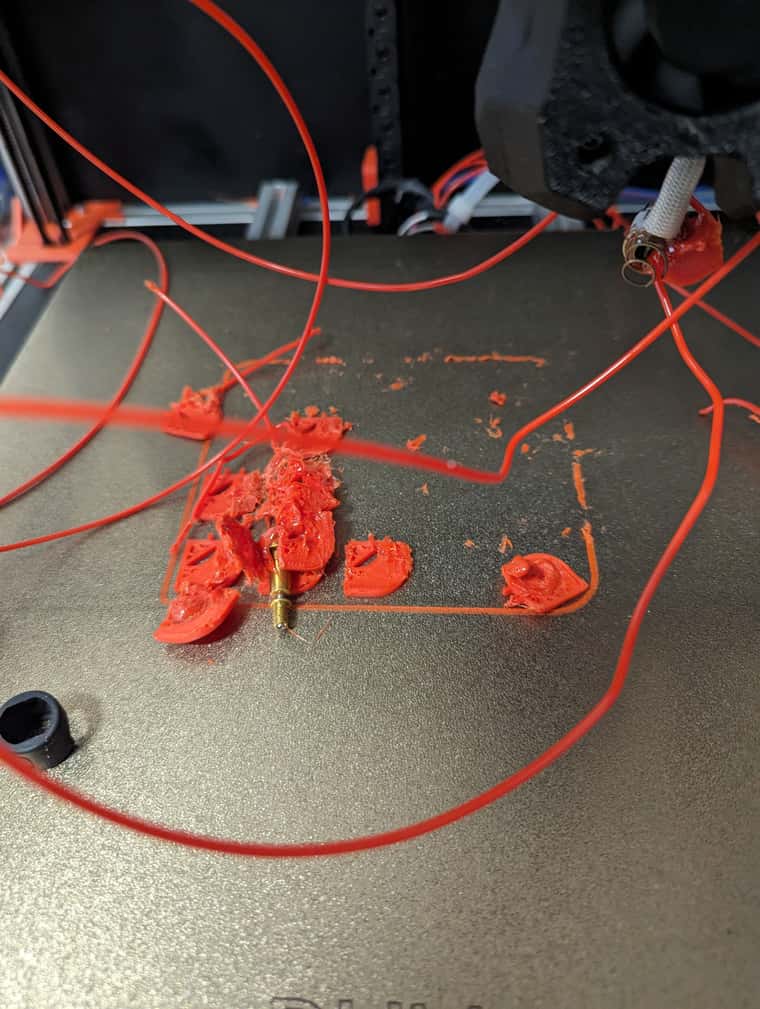

Hello Ian, thanks for the links, I tried the new commands straight away, unfortunately no success, so I have to measure the cables again and connect another LED. Then, today at noon there was a crash. The V6 nozzle broke off during an unattended print job. Since I wasn't there, I have no idea what exactly happened.

Now I have to order and install a new Revo V6 hotend, which may take a while. In the meantime I have listed the defective Voron on eBay, let's see what happens.

-

@Wobi Oh dear, that's not good! I can't imagine what would have caused that, unless the nozzle unscrewed itself and dropped out. Does this mean you're getting rid of the whole printer?

I'm going to order myself some SK6812 RGBW LEDs to test various ways of connecting them.

Ian

-

@droftarts

Hello Jan, I don't think I can sell the broken Voron, I will repair and finish it and then decide. I'm looking forward to your results. greeting -

@Wobi

Hello Ian,

I've tried everything but the Stealthburner LEDs just don't light up. Even a direct connection to the external power supply, which is connected to the 24 volt power supply, did not bring any improvement. I probably need to use a different pin to control the LEDs but which one?

Here are the commands that I entered in config.g:

M950 E0 C"led" T2 Q800000

M150 E0 U255 B255 P255 S1 F1

M150 E0 U255 B255 P255 S2 F1

M150 E0 U255 B255 P255 S3 F0By the way, with the 0.6 nozzle it prints perfectly. Even the long print job in which the 0.4 nozzle broke was printed perfectly.

Greetings Wolfgang

-

@Wobi I’ve just got some LEDs today, to experiment with myself, to check how to get them working. Nothing to report yet!

Ian

-

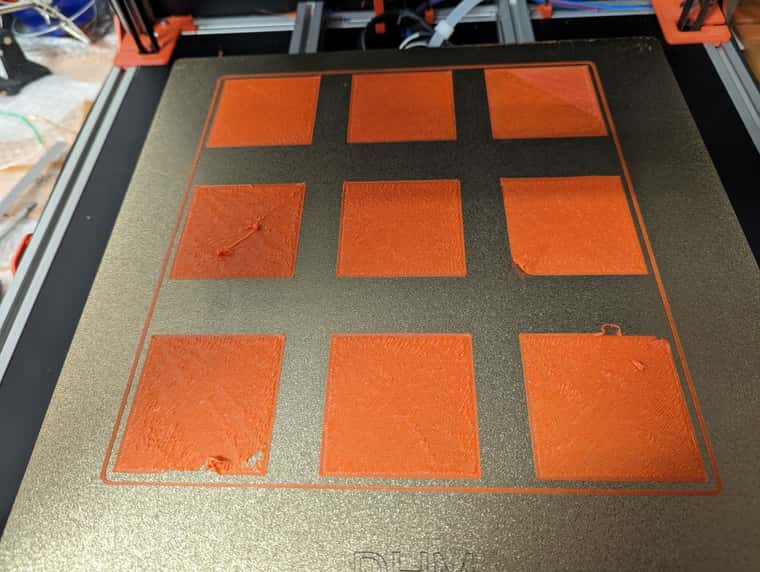

@droftarts Good morning Ian, the printer is running again with the 0.6 nozzle. I'm currently printing a large part as an endurance test, see photo. Do you see anything unusual in the photo?

When I started the Prusa Slicer, I entered the following codes and commented out the one from Prusa:

;print_start EXTRUDER=[first_layer_temperature[initial_tool]] BED=[first_layer_bed_temperature]

G32

G29

This also works well, only after the mesh, the nozzle temperature is set to 0. This means that the first few cm don't stick because the temperature drops quickly. The plate temperature is maintained.

Which code do I have to enter where so that this doesn't happen?

When I start the machine, I would like the printer to automatically reference its axes immediately. Where do I have to enter something in config.g?

Thank you for your competent help and I wish you a nice weekend, greetings

wolfgang

-

@Wobi while you can put movement commands in config.g, generally we don’t recommend automatic homing, heating or movement to be put in config.g, mainly because the state of the machine may be unknown at power on. What if there has been a power cut during print, or you did an emergency stop (effectively a reset) because of a problem?

For the temperature setting problem, I expect Prusa slicer is putting in the temperature that you have set for the filament, which may be 0C. Post the first 50 or so lines of a GCode file, up to where the G1 move commands start, so we can see what it is doing.

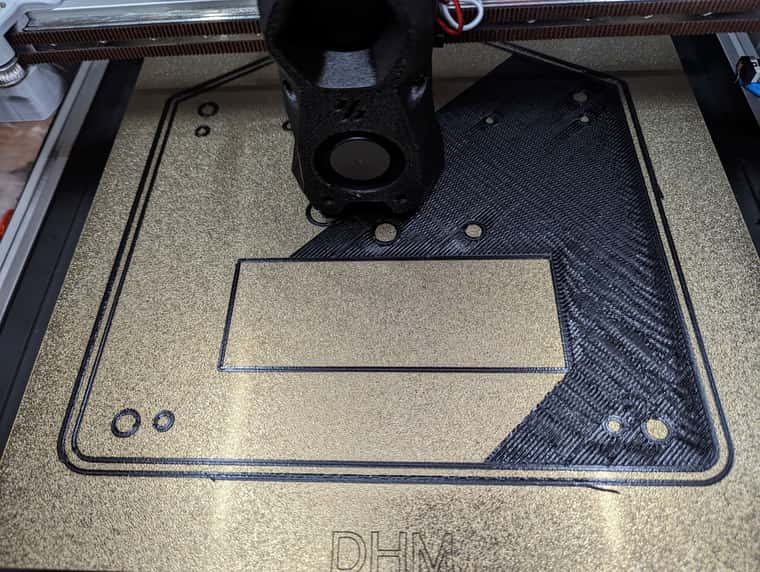

I successfully connected 7 RGB LEDs to my Mini 5+, using the ‘led’ header and pin name. I connected 5V and ground to an IO header, as these were quite low power LEDs (30mA each, so about 0.2A, within the 5V regulator’s capability). Please check your firmware version by sending M115 and post the result. Also post a link to the LEDs you are using (same as my link earlier?) and post a picture of how they are wired, and finally post the M950 code you’re using to configure them and M150 code to turn them on. Also send M98 P"config.g" in the console, and see if it produces any errors.

Ian

-

@droftarts

Thank you for your quick and competent answer.

Your arguments are convincing, thank you, I'll leave it that way.

I can't say which LEDs are installed, they are not specified in the invoice, but they are RGBW LEDs that were completely soldered and all lines have continuity to all three LEDs, but I was only able to measure the data line up to the first LED.

I will deliver everything else when the printer has hopefully completed its print job tomorrow morning without any errors. -

@Wobi Change the Q parameter in this line:

M950 E0 C"led" T2 Q800000back to Q3000000. I've found that my LEDs don't work correctly with Q800000. I mistakenly thought Q was the bits per second rate, but it is the SPI clock frequency, which is 4x the bit rate, hence 800000 x 4 is 3200000. 3000000 is just below this, and has been check that it works fine on most LEDs.

For reference, I use:

M950 E1 C"led" T1 Q3200000 M150 E1 R255 S3 F0 ; sets first 3 LEDs to redIan

-

@droftarts

Hello Ian,

Thanks, I can't try that until tomorrow.

To which pins did you connect the LEDS, to the Neopixel pins (do) directly next to the power connection of the Mini5 or directly to the 1LC and where exactly?

And have you connected an external power supply and if so where? Everything please, please with a photo.

I have attached a shortened G-code file of the Prusa Slicer.

Thank you for your patience and perseverance.wolfgang

Grundplatte_teil2_02.gcode