PasteExtrusion - Viscotec Preeflow Connection

-

Hello everyone,

Here is a little challenge that i'm facing and i wanted to share it with the Duet Community, maybe some great idea will come out

Context : I'm currently in the process of implementing a Viscotec Preeflow Ecopen600 inside a Duet controlled Machine.

Extrusion system :

This type of extrusion system uses a continuous cavity pump principle to push material threw a screw, this device come with this electronic control box :

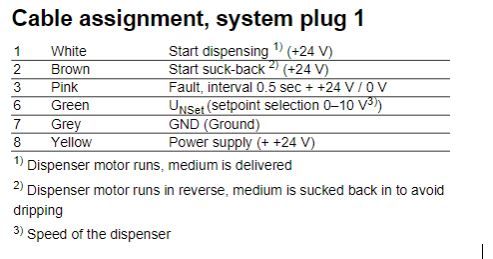

For the moment the only documentation that i have managed to find are the input wire of this electronic box.

Do you have any idea to control this extruder using the Duet 2 wifi. I though about using fan output to generate 0-24V signal for CW and CCW signal and a buck converter set o 10V for the speed Control.

Regards,

Tom

-

@reFlexlab To get started check out M571. Converting the requested speed to an analog signal isn't supported AFAIK, to implement that firmware changes or a custom electronics board which turns E steps into an analog speed signal would be required. Similiar changes would have to be made to add support for the suck-back functionality.

To see if it just works, perhaps slice a part with a fixed extrusion speed and try to fine-tune the dispenser speed by hand.

-

@reFlexlab Hello,

Thank very much for your answer, i will start by doing that.

As you said, for speed it's not a problem because i want to use constant extrusion speed, but i would love to implement suckback functionnality.

I have seen these type of boards, do you think that could be of any help to control the device and convert step/dir signal ?

Tom

-

@reFlexlab you could post process the gcode. If you set the slicer to use firmware retraction, that will put G10/G11 in the gcode. Then just change the gcode G10/G11 to another code (an unused Mcode e.g. M5000/M5001) and create your own little macro that pulls back the clay and puts it back, simulating retraction.

-

@reFlexlab

Also i have thought about using M670 which enable the IO Port mapping, maybe i could combine M571 with M670 to add suckback functionnality ? -

@jay_s_uk Thanks, thats a Great Idea.

-

@reFlexlab you would call the macro

M5000.gand put it in the sys folder.

The macro could contain something likeM42 P1 S1 G4 P500 M42 P1 S0That would enable an output that you've mapped (probably a fan) for half a second. obviously you may have to adjust that.

Then do a similar macro for M5001 to unretract -

@reFlexlab I have some experience with these extruders. I would recommend swapping the motor out for a geared stepper (just to slow it down) and run it like a normal stepper motor in the system. There is a max allowable speed for these that must be adhered to.