What to use for external chamber panels

-

For those who have built enclosed printers (or those who own them), what do use for panels to "clad" the outside? I'm looking for the cheapest option. The best I can come up with here in the UK, is aluminium sheet but I'm wondering what is the minimum thickness that I can get away with. The frame dimension are 600mm X 600mm X somthing like 1.5metres tall. There will be plenty of rails to which the sheet can be fixed (and I could add more). Oh, and I don't have anything to cut them other than a jigsaw so they'll likely need to be cut to size.

-

@deckingman for my voron, I used 3mm polycarbonate sheet. I got it from here https://plasticonline.co.uk/clear-polycarbonate-sheet.html as they cut to size and were the most reasonably priced.

-

@jay_s_uk @deckingman and you can get thicker polycarbonate for the larger size.

Have you looked at dibond or similar aluminium/plastic sandwiched together panels?

-

I used aluminium composite panels for the base and rear. Vorons that use plastic for the base panel tend to have issues with the panel warping over time.

-

I used ACM for mine. It works quite well as a bracing element as well. I think it’s 4-5mm thick. Can measure tomorrow.

Cheers

Sam -

@T3P3Tony said in What to use for external chamber panels:

........................ Have you looked at dibond or similar aluminium/plastic sandwiched together panels?

Briefly - but unless I win the lottery (difficult as I don't play it), then it's just too expensive. It needs to be cheap (but look reasonable). It doesn't need to be structural in any way - the frame will take care of that.

I'm leaning towards aluminium sheet because it'll be easy enough for me to drill fixing holes where I need them, whereas polycarb is a bit more tricky and too easy to crack. So I'd likely end up paying to have the holes drilled as well as the cutting to size service which all ramps up the price.

Basically I have a budget of bugger all and don't want to exceed that by much

-

@deckingman all my panels are held in by latches, rather than drilled. doesn't help you where you want to secure them mid panel though. These are the latches i've used https://mods.vorondesign.com/detail/9Rdnf5vD2oaJLmR7BpAuQ

-

I've been using this double wall plastic, the link is just an example I'm pretty sure you can buy sheets at places like Wicks or B&Q in the UK.

10mm Polycarbonate Roofing Sheet Clear Various Size 10 Year Warranty UV Protection (Width:1.20m x Length:0.60m) for Greenhouse Canopy Carport Cold (ONLY Available Mainland UK)

It's fairly rigid, a relatively good insulator and if you slide a piece of wood or plastic into the cells relatively easy to fix to. I believe you can also get them in various colours too.

-

@deckingman I think I remember @mrehorstdmd saying he used the (polystyrene?) panels used for greenhouse insulation as non-structural panels. The size he has slotted into the aluminium extrusion. Those panels are cheap at B&Q etc. Not sure what temperature they can handle, though.

Edit: @CNCModeller seems to have covered it!

Ian

-

@droftarts said in What to use for external chamber panels:

@deckingman I think I remember @mrehorstdmd saying he used the (polystyrene?) panels used for greenhouse insulation as non-structural panels. The size he has slotted into the aluminium extrusion. Those panels are cheap at B&Q etc. Not sure what temperature they can handle, though.

Edit: @CNCModeller seems to have covered it!

Ian

I hadn't thought of slotting the panels into the extrusion - what an excellent idea ! That'll save a lot of grief and would mean that sizes needn't be critical. I could probably cut them myself from larger sheets as the edge finish (and straightness) would be hidden and they wouldn't need fixing holes.

That's genius..............

-

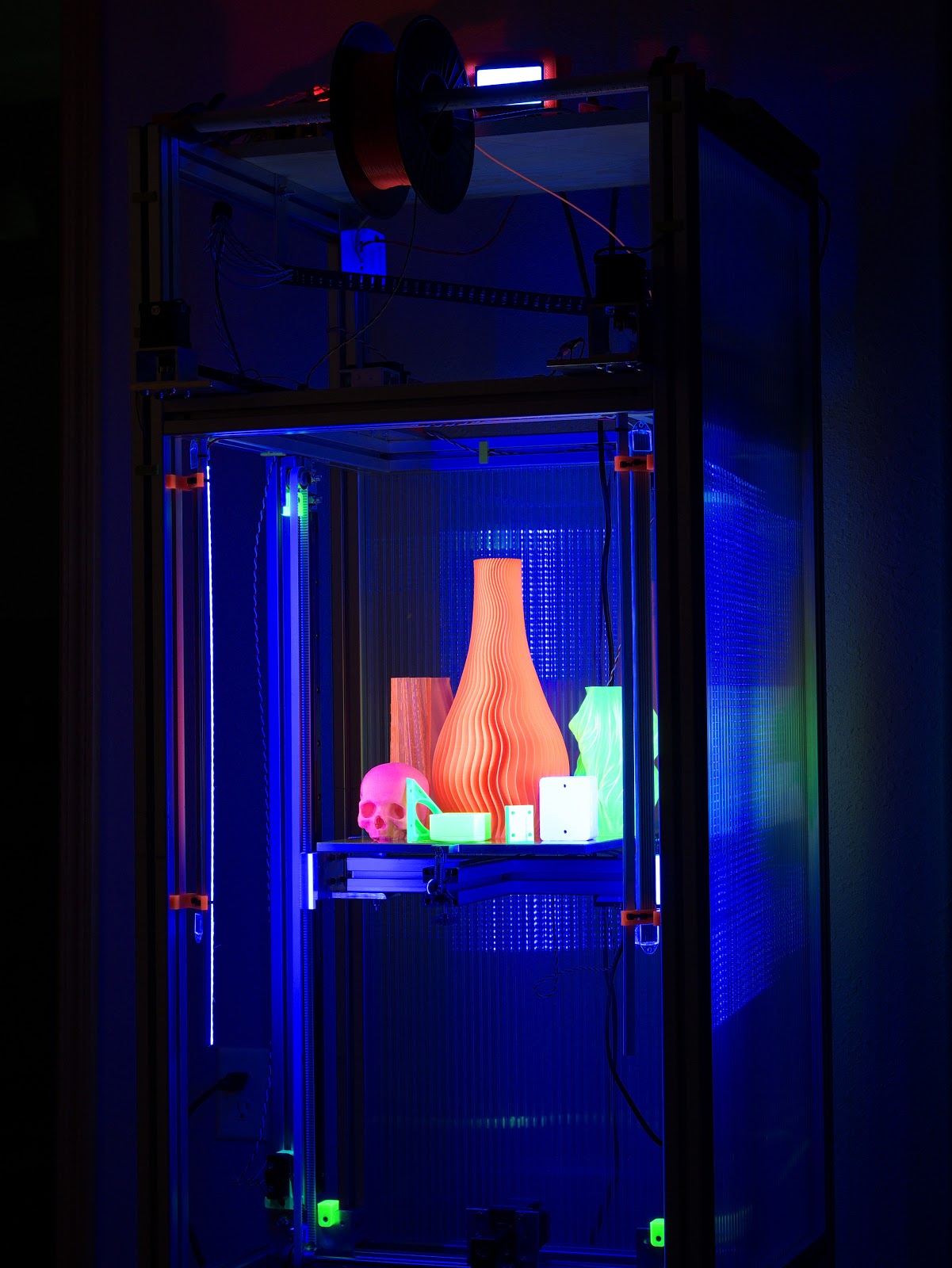

@droftarts The stuff I used is double wall polycarbonate that is sold in the US mainly for greenhouses. I used 8mm thick stuff that slots right into the 8mm slots in the 4040 t-slot frame. The stuff cuts easily with a saw and you can seal the open ends with clear packing tape (sealing it improves the ability to insulate and keeps bugs from nesting inside the material). After cutting I blew out the saw crumbs with compressed air before sealing.

PC should be able to handle pretty high temperatures.

The double wall PC allows light in and out of the machine and yields some attractive optical effects...

-

@mrehorstdmd Mark, what did you do about a door/access?

-

@deckingman He talks about it here: https://forum.duet3d.com/post/309670

Front doors are polycarbonate sheet, the larger one held onto the frame by magnetic tape.

Ian

-

Hi All,

For info I use magnets to attach all of my panels to make access easy for maintenance etc.Similarly I use printed hinges with open barrel design and a magnetic latch so the door can be lifted off.

Cheers

Barry M -

A truly cheap option is to use foamcore boards (Foam boards in the UK). These are plastic foam sandwiched between sheets of thin cardboard. Cuts easily with an X-acto knife and insulates to some extent.

I tape it in place with painter's tape when I need to use it.

Not transparent but it does the job for me.

-

Thanks for all the suggestions guys. Some great ideas there.

I guess while we are on the subject of access/doors, when I built my existing "booth" I used something called an "easyfix" system for the doors. The system consists of rectangular aluminium tubing and various assorted connectors that are pushed/hammered in to form right angled corners and such. One of the profiles is called "easyfix tube mount" which has a lip on one side. I made the door frames using this with the lip facing inwards and stuck polycarb sheet onto the inside using clear silicone sealant, which is invisible on the outside. https://www.aluminiumwarehouse.co.uk/easyfix-and-more/easyfix

I just used some plain door hinges which I attached using self tapping screws. The only thing I would say is that the plastic joint can work loose over time so I just used some more self tappers screwed through the aluminium into the plastic. I guess some sort of glue would work too (as long as you never want to take it apart again).

-

@deckingman said in What to use for external chamber panels:

@mrehorstdmd Mark, what did you do about a door/access?

The lower front door is a sheet of clear PC held in place with magnetic tape applied to the door and the printer frame. The upper door is another piece of clear PC that slides into the t-slot above the XY stage. IRIC, the upper door PC is a scratch resistant type, 5 mm thick. The lower door is normal stuff about 3 mm thick (1/8"?).

-

@mrehorstdmd, do you happen to have a source from Aliexpress for the magnetic tape you used?

-

@jens55 Sorry, I bought the stuff about 6 years ago, I think I ordered it directly from the manufacturer in the US.

-

@mrehorstdmd, no problem, thank!