Want input on frame design

-

@gnydick said in Want input on frame design:

What are the tricks?

On the ratrig design, one trick is to build bottom and top square of the frame first, then add the uprights to the bottom frame while the bottom is oriented vertically, then put the top frame in place.

@deckingman s cross laser approach works, but I made do with 1-2-3 blocks in the corners.

Due to the "tank plate" design, its possible to adjust a nonsquare frame easier than with a blind mate setup.

If you use printed parts for motor mounts etc., there may be an ideal way to put the bolts in to make sure they mate properly with the flat surfaces of the extrusion.

Understand the tolerances of the printed parts and adjust for shrinkage of the plastic you print them with. To stick with the ratrig example, the parts are designed with little to no tolerances, so the holes are very tight, and you may need to scale the parts to 101% size and use hole shrinkimg compensation or drill/ream all holes after printing for easier operation.

-

@gnydick here is the video I mentioned which might explain it a bit better - https://www.youtube.com/watch?v=H9O1r46Izn8

Essentially what I'm saying is use normal 3 point levelling but rather than probe close to each lead screw attachment point, probe across the centre of the bed. That is to say, to level from left to right, probe at the left hand edge of the plate but halfway along in the Y direction from front to back. Do the same at the right hand edge and adjust one levelling screw as necessary. Then probe the font edge of the bed but halfway along in the X direction. Do the same at the rear and adjust as necessary. That'll give you a bed which is a level plain about it's centre (assuming it's flat which it should be). So once you have that level plain, you then need to probe the left hand edge from front to back. That'll tell you if the the levelled bed is tram with the Y gantry. If it isn't, adjust the upper frame member to which the linear guide is mounted. Do the same on the right hand edge. Repeat for the front and back edges. It's a bit of an iterative process but at the end of it, you'll have a bed which is not any level, but it's level with respect to the XY gantry - i.e. tram. Once that's set, you can do any future bed levelling close to the lead screws if you want.

Personally, I don't have any levelling screws on the bed. I use a single motor and continuous belt. So to level the bed, I slacken the grub screws on the pulleys and rotate the lead screws by hand, then tighten up the pulleys. I've only ever done that once after the initial build and that was after the machine had been partially stripped and transported to the TCT show in Birmingham. In fact, the second time the machine was transported, no adjustment was necessary.

I never check or adjust bed level or flatness. If I had a problem with the first layer I would but that hasn't happened in the last 9 years or so.

-

This post is deleted! -

My 2 cents - I built a printer to my own design and find it to be plenty sturdy. As with any design, you end up optimizing some parameters vs other based on your personal preferences, opinions, tastes, etc. So here are the things I optimized for and why.

-

I made a CoreXY machine because... that's what seemed fashionable at the time. Someone else will say why that's the best and someone else will say why it's the worst.

-

My frame is like Rat Rig design. I used extrusions and plates in the corners. I opted for 2040 (vs 2020) because I thought it would be more rigid. Remember that the t-nuts do not force the screws to be centered in the slots. You can clamp down a non-square frame. I did use slide in t-nuts vs those twist in nuts because the twist in ones can be hard to know they have grabbed.

-

I used a 2020 extrusion as the gantry to bridge between the rails. I wanted this piece to be very rigid.

-

I used NEMA23 motors because I wanted the power to move more mass on the gantry.

-

The two rails the gantry rides on need to be parallel. If not, you'll likely get jams, particularly on a coreXY layout. I used sliding T-nuts to hold them in place - on every hole. Tip - these can be a pain to get right under the holes in the rails. I printed a lot of little spacers to keep the T-nuts spaced properly.

-

I opted to not use any printed parts for structural applications, or where they'd be under stress and also get warm. Metal seems less risky. And I designed all my metal parts to use plates because I could get them laser cut cheaply.

-

I located the belts and pulleys to minimize their offsets from the sliding blocks (on both the gantry and gantry support rails). I wanted any hard tugs from the belts to only tug in the direction of the rail and not have much leverage for twisting.

-

I used sliding rails on for the Z-axis X, and kept the Z lead screws as close the the rail blocks as possible. Again, minimize torques on the blocks.

-

I had great expectations for using only three legs between the top frame and the bottom, one for each Z rail (front right and left, plus center rear). I ended up adding support legs at the rear corners.

-

I wanted to keep all the belt pulley stand offs as short as possible so so they would not bend, so I designed a "twisted belt" arrangement, despite cautions from some people. I've run it for over 140 print hours in the past year with no noticeable belt wear so far, and no rubbing of the belts against each other.

-

Assuming you don't get scared off by all the responses to your question, I'd also recommend doing a lot of prototyping. I made prototypes of all my metal parts from laser cut wood at my local makespace, and assembled the whole printer. I went through several iterations of almost all of the pieces before I was satisfied.

-

I'm also in the camp that likes bed mesh compensation. I say make everything as square as possible, then use mesh compensation anyway. Belt and suspenders.

Here's a picture of the near-final result, which I call the Bulldog

If I were to build it again, I'd investigate some more exotic belt arrangements that keep cartesian movement without having a morot on the gantry. -

-

@mikeabuilder very cool. I haven't really thought about doing it all metal.

3030 vs 2040, which is stiffer?

-

@gnydick if your going big 4040, having built a core xy with 4040 its very ridged but heavy

-

I know of one self sourced ratrig build using 6060s even ... that's quite chonky, but for a large frame printer, why not overdo it a bit?

-

@oliof said in Want input on frame design:

I know of one self sourced ratrig build using 6060s even ... that's quite chonky, but for a large frame printer, why not overdo it a bit?

The trouble is, you lose XY travel unless you build the frame even bigger. 6060 will give you 40mm less travel in X and Y than say 4040, for a given outside frame size. Using mostly 2040 on my 600mm X 600mm frame, I only have about 370mm of travel in X and Y. 4040 would reduce that to around 330mm and 6060 would reduce it to 290mm. So if 2040 gives the requisite rigidity, then larger extrusion only has a downside by losing print volume but no upside.

-

@gnydick said in Want input on frame design:

3030 vs 2040, which is stiffer?

Depends how you load it.

Openbuilds show their section properties to be (all mm^4) (pdf from https://openbuilds.com/projectresources/how-to-calculate-v-slot

-deflection.175/ but you need to be registered to download it)

-deflection.175/ but you need to be registered to download it)- 20x20: 6.988E3

- 20x40: 48.163E3 and 12.305E3

- 20x60: 149.336E3 and 17.602E3

- 20x80: 336.24E3 and 22.938E3

Misumi show their section properties to be

- 20x20: 7.42E3 (https://uk.misumi-ec.com/vona2/detail/110302683830/)

- 20x40: 51.3E3 and 13.58E3 (https://uk.misumi-ec.com/vona2/detail/110302684350/)

- 30x30: 26.8E3 to 34.7E3 depending on section type (https://uk.misumi-ec.com/vona2/detail/110302686450/)

So, 20x40 in major axis bending is about 1.7x as stiff as 'standard' 30x30. In minor axis bending it's about 0.4x as stiff.

I can't find anyone quoting cross-sectional area, but axial stiffness will just be in proportion to cross-sectional area.

I can't find anyone quoting torsional parameters, but I'd expect the 20x40 to be significantly stiffer torsionally than the 30x30 because of the big central cell (tubes are good in torsion, and a large diameter thin-wall tube is much better than a small diameter thick-walled tube with the same quantity of material).

This all assumes like-for-like material. However, typical aluminium alloys are generally within about 5% of each other, so won't change the conclusion. There's much more variation in strength, so if you were worried about that you would need to think about the alloy.(https://www.engineeringtoolbox.com/properties-aluminum-pipe-d_1340.html)

-

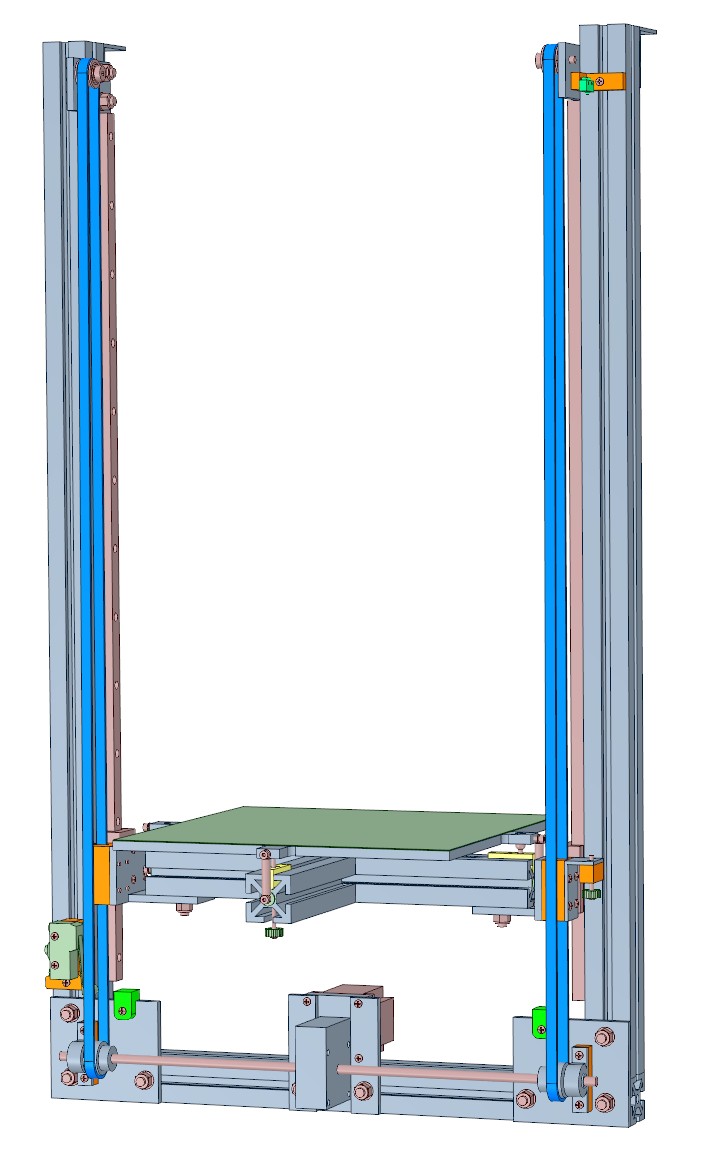

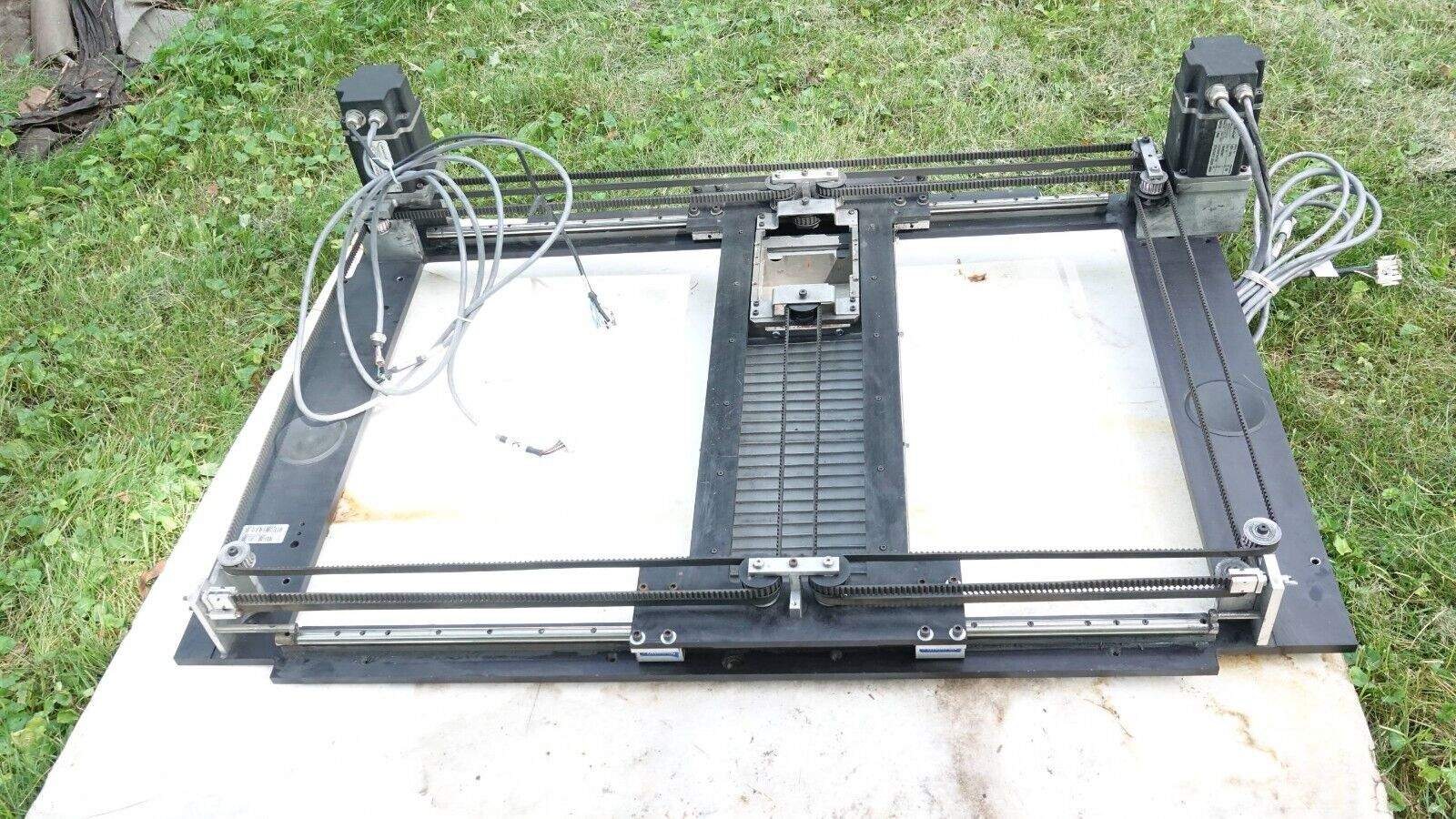

I took a slightly different approach to my corexy build. I wanted to design the XY stage to make it easy to align the Y axis guide rails, and that's easiest if they start in the same plane, so I built a 4040 square subframe, bolted on two pieces of cast tooling plate, and then the guide rails. This method ensures that the Y axis rails start in the same plane so I only had to align them in XY and not XYZ. Motor and pulley mounts are made from rectangular aluminum tubing, minimizing the machining required, and acting as heat sinks for the motors (but probably not important as the motors don't get hot anyway).

I used a belt lifted Z axis, about 700 mm long, with a 30:1 worm gear drive that doesn't move at all when Z motor power is cut. The bed assembly weighs about 3.5 kg and I have loaded the bed with 4 kg extra weight and the worm drive has no trouble lifting it.

The bed is a piece of 8mm cast tooling plate on a kinematic mount. The print surface is a piece of 0.7 mm PEI. The bed plate, heater, and PEI are all 300x300 but the plate has "ears" for the kinematic mount. I don't use mesh compensation because it isn't needed. The plate is flat and stays flat when heated, and the kinematic mount is stable. I only have to retram the bed if I take the Z axis apart- last time was over a year ago. It just works, every time, even after I transport the machine laying on its back in my car.

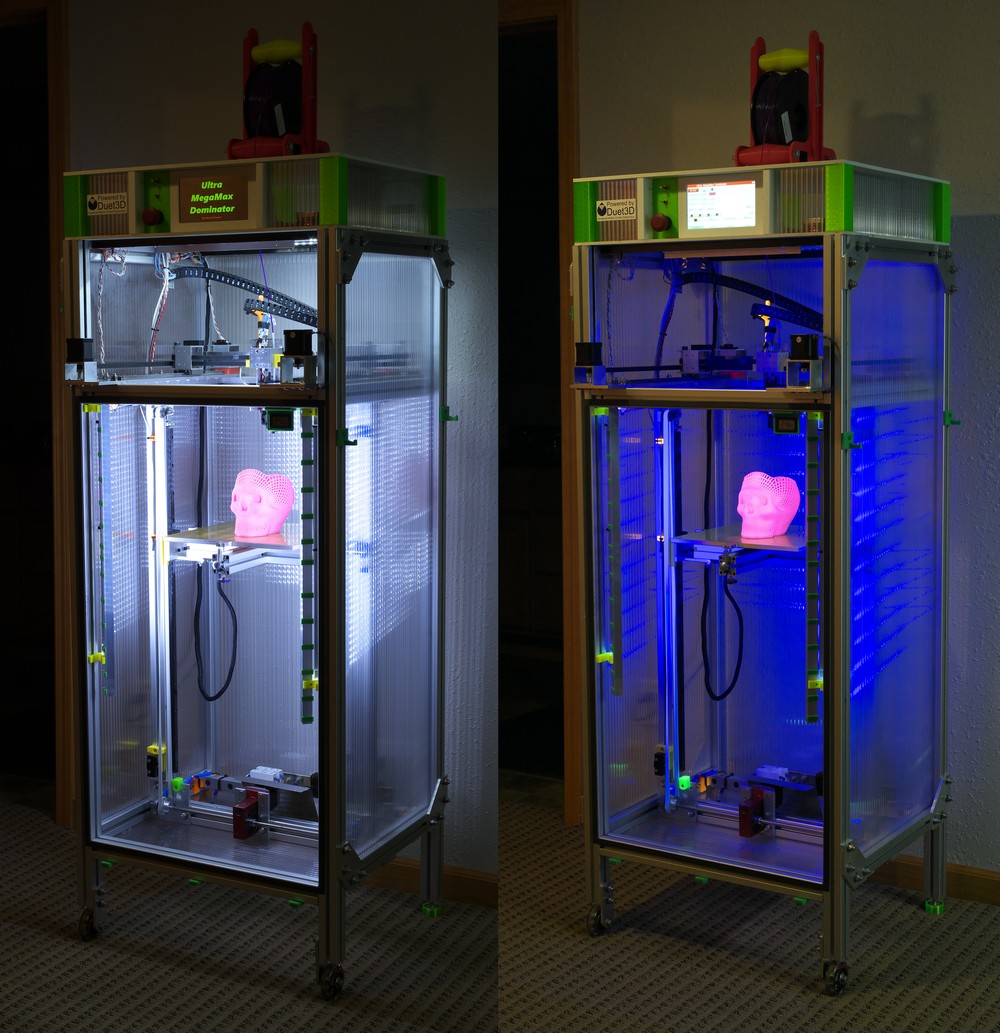

In many designs enclosure seems to be an afterthought and becomes difficult, especially when the XY stage is sitting on top of the frame. I used to print a lot of ABS so I designed the frame to allow easy enclosure by making it large enough that the XY stage can fit inside the printer's frame. Adding PC or plywood panels to the sides of the frame can increase rigidity, but I used double walled PC sheet commonly used to make greenhouses. It fits in the t-slot, provides thermal insulation, and allows light in and out of the printer but does nothing to improve rigidity of the frame. Front doors are polycarbonate sheet, the larger one held onto the frame by magnetic tape. I also installed white and UV lighting.

In a corexy machine, most of the wiring connects to the printer at the XY stage, so I put the electronics at the top to minimize cable lengths and to make it easy to access the electronics without having to crawl on the floor or turn the printer over.

-

@mrehorstdmd d,d,d,d,damn. That's impressive.

I'm trying to design it very simply, minimal machining if any. I'd like to use geometry to the utmost as the source of rigidity.

-

@gnydick Machining in UMMD (the corexy printer) was limited to cleaning up the edges of the bed and making the hole and slot for the kinematic mount, milling and drilling the teflon blocks for the kinematic mount, cleaning up edges of the rectangular tubing and drilling holes accurately, and squaring and matching lengths of the 4040 t-slot so the frame would squarely bolt together. There were probably one or two other simple operations on other parts as well, but nothing difficult, even on a manual milling machine.

-

most of my frame is 2040 and some 2020 , main cube is made of 500x500x1000 2040 with a few reinforcement in middle and other place , with a mix of 2040 and 2020 , this screenshot aint up to date fully unfortunately , i need one of these days to update everything !

-

A couple more random thoughts. Aluminium is preferable to plastic parts of you have access to the necessary machining capabilities. If you do need to print any parts, avoid PLA like the plague, especially if you live somewhere that has warm summers or if you want to use a heated enclosure. Use a more heat tolerant filament. In any case, I'd highly recommend using aluminium for all motor mounts. It's a good conductor of both heat and electricity so the entire frame will act as giant heat sink and the motors will run so much cooler. Also, it'll act as a ground plane for any static that might build up. On that topic, earth the frame - preferably in several places. Tie the frame to PSU gnd and make sure that the print head is also tied to gnd.

I'd also highly recommend that anything that carries idler pulleys or wheels is supported at both ends. Otherwise they'll twist under tension.

-

@deckingman yeah, the only access I have is if I use a CNC mail order service.

-

I designed my bulldog printer to not use any custom machined parts (and no structural 3D printed parts either). All custom metal was designed to be lasercut. I primarily used 1/8" (3mm) plate, with a few thicker parts. I've had very good service from a place in the US (Reno Nevada) called sendcutsend.com. I'm not affiliated, just a happy customer. Good prices, fast service, and instant quotes on uploaded DXF files. I've had some orders shipped in less than 3 days.

-

@mikeabuilder Sendcutsend is getting awesomer by the day. Documentation has gotten even better, great value with the insert/stud capabilities, finishing turns out great. Both personal project and work related parts have all turned out fantastic.

-

@sebkritikel I've played with their quoting tool, IIRC, it was prohibitively expensive. Worth looking again though.

-

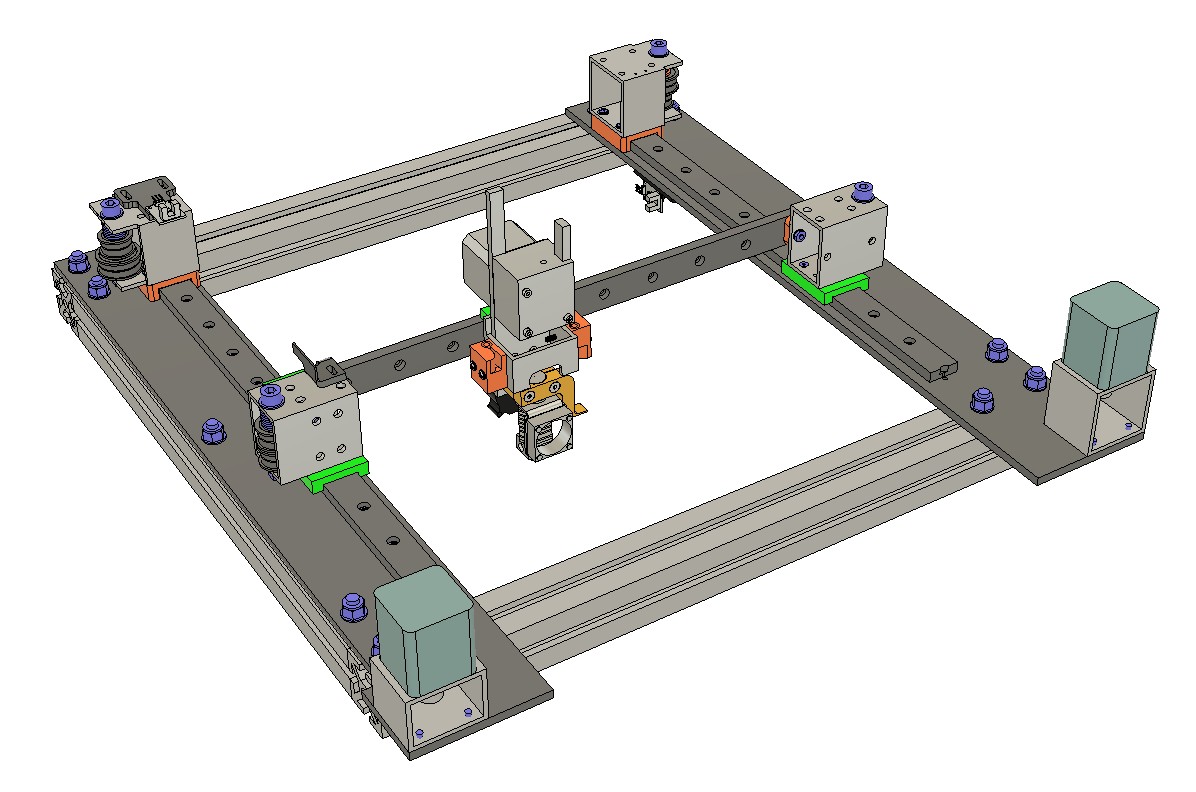

Playing around. I've done double gantry rails before, was super rigid. Thoughts?

It's a 6x6.

-

@gnydick Honestly I think the combination of the aluminum frame assembly, double gantry rails for the X and Y axes, and the associated belt pathing is unnecessarily complicated and would be really tough to assemble (and maintain).

I think sticking to a single linear rail profile of a beefier profile for the Y-axis is a better option than the double stack you have shown. I'm thinking something greater than a rail width of 15mm (vs the 9mm or even 12mm thats common for DIY printer builds).

For the X axis segment, I also thing the double stacked system is overly complicated. You could do a similar setup as my below image where two rails are arrayed horizontally rather than vertically, but if your goal is tool changing, this might not be feasible.

I think the aluminum profile can be a really good option for vertical members of the build, but I think for a CoreXY (or really any sort of motion system where the bed does NOT move horizontally) a large, flat surface with limited vertical beams gives you the best chance to have a quality mechanical layout.