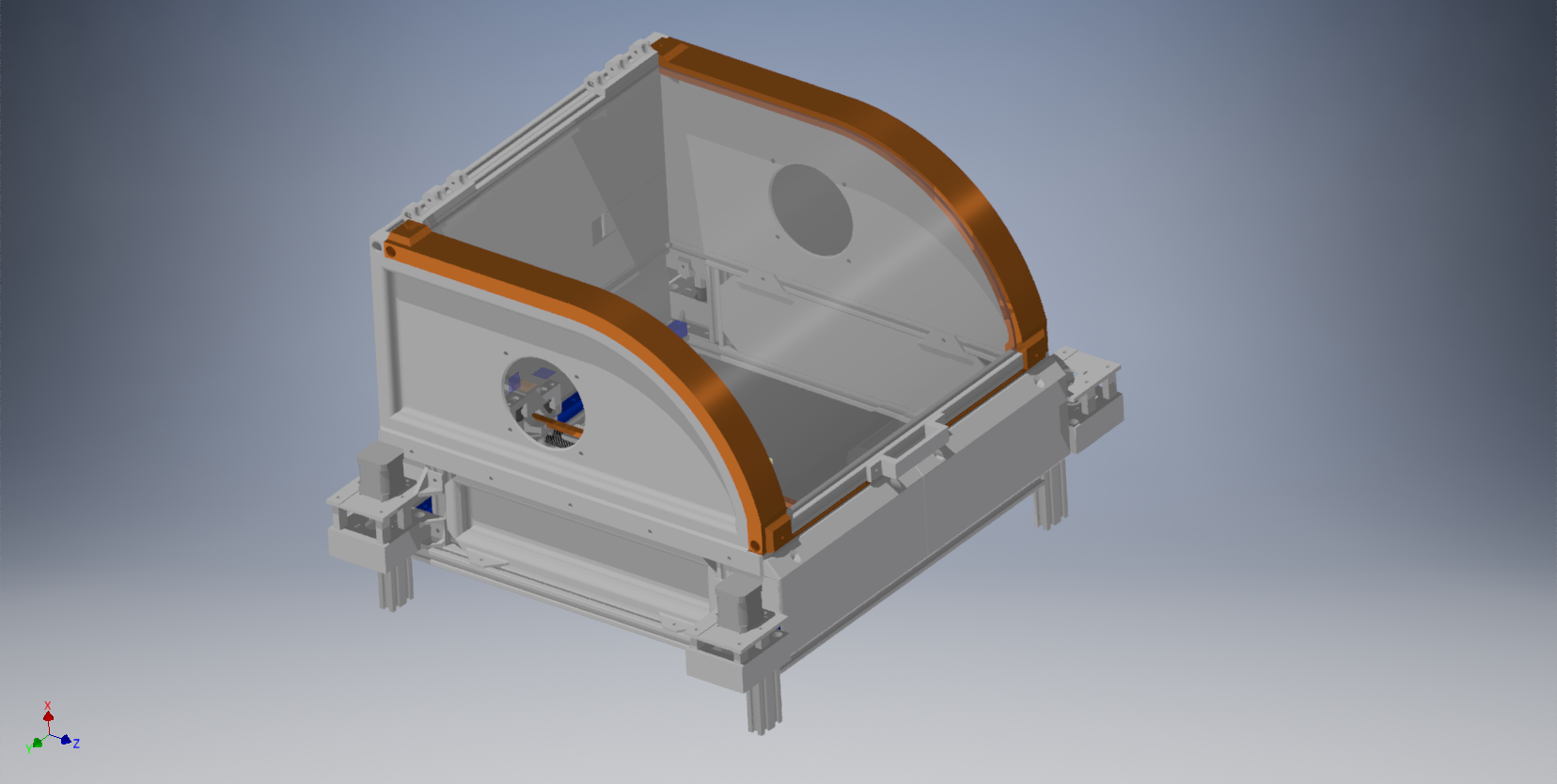

The Mean Machine

-

here a small update , got a few things printed and mounted has well , got more part to print still and waiting for part to come from the mail as well , had to change the spool setup since i decided i was going to install the double extruder in the back as a feeder magazine for the orbiter mosquito combo , just need to make Y filaments guide and a bit of tinkering so i can still have dual material abilities. Spool now sit vertically at the top in the back of the printer , with filaments switch udner it doing a nice curve to the dual extruder than to the orbiter .

-

early mount for orbiter/mosquito

-

undefined Dad003 referenced this topic

undefined Dad003 referenced this topic

-

Did the swap over , using the bmgx2 has Feeder magazine heading to a y adapter , to the orbiter , only did a few test but everything seem to work as intended . I accidentally burn one of the fan mosfet , error in config , I just moved it to another pin my fault on that one . Just need to tweak and make some duck fory cooling fan.

I think I can call this v3 of my printer

-

fully enclosed top once i swap the Y gantry for the lighter version . Need to work something better for my fan duct as well , i have an idea .

-

New fan duct and lift support installed for top

-

Well I have ordered the last few things I need to make the lighter y carriage going in , all the side panel to enclose the top have been printed as well , him now printing the new motor mount , so once I receive those carbon fiber tubing I can swap the whole things and test again . When with a hiwin mgn9 rail with short block . Decide to go with quality components over cheaper one

-

Well new y gantry and axis is nearly done building got a few more part to print to be able to swap over , everything is printed in nylon pa6 cf , overall weight savings on moving axis will be from 500g to 1000g at least , I shrinked a few part as well for more weight savings. Hgr 15 weight 750g for 500mm new mgn9 with rail, block and carbon fiber tubing is like 280g .

-

@Dad003 nice! hope you will have an accelerometer on the print head for testing.

-

@T3P3Tony i do , i just need to make a new connector for it

-

@Dad003 Well ive installed the new rail this week but found that i messed up the heigh of my motor mount unfortunately lol , had made a mistake on some part when i drawn then on my cad software so about 12mm too high, so i had to put some spacer to lift up the rail higher . so got the corrected motor mount reprinted and did a few tweak as well , waiting for more brass heat set insert to swap over again.

so far printing look very good on new motor mount , i think it an improvement from 1-1.5lbs lighter at least than last iteration , ordered 4 more stepper motor with different spec which i think will help me achieve the acceleration and speed him looking . him definitively getting closer to the end of this build i think . Speed an quality.

-

Here a few updates after I swapped my y axis , it working good , still need to modify my motor mount

a

a