control screen shows a temperature range of -273.1 degrees

-

connected my new thermistor. The sensor shows the correct temperature. But the control screen shows a temperature range of -273.1 degrees Celsius. What's wrong?

-

@axiom said in control screen shows a temperature range of -273.1 degrees:

connected my new thermistor. The sensor shows the correct temperature. But the control screen shows a temperature range of -273.1 degrees Celsius. What's wrong?

Where abouts do you see the correct temperature? Or are you measuring it some other way when you say it shows the correct temperature? If it's a normal ntc thermistor, the temperature temperature will drop as the resistance increases. So a large negative temperature would indicate that it's open circuit - i.e. not connected. Suggest you check your wiring.

-

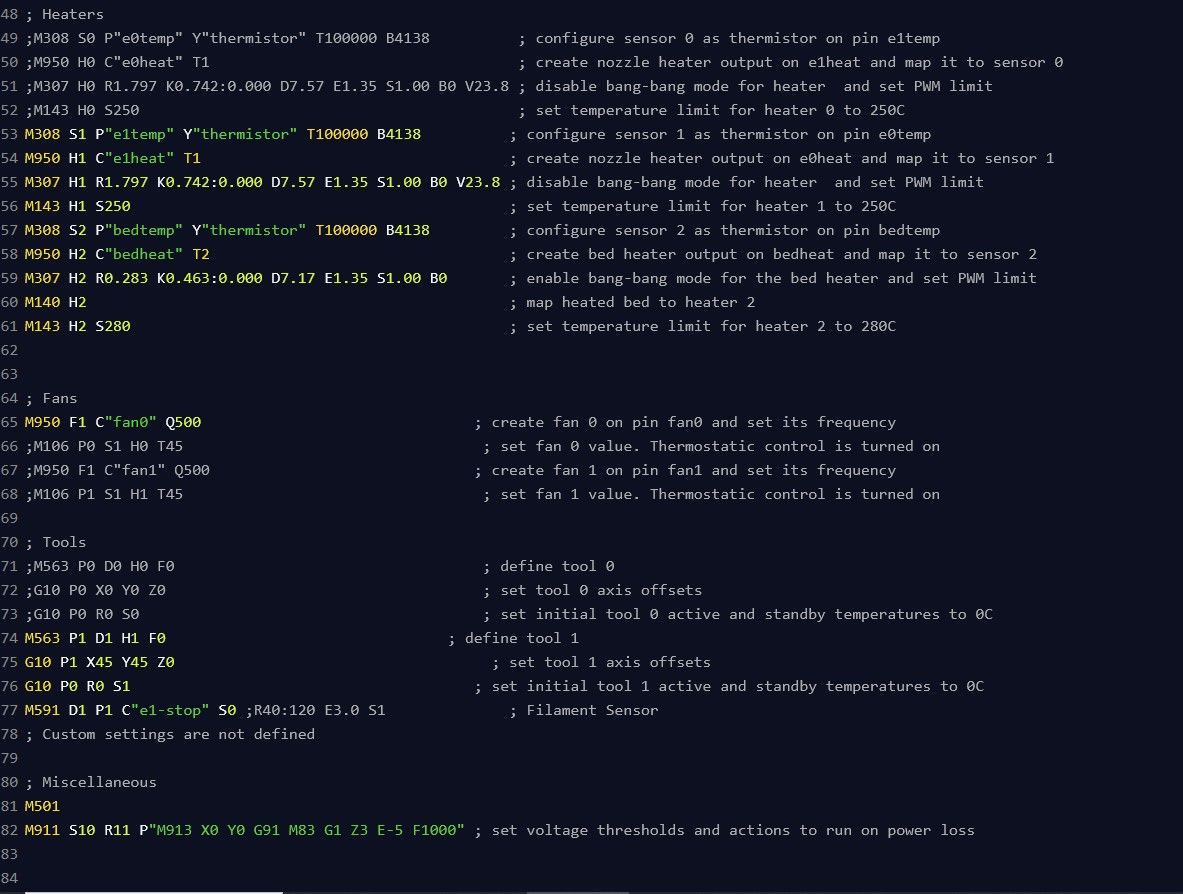

I probably expressed myself awkwardly, so now two screenshots (the control screen and the code). The actual temperature is displayed correctly, so the thermistor is working. But the heating cartridge starts in the selection area with minus temperatures. It's heating...but something isn't right

-

@axiom The active and standby temperatures are values that you input as set points. i.e The active temperature is the temperature that the controller will heat the tool tool when it's selected, while the standby temperature is the temperature that the tool will stay at when it is deselected. These active and standby temperatures are generally set as part of the slicer start gcode or any other "pre-print" macro that you might choose to use. See M568 https://docs.duet3d.com/User_manual/Reference/Gcodes#m568-set-tool-settings

If you want, you could put M568 P0 R0 S0 at the end of your config.g file or in your "tools" section. This will set the active and standby temperatures to 0 (zero) when you first switch on the machine. I see that you once used G10 P0 R0 S0 but that this has been commented out. It is a now deprecated way of setting the active and standby temperatures to 0. You can still use it by removing the ";" at the start of that G10 command but because it is deprecated, using M568 instead is better.

EDIT. -273.1 is the default value used if no other values have been input. It will effectively keep the heater turned off if a tool is selected (by accident).

-

@deckingman Wow, thank you so much, it was so easy!

I have a volcano hot end

https://www.3djake.de/e3d/supervolcano-upgrade-kit-300-mm?sai=7419

Can I also enter 285 or 400 degrees as the maximum temperature, or does the board reach its limits?

And can I also set the standby temperature for the heating bed myself...I didn't find it in the documentation for unger Bedheater standby. -

@axiom said in control screen shows a temperature range of -273.1 degrees:

@deckingman Wow, thank you so much, it was so easy!

I have a volcano hot end

https://www.3djake.de/e3d/supervolcano-upgrade-kit-300-mm?sai=7419

Can I also enter 285 or 400 degrees as the maximum temperature, or does the board reach its limits?

And can I also set the standby temperature for the heating bed myself...I didn't find it in the documentation for unger Bedheater standby.You can set pretty much any temperature you like. It's not a question of if the board will reach a limit, but rather will the hot end? If the hot end fails to reach the set temperature, this will result in a fault condition and the board will turn the heater off.

As for setting a standby temperature for the bed, you could in theory but it wouldn't be wise. The reason for having standby and active temperatures is mostly for machines which have multiple tools. In this situation, when you change from one tool to another, it's better to keep the unused tools warm as it will save time when it is next used. But with a single tool, there isn't really a use case for using standby temperatures and it's generally safer to turn it off when not in use. The same applies to the bed. You can of course use any active temperature you like. This is what I do on my pre-print macro. I start by setting the bed temperature to around 40 Deg C then wait. Once it reaches 40, I then set it to 60 (or whatever value I need for the filament) but in this case, I don't wait. While the bed is heating to the higher temperature, I then home the printer and set the hot end to the active temperature. Then finally I wait for both the heaters to attain their set point temperatures by using M116.