Can I Use SCARA Kinematics For This? M669 Question.

-

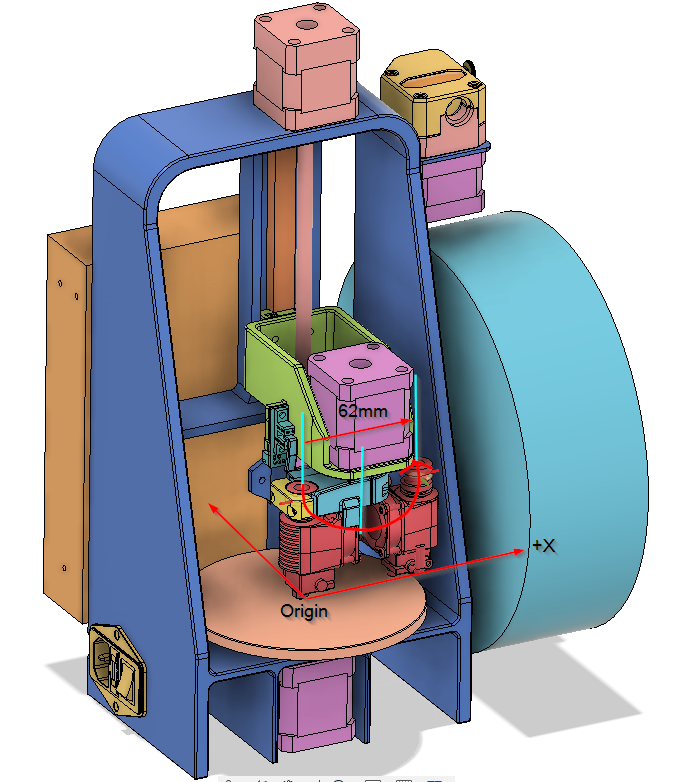

I'm designing a fun little printer with minimal components but I am struggling with the kinematics. I believe that this is equivalent to SCARA kinematics but the bed spins and acts as the proximal arm which means that the X direction changes as the bed spins. If I am incorrect about this then what kinematic style would this be?

I would consider the center of the bed to be 0,0.

The distal arm is 31mm long and its axis of rotation is exactly 31mm from the center of the bed in what I would call the +X direction. This means that there is theoretically no dead-zone in the center of the bed.

The bed (proximal arm) can spin continuously because there is no heated bed and in theory doesn't require homing.

The distal arm has 180 degrees of rotation. According to the documentation, a positive rotation is counter-clockwise when viewed from above and 0 degrees for the distal arm is defined as when the distal arm is in line with the proximal arm. This makes me think that the B parameter of the M669 command would be -180:0 since the arm swings 180 degrees in the negative (clockwise) direction from 0 degrees which is the maximum angle the distal arm can reach.

Would this be the correct M669 command?

M669 K4 P31 D31 A0:3600 B-180:-0 X0 Y0Would the crosstalk parameter be 0?

Would the X and Y parameters be 0 since the nozzle can reach the center of the bed?Even the example provided here seemed confused about the crosstalk parameter.

https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareSCARAPrinter#Section_Movement_section_of_config_g_fileEdit: here is more of my config file so far.

; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X8.889 Y8.889 Z400 E415 ; set (steps/mm) or (steps/degree) θ Axis: 200 steps/rotation * 16 microsteps/step / 360 degrees/rotation = 8.889 steps/degree M566 X300 Y300 Z10 E400.00 ; set maximum instantaneous speed changes (mm/min) or (degree/min) M203 X12000 Y12000 Z450 E1200 ; set maximum speeds (mm/min) or (degree/min) M201 X400 Y400 Z30.00 E250.00 ; set accelerations (mm/s^2) or (degree/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-62 Y-62 Z0 S1 ; set axis minima. Are these in mm or degrees? M208 X62 Y62 Z110 S0 ; set axis maxima. Are these in mm or degrees? -

@binterryan76 Maybe the dual disk thread is helpful for you?

Printing close to the center of bed will be impossible for your printer. There are two singularities AFAI understand.

-

@binterryan76 please check the polar kinematics with a rotating, one linear and one Z linear movement. Your image confuses me with the big blue wheel on right, because according to your description it is a linear movement. If not, please tell the kind of movements.

If your axes are one rotational for the plate, one linear actuated from the right stepper and Z from top linear, then it is Polar kinematics:

https://docs.duet3d.com/User_manual/Machine_configuration/Configuration_Polar

so it's K7.As @o_lampe said, at 0,0 would be a singularity, which is an unprintable point.

-

@JoergS5 @o_lampe

That's ok if the center is unusable, it will just have a smaller donut shaped build volume.Sorry, the big blue wheel on the right is just a filament spool and is unrelated to the kinematics.

X is rotational, Y is rotational, and Z is linear.

The arrow labeled 62mm is just a distance measurement from the min and max travel points.

It is similar to the dual disk printer but I think mine wont have crosstalk parameters if I am understanding crosstalk correctly for polar kinematics. -

@JoergS5 said in Can I Use SCARA Kinematics For This? M669 Question.:

Your image confuses me with the big blue wheel on right,

That's a role of filament, I'd say...above is the extruder.

The motion part are two rotational axes with linear Z.@binterryan76 Maybe it's better to rotate the X-arm 90° or less? Place the X-stepper further back, right next to the linear guide of the Z-axis.

Think of an old vinyl-record player...

That would reduce the steps/degree, but required accelerations would be on the healthy side. -

@binterryan76 ok, thanks for explanation, I confused it with polar because I don't see your second rotary axis in the image. And I already commented on this construction in the other thread

It's a long time ago, I forgot about it...

It's a long time ago, I forgot about it...Comparing it with the printer dual-disc on hackaday, I would say they're different: the hackaday second rotary is mounted on the first rotary one.

Your one, if it's the violet stepper in the middle is fixed in XY position (only moving in Z) as well as the lower plate, so it's not Scara.

IMHO: if you place the nozzle to 0,0, in my understanding you can reach all positions (maybe 0,0 excluded), but the kinematics is not available (yet) in RRF, because it is of type three independent axes with respect to XY, but two of them rotary. The idea is interesting, because the steppers are on non-moving (only the middle slow Z-moving). In my opinion added gears may be necessary to get precision.

I

hate it to say*), but robot kinematics will support this kinematics perfectly. But this kinematics is in the middle of a major redesign and not ready to use it.

https://docs.duet3d.com/User_manual/Machine_configuration/Configuring_RepRapFirmware_for_a_Robot_printer*) because it sets me under time pressure. It will take a few weeks until I have a new RRF build. Most of those 2 to 7 axis constructions will be supported.