-

Hello, I've got multiple toolheads each with multiple heaters and thermistors. From what I've read, I think I've configured them correctly, however, I don't understand why I have redundant tool icons for T1 and T2 on my PanelDue, where I only have one tool icon on T0. Have I made a mistake? Also, despite the header of my config file, I'm running 3.4.5.

; Configuration file for Duet 3 MB 6XD (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Fri Dec 09 2022 12:10:26 GMT-0600 (Central Standard Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Printer" ; set printer name ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drive setup ; TX:X:X:X Min stp pls width, stp ple interval, dir setup time, dir hold time, in microseconds M569 P121.0 S1 R1 T2:4:2:2 ; physical drive X M569 P0.0 S1 R1 T2:4:2:2 ; physical drive Y1 M569 P0.1 S1 R1 T2:4:2:2 ; physical drive Y2 M569 P0.2 S1 R1 T2:4:2:2 ; physical drive Z1 M569 P0.3 S1 R1 T2:4:2:2 ; physical drive Z2 M569 P0.4 S1 R1 T2:4:2:2 ; physical drive Z3 M569 P0.5 S1 R1 T2:4:2:2 ; physical drive Z4 M569 P3.0 S0 R1 ; physical drive E1 Pulsar Extruder M569 P4.0 S1 R1 ; physical drive E2 Mosquito 1 extruder M569 P4.1 S1 R1 ; physical drive E3 Mosquito 2 extruder M569 P3.1 S0 R1 ; physical drive actuator 1 M569 P3.2 S1 R1 ; physical drive actuator 2 M569 P1.0 S1 R1 ; physical drive garage door G4 S1 ; wait for drive to setup ; Drive mapping M584 X121.0 ; set drive mapping for x axis M584 Y0.0:0.1 ; set drive mapping for y axis M584 Z0.2:0.3:0.4:0.5 ; set drive mapping for z axes M584 E3.0:4.0:4.1 ; set drive mapping for extruder axes M584 U3.1 ; set drive mapping for mosquito actuator 1 M584 V3.2 ; set drive mapping for mosquito actuator 2 M584 W1.0 ; set drive mapping for garage door G4 S1 ; wait for drives to be mapped to letters ; Drive config M350 E1 U1 V1 W1 ; configure microstepping with interpolation M92 X128 Y128 Z12800 E420:420:420 U200 V200 W128 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120:120:120 U120 V120 W120 ; set maximum instantaneous speed changes (mm/min) M203 X42000 Y76050 Z3000 E1200:1200:1200 U500 V500 W100 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250:250:250 U250 V250 W250 ; set accelerations (mm/s^2) M906 E2700:650:650 U400 V400 W800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Brakes M569.7 P0.2 C"out3" ; driver 2 on board 6XD uses port out3 to control the brake M569.7 P0.3 C"out4" ; driver 3 on board 6XD uses port out4 to control the brake M569.7 P0.4 C"out5" ; driver 4 on board 6XD uses port out5 to control the brake M569.7 P0.5 C"out6" ; driver 5 on board 6XD uses port out6 to control the brake ; Endstops M574 X1 S1 P"3.io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 3.io0.in M574 Y1 S1 P"0.io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z M574 U1 S1 P"3.!io4.in" ; configure actuator 1 endstop, high end, microswitch M574 V1 S1 P"3.!io5.in" ; configure actuator 2 endstop, high end, microswitch M574 W1 S1 P"0.io7.in" ; configure garage door endstop, low end, microswitch ;Bed Leveling M671 X-405.7848:1541.3704:1541.3704:-405.7848 Y-226.27405:-226.27405:1472.34965:1472.34965 S1 P5 F1 ;Define Z screw X Y locations, max correction, pitch, fudge factor ; Axis Limits M208 X0 Y0 Z0 U0 V0 W0 S1 ; set axis minima M208 X1200 Y1200 Z1200 U17 V17 W100 S0 ; set axis maxima ; Z-Probe ; servo pin defined in fan accessories section ; create servo pin for BLTouch M558 P8 C"0.io8.in" H5 F120:12 T6000 ; set Z probe type and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X0:1200 Y0:1200 P10:10 ; define mesh grid ; Heaters M308 S0 P"0.temp0" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed sensor 0 as thermistor on pin temp0 M950 H0 C"0.out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang for bed and set pwm M140 P0 H0 S0 R0 ; bed heater 0 uses heater 0 M143 H0 S255 P0 T0 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S1 P"0.temp1" Y"thermistor" A"Chamber" T100000 B4725 C7.06e-8 ; configure chamber sensor 1 as thermistor on pin temp1 M950 H1 C"0.out1" T1 ; create chamber heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang for chamber and set pwm M141 P0 H1 S0 R0 ; chamber heater 1 uses heater 1 M143 H1 S255 P0 T1 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S2 P"3.spi.cs0" Y"rtd-max31865" A"Pulsar Top" ; configure pulsar sensor top as PT100 on pin spi.cs0 M950 H2 C"3.out6" T2 ; create pulsar heater output on out3 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H2 S505 P0 T2 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S3 P"3.spi.cs1" Y"rtd-max31865" A"Pulsar Middle" ; configure pulsar sensor bottom as PT100 on pin spi.cs1 M950 H3 C"3.out7" T3 ; create pulsar heater output on out4 and map it to sensor 3 M307 H3 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H3 S505 P0 T3 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S4 P"4.spi.cs0" Y"rtd-max31865" A"Pulsar Nozzle" ; configure pulsar sensor nozzle as PT100 on pin spi.cs0 M950 H4 C"4.out8" T4 ; create pulsar heater output on out0 and map it to sensor 4 M307 H4 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H4 S505 P0 T4 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S5 P"3.temp0" Y"PT1000" A"Mosquito 1A" ; configure mosquito 1 sensor A as PT1000 on pin temp0 M950 H5 C"3.out0" T5 ; create mosquito heater output on out0 and map it to sensor 5 M307 H5 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H5 S505 P0 T5 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition; M308 S6 P"3.temp1" Y"PT1000" A"Mosquito 1B" ; configure mosquito 1 sensor B as PT1000 on pin temp1; M950 H6 C"3.out1" T6 ; create mosquito heater output on out1 and map it to sensor 6 M307 H6 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H6 S505 P0 T6 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S7 P"4.temp0" Y"PT1000" A"Mosquito 2A" ; configure mosquito 2 sensor A as PT1000 on pin temp2 M950 H7 C"4.out0" T7 ; create mosquito heater output on out2 and map it to sensor 7 M307 H7 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H7 S505 P0 T7 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S8 P"4.temp1" Y"PT1000" A"Mosquito 2B" ; configure mosquito 2 sensor B as PT1000 on pin tem;p0 M950 H8 C"4.out1" T8 ; create mosquito heater output on out0 and map it to sensor 8 M307 H8 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H8 S505 P0 T8 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition ; Accessories M950 F0 C"0.out7" ; create chassis fan 0 on relay M106 P0 S0 H-1 C"Chassis Fan" ; set fan 0 value, thermostatic control off M950 F1 C"0.out8" ; create chamber fan 1 on relay M106 P1 S0 H1 T30 C"Chamber Fan" ; set fan 1 value, thermostatic control from sensor 1 M950 F2 C"0.out2" ; create pulsar pc fan 2 M106 P2 S0 H-1 C"Pulsar PC Fan" ; set fan 2 value, thermostatic control off M950 F3 C"1.out1" ; create mosquito pc fan 3 M106 P3 S0 H-1 C"Mosquito PC Fan" ; set fan 3 value, thermostatic control off M950 F4 C"1.out2" ; create bed vac valve 1 M106 P4 S0 H-1 C"Vacuum Zone 1" ; set fan 5 value, thermostatic control off M950 F5 C"2.out0" ; create bed vac valve 2 M106 P5 S0 H-1 C"Vacuum Zone 2" ; set fan 5 value, thermostatic control off M950 F6 C"2.out1" ; create bed vac valve 3 M106 P6 S0 H-1 C"Vacuum Zone 3" ; set fan 5 value, thermostatic control off M950 F7 C"2.out2" ; create bed vac valve 4 M106 P7 S0 H-1 C"Vacuum Zone 4" ; set fan 5 value, thermostatic control off M950 F8 C"1.out3" ; create door locks on relay M106 P8 S0 H1 T65 C"Door Locks" ; set fan 5 value, thermostatic control on M950 F9 C"2.out4" ; create radiator on relay M106 P9 S1 H2:3:4:5:6:7:8 T45 C"Radiator Fans" ; set fan 8 value, thermostatic control on M950 F10 C"1.out4" ; create probe on relay M106 P10 S0 H-1 C"Probe Solenoid" M950 F11 C"1.out0" ; create venturi valve M106 P11 S0 H-1 C"Venturi" ; set fan 11 value, thermostatic control off M950 F12 C"4.out6" ; create head electronics fan M106 P12 S255 H-1 C"Head Elec Fan" ; set fan 12 value, thermostatic control off ; Trigger Inputs M950 J0 C"1.io0.in" ; assign input j0 to 1.io0.in for right door lock status M581 P0 T0 S0 R1 ; configure external trigger, pin 0, trigger 0, active-inactive, during print M950 J1 C"1.io1.in" ; assign input j1 to 1.io1.in for left door lock status M581 P1 T1 S0 R1 ; configure external trigger, pin 1, trigger 1, active-inactive, during print M950 J2 C"1.io2.in" ; assign input j2 to 1.io2.in for front door lock status M581 P2 T2 S0 R1 ; configure external trigger, pin 2, trigger 2, active-inactive, during print M950 J3 C"1.io3.in" ; assign input j3 to 1.io3.in for right door open status M581 P3 T3 S0 R1 ; configure external trigger, pin 3, trigger 3, active-inactive, during print M950 J4 C"1.io4.in" ; assign input j4 to 1.io4.in for left door open status M581 P4 T4 S0 R1 ; configure external trigger, pin 4, trigger 4, active-inactive, during print M950 J5 C"1.io5.in" ; assign input j5 to 1.io5.in for front door open status M581 P5 T5 S0 R1 ; configure external trigger, pin 5, trigger 5, active-inactive, during print M950 J6 C"3.io1.in" ; assign input j6 to 3.io1.in for pellet hopper status M581 P6 T6 S1 R1 ; configure external trigger, pin 6, trigger 6, active-inactive, during print M581 P6 T7 S0 R0 ; configure external trigger, pin 6, trigger 6, inactive-active, any time ; Tools M563 P0 S"Pulsar" D0 H2:3:4 F2 ; define tool 0 as pulsar, extruder 0, Heaters 2 3 4, Fan 2 G10 P0 R0 S0 ; set tool 0 active and standby temperatures to 0C G10 P0 X0 Y0 Z0 U0 V0 W0 ; set tool 0 axis offests M563 P1 S"Mosquito 1" D1 H5:6 F3 ; define tool 1 as Mosquito 1, extruder 1, Heaters 5 6, Fan 3 G10 P1 R0 S0 ; set tool 1 active and standby temperatures to 0C G10 P1 X0 Y0 Z0 U10 V0 W0 ; set tool 1 axis offests M563 P2 S"Mosquito 2" D2 H7:8 F3 ; define tool 2 as Mosquito 1, extruder 1, Heaters 7 8, Fan 3 G10 P2 R0 S0 ; set tool 2 active and standby temperatures to 0C G10 P2 X0 Y0 Z0 U0 V10 W0 ; set tool 2 axis offests ; Custom settings are not defined ; Miscellaneous T0 ; select first tool -

What firmware version are you running on the PanelDue?

-

@Phaedrux 3.4.0

-

Give 3.4.1 a try.

https://github.com/Duet3D/PanelDueFirmware/releases/tag/3.4.1

There's also a setting on the setup page to collapse redundant heaters I believe. Give that a try.

-

@Phaedrux That sort of fixed it short term, but after making some other changes, or just back luck they are separate again. It seems if I power cycle it though, it goes back to normal.

Here's my new config.g after the changes to how the extruders are set up:

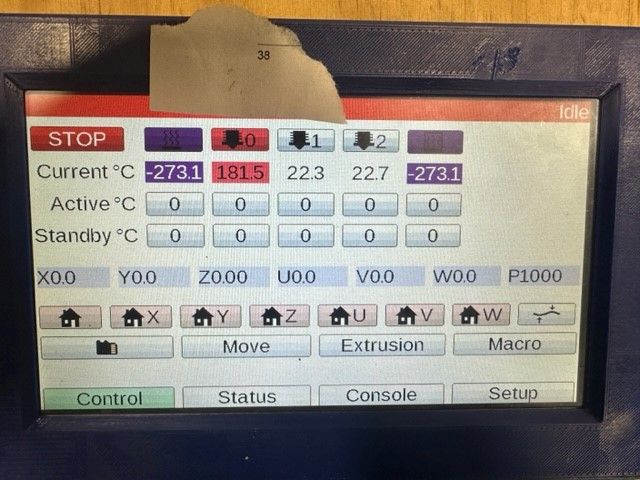

; Configuration file for Duet 3 MB 6XD (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Fri Dec 09 2022 12:10:26 GMT-0600 (Central Standard Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Printer" ; set printer name ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drive setup ; TX:X:X:X Min stp pls width, stp ple interval, dir setup time, dir hold time, in microseconds M569 P121.0 S1 R1 T2:4:2:2 ; physical drive X M569 P0.0 S1 R1 T2:4:2:2 ; physical drive Y1 M569 P0.1 S1 R1 T2:4:2:2 ; physical drive Y2 M569 P0.2 S1 R1 T2:4:2:2 ; physical drive Z1 M569 P0.3 S1 R1 T2:4:2:2 ; physical drive Z2 M569 P0.4 S1 R1 T2:4:2:2 ; physical drive Z3 M569 P0.5 S1 R1 T2:4:2:2 ; physical drive Z4 M569 P105.0 S0 R0 ; physical drive E2 Pulsar Extruder M569 P4.0 S1 R1 ; physical drive E0 Mosquito 1 extruder M569 P4.1 S1 R1 ; physical drive E1 Mosquito 2 extruder M569 P3.1 S0 R1 ; physical drive actuator 1 M569 P3.2 S1 R1 ; physical drive actuator 2 M569 P1.0 S1 R1 ; physical drive garage door G4 S1 ; wait for drive to setup ; Drive mapping M584 X121.0 ; set drive mapping for x axis M584 Y0.0:0.1 ; set drive mapping for y axis M584 Z0.2:0.3:0.4:0.5 ; set drive mapping for z axes M584 E4.0:4.1:105.0 ; set drive mapping for extruder axes M584 U3.1 ; set drive mapping for mosquito actuator 1 M584 V3.2 ; set drive mapping for mosquito actuator 2 M584 W1.0 ; set drive mapping for garage door G4 S1 ; wait for drives to be mapped to letters ; Drive config M350 E16:16 U1 V1 W1 ; configure microstepping with interpolation ******UPDATE XYZ FOR TEKNIC SERVOS******** M92 X128 Y128 Z12800 E224.6:410:410 U200 V200 W128 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120:120:120 U120 V120 W120 ; set maximum instantaneous speed changes (mm/min) M203 X42000 Y76050 Z3000 E9000:1200:1200 U500 V500 W100 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E0.25:3000:3000 U250 V250 W250 ; set accelerations (mm/s^2) M906 E450:450 U400 V400 W800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Brakes M569.7 P0.2 C"out3" ; driver 2 on board 6XD uses port out3 to control the brake M569.7 P0.3 C"out4" ; driver 3 on board 6XD uses port out4 to control the brake M569.7 P0.4 C"out5" ; driver 4 on board 6XD uses port out5 to control the brake M569.7 P0.5 C"out6" ; driver 5 on board 6XD uses port out6 to control the brake ; Endstops M574 X1 S1 P"3.io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 3.io0.in M574 Y1 S1 P"0.io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z M574 U1 S1 P"3.!io4.in" ; configure actuator 1 endstop, high end, microswitch M574 V1 S1 P"3.!io5.in" ; configure actuator 2 endstop, high end, microswitch M574 W1 S1 P"0.io7.in" ; configure garage door endstop, low end, microswitch M208 X1200 Y1200 Z1200 U17 V17 W100 A1000000 S0 ;Bed Leveling M671 X-405.7848:1541.3704:1541.3704:-405.7848 Y-226.27405:-226.27405:1472.34965:1472.34965 S1 P5 F1 ;Define Z screw X Y locations, max correction, pitch, fudge factor ; Axis Limits M208 X0 Y0 Z0 U0 V0 W0 S1 ; set axis minima M208 X1200 Y1200 Z1200 U17 V17 W100 A100000 S0 ; set axis maxima ; Z-Probe ; servo pin defined in fan accessories section ; create servo pin for BLTouch M558 P8 C"0.io8.in" H5 F120:12 T6000 ; set Z probe type and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X0:1200 Y0:1200 P10:10 ; define mesh grid ; Heaters M308 S0 P"0.temp0" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed sensor 0 as thermistor on pin temp0 M950 H0 C"0.out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang for bed and set pwm M140 P0 H0 S0 R0 ; bed heater 0 uses heater 0 M143 H0 S255 P0 T0 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S1 P"0.temp1" Y"thermistor" A"Chamber" T100000 B4725 C7.06e-8 ; configure chamber sensor 1 as thermistor on pin temp1 M950 H1 C"0.out1" T1 ; create chamber heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang for chamber and set pwm M141 P0 H1 S0 R0 ; chamber heater 1 uses heater 1 M143 H1 S255 P0 T1 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S2 P"3.spi.cs0" Y"rtd-max31865" A"Pulsar Top" ; configure pulsar sensor top as PT100 on pin spi.cs0 M950 H2 C"3.out6" T2 ; create pulsar heater output on out3 and map it to sensor 2 M307 H2 A940 C810 D22 S1.0 B0 ; disable bang-bang for pulsar and set pwm M143 H2 S480 P0 T2 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S3 P"3.spi.cs1" Y"rtd-max31865" A"Pulsar Middle" ; configure pulsar sensor bottom as PT100 on pin spi.cs1 M950 H3 C"3.out7" T3 ; create pulsar heater output on out4 and map it to sensor 3 M307 H3 A940 C810 D22 S1.0 B0 ; disable bang-bang for pulsar and set pwm M143 H3 S480 P0 T3 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S4 P"4.spi.cs0" Y"rtd-max31865" A"Pulsar Nozzle" ; configure pulsar sensor nozzle as PT100 on pin spi.cs0 M950 H4 C"4.out8" T4 ; create pulsar heater output on out0 and map it to sensor 4 M307 H4 A795 C920 D10 S1.0 B0 ; disable bang-bang for pulsar and set pwm M143 H4 S480 P0 T4 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S5 P"3.temp0" Y"PT1000" A"Mosquito 1A" ; configure mosquito 1 sensor A as PT1000 on pin temp0 M950 H5 C"3.out0" T5 ; create mosquito heater output on out0 and map it to sensor 5 M307 H5 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H5 S505 P0 T5 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition; M308 S6 P"3.temp1" Y"PT1000" A"Mosquito 1B" ; configure mosquito 1 sensor B as PT1000 on pin temp1; M950 H6 C"3.out1" T6 ; create mosquito heater output on out1 and map it to sensor 6 M307 H6 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H6 S505 P0 T6 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S7 P"4.temp0" Y"PT1000" A"Mosquito 2A" ; configure mosquito 2 sensor A as PT1000 on pin temp2 M950 H7 C"4.out0" T7 ; create mosquito heater output on out2 and map it to sensor 7 M307 H7 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H7 S505 P0 T7 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition M308 S8 P"4.temp1" Y"PT1000" A"Mosquito 2B" ; configure mosquito 2 sensor B as PT1000 on pin tem;p0 M950 H8 C"4.out1" T8 ; create mosquito heater output on out0 and map it to sensor 8 M307 H8 B0 S1.00 ; disable bang-bang for pulsar and set pwm M143 H8 S505 P0 T8 A2 C0 ; Max heater temp: Heater number, max temp, monitor number, sensor number, action, condition ; Heater Faults M570 H2 P1000 T15 R10 M570 H3 P1000 T15 R10 M570 H4 P1000 T15 R10 ; Accessories M950 F0 C"0.out7" ; create chassis fan 0 on relay M106 P0 S0 H-1 C"Chassis Fan" ; set fan 0 value, thermostatic control off M950 F1 C"0.out8" ; create chamber fan 1 on relay M106 P1 S0 H1 T30 C"Chamber Fan" ; set fan 1 value, thermostatic control from sensor 1 M950 F2 C"0.out2" ; create pulsar pc fan 2 M106 P2 S0 H-1 C"Pulsar PC Fan" ; set fan 2 value, thermostatic control off M950 F3 C"1.out1" ; create mosquito pc fan 3 M106 P3 S0 H-1 C"Mosquito PC Fan" ; set fan 3 value, thermostatic control off M950 F4 C"1.out2" ; create bed vac valve 1 M106 P4 S0 H-1 C"Vacuum Zone 1" ; set fan 5 value, thermostatic control off M950 F5 C"2.out0" ; create bed vac valve 2 M106 P5 S0 H-1 C"Vacuum Zone 2" ; set fan 5 value, thermostatic control off M950 F6 C"2.out1" ; create bed vac valve 3 M106 P6 S0 H-1 C"Vacuum Zone 3" ; set fan 5 value, thermostatic control off M950 F7 C"2.out2" ; create bed vac valve 4 M106 P7 S0 H-1 C"Vacuum Zone 4" ; set fan 5 value, thermostatic control off M950 F8 C"1.out3" ; create door locks on relay M106 P8 S0 H1 T65 C"Door Locks" ; set fan 5 value, thermostatic control on M950 F9 C"2.out4" ; create radiator on relay M106 P9 S1 H2:3:4:5:6:7:8 T45 C"Radiator Fans" ; set fan 8 value, thermostatic control on M950 F10 C"1.out4" ; create probe on relay M106 P10 S0 H-1 C"Probe Solenoid" M950 F11 C"1.out0" ; create venturi valve M106 P11 S0 H-1 C"Venturi" ; set fan 11 value, thermostatic control off M950 F12 C"4.out6" ; create head electronics fan M106 P12 S255 H-1 C"Head Elec Fan" ; set fan 12 value, thermostatic control off ; Trigger Inputs M950 J0 C"1.io0.in" ; assign input j0 to 1.io0.in for right door lock status M581 P0 T0 S0 R1 ; configure external trigger, pin 0, trigger 0, active-inactive, during print M950 J1 C"1.io1.in" ; assign input j1 to 1.io1.in for left door lock status M581 P1 T1 S0 R1 ; configure external trigger, pin 1, trigger 1, active-inactive, during print M950 J2 C"1.io2.in" ; assign input j2 to 1.io2.in for front door lock status M581 P2 T2 S0 R1 ; configure external trigger, pin 2, trigger 2, active-inactive, during print M950 J3 C"1.io3.in" ; assign input j3 to 1.io3.in for right door open status M581 P3 T3 S0 R1 ; configure external trigger, pin 3, trigger 3, active-inactive, during print M950 J4 C"1.io4.in" ; assign input j4 to 1.io4.in for left door open status M581 P4 T4 S0 R1 ; configure external trigger, pin 4, trigger 4, active-inactive, during print M950 J5 C"1.io5.in" ; assign input j5 to 1.io5.in for front door open status M581 P5 T5 S0 R1 ; configure external trigger, pin 5, trigger 5, active-inactive, during print M950 J6 C"3.io1.in" ; assign input j6 to 3.io1.in for pellet hopper status M581 P6 T6 S1 R1 ; configure external trigger, pin 6, trigger 6, active-inactive, during print M581 P6 T7 S0 R0 ; configure external trigger, pin 6, trigger 6, inactive-active, any time ; Tools M563 P0 S"Pulsar" D2 H2:3:4 F2 ; define tool 0 as pulsar, extruder 0, Heaters 2 3 4, Fan 2 G10 P0 R0 S0 ; set tool 0 active and standby temperatures to 0C G10 P0 X0 Y0 Z0 U0 V0 W0 ; set tool 0 axis offests M563 P1 S"Mosquito 1" D0 H5:6 F3 ; define tool 1 as Mosquito 1, extruder 1, Heaters 5 6, Fan 3 G10 P1 R0 S0 ; set tool 1 active and standby temperatures to 0C G10 P1 X0 Y0 Z0 U17 V0 W0 ; set tool 1 axis offests M563 P2 S"Mosquito 2" D1 H7:8 F3 ; define tool 2 as Mosquito 1, extruder 1, Heaters 7 8, Fan 3 G10 P2 R0 S0 ; set tool 2 active and standby temperatures to 0C G10 P2 X0 Y0 Z0 U0 V17 W0 ; set tool 2 axis offests ; Custom settings are not defined ; Miscellaneous T0 ; select first toolIf I combine the heaters it does this, but I actually want individual heater control on T0 so I can't use this.

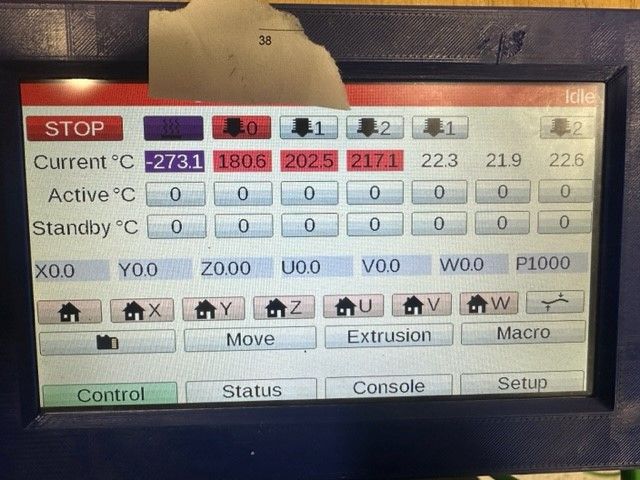

When I press the separate button it does this mess, and stays that way after an E-Stop.

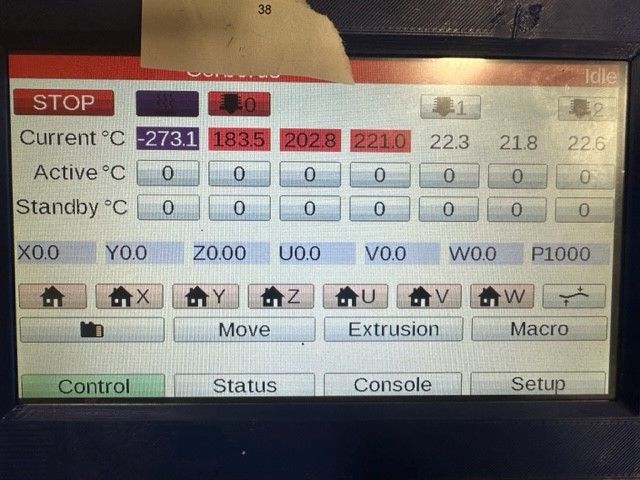

Power cycle returns to this which is better, but I can't see all my heaters.

Ideally, I'd like to see all the heaters and my heated chamber, but I realize that's a lot to ask. Any chance there's an easy way for me to modify the firmware to make the icons smaller to all fit? Perhaps removing the decimal place would help?

Thanks

-

undefined Phaedrux moved this topic from General Discussion

undefined Phaedrux moved this topic from General Discussion

-

The PanelDue is a bit of a limited environment for complex tool/heater arrangements. For more detailed control you'd have to use the web interface.

Can you give some details about your tool setups and the usage cases?

-

@Phaedrux I've got a 3-zone pellet extruder, and two dual-heater filament heads. The pellet extruder needs individual temperature control, however, the secondary heaters/thermistors on the filament heads are ran at the same temperatures. Is it possible to only combine the filament heads but leave the temperature control on the pellet extruder separate?