Help on custom Delta printer build

-

Hello everyone!

I am building a custom delta 3d printer and I could use some help on calculating the rod lengths.

I made a simulation of the geometry in the following link

http://danalspub.com/DKcalc/?he=1000&ve=2000&dr=900&lr=1550

The vertical extrusions will be 2000mm as I already have them.

The horizontal extrusions at 1000mm give me a printable radius of 316mm which I am happy with.

Is the ratio of the horizontal extrusions and rod lengths in the simulation correct or is there is a better solution?

Thanks in advance for any help!

-

I don't know much about delta printers, but everything I do know comes from here

https://docs.duet3d.com/en/User_manual/Machine_configuration/Configuration_linear_delta

https://docs.duet3d.com/en/User_manual/Tuning/Delta_calibration

-

@yiannis i used the openscad delta simulator to maximize my stability for my delta over the print area when designing the parts : effector carriages, and arm spacing. The frame is a rostock max metal, and the arms are 360mm haydn magball arms. I did get improvements in my printer optimizing for stability so it's what i'd recommend using for any variables you don't have locked down.

-

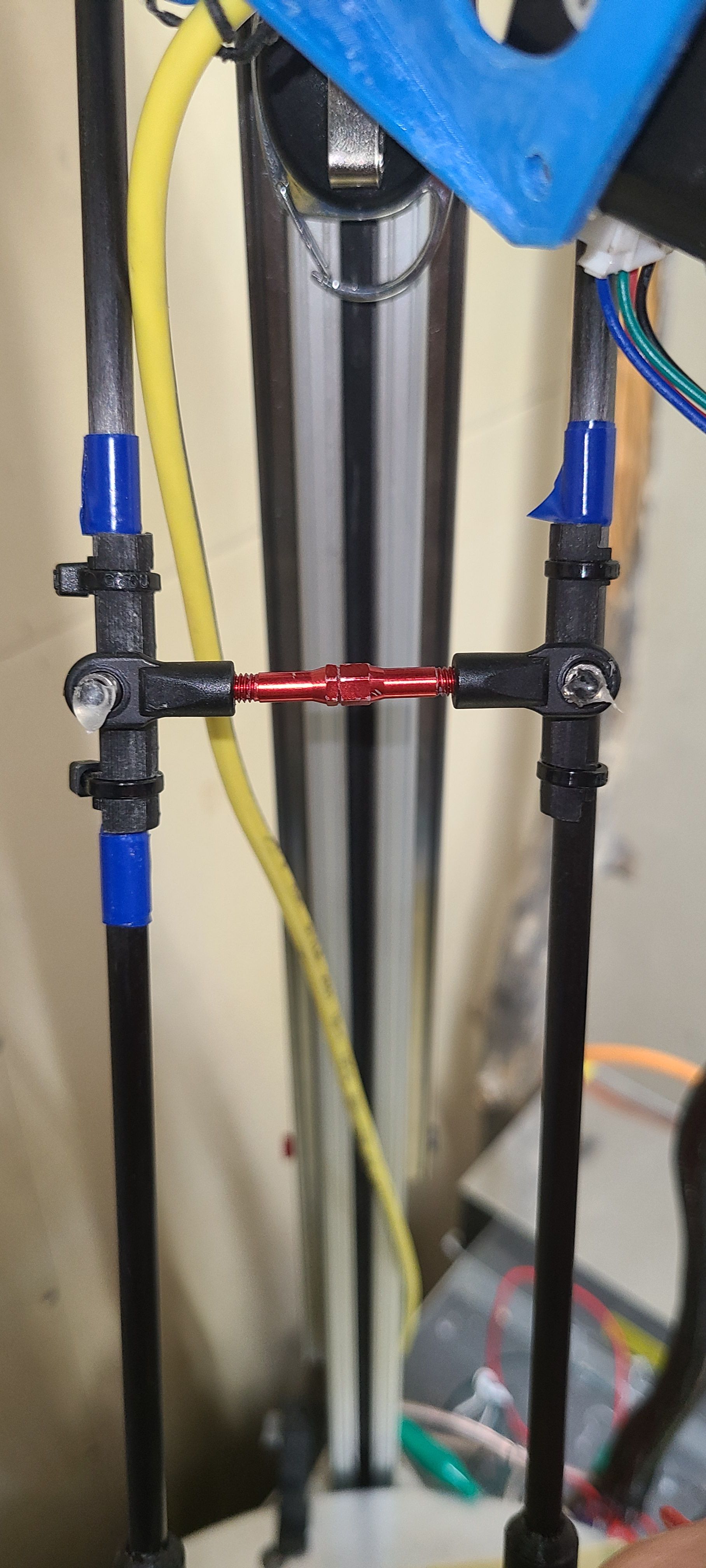

If your making your own arms, I did a test (yes i haven't shared it before now but i had another trick up my sleeve i wanted to test out and grab comparison data from the accelerometer) and got improvements on ringing/ on 360mm arms by reinforcing them midway. It does not affect the arms as long as the articulation is centered on the arms.

-

@yiannis wow. Big delta. Where you getting a 640mm dia heated bed?

-

@breed No need for a heated bed I am printing ceramics