Magnum+ (LGX Directdrive) Feedrate Config problem

-

I have the following setup: Duet2 Board, Magnum+ Hotend with LGX Etruder.

So far everything is going great.

My problem is that I occasionally get sawtooth on straight lines and I have already tried with feedrate etc. I can't get any further here because the approach is missing. The more flow I give, the bigger the problem becomes.

The Printer is Delta with a full-metal Chassis an Carbon arms. The problem is also seen at slow speed 100 mm/sec.

I print the following:

ASA, 170mm/sec, 260 degrees with 1mm CHT Nozzle. Extrusion width 1.20mmBevor i change to Magnum+ with LGX directdricre, i have printed with a Bowden with a Supervolcano, without problems 140mm/sec. So I think the problem can found in the Config.

Bowden > Directdrive with Magnum+.I have attached my current config and a picture of the problem.

Maybe someone can give me a direction.

-

Post your full config and the results of M122 and M98 P"config.g".

-

Hello and thank you for the answer. I have attached the files here.

I did some more testing yesterday. I have changed the Printer (same Model) for check. In advance I determined the maximum feed rate and thus the possible volume. E-Steps calibrated fine with 408 steps.This is at 260 degrees at 111mm3. So the point should be closed.

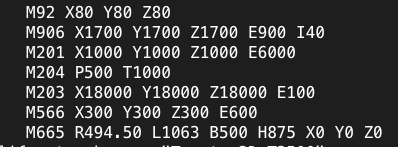

Single-walled prints brought the result as shown in the picture. 1x pressure test at 130mm/s with 1.0mm extrusion width and 1x pressure test at 130mm/s with 1.2mm extrusion width. The test starts at 100mm/sec and gradually increases to 130mm/sec.

The Wall thickness was nice, 1.05-1.01 / at test 2 1.22 - 1.24mm. The Flow should be correct. Temperature changes didn't help to solve.

I have also done various tests with other values in the M566, but very ignorantly and unsuccessfully. The Body I test ist a Quader with 200x200 / 400x400 / 500x500mm.

Slicer Ideamker as well as S3D are identical results.

I have only changed the Supervolcano in an Bowdensetup against:

• Bondtech LGX ACE with Magnum+

• 2 Heater at 50W (parallel wired), with CHT 1.0 Highflow-Nozzle. Std. ThermistiorI used different Filaments of ASA Formfutura, same Material worked on my other machines fine. The result of my test are the more material is used, the worse the problem become.

M122.txt

M98.txt

config.g

Last Testprint file: Test_200x200_V7.gcode -

What layer height?

What is your measured volumetric flow rate? 111m^3/s? I know the CHT is impressive, but that seems excessive. Maybe I misunderstand you there.

-

@phaedrux

Hello, I heated the nozzle to 260 degrees, extruded 500mm material, and gradually increased the speed until the extruder skipped. This happens at 47 mm/sec. I determined this using a formula. If I have an error, feel free to correct me.I have a layer height of 0.4mm. The problem occurs at 0.3 as well, just not as severe.

Can you give me a starting point to find the problem. 130mm/sec shouldn't be too fast, because I can also print this speed with the Supervolcano with a 1.2mm nozzle and 0.4 layer height. I can't imagine the Magnum+ being weaker than the Supervolcano.

I discovered your tuning macros and would like to test them further, but I don't currently know what the problem is. (Acc, Jerk, XY or E) ?

-

I don't think it has anything to do with acc, jerk, XYE as that doesn't really come into play. But it does sounds like you're running into the volumetric extrusion limits. As you describe it, the problems gets less severe when you slow down or reduce the extrusion height and width. And your photos look like inconsistent extrusion.

Putting 47mm/sec into my formula also gives ~110mm^3/s but how long are you able to sustain that? It could be that you're just pushing it a bit too far.

As for what the Magnum+ should be able to do versus a super volcano I can't say. You'd have to check with Slice to see if it's meeting expectation.

Are you noticing a drop in the temperature graph when pushing the extrusion fast? if so you could try tuning the extrusion heater feed forward to compensate for the dip.

https://docs.duet3d.com/User_manual/Reference/Gcodes#m309-set-or-report-heater-feedforward

-

@phaedrux

Hello, thanks for the approach. This setup, which I am currently using, is already available from the manufacturer (is currently being presented). This works here with speeds of 200mm/sec.According to Slice, the hotend with the CHT Nozzel performs significantly better than the Supervolcano (but every manufacturer will say that).

Anyway, thanks for the M309 approach, I'd like to pursue that as I can indeed see a steady fall and rise (minimal but present). All of your tests with the tuning macros today also point to your opinion that it is simply a flow break at the corners. With a reduced M204 P260 (instead of P500)

I was able to print cleanly at 160mm/sec. Which is clear as it slows down to 140mm/sec in the corners. Even with a provoked underetrusion (1mm nozzle, with 0.8mm extrusion runs clean) which also suggests that the flow breaks off at the high rates. What I just don't understand is why doesn't he do that on the long straights where he runs fast and has to encourage a lot.

Why in the corners? Doesn't he manage to heat it up as quickly and as much because of the change of direction?

I looked at the rather short documentation for the M309 and unfortunately I can't figure out what values to set here? Unfortunately, Google doesn't really help here either.

-

@phaedrux

I have tested the Temperatur with a Long and fast extrusion (1000mm) the tempersture falls down 5-7 degrees.Can this are the Problem what you mean?

Can you explain me, how i have to configure M309?

-

Yes that seems like a pretty significant drop in temp.

Have you done a PID tune at 260c using M303 T0 S260?

For feed forward all I have for tips on usage at the moment is found in the wiki

Calibration

Heat the nozzle and let the temperature stabilise. Then commence extrusion at a fast rate (as fast as the extruder can reasonable manage without skipping) and watch the temperature. If there is an initial drop, then increase the feedforward. What you are looking for is either the temperature remaining steady, or rising by a small amount followed by a drop below target of a similar amount. When extrusion stops the reverse will happen, i.e. with no feedforward the temperature will rise and then gradually return to target.If you send M309 P0 it should report the current S value. Adjust from there.

-

Slice's published numbers for Magnum+ printing ABS were 91mm³/s, printing at 300°C, 60 degrees above the manufacturer-recommended print temperature (53mm³/s if printed at the recommended temperature of 240°C).

CHT nozzle supposedly gives 30%+ higher volumetric flow rate (probably more for a 1.0mm nozzle).Super Volcano claims a max volumetric flow rate of 110mm³/s.