Best Choice of Motor for a Delta Printer

-

@bberger Sorry for not answering earlier. Yes, I have accepted to never try to use Stealthchop again.

I have ordered the third set of motors for this machine. First LDO, then OMC and now the Wantai you suggested me, that seem to be the best in the category according to the results obtained in the EMF Calculator. Hope I will give the older motors good use in another project.

I will report my findings when I install the Wantai in the next weeks.

I am opposed to use the dampers with TMC drivers. They were needed in the old times (A4988) but now I think they are obsolete and they introduce a elastic joint which can lead to lack of precision. The noise came from motors and does not seem to resonate in the frame.

I plan to build an enclosure in the near future but I am designing one of my own that can be easily attached via magnets and removed when not needed or for doing maintenance.

I will have a look again at pulleys for sure.

Thank you for your help. I will keep posting here when I have updates to share

-

@ignacmc don't forget to share you enclosure please

Still trying to get away from the parabolic resonance hell the CarstenD enclosure gives me (it also is too narrow for my cooling solution).

Still trying to get away from the parabolic resonance hell the CarstenD enclosure gives me (it also is too narrow for my cooling solution).I know Chris W. in the Advanced Predator group has designed a flat enclosure with more spacing from the same panel sizes that Carsten used, but haven't gotten around to print the parts yet..

-

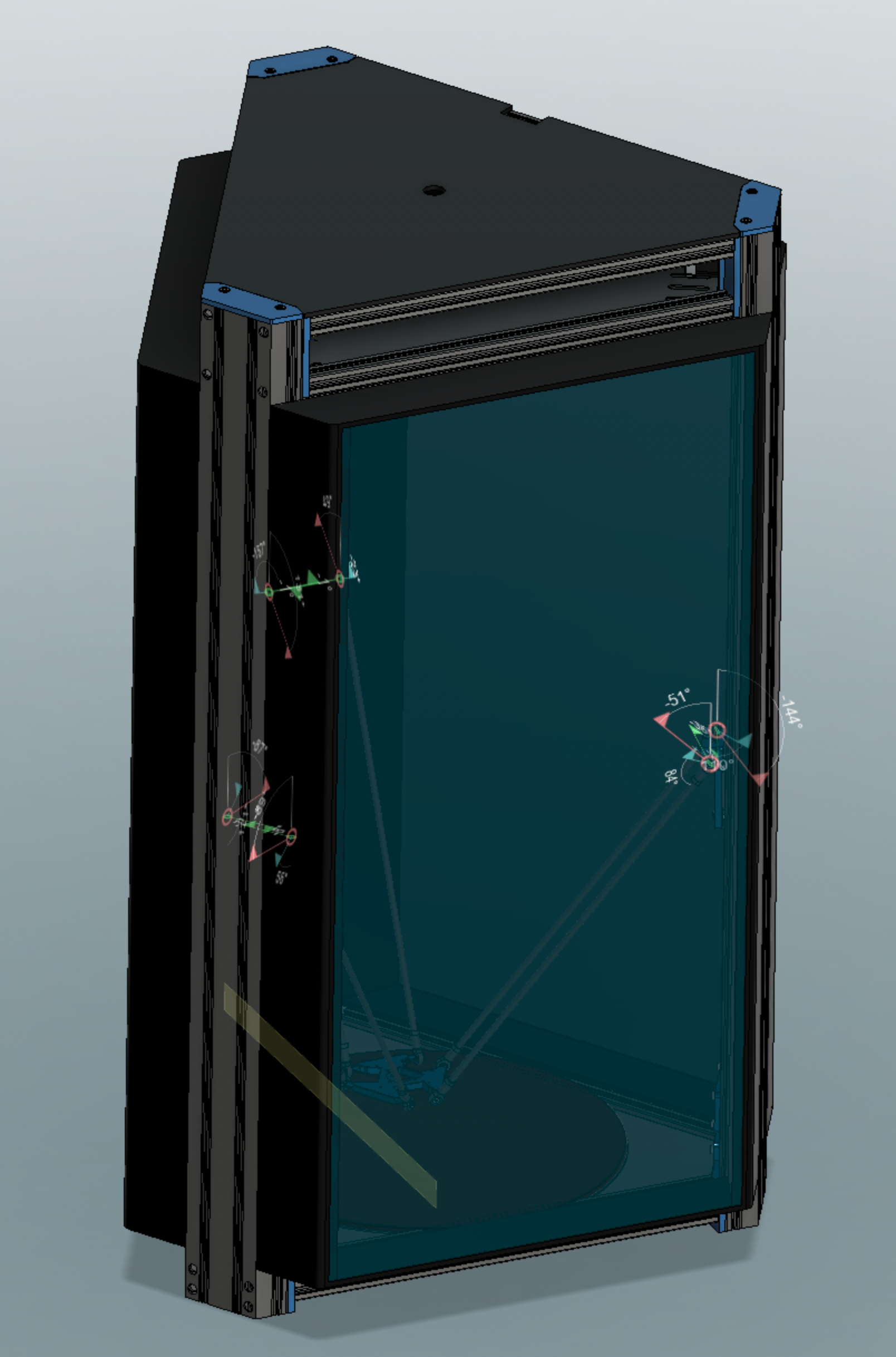

@bberger My idea is something like this:

I can send you the Fusion360 files if you want. I intend to place some steel tape on the towers and some embedded magnets or magnetic tape on the enclosure panels

-

@ignacmc I'd happily take the F360 files

-

@bberger Here you have them...still a work in progress, but can be printed so far...I tried to avoid all collissions with bolt heads and so on. You have on FRONTAL part and TWO sides...If you develop them further, please share

Change extension from STL to F3D

-

@bberger said in Best Choice of Motor for a Delta Printer:

Wantai 42BYGHM810

I use the Wantai 42BYGHM810 on my delta. I don't use dampers and the motors are basically silent. I have gone through 3 different sets of dampers and after chasing every other mechanical issue I could and tuning the drivers, they very much were unnecessary and only added to ghosting. Whatever your choice if you don't have a pillow block (most printers don't) then I highly recommend putting a roller bearing between the pulley and the motor case (my current preference is the needle bearings). You have to measure the space available and account for possibly adding some washers to keep your pulley centered. What this does it reduce the tension on the motor shaft, the tension on the pulley instead is applied to the thrust bearing and motor to the motor case saving your internal motor bearings. Before I started doing this my previous motors needed replacement every 2-3 years because of bearing issues on my deltas, and I feel like it helps on ghosting and tension too (that's just an added bonus so wasn't worth testing for me).

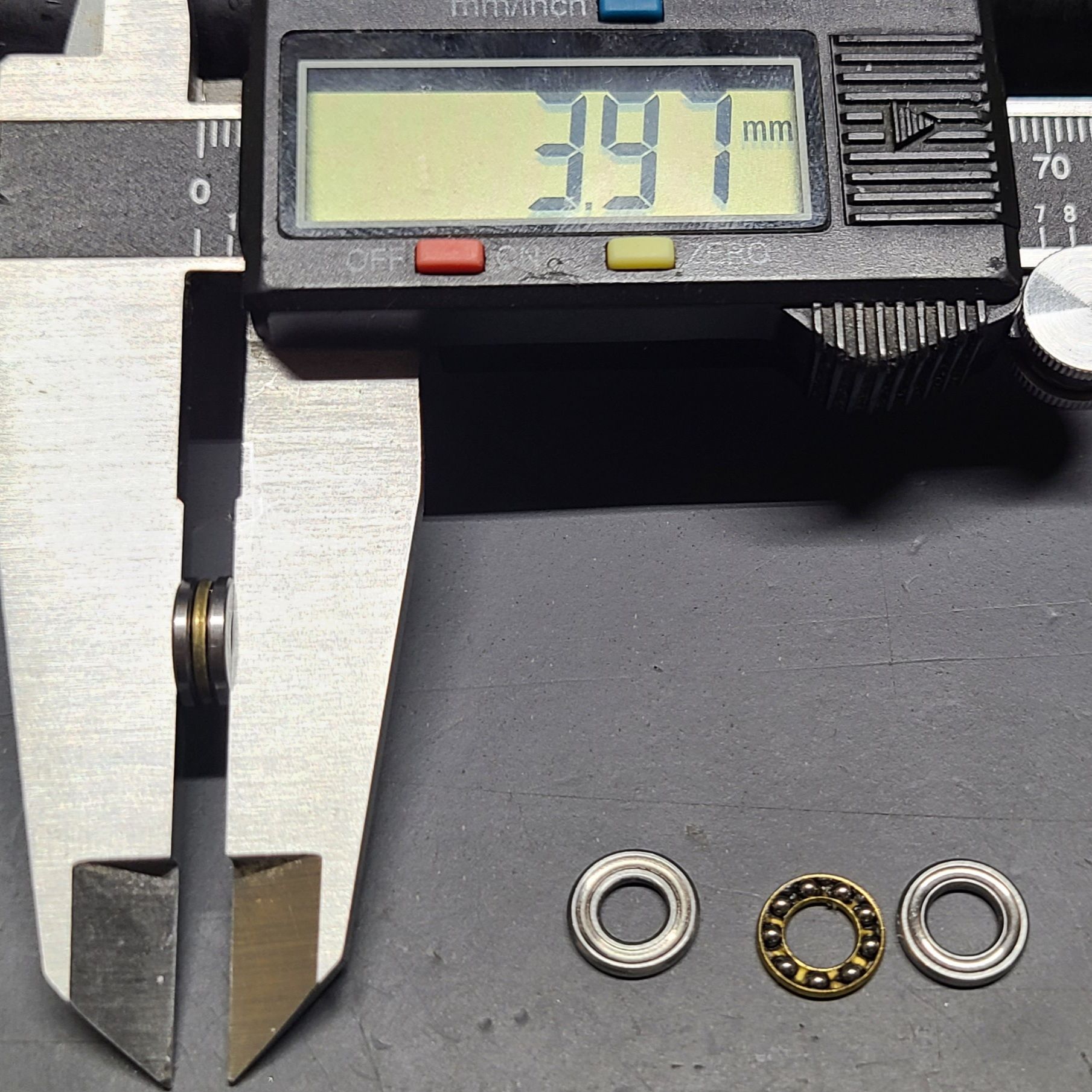

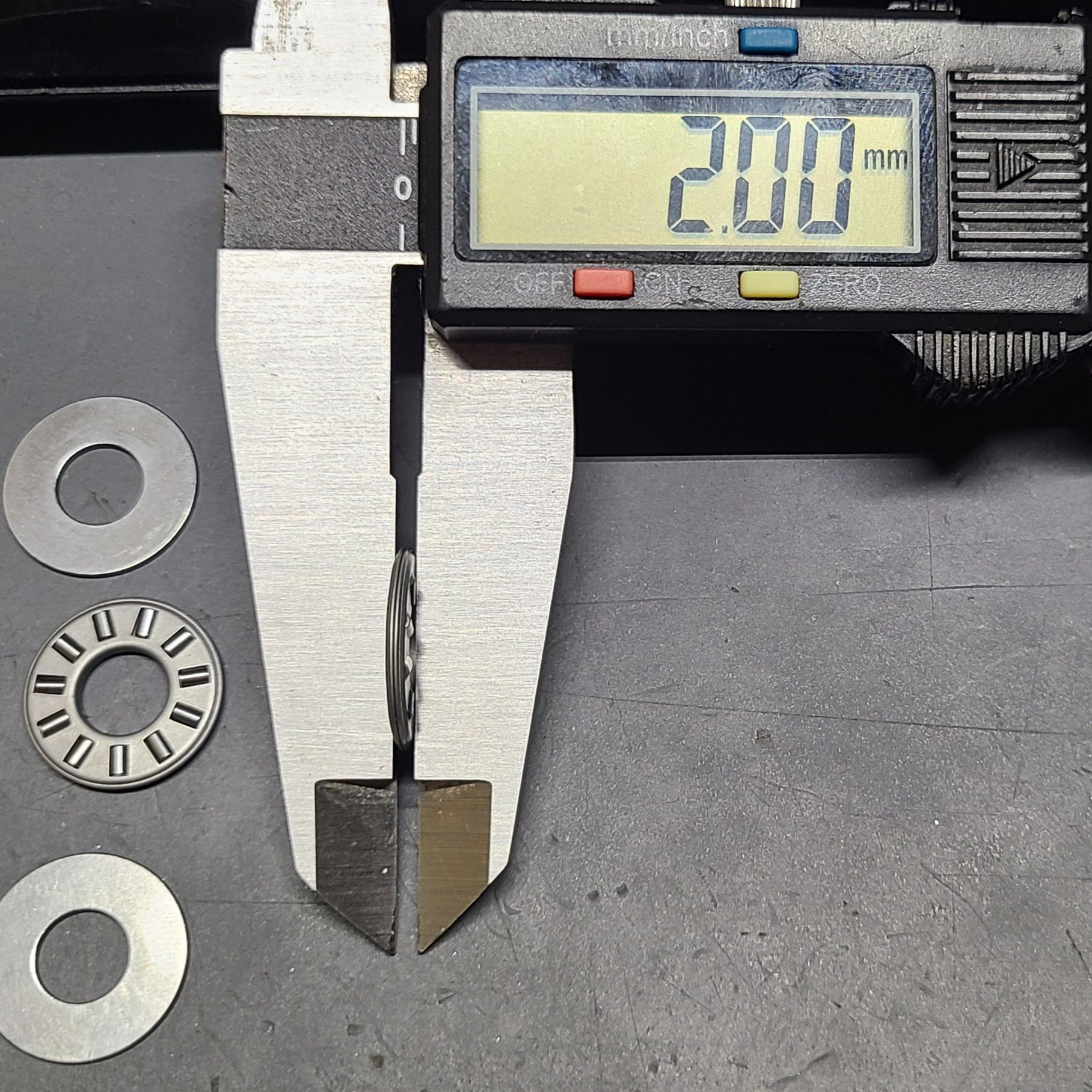

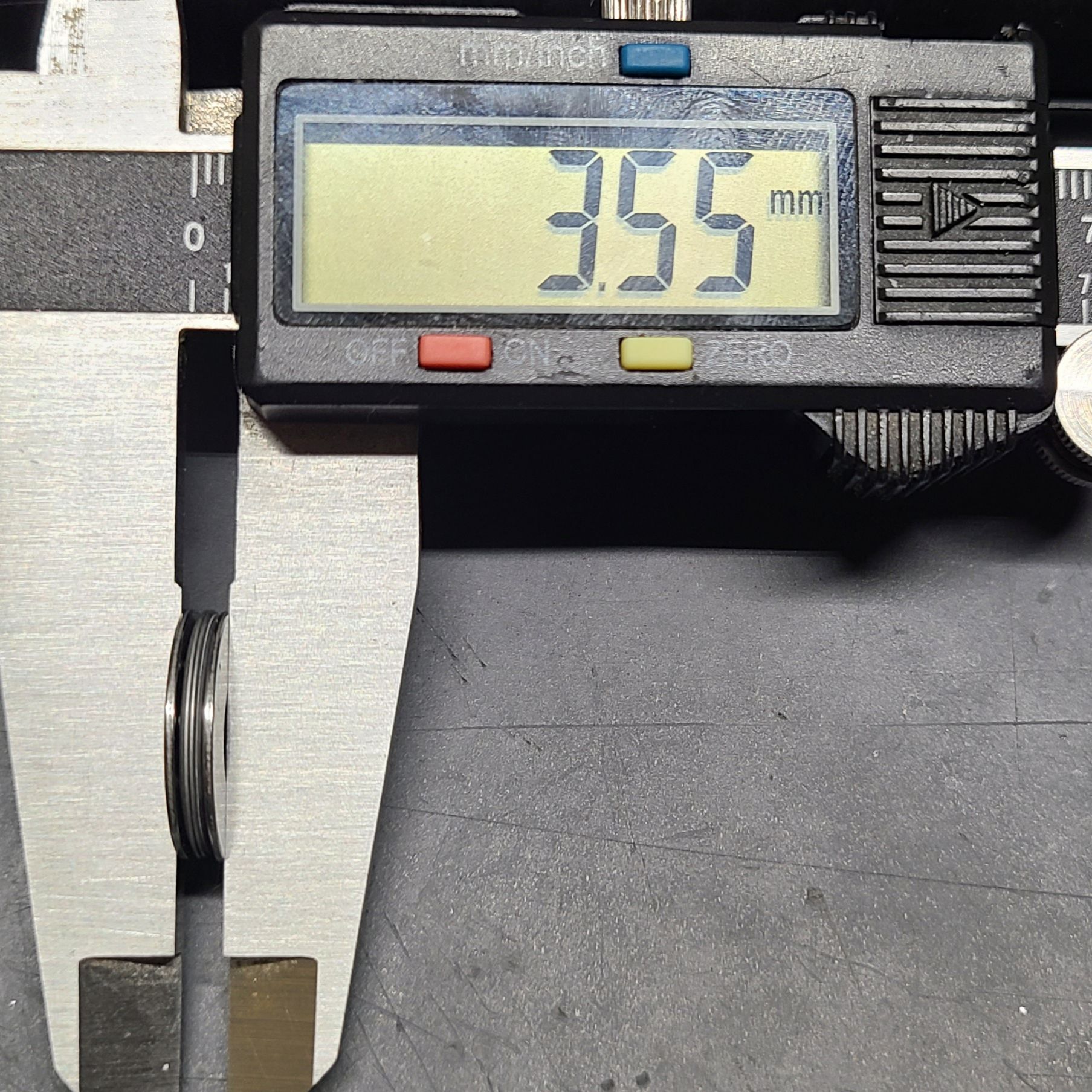

uxcell TC512 Thrust Needle Roller Bearings with Washers 5/16" Bore 3/4" OD 5/64" Width 5pcs

https://www.amazon.com/gp/product/B07VZXWSG6/uxcell F5-10M Thrust Ball Bearings 5mm x 10mm x 4mm Chrome Steel Single Direction 4pcs

https://www.amazon.com/gp/product/B07QKKYKR8/ -

@lord-binky I am afraid there is not enough space to fit a Bearing here....

-

@ignacmc the needle bearings suggested here are super thin though.

But yes, with the suggested tension of Gates for their belts in linear positioning applications we're at the upper end of what Nema 17 bearings usually are rated for. On my Moon's it just barely within "extended" spec (they're in the rated "can be up to this load, but expect reduced bearing life).

Haven't looked up the Wantai specs though. I don't think that they'll be a problem in our application. At least not for the lifetime of the printer unless it's maybe running 24/7 in a farm.

The thing with pillow blocks / bracings is: they need to be accurate or they will introduce crooked sideload themselves on the motor bearings.

Has anyone been able to find the Wantai with a D-Shaft and connectors? That's the primary reason why I have been to lazy to switch back to them.. I know they exist as they can be ordered to spec that way, but haven't seen any retailer carrying them

-

@lord-binky But I don't get your idea...you are recommending Thrust Bearings, that are designed to take axial loads (in the direction of the motor shaft). But the belt tension is acting perpendicular to the motor shaft, that is RADIAL loads. What is the use for a thrust bearing here? They cannot absorb any of the belt loads

-

@ignacmc i think what he suggests when the belts displace the motor shaft, this bearing would prevent or alleviate the displacement of the motor shaft and thus reduce strain on the motor bearings . The strongest force would be on the lower side of this flat bearing.

I liked this idea and never thought of it before, I’ll look into that.

I’m planning to make an automatic belt tensioner and a more sturdy motor shaft would help a lot. -

@cabalsoul I think that this thrust bearing only works when subject to compression. And this is only going to happen when there is a noticeable bending on the shaft which is not going to be the case (or the motor will be destroyed) ;-)...Here we have mainly a shear force and this bearing is not taking any load...Just my opinion, a photo of the setup would help me to understand it better

-

Duet documentation states that low inductance = higher speed or rather holding its torque for a wider range of speed so looking at just the spec sheet LDO one seems to be better. I've also found these motors (if you're in europe) to be good on paper too: https://www.reichelt.com/de/en/hybrid-stepper-motor-nema-17-0-9-2-4-a-2-4-v-act-17hm5424-p237911.html

It's both 0.9 and low inductance compared to a lot of offerings from different brands.

-

@ignacmc once Ive installed a pulley flush to the stepper motor.

After I’ve tensioned the belts with 25N and started up I heard a grinding noise. The deflection was not noticeable with bare eyes but there was definitely one, and the pulley started grind against the motor.So from my experience displacement occurs also with light loads .

Setup is the same as yours on the Anycubic predator.

The stepper motor in question was a moons ms17ha2p4200

-

@ignacmc this is right, snug the pulley against the thrust bearing will limit the amount of deflection on the motor shaft. Next time you have the chance watch closely before and after tensioning motors on a delta for me the amount of force for visible deflection on the shaft is actually very little when tensioning directly against the motor (especially if you use dampers!). At the temps we are comfortable running the motors I'd wager bearing wear is in the top two motor issues after a year of use.

-

Ok, here's some pics. The first is an example of the setup. The others show thickness, the needle bearing you have options depending on the surface of the motor face, the ball bearing set while the ID being the same as the motor shaft is nice i prefer the needle bearings for contact area against the pulley.

-

@lord-binky Well you have conviced me, and I will give it a try. I have just received the Wantai 42BYGH810 I ordered a couple of weeks ago, looking a the datasheet they seem the best in class. I will have to file a flat in the shaft as they come without it. Then I will install a bearing and a pulley on top. How did you tensioned the belt to 25N? Some people use a frequency meter (Mersenne Laws), but it does not seem very accurate. Shouldn't it be a better idea to apply a 2x25=50 Newton force to the idler pulley and tighten the plate bolts in that position?

-

@ignacmc i just push the carriages all the way up and tension to an equal frequency using an app. I ballpark the base tension at the idler pulley for tight but not too tight and tune from there. You have a lot more wiggle room than you'd expect, just make sure they're the same.

I've been using deltas for years (my first was a the seemecnc rostock max v2) and I've found it isn't as necessary to hit a specific tension than it is to just maintain a reasonable and equal tension on the towers. I've done all sorts of gauges and tricks for targeting a specific tension and it just hasn't mattered. That goes for pretty much all aspects of a delta though, carriage resistance, arm lengths, rod spacing, etc. The more each tower responds the same the less weird stuff you chase and are able to compensate with a setting change in software for or identify the root cause like joints.

-

I'll also add for me if you exclude bearing issues in motors or pulleys (I've blown the tiny bearings in idler pulleys multiple times which is why i used flanged bearings now). The next issue of high belt tension is going to be eating up the belts and teeth when your hotend or carriage eventually crashes. I think it's easy enough to tension a little more and recalibrate starting low and then go high until nothing improves.

-

@lord-binky Exactly the same story for me....a Rostock Max v2 was my first delta...How many Hertz do you aim for?