Driver Errors Duet2 Railcore 3D Printer

-

Please post your config.g and the results of M98 P"config.g"

Are the driver chips themselves hot?

Do the errors remain if you disconnect all of the motors (when the board power is off)?

-

M98 P"config.g"

Error: in file macro line 7: M540: invalid MAC address

ok; Configuration file for My Printer

; Communication and general

M111 S0 ; Debug off

M550 PRailCore 4 ; Machine name and Netbios name (can be anything you like)

;M551 Pmyrap ; Machine password (used for FTP)

;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xEE ; MAC Address

;*** Wifi Networking

M552 S1 ; Enable WiFi

M555 P2 ; Set output to look like Marlin

M575 P1 B57600 S1 ; Comms parameters for PanelDueG21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Axis and motor configuration

M669 K1 ; RRF3 change M667 to M669 ; set CoreXY modeM584 X0 Y1 Z5:6:7 E3:4:8:9 ; Map Z to drivers 5, 6, 7. Define unused drivers 3,4,8 and 9 as extruders

M569 P0 S0 ; Drive 0 goes forwards (change to S0 to reverse it) X stepper (Rear)

M569 P1 S1 ; Drive 1 goes backwards Y Stepper (Front)

M569 P2 S1 ; Drive 2 goes forwards Unused

M569 P3 S0 ; Drive 3 goes forwards Extruder

M569 P4 S1 ; Drive 4 goes forwards Extruder (unused)

M569 P5 S0 ; Drive 5 goes backwards Front Left Z

M569 P6 S0 ; Drive 6 goes backwards Rear Left Z

M569 P7 S0 ; Drive 7 goes backwards Right Z;Leadscrew locations

M671 X-10:-10:333 Y22.5:277.5:150 S7.5 ;Front left, Rear Left, Right S7.5 is the max correction - measure your own offsets, to the bolt for the yoke of each leadscrewM350 X16 Y16 Z16 E16 I1 ; set 16x microstepping for axes& extruder, with interpolation

;RRF3 comment out: M574 X1 Y1 Z0 S1

M574 X1 S1 P"xstop" ; RRF3 set X endstop to xstop port active high

M574 Y2 S1 P"ystop" ; RRF3 set Y endstop to ystop port active low

M906 X1400 Y1400 Z1000 E800 I60 ; Set motor currents (mA)

M201 X3000 Y3000 Z100 E1500 ; Accelerations (mm/s^2)

M203 X24000 Y24000 Z900 E3600 ; Maximum speeds (mm/min)

M566 X1000 Y1000 Z100 E1500 ; Maximum jerk speeds mm/minute

M208 X290 Y290 Z280 ; set axis maxima and high homing switch positions (adjust to suit your machine)

M208 X0 Y0 Z-0.5 S1 ; set axis minima and low homing switch positions (adjust to make X=0 and Y=0 the edges of the bed)

M92 X200 Y200 Z1600 E837 ; steps/mm; Thermistors

;RRF3 comment out: M305 P0 T100000 B3950 R4700 H0 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction

M308 S0 P"bedtemp" Y"thermistor" A"bed_heat" T100000 B3950 R4700 H0 L0 ;RRF3 Bed thermistor, connected to bedtemp on Duet2;If you have a Slice Engineering thermistor, comment out the next line

;RRF3 comment out: M305 P1 T100000 B4725 R4700 H0 L0 C7.06e-8 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction

M308 S1 P"e0temp" Y"thermistor" A"e0_heat" T100000 B4725 R4700 C7.06e-8 H0 L0 ;RRF3 duet3 e3d;If you have a Slice Engineering thermistor, uncomment the next lines. KITS DO NOT SHIP WITH A SLICE THERMISTOR - ONLY UNCOMMENT IF YOU ORDERED ONE

;M308 S1 P"e0temp" Y"thermistor" A"e0_heat" T500000 B4723 R4700 C1.196220e-7 ;RRF3 slice thermistorM950 H0 C"e6temp" T0 ;RRF3 define Bed heater is on bedheat

M950 H1 C"e0heat" T1 ;RRF3 define Hotend heater is on e0heatM307 H0 A240.3 C608.7 D8.2 S1.00 V24.1 B0 ; Bed Heaters

M307 H1 A270.7 C90.4 D6.7 B0 S1.0 ;Heater 1 model

M570 S360 ; Hot end may be a little slow to heat up so allow it 180 seconds

M143 S300; Fans

M950 F0 C"fan0" ;RRF3 define fan0

M950 F1 C"fan1" ;RRF3 define fan1

M950 F2 C"fan2" ;RRF3 define fan2

M106 P0 H-1 ; disable thermostatic mode for fan 0

M106 P1 H-1 ; disable thermostatic mode for fan 1

M106 P2 H-1

M106 P0 S0 ; turn off fans

M106 P1 S0

M106 P2 S0; Tool definitions

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a single-nozzle build, comment the next 2 lines

;M563 P1 D1 H2 ; Define tool 1

;G10 P1 S0 R0 X0 Y17 ; Set tool 1 operating and standby temperatures; Z probe and compensation definition

;*** If you have a switch instead of an IR probe, change P1 to P4 in the following M558 command

; IR PRobe - uncomment the following 2 lines if you have a and IR Probe, and comment out the BLTouch section below

;RRF3 IR Probe only comment out: M558 P1 X0 Y0 Z1 ; Z probe is an IR probe and is not used for homing any axes

;M558 P1 C"^zprobe.in" H5 F120 T6000 A5 S0.02 ; RRF3 IR Probe connected to Z probe IN pin

;G31 X0 Y30 Z2.00 P500 ; Set the zprobe height and threshold (put your own values here);BLTouch - comment out the following 3 lines if using a IR Probe

;RRF3 comment out: M307 H3 A-1 C-1 D-1

;RRF3 comment out: M558 P9 X0 Y0 Z1 H5 F50 T6000 A5 S0.02

M558 P9 C"^zprobe.in" H5 R1 F50 T6000 A5 S0.02 ; RRF3 BLTouch connected to Z probe IN pin

M950 S0 C"duex.pwm1" ; RRF3 Define BLTouch Servo (S0) on duet pwm1

G31 X2 Y42 Z2.65 P25 ; Customize your offsets appropriately - do a paper test, and put the probed value in the Z value hereT0 ; select first hot end

-

Yes the chips do seem to be hot and there are no errors when I turn the machine on without the motors connected

-

Overtemp shutdown would mean too hot to touch for more than a second.

Do they still get hot when motors disconnected?

-

They do not when the motors are disconnected

-

Then I would double check that your motor wiring is correct.

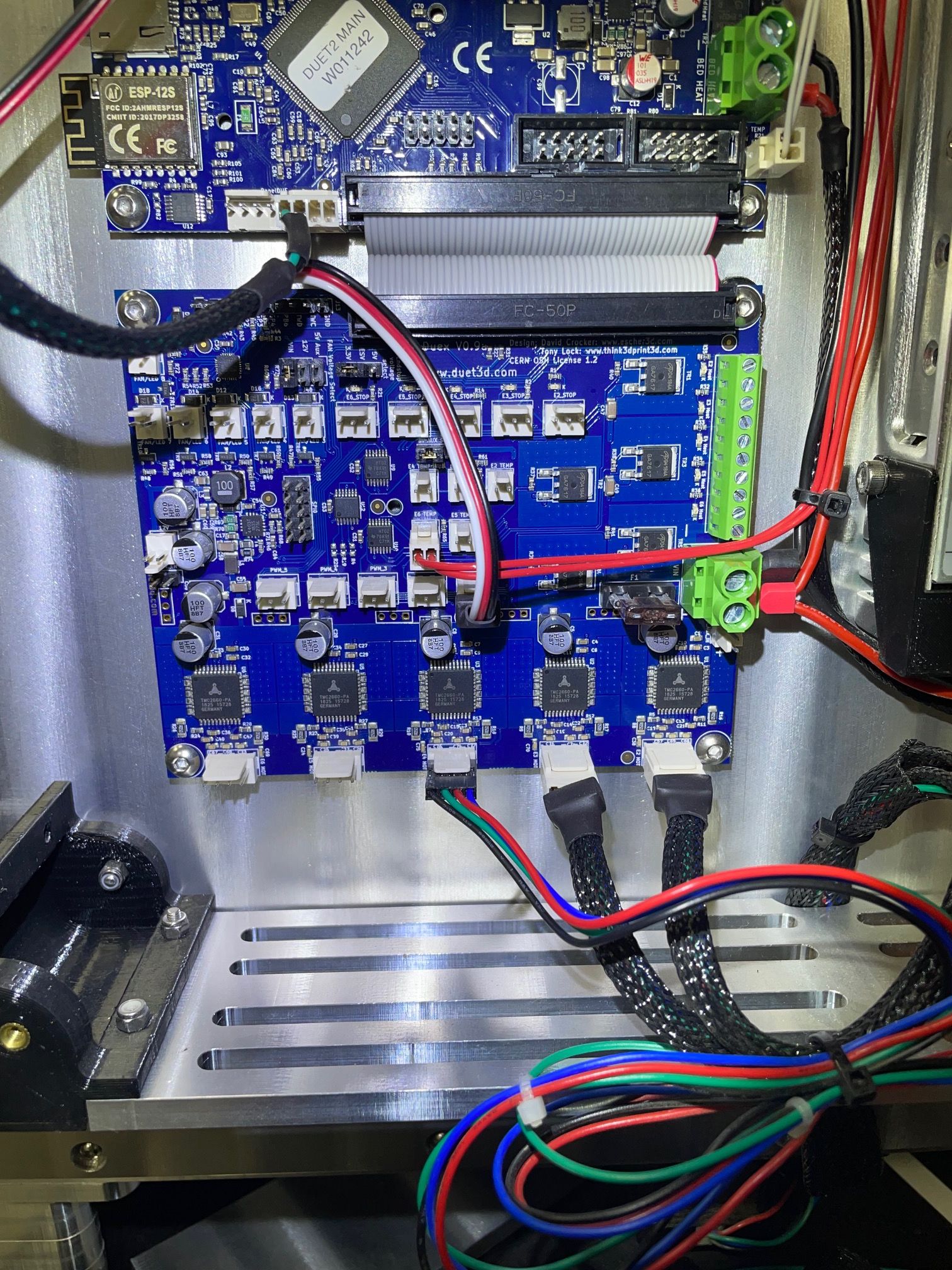

Are you using a Duex as well? Can you test the drivers there?

Has anything changed recently on this printer?

-

Yes it is using a duex, how would I test the drivers from there?

The board we had before failed, it was working fine for a few years. The wiring is the same as before, the main visible damage was on the MicroSD card

-

So this is a new board? Has it ever worked?

Do you know what the cause of the previous failure was? Seems like a pretty bad short. Was the cause corrected?@mkmachining-0 said in Driver Errors Duet2 Railcore 3D Printer:

The wiring is the same as before

I fear history may be repeating.

-

This board has only been hooked up for a couple of days now.

We are not entirely sure what the cause of the previous short was. Like I said earlier this printer was running fine for quite a few years. It happened when there was an issue with the "always on" port that was being test. It smelled like something was burning which was found to be the SD card. I'm not sure how testing that caused such a big reaction.

-

I think you need to closely inspect the wiring and the board and surrounding area. Something seems to be shorting. Are you able to test the motors in another printer? I fear that whatever caused the previous damage is still present.

-

Yes there are other printers that could test the motors. Do you have any suggestion on how to go about this?

-

@mkmachining-0 said in Driver Errors Duet2 Railcore 3D Printer:

Do you have any suggestion on how to go about this?

connect the motor to the other printer and configure them appropriately and see if they work correctly there or not.

-

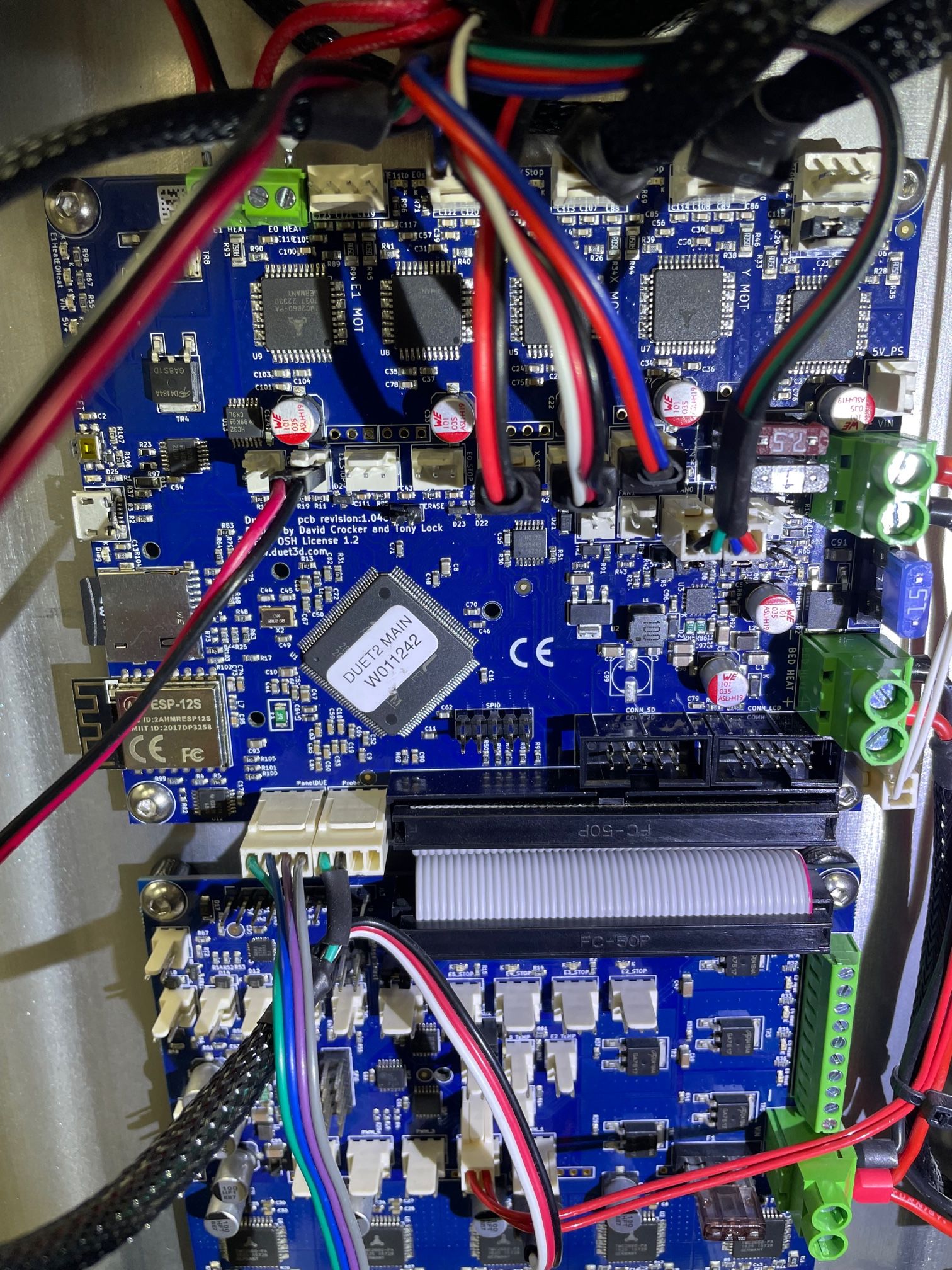

That SD card damage looks to me like something is shorting +3.3v to a 5v or 24v rail...

-

I tried the motors on a different working printer which then showed the same errors.

I then put working motors on the broken printer, the motors then read the same short error

Could it be and issue with the power supply?

-

@phaedrux said in Driver Errors Duet2 Railcore 3D Printer:

Please post your config.g and the results of M98 P"config.g"

Are the driver chips themselves hot?

Do the errors remain if you disconnect all of the motors (when the board power is off)?

After some time the errors do occur with the disconnected motors

-

So you tried the motors from your railcore on a different printer and it had the same overtemp/short to ground errors?

And new motors on the railcore had the same as well?

It sounds like you've had a pretty significant short that has maybe damaged the coils of the motors and damaged the drivers.

As I said before, I think you need to closely inspect the wiring and the board and surrounding area. Something seems to be shorting. And I think some damage has already been done.

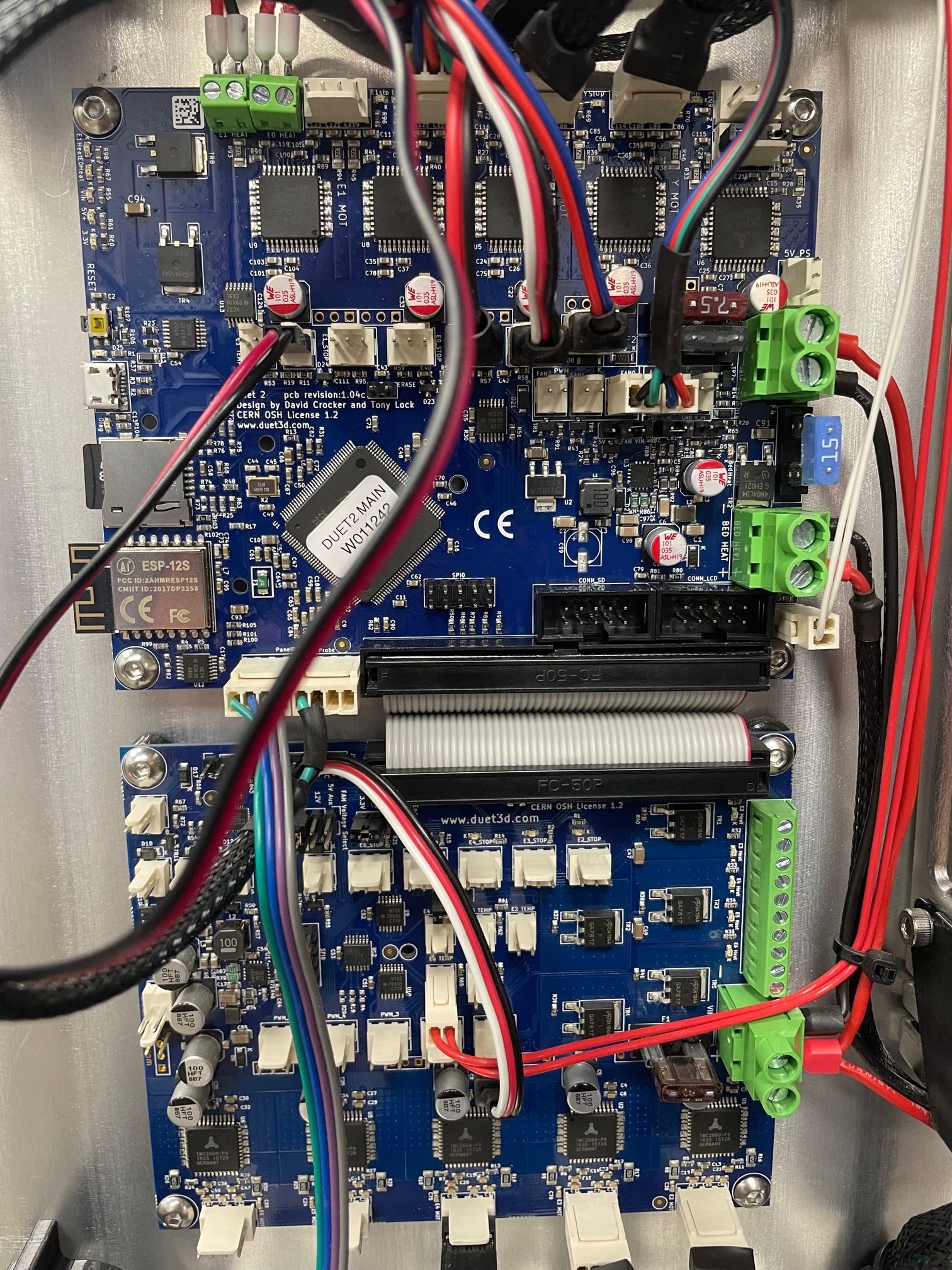

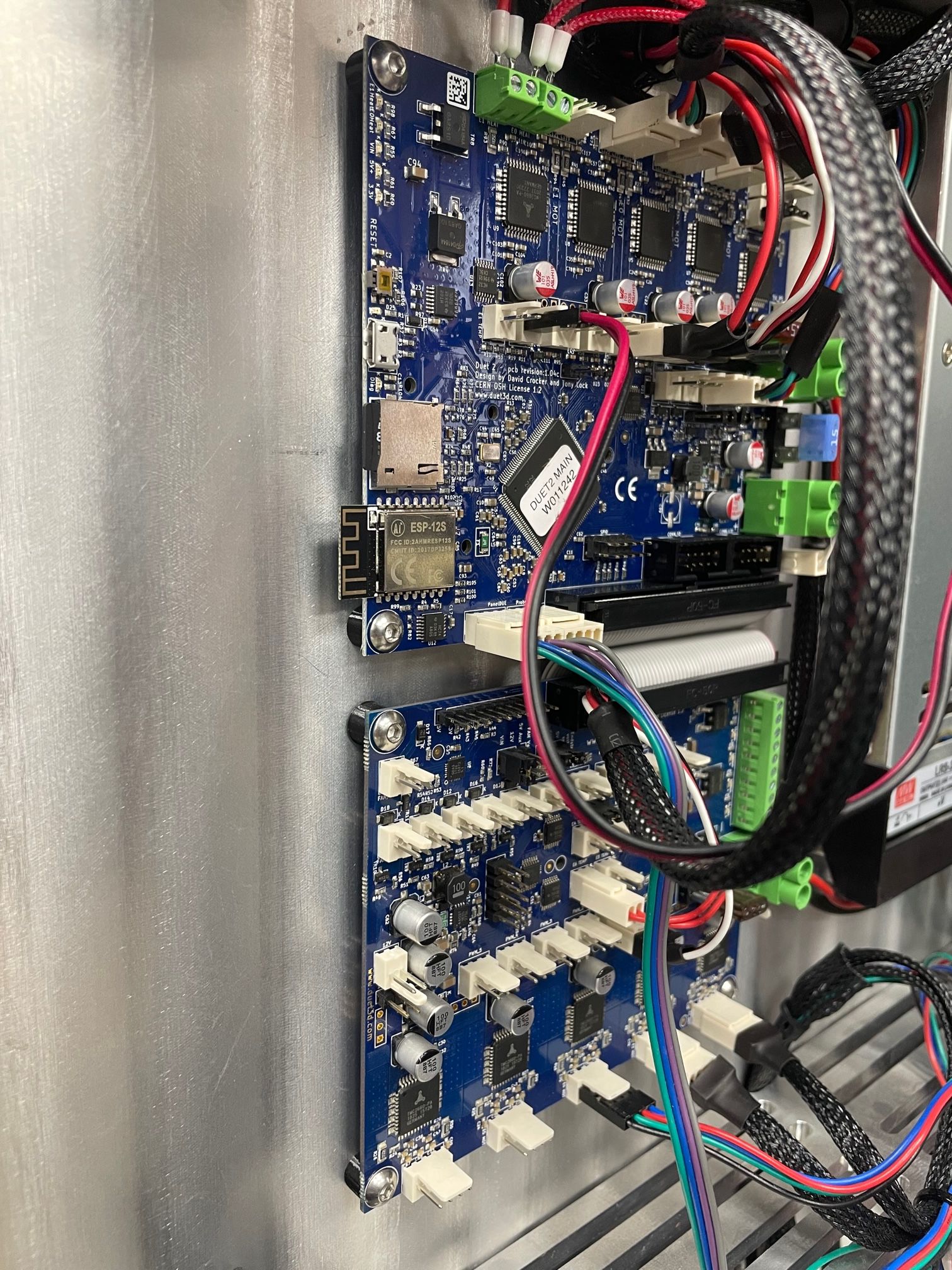

Can you post some close up well lit photos of the duet? There may be some damaged chips.

-

This post is deleted! -

@phaedrux said in Driver Errors Duet2 Railcore 3D Printer:

So you tried the motors from your railcore on a different printer and it had the same overtemp/short to ground errors?

And new motors on the railcore had the same as well?

It sounds like you've had a pretty significant short that has maybe damaged the coils of the motors and damaged the drivers.

As I said before, I think you need to closely inspect the wiring and the board and surrounding area. Something seems to be shorting. And I think some damage has already been done.

Can you post some close up well lit photos of the duet? There may be some damaged chips.

-

-

Have you taken it out of the enclosure and tested it on a bench yet?

If the original cause of the short is still present and has damaged the new board as well I'm not sure what more we can do.