Dual Print Layers Uneven vs Single Color Layers

-

Hey all,

I don't have a Duet3D printer, but I saw a topic about dual printers here and I wanted to get your guys' opinions on this

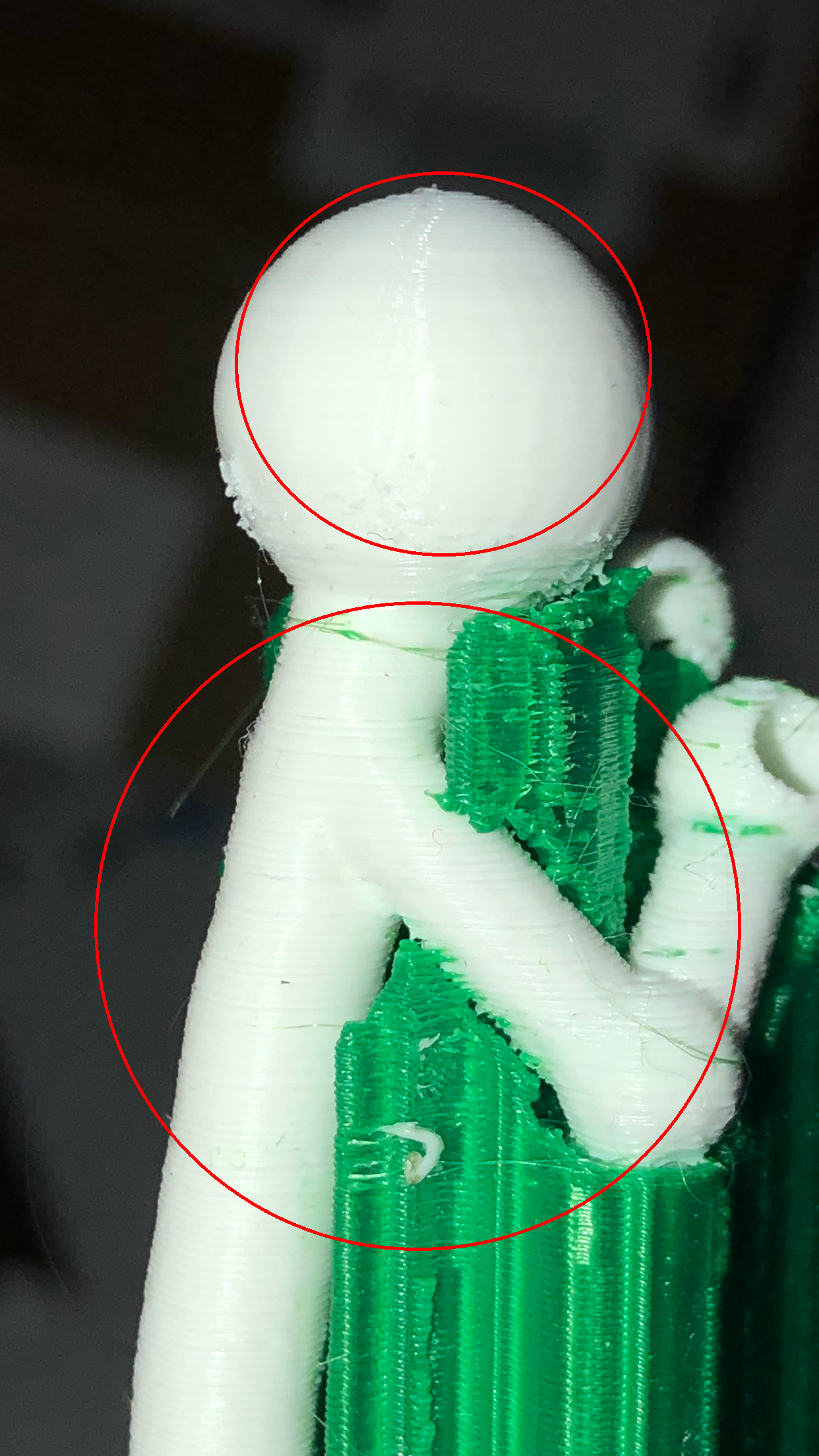

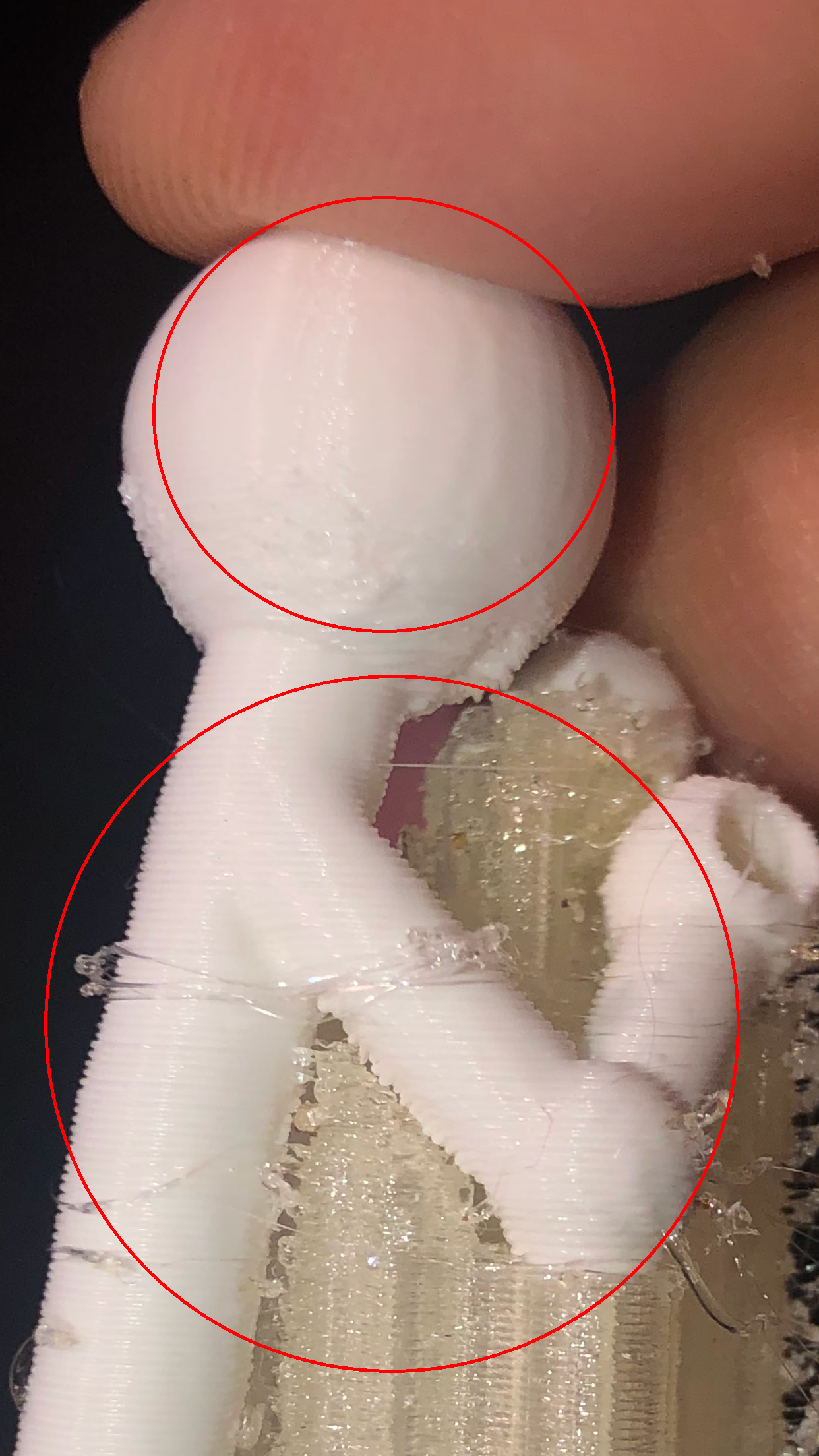

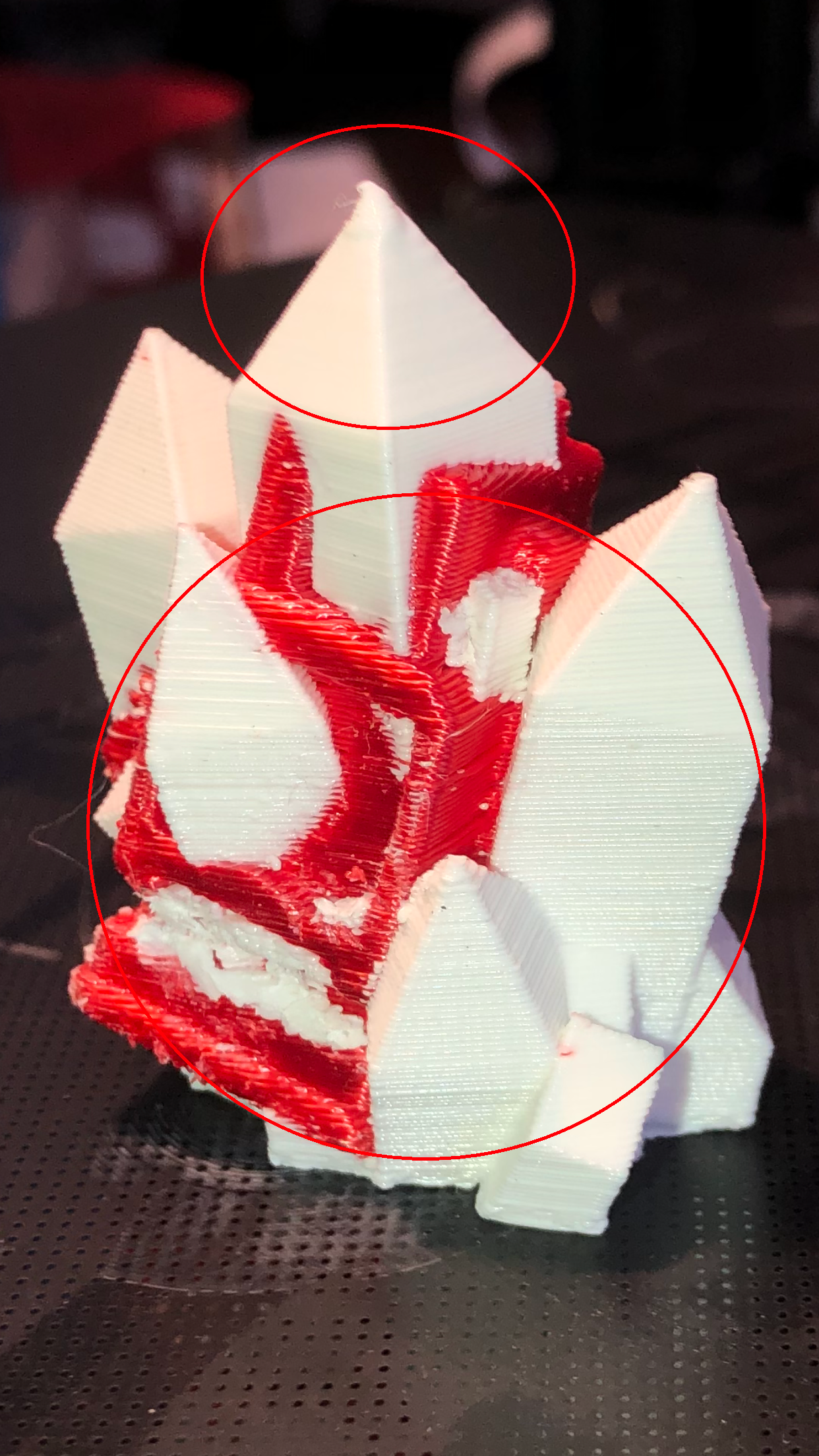

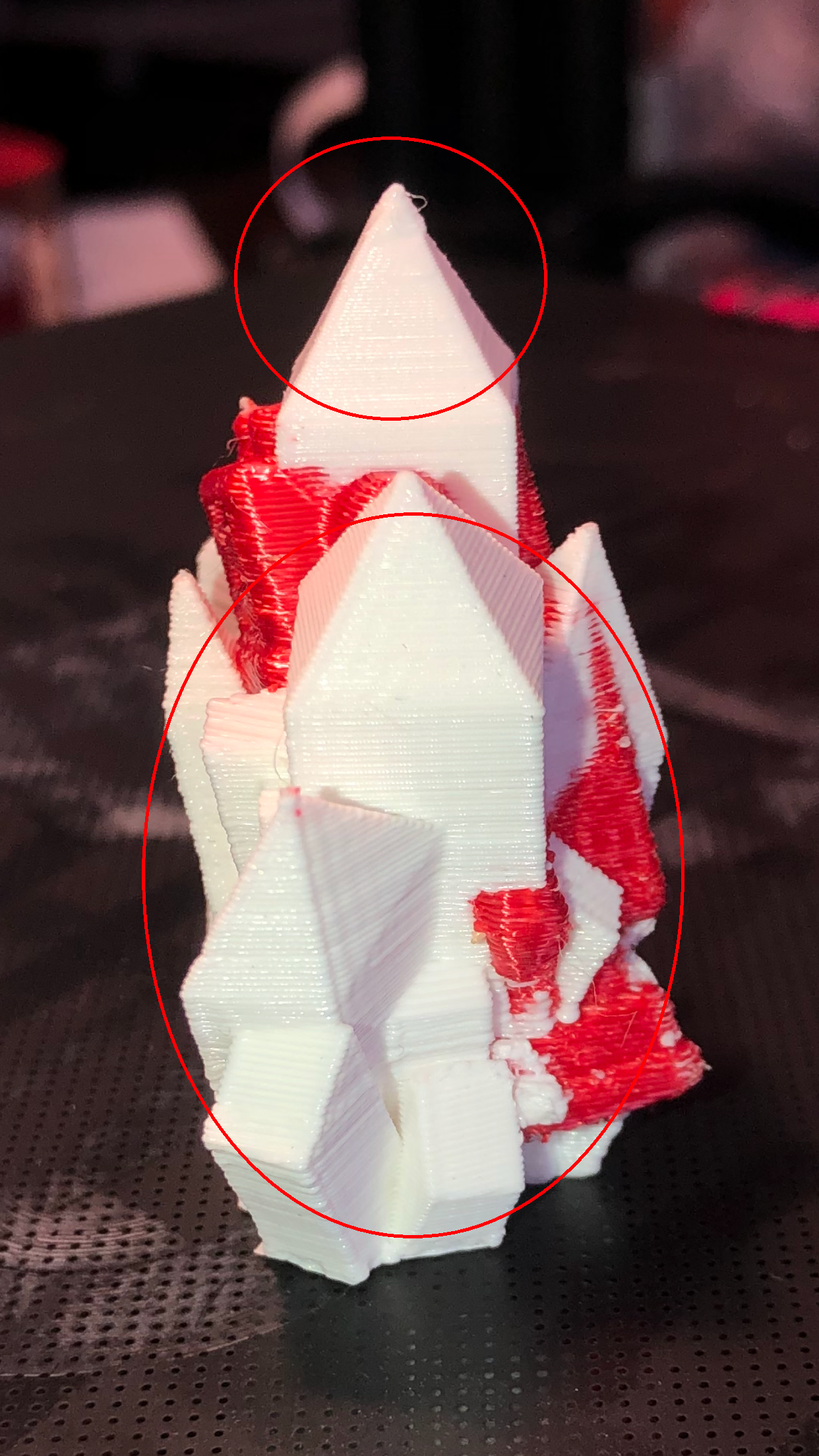

I purchased the Sen3D ender IDEX for my Ender 3 Pro so I can dual print. It is able to print successfully but I've been experiencing a consistent problem with it. On layers that only require 1 extruder, the layers are smooth and even, but on layers that require both extruders the layering takes a noticeable dip in smoothness. It's not just cosmetic either, it causes the prints to be weaker overall. I added pictures and circled the comparison between the two

I've tried dual printing with both PLA and PVA supports and I encounter this same problem. I've spent the past couple of months trying to fix this problem, and I've been in a constant dialog with the creator of the IDEX addon trying to fix this, but to no avail so far. So I'm posting this here to see if anyone else knows how to fix this issue. Here's an outline of all the fixes I've tried so far

• Increasing/Decreasing Layer Height (0.05,0.1,0.15 mm) • Increasing/Decreasing Initial Layer Height • Printing at different temperatures (200, 205, 210, 215C) • Changing PLA filament brands • Decreasing print speed (30mm/s, 40mm/s, 50mm/s) • Changed Z support distance (0mm to 0.15mm) • Increased/Decreased Nozzle Retraction distance • Turned on/off print combingI haven't seen many posts about this, so I'm wondering if it's a rare problem. Here's a post from another person on duet 3D that had the same topic, but no solution to it

https://forum.duet3d.com/topic/22461/bad-print-quality-with-dual-prints-vs-single-extruder-printsI'm curious to see what your guys thoughts are on this. The issue seems complicated but maybe I'm missing something? Thanks

-

@printguy111

How much ooze do you see on the unused nozzle? Is there any ooze-compensation in your toolchange codes or a ooze prevention device to close the parked nozzle?

I'm now using my dual nozzle printer only to speed up prints with different nozzle sizes: 0.3 nozzle for perimeters and 0.8 nozzle for infill.Dual color/material stuff turned out to be a big mess and I didn't see too many designs I wanted to print.

I'd lean now to a single nozzle/multi extruder setup like the Prusa MMU or Enraged Rabbit if I wanted to follow the multi color road.

But frankly speaking: there is more than enough waste plastic in the world.

IDK if there's a word for it, but it feels similar to 'flight shame' -

@printguy111 I've dabbled a bit with multi-material 3D printing (E3D Toolchanger).

My theory on this is:- there is a small offset between the outline of every other layer, this is what you call "uneven" or "less smooth".

- the "smaller" layer should be the first layer of this material after a toolchange. The extruder is not properly primed at this point, the material has been sitting for a while in the nozzle and some might have oozed out.

- Edit: also check the temperatures. Cura uses standby temp, initial printing temp, printing temp, and final printing temp. Don't know why, it starts the layer with "initial printing temp" which at default might be 10-15 °C lower than printing temp. For consistent extrusion, I suppose all printing temperatures should be the same.

- after finishing this layer, the printer directly jumps to the next layer from the same material. This time the extruder is perfectly primed since it has just finished the layer before.

- to solve this problem, you could try the following:

- print the infill before the walls. This should prime the extruder accordingly before it reaches the walls. Doesn't work however with small cross-sections.

- add a prime tower or waste part that is printed first for each layer. The last bit is important and might not be quite easy to reach - IIRC, Cura for example seems to scan the build platform from left to right.

hope this helps,

Niklas