Heater fault issue while tool 0 fan is on

-

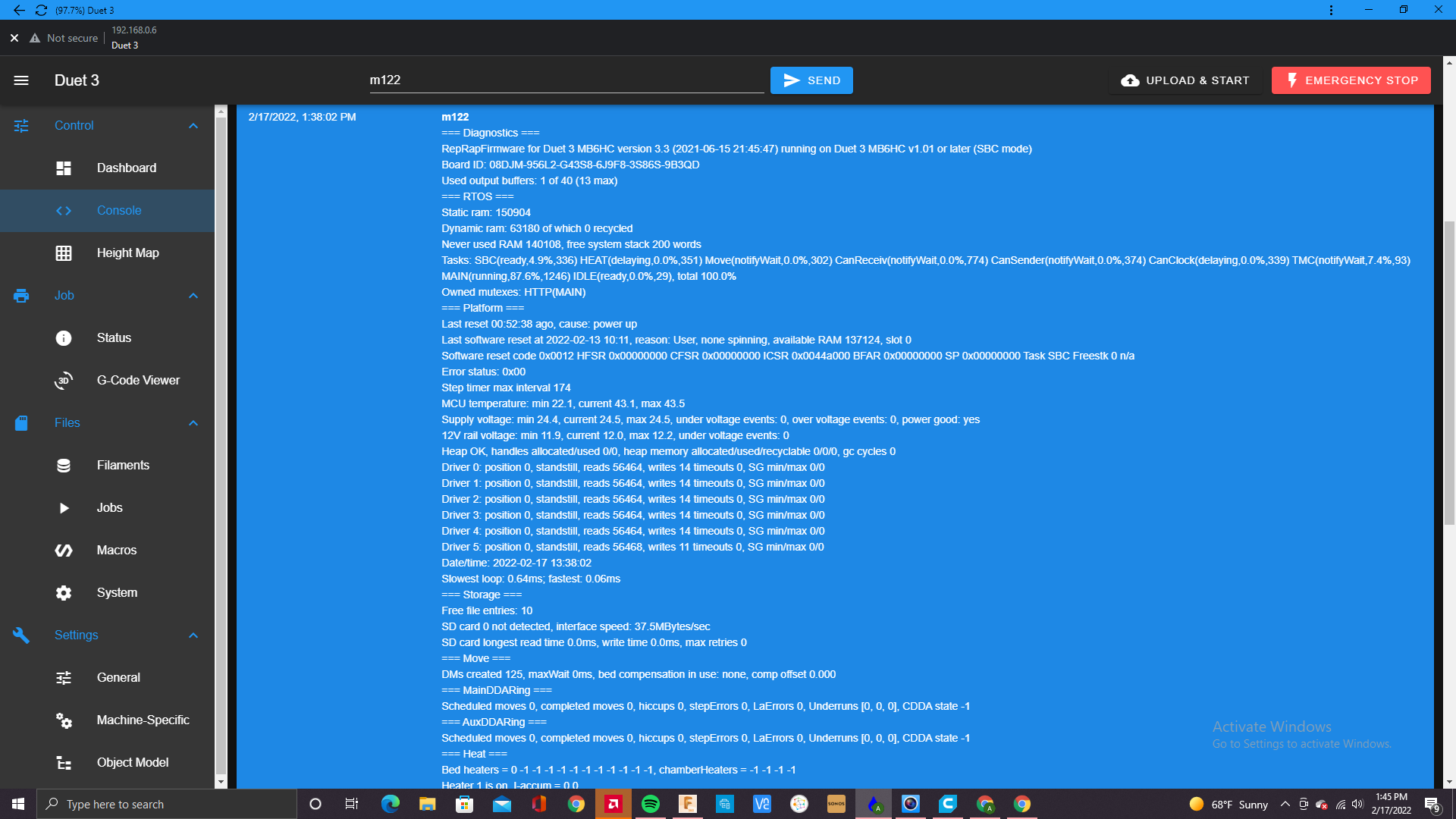

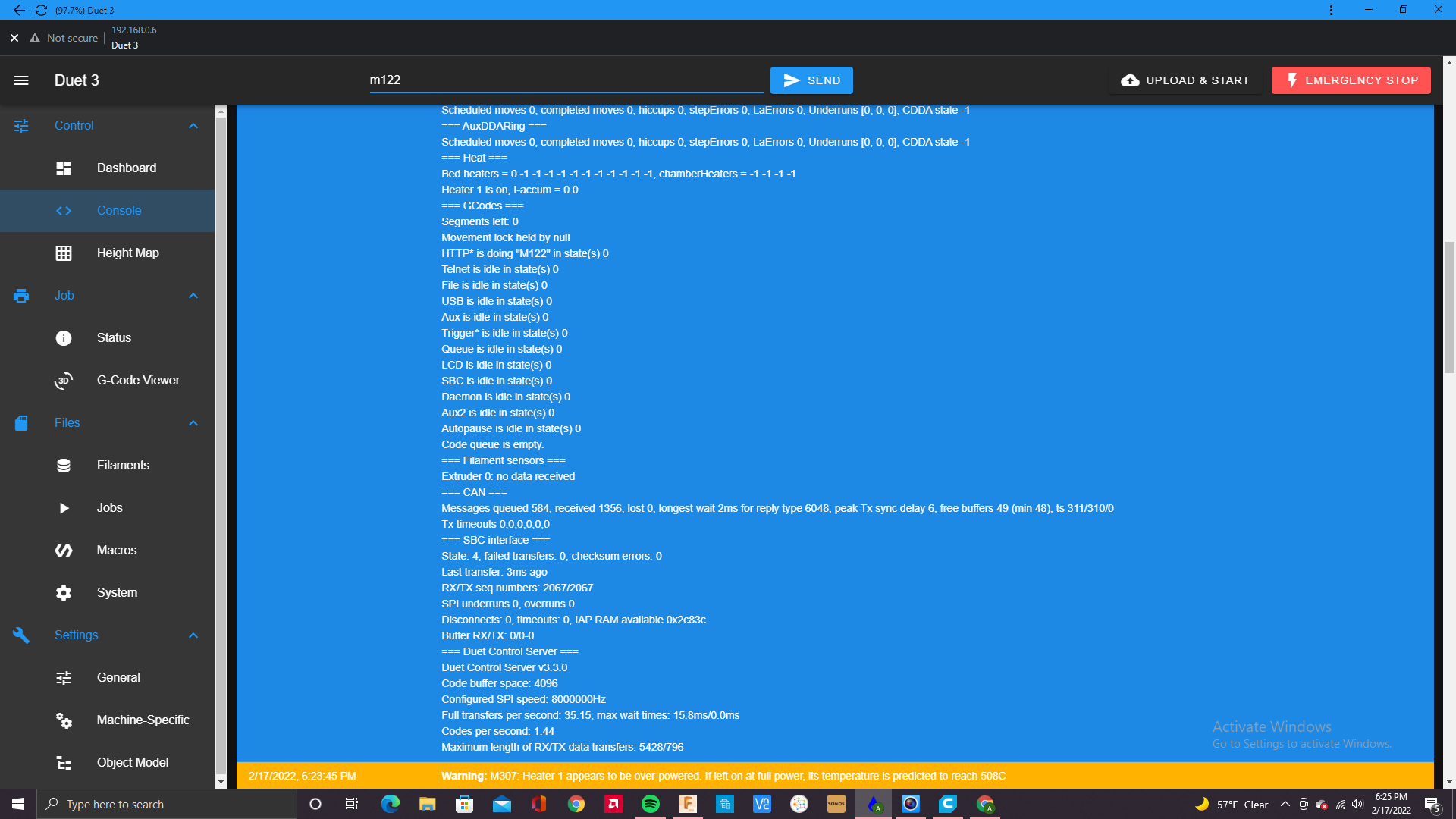

I've been having an issue recently with the heater faulting while the part cooling fan is on during a print. I'm assuming its a gcode error but would appreciate any help and suggestions. Also, after doing a heater calibration I noticed the voltage for the heater is 22.2, (M307 H1 R1.683 C322.300:307.700 D4.10 S1.00 V22.2 B0) is that normal.

Thanks.Here's my config file:

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network ;M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP ;M586 P0 S1 ; enable HTTP ;M586 P1 S0 ; disable FTP ;M586 P2 S0 ; disable Telnet ; Drives M569 P0.4 S1 ; X axis right motor physical drive 0.4 goes forwards M569 P2.2 S1 ; X axis left motor physical drive 2.2 goes forwards M569 P2.0 S1 ; Y axis physical drive 2.0 goes forwards M569 P2.1 S1 ; Y axis physical drive 2.1 goes forwards M569 P1.1 S0 ; Y axis physical drive 1.1 goes forwards M569 P1.0 S0 ; Y axis physical drive 1.3 goes backwards M569 P0.0 S1 ; Z axis physical drive 0.0 goes forwards M569 P0.1 S1 ; Z axis physical drive 0.1 goes forwards M569 P0.2 S1 ; Z axis physical drive 0.2 goes forwards M569 P0.3 S1 ; Z axis physical drive 0.3 goes forwards M569 P20.0 S0 ; Tool 1 physical drive 20.0 goes forwards M569 P21.0 S1 ; Tool 2 physical drive 21.0 goes forwards M584 X0.4:2.2 Y2.0:2.1:1.1:1.0 Z0.0:0.1:0.2:0.3 E20.0:21.0 ; Four Z motors connected to driver outputs Z axis M671 X-30:-30:890:890 Y-30:890:890:-30 S2 ; leadscrews at rear left, front left, front right, rear right (connected to Z) M208 X0:820 Y0:820 Z0:800 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X52.49 Y104.99 Z3200.00 E837.00:837.00 ; set steps per mm M566 X420.00 Y420.00 Z270.00 E7000.00:7000.00 ; set maximum instantaneous speed changes (mm/min) M203 X7250.00 Y7250.00 Z350.00 E10000.00:10000.00 ; set maximum speeds (mm/min) M201 X300.00 Y300.00 Z270.00 E8000.00:8000.00 ; set accelerations (mm/s^2) M906 X3600 Y2900 Z2500 E1100:1100 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits ;M208 X0:845 Y0:890 Z0:800 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 ; Filament sensors M591 D0 P3 C"20.io1.in" S1 R82:131 L27.47 E90.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 80% to 135% tolerance, 5mm detection length ;M591 D1 P1 C"21.io1.in" S1 ; filament monitor connected to pin 21.io1.in ;M591 D0 P1 C"0.io0.in" S1 ; filament monitor connected to pin 3.io3.in ;Extra sensor M308 S10 Y"mcu-temp" A"MCU" ; Endstops M574 X1 S1 P"2.io2.in" ; configure active-low endstop for low end on X via pin 2.io2.in M574 Y1 S1 P"1.io2.in" ; configure active-low endstop for low end on Y via pin 1,io2.in M574 C0 Z0 ; No C Z endstop ; Z-Probe M558 P8 C"!21.io0.in" H3 F150 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z1.62 ; set Z probe trigger value, offset and trigger height M557 X0:800 Y0:800 S50 ; define mesh grid X/Y and probe spacing ; Heaters M308 S0 P"temp0" Y"thermistor" A"Bed" T100000 B3950 ; configure Bed sensor 1 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 1 M307 H0 R0.224 C219.6 D7.78 S1.00 V24.1 ; PID auto tune results for Tool 1 bed heater M140 H0 ; map heated bed to heater 1 M143 H0 S120 ; set temperature limit for heater 1 to 120C M308 S1 P"20.temp0" Y"pt1000" A"Tool 0" ; configure sensor 0 as thermistor on pin 20.temp0 M950 H1 C"20.out0" T1 ; create nozzle heater output on 20.out0 and map it to sensor 0 M307 H1 B0 R1.572 C361.9 D4.16 S1.00 V22.4 ;M308 S2 P"21.temp0" Y"pt1000" A"Tool 1" ; configure sensor 0 as thermistor on pin 20.temp0 ;M950 H2 C"21.out0" T2 ; create nozzle heater output on 20.out0 and map it to sensor 0 ;M307 H2 B0 R1.717 C105.7:98.6 D2.95 S1.00 V23.9 ; PID auto tune results for Tool 0 Titan Aqua 1.75 ;fan M950 F0 C"out8" Q250 ; create fan 0 on pin out8 and set its frequency M106 P0 T115 S0.10 C"Radiator Fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"20.out2+out2.tach" Q250 ; create fan 1 on pin 20.out2 and set its frequency M106 P1 H-1 R1 C"Titan Aqua 1.75 T1" ; set fan 1 value. Thermostatic control is turned on M950 F2 C"21.out2" Q250 ; create fan 2 on pin 21.out2 and set its frequency M106 P2 T205 S0.10 H2 C"Titan Aqua 1.75 T2 support material Fan" ; set fan 2 value. Thermostatic control is turned on M950 F3 C"1.out3+out3.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P3 H-1 R1 C"Motor Fan 1" ; set fan 1 value. Thermostatic control is turned on M950 F4 C"1.out4+out4.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P4 H-1 R1 C"Motor Fan 2" ; set fan 1 value. Thermostatic control is turned on M950 F5 C"1.out5+out5.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P5 H-1 R1 C"Motor Fan 3" ; set fan 1 value. Thermostatic control is turned on M950 F6 C"2.out3+out3.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P6 H-1 R1 C"Motor Fan 4" ; set fan 1 value. Thermostatic control is turned on M950 F7 C"2.out4+out4.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P7 H-1 R1 C"Motor Fan 5" ; set fan 1 value. Thermostatic control is turned on M950 F8 C"2.out5+out5.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P8 H-1 R1 C"Motor Fan 6" ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Titan Aqua 1.75" D0 H1 F0:1 ; define tool 0 ;M567 P0 E1.00:1.00 ; Mix drive E0 and drive E2 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P1 S"Titan Aqua 1.75 support" D1 H2 F0:2 ; define tool 1 G10 P1 X-15.4 Y0 Z0 ; set tool 2 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined T0 ; select first tool M501 ;read stored parameters

-

Did you tune as a heater or as a tool?

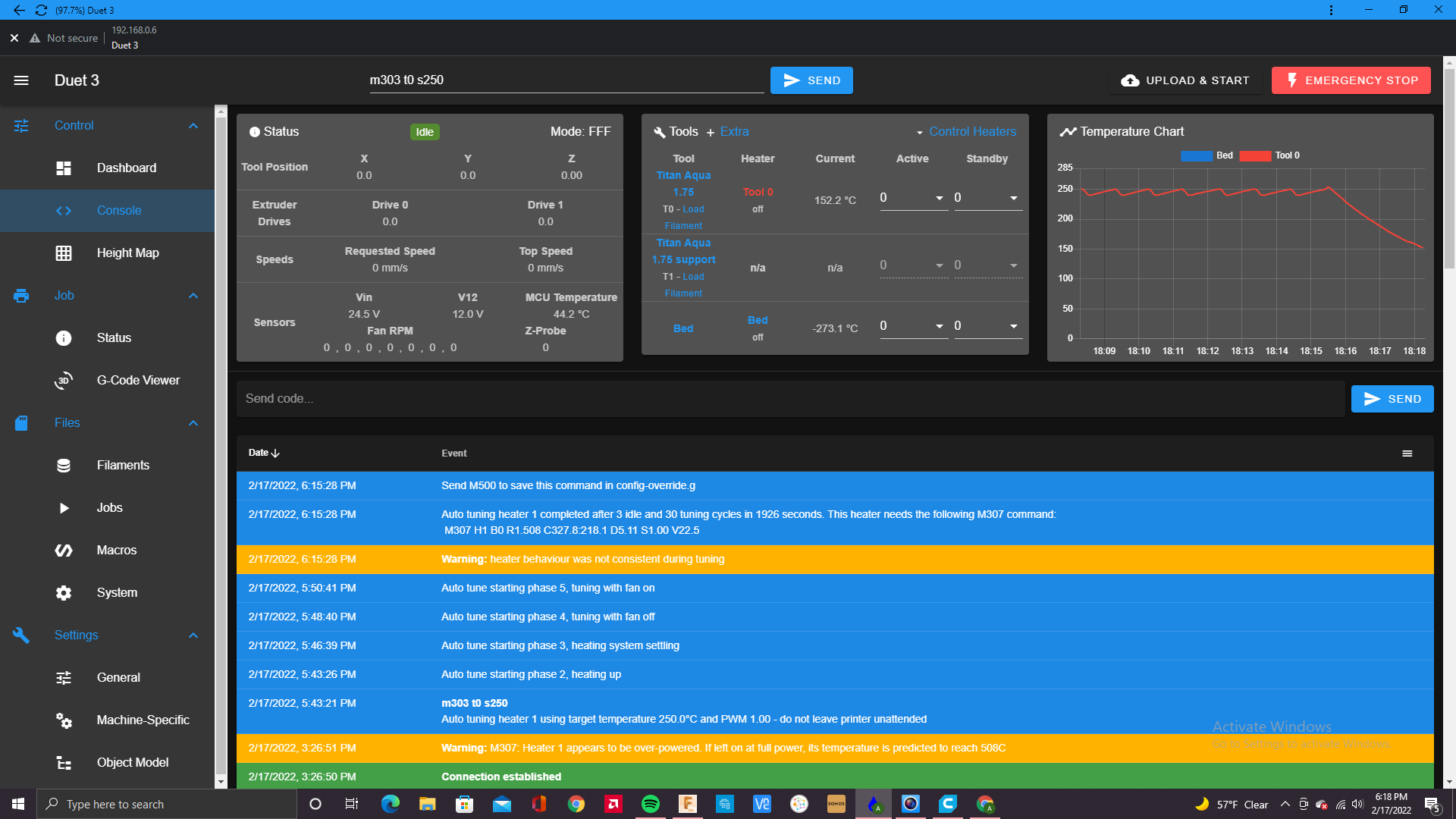

M303 H1 S250 would tune as a heater

M303 T0 S250 would tune as a tool and will control the associated part cooling fan during the tuning process to get an idea of how much the fan impacts heater performance. -

@phaedrux Thanks. I'll recalibrate with the M303 T0 S250 instead of the other, that may be why the fault keeps occurring.

-

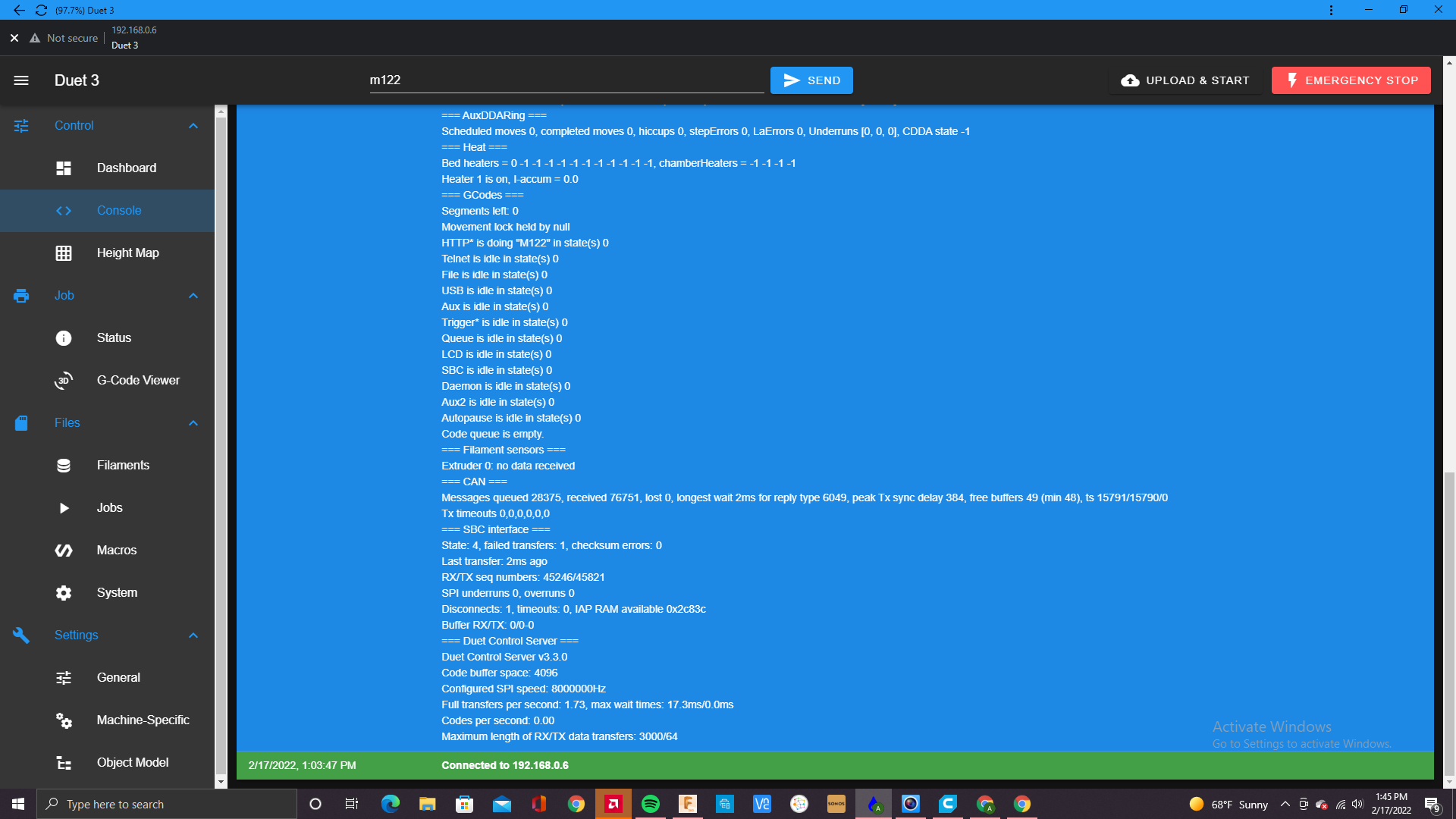

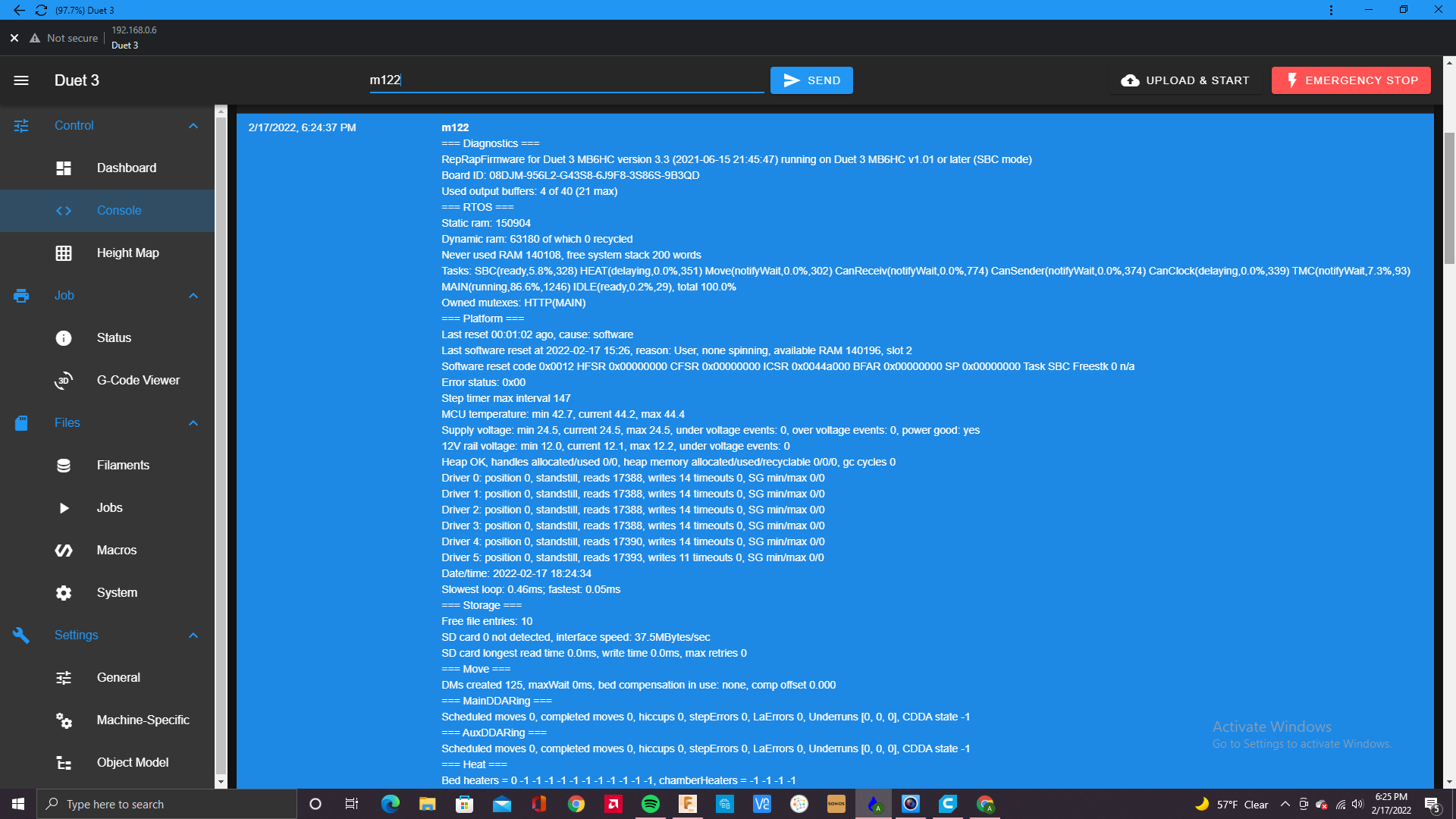

@phaedrux I ran the M303 H0 S250 twice and the message I got in the event log, below is a screen shot. I'm not sure what is causing that warning. I've changed the heater as well but didn't seem to fix the issue, what else could it be? Again thanks for the help.

-

After tuning are you able to run the heater normally or does it still fault?