3.3 Heater Fault: M307 & Error Expected Value Mismatch?

-

Problem: After updating to 3.3 have been experiencing consistent heater 1 fault: temperature rising much more slowly than the expected xxC/s. Reported expected values in heater fault messages are in the range of 5.9 to 6.8C vs an M307 R value (determined by 3.3 auto tuning) of ~ 1.96.

While this problem is easily worked around by setting the M307 R value to around 0.5 or so, i have a few questions:

-

Should the expected rise rate value that triggers the heater fault be ~75 % of the M307 R value? (thought i read that somewhere in the documentation)

-

Is the expected rise rate fixed or does it vary based on the hotend temperature at the time of the request for increased temperature?

-

Is the M307 R value solely used for heater fault purposes or is it also a parameter of the heater temperature control algorithm?

-

Do i have an error or omission in my config.g that is preventing the tuned R value from being applied to the T0 heater?

-

Is it likely that there is something about my hotend setup that is less than suitable for the current auto tuning algorithm?

-

Other avenues that i should consider for trouble shooting?

Thank you,

BruceFirmware 3.3

DWC 3.3

Hardware Duet2(Ethernet) PCB 1.04b

Printer has one hotend (T0/H1) with an ~40W heating element. Part cooling is via an air pump and nozzle surrounding duct (which is quite efficient - 10% is a lot of cooling).

Hotend and bed are powered by 12V and Duet2 is powered from 24V.

Hotend has SeeMeCNC accelerometer board (not used for leveling) which uses a common ground for all components including thermister.

Bed heater functions well with 3.3 auto tuned values.Problem appeared after update from 2.05.1 to 3.3 (with an intermediary update to 3.0). Prior to update hotend and auto tuning +/- some minor tweaks have functioned well. Indicated hotend temperatures usually fluctuated ~ +/- 0.2 C or less during reasonably steady state printing conditions.

Heater and Fan section of config.g below, complete config.g here config.g.

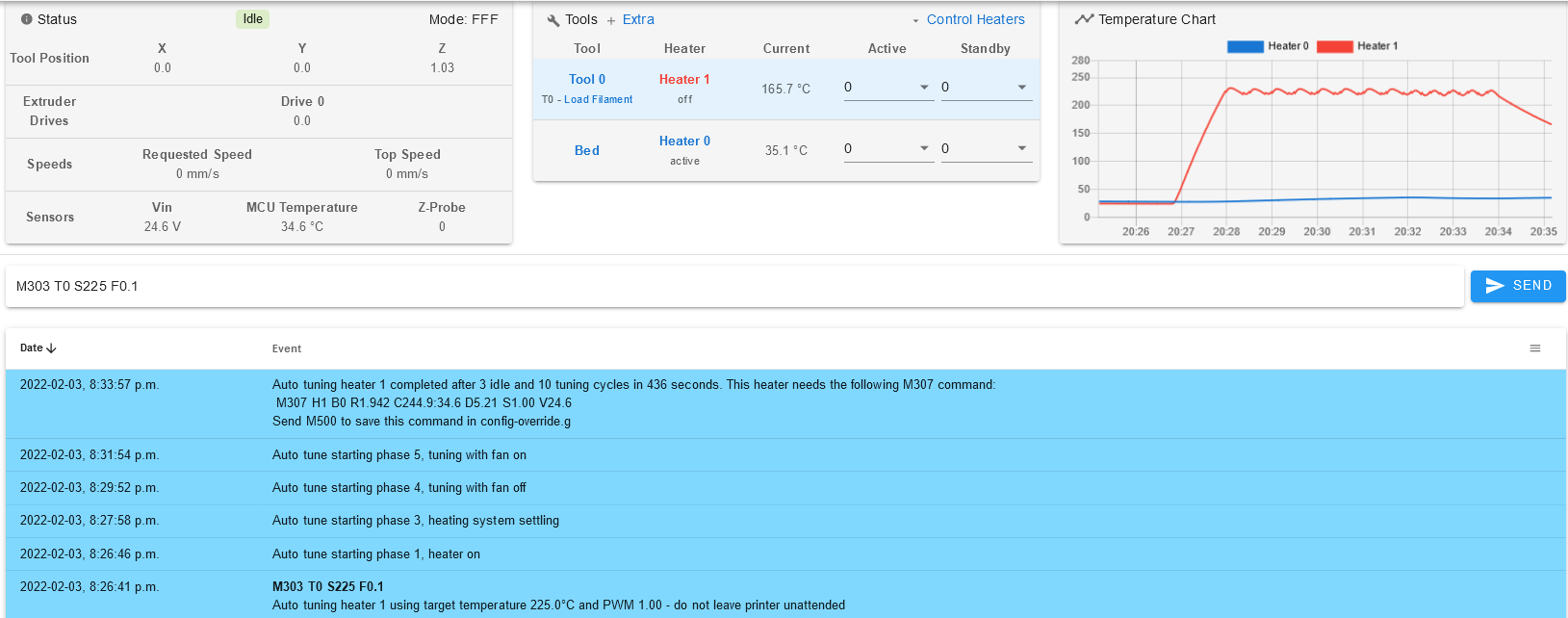

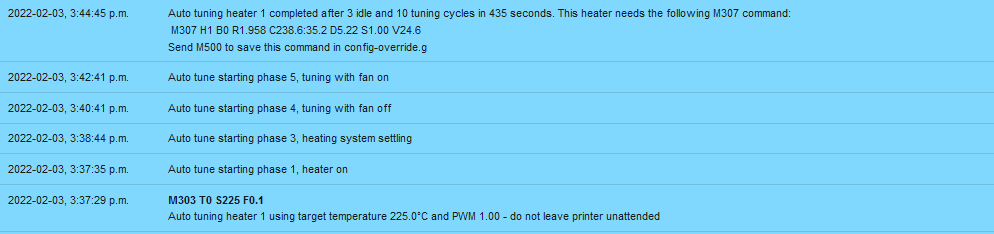

; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S4 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper ; Fans M950 F0 C"fan0" Q20000 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T55 ; set fan 1 value. Thermostatic control is turned on ###No effect until accelerometer board replaced### M950 F2 C"fan2" Q100 ; create fan 2 on pin fan2 and set its frequency M106 P2 H2:4 L0.25 X0.05 B0.25 T35:60 ; set fan 2 value, turn on at 5% if the CPU temperature reaches 35C, and increase to full speed gradually as the temperature rises to 60C ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0CAutotuning results with nozzle ~ 1 mm above bed and bed heater off

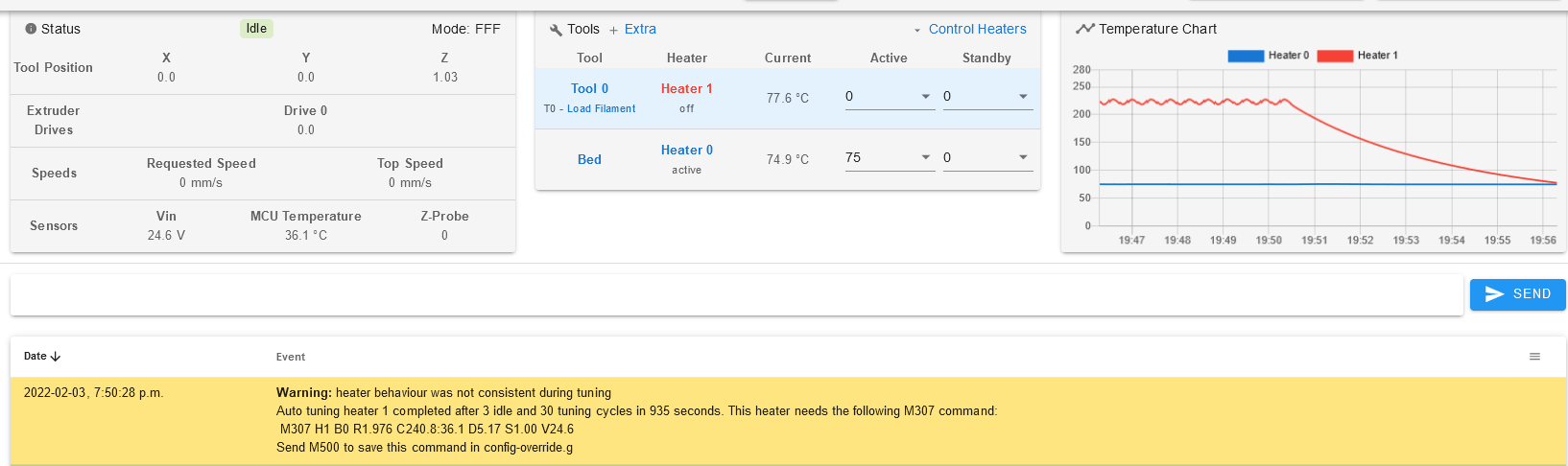

Autotuning results with nozzle ~ 1 mm above bed and bed heater on at 75C

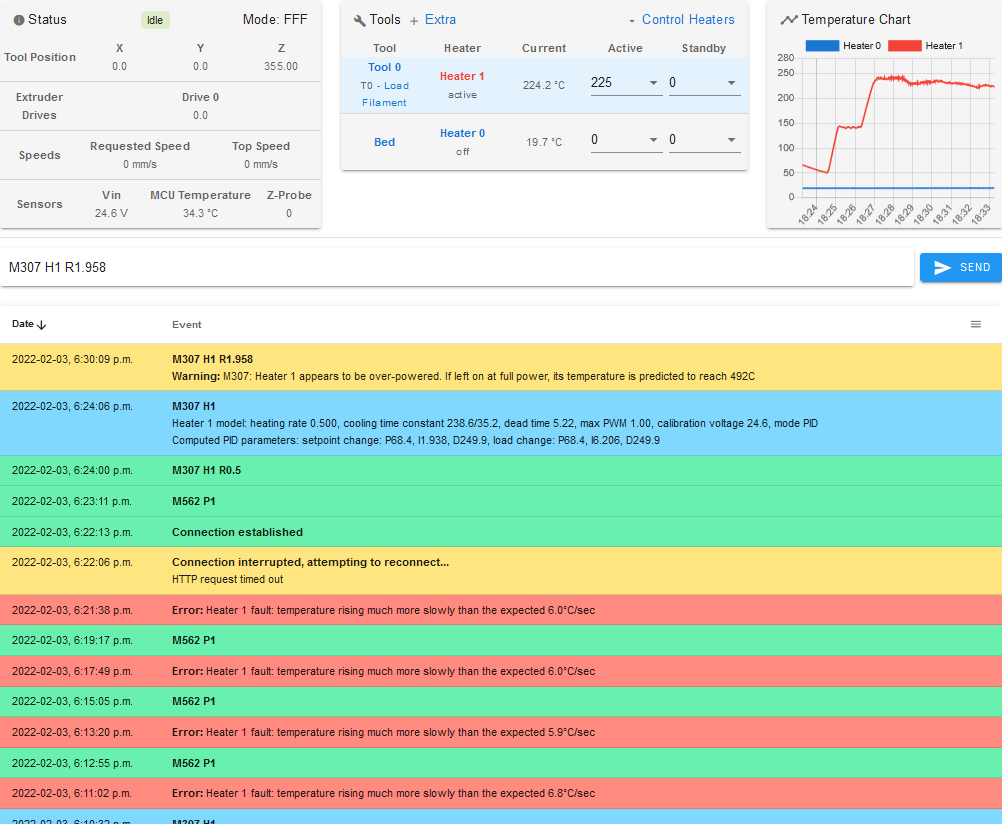

Temperature Chart and upper portion of console (6:23 p.m. and later) show hot end response with M307 R value set to 0.5. Air pump running at 10%. Temperature initially set to 140C then 235C then 225C. M307 R value changed to 1.958 at 6:30 p.m.. Air pump turned off at ~6:32:30 p.m..

Lower portion of console (6:21 p.m. and earlier) shows variation in heater fault expected rise rate. Starting temperature ~ 50C in each instance.

-

-

Did you tune the hotend as a heater, or as a tool?

Try

M303 T0 S250for tuning it.Your graph appears to have a lot of noise. Perhaps bad wiring?

-

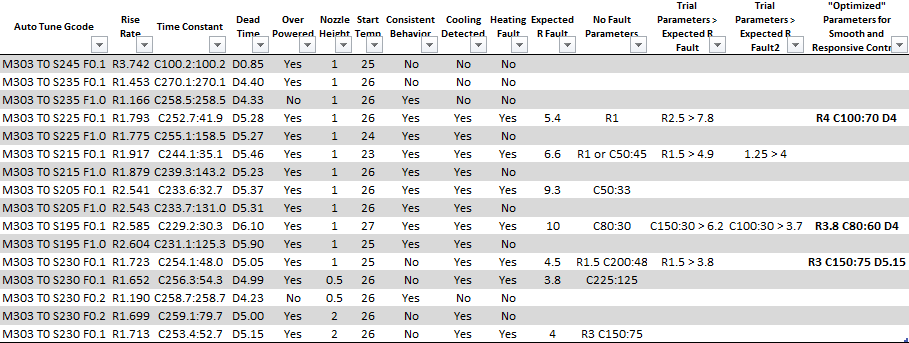

Sorry, forgot to include the M303 parameters used (yes was tuned as tool), here they are

Well i have certainly have had some fun with intermittent hotend wiring connections in the past, i think the current noise at higher temperatures is associated with the tuning parameters as the temperatures are relatively steady at lower temperatures and when heater is off as well as during the tuning cycles. Also temperature indication was stable at printing temperatures just prior to the update to 3.3.

Will try your suggestion of tuning to a higher temperature (will use 245 as the hotends are fully lined with PTFE).

Given that wiring problems always need to be considered, will also tweak the tuning parameters to see noise improves or not. If not will go hunting.

Thanks,

Bruce -

Could it be picking up noise from the air pump?

-

@phaedrux

Certainly possible but i don't think so as i have had the air pump for several years and have not noticed an effect in the past. The pump is driven through optoisolators and external mosfets - but could always have something coming back on the common 24VDC ground i suppose (a circuit diagram is linked in an earlier post of mine which is linked the first post of this topic in the section explaining the 12/24V setup).Just playing with tuning parameters now, increasing dead time is helping. Once something workable is reached will do a trial with the pump on and off.

-

Well, having some good entertainment with the auto tuning. Need to do a few more trials and collate some hopefully coherent findings. In the mean time did some manual tuning of the R and D values. R = 5 combined with D = 4 in conjunction with the model produced from M307 H1 S245 F0.1 (behavior was intriguing) do not invoke a heater fault of the temperature rising much more slowly than the expected variety, and produce a reasonably stable temperature at 235, albeit with a response that is a little on the sluggish side.

Think at the moment pump interference can be ruled out unless there is a diabolical feedback through the ground affecting heater voltage in a way which interacts with highly responsive tuning parameters.

Attached image shows response to temperature set point of 235 from ambient of ~25 and pump running at 20%. Nozzle is 1 mm above bed (directly over the bed thermistor hence slow rise of bed temp despite bed heater being off). Pump is turned off at ~ 17:34:20

-

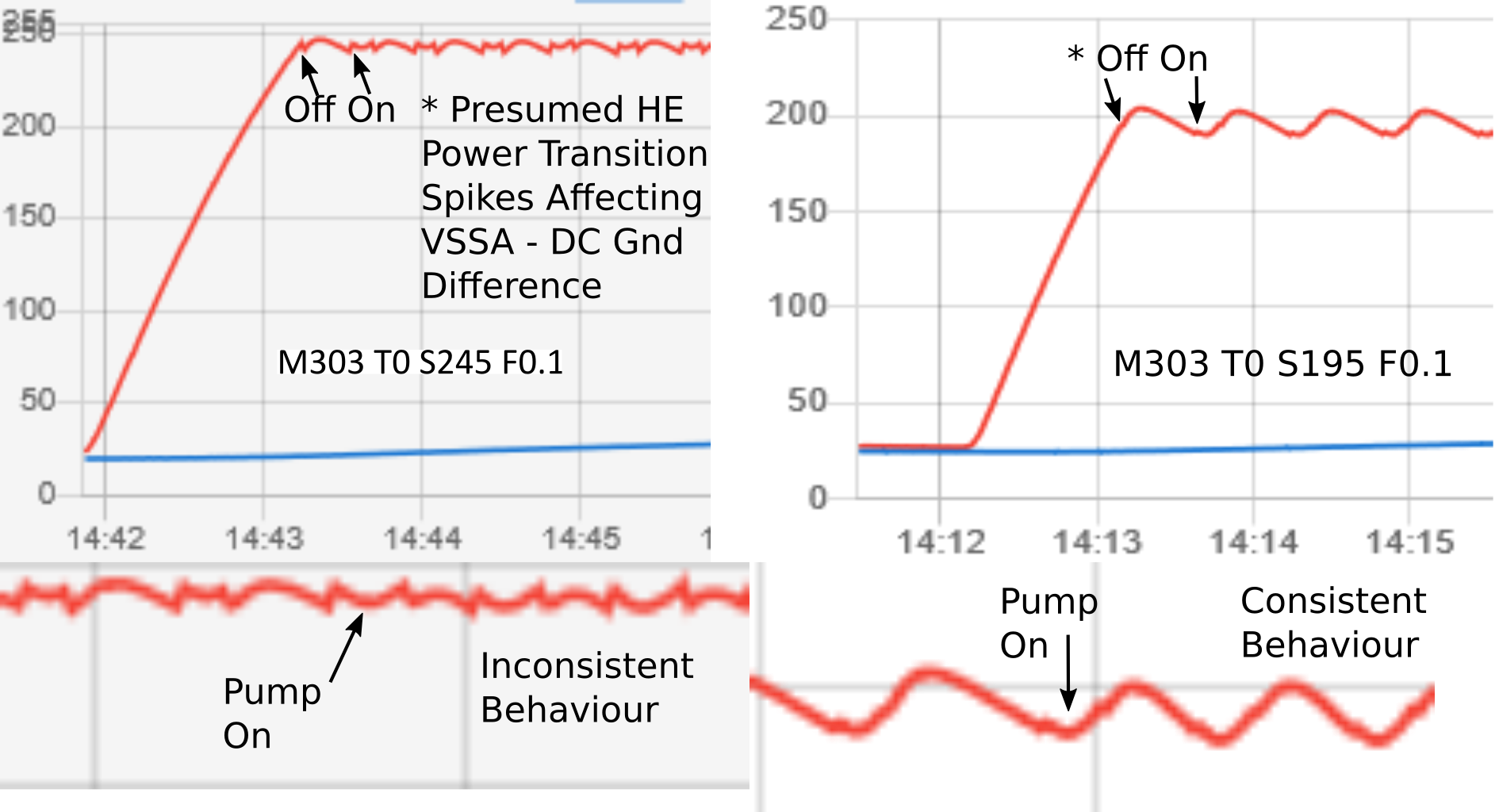

It turns out that there is a down spike or up spike in the hotend temperature signal on my machine that appears to coincide with the hotend heater turning on and off respectively. Presumably these spikes are, quite understandably, interfering with the auto tuning algorithm and are causing it to produce parameters which result in "temperature rising much more slowly than the expected" heater fault errors.

My first thought is that, due to my convoluted 12/24 VDC power system - v2max_duet_upgrade_dual_power_accelerometer_v1.0.pdf, there is some sort of VSSA-DC ground mismatch occurring when the heater goes from on to off during the auto tuning cycle. The effect is greater at higher temperatures - see below. My thinking is that, as thermister resistance is lower at higher temperatures producing a lower voltage at the Duet input pin, any change in VSSA-DC ground levels would have a relatively larger impact at higher temperature.

To my mind, the drop in temperature occurring when the hotend heater turns off suggests a lowering of the DC ground ground level relative to VSSA producing a higher voltage at the Duet input and visa versa when the hotend heater turns on.

The image below shows the difference in the temperature signal spikes at 245 vs 195C and the zoomed in lower panels show the point in the auto tuning process when the pump is turned on as well as the behavior reported by the tuning algorithm. Looking at the 245C temperature signal it is amazing that the algorithm comes up with anything at all!

For the moment, in order to have good response to cooling pump transitions etc, i will need to hand tune a set of parameters for every 5C or so due to the increased spiking effect at higher temperatures causing instability. Temperature chart below shows response for 225C "optimized" tuning at initially 225, then 235 and finally 230C.

The approach i took to get past the expected rise rate error was to (somewhat counterintuitively to my dim mind) lower the R and/or C values until the error resolved, get the hotend up to temperature, then increase R until the "spikiness" in the temperature response at steady state resolved followed by adjustment of the dead time to remove the slow oscillation but retain responsiveness to cooling changes. For most temperatures, a fairly significant reduction of the auto tuning generated C parameters was required in order to avoid the expected rise error heater fault after the manual adjustments.

On the off chance it may be of some to use to someone running into a similar situation with a less than ideal hotend temperature signal causing the auto tuning algorithm to generate expected rise rate error heater faults, some data from my testing and resolution process is included below.

It is interesting to note the effect of nozzle height above the bed (last 4 lines of the table above) and cooling pump speed on the cooling off:on C parameters. Based on some flow visualization studies i did with the pump duct, i suspect the paradoxical reduction in C parameter differences at full pump speed may be due to a bigger proportion of each air jet stream escaping under the lower surface of the duct at higher velocities and consequently reducing impingment on the nozzle.I will try another hotend with the same heater/thermister setup shortly to see if the problem follows and at some point in the next few months will finally convert the machine to straight 24V.