Issues with PID Tuning (RRF 3.4.0-b7)

-

@argo I think it would help if you explain what is wrong with your pid control and what the two graphs you have posted are showing.

-

Well, the graph is not flat and jumping around. The extruder temp is set to 210°C and the graph on the right shows that it is jumping around. Sometimes it almost hits 220°C.

I did PID calibration for T0 and it gives me this gcode to use:

M307 H1 R5.035 K0.663:0.153 D4.06 E1.35 S1.00 B0 V24.4 -

I just retuned my hotend heater which has a copper block with a 50w heater.

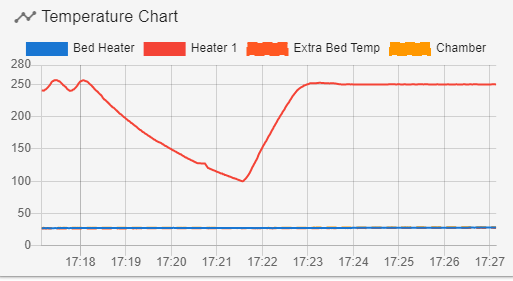

2022-01-15 17:28:08 m115 FIRMWARE_NAME: RepRapFirmware for Duet 3 Mini 5+ FIRMWARE_VERSION: 3.4.0beta7+7 ELECTRONICS: Duet 3 Mini5plus WiFi FIRMWARE_DATE: 2022-01-14 08:58:342022-01-15 17:10:37 M303 H1 S250 Auto tuning heater 1 using target temperature 250.0°C and PWM 1.00 - do not leave printer unattendedThe result was this:

M307 H0 R0.620 K0.495:0.000 D0.91 E1.35 S1.00 B0and my temp regulation seems to work pretty good:

I suggest you show what commnd you use for pid calibration (heater tuning) and an M115 and M122.

Are you sure your PSU is not on the limit or you have some voltage drop somewhere? (I'm not an electrical engineer

)

)I'm going to start a print soon just to verify that it can respond correctly during the print.

-

@argo Was it any different on other versions of RRF with the same hotend? I'm trying to help separate out any possible regression in this beta release from a possibly general problem with supporting your type of hotend with RRF.

If the same hotend worked better on a previous release, then please ignore the rest of this post. If it didn't then maybe the following will help....

What does the graph look like if you are not printing (just set the hotend to a fixed temperature), is it more stable then?

What happened at 15:55 on the first graph? Did anything (like the cooling fan level) change at that point? There seems to be a particularly large change in temperature at that point.

There seems to be a relatively large difference between the fan on and fan off values for the K parameter. Does the Rapido Hotend have any sort of "sock" on it? I wonder if the cooling fan is blowing back from the print surface and causing problems?

-

@argo It climbs up temp because of the secound K value

M307 H1 R5.035 K0.663:0.153 D4.06 E1.35 S1.00 B0 V24.4

Thats for fan compensation

-

I changed the hotend while running RRF 3.4b7 (official b7 from github) so can't tell yet if it works well with 3.3 stable.

The Rapido Hotend comes with a full silicone sock and only a small tip of the nozzle is visible and can be targeted by the parts cooling fan.

The fan speed changes from 85% to 100% during a print. Before that I had a Mosquito Magnum which did not have any sock and did not have issues with temperatures (also 3.4b7).I just flashed 3.3 stable to compare the results and did PID tuning:

M307 H1 B0 R4.821 C119.7:101.0 D4.26 S1.00 V24.4

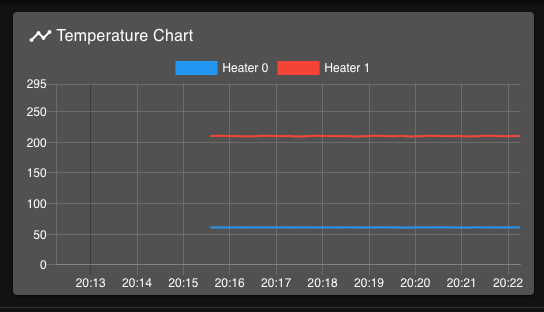

And here is the graph whilst printing with 3.3 stable:

Target temp is again 210°C and it keeps jumping between 209.3 - 210.5°C.

It's not perfect but far better than with 3.4b7 but still it struggles to hold the temperature whilst printing with that kind of heater. When idling and without the parts cooling fan running the temperature stays perfectly at 210°C.Next I'll try the classic heater PID without the fan included.

-

-

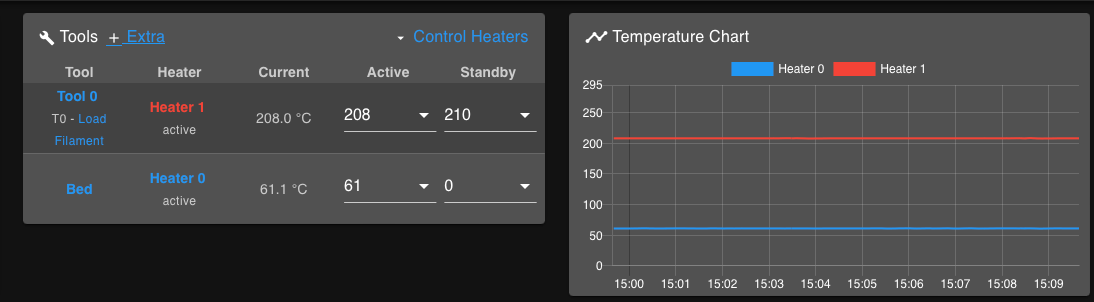

Just did a new PID (still RRF 3.3) as a H(eater) and not T(ool) so there is no calibration with the fan included.

M307 H1 B0 R4.676 C121.5 D4.48 S1.00 V24.3

And the temperature is pretty stable during a print:

Should make no difference with RRF 3.4.0-b7 but I'll also test the PID as a heater and not tool.

-

try firmware 3.4 beta 7+7

https://www.dropbox.com/sh/i5vox3xmkd55gaz/AAC19mI0WEC5GmEjLOBRbKs-a?dl=0

if you still have problems I help you in another way

-

3.4 beta7+7 - the results were even worse with PID

-

This post is deleted! -

then for the bed try to give this code in duet web control

M303 H0 S80 Y3

Y3= 3 hysteresis cycles

-

I have no PID issues with the bed.

The extruder PID calibration does not work for me when the parts cooling fan is included. Therefore I need to start the PID calibration as a heater and not as a tool.

The Rapido uses a different kind of heater which needs less power at higher temperatures. Maybe that is causing trouble for the PID calibration.

-

ok try this code to calibrate as a tool M303 T0 S205 Y3

-

undefined Phaedrux moved this topic from General Discussion

undefined Phaedrux moved this topic from General Discussion

-

Y3 or Y5 produce the same PID results which cause issues. Only solution I have atm is to use the old PID calibration which does not include the fan.

-

then try to change these parameters:

I put my values try to use suitable values for you. you can find in config-override.g

try for example starting from your values to lower R and increase D

M307 H1 R2.762 D6.75

then put the string in duet web controll and press enter

digit M500 and press enter

make sure you have M501 at the end of config.g

-

This post is deleted! -

ok the geometry and type of material affect the pid adjustment

-

undefined droftarts referenced this topic

undefined droftarts referenced this topic