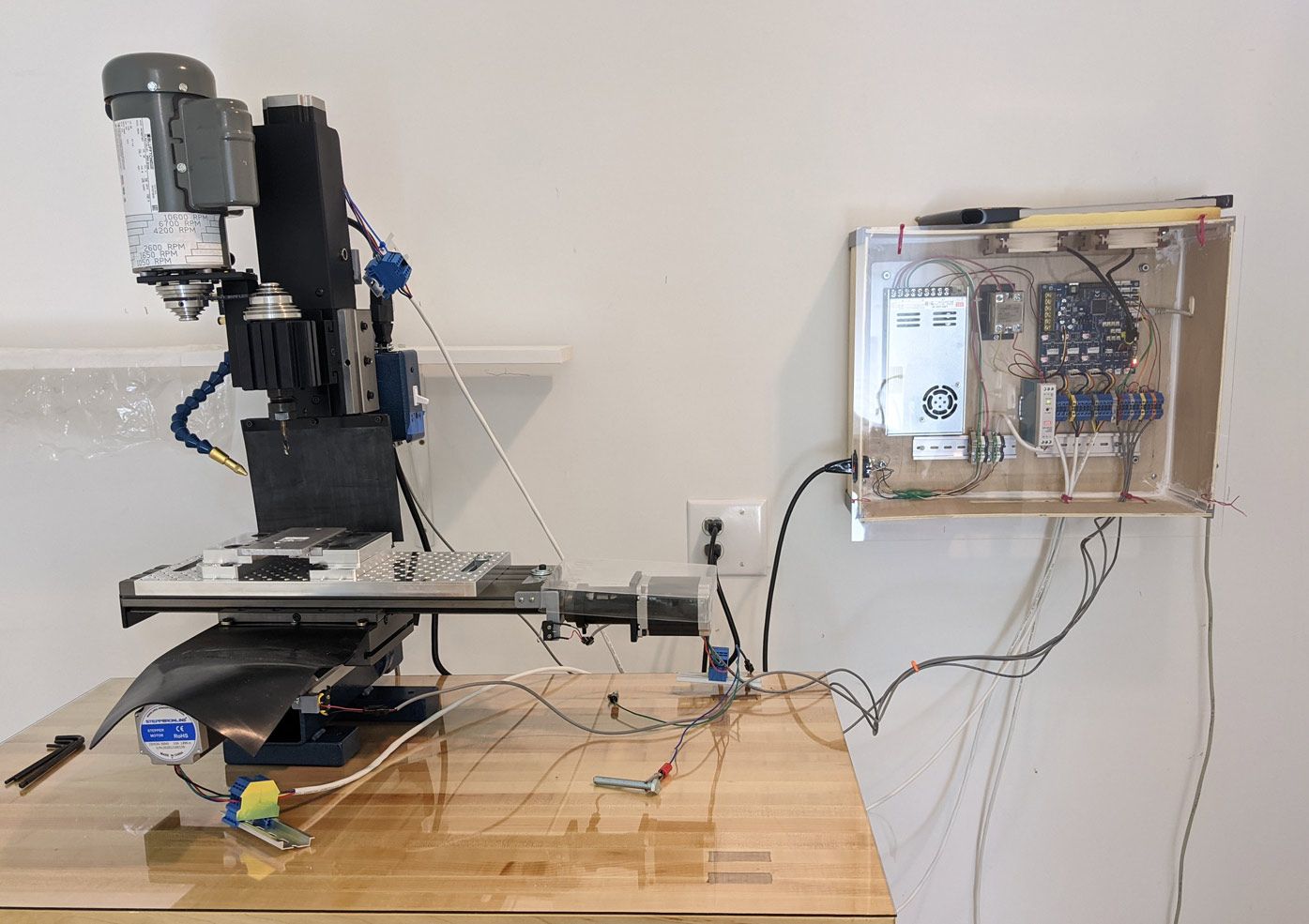

Taig Micro-mill installation

-

I've just put together (ignore the wires all over the table and yucky connectors) a system to run a Taig Micro-Mill.

A couple of photos follow. I'm hoping it has enough current capacity and enough torque at 30V but it seems to be ok - it was enough torque to grab and tilt the spindle column when the bit jammed!

-

@markz looks good. What lead is on the screws?

heres my micro mill

https://forum.duet3d.com/topic/11581/duet-controlled-micro-mill?_=1619476416966 -

@3dpmicro The ballscrews are 2.5mm/turn. Thanks.

Here's a final photo of the controller setup. It runs the 3 motors, 3 limit switches, an E-stop, power control for the spindle (using a really nice IoT power control), power control of compressed air for the mister (with a pneumatic relay and buck converter), and a way to measure tools. Sweet.

Nice looking micro-mill. How's the spindle working out for you?

-

Spindle works good. Cant do any hogging obviously but it will cut about anything with a light enough chip load and DOC including hardened tool steel. I have a 10-50k rpm electric version too.

Be sure to post some part pics