need advice on Delta backlash

-

I'm hoping to get some advice/suggestions on a backlash issue I'm experiencing with my delta. The quick background is that this backlash is somewhat new and corresponds to me changing from using a smart effector and the included carriage adapters to using the same same smart effector with a 74mm arm spacing adapter and new (printed) carriages also for 74mm spacing. The carriages and adapter are printed with PLA. I've included STLs for the adapter and carriages below in case there's a design flaw with them.

The delta arms are Haydn Huntley's 400mm arms with magballs, and everything is secured with M3 screws, locking nuts (nylocks) and 1mm M3 nylon washers. (I'm using the washers everywhere a screw head or nut comes in contact with even plastic - to ensure that the screw/nut isn't digging into the plastic.)

The carriages are MGN12H's

(Note that the bed is known to not be flat. It's an aluminum bed with magnets embedded and a spring steel sheet on top, and some of the magnets aren't flush with the rest of the surface of the aluminum.)

I've checked all the usual suspects. Belts are tensioned, pulleys are secured properly to steppers, idlers are single pieces in bearings that are fine/secure, all the effector and carriage screws/nuts are tight (not moving), and I've cleaned and re-lubricated the magballs (superlube with PTFE, only a very slight amount.)

I'm not entirely sure if I'm interpreting this correctly, but it seems to suggest that the backlash is at the "Y" tower (also called the "B" tower.) (Doing backlash tests, there's certainly more backlash nearest that tower.)

I know the rails, idlers, and pulleys are all good, as this backlash only showed up when I switched to using the PLA printed effector adapter and PLA printed carriage adapters. I could say the same for the belts, but I obviously had to detach and re-attach the belts when I changed the carriages. (However, all three belts are the same tension and plucking the belts like a guitar gives a sound frequency of 40Hz on all of them.)

-

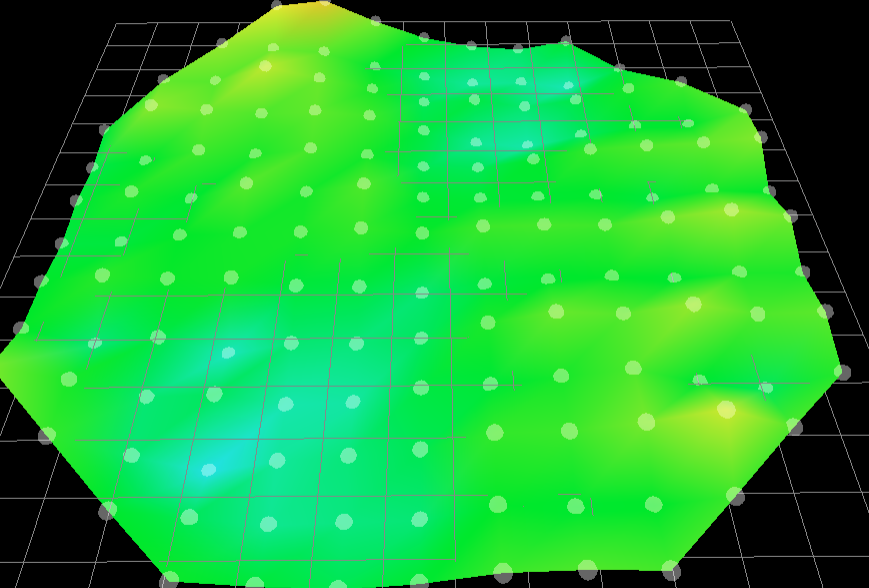

I'm there with you on being stumped by it. I finally got the last of my surface patterns gone (I've been chasing it down a rabbit hole for a LOOOONG time, but existed running under 45 mm/s print speed. I ended up swapping the bearings in a linear rail carriage a third time and it just disappeared completely woo woo!) I just called it good enough though on the height map after reaching -0.045 / 0.042 max deviation and .017 mm RMS error shown below. So I don't know how to get rid of the alternating pattern with my similar build.

If I was to guess though from the map, I'd say you're Y tower ballends+arms (basically the sum of everything from effector to carriage) are either a hair longer than the other towers or the tower is slightly inset in respect to a perfect equilateral triangle. I don't believe individual arm tower distances are handled by the auto-calibration yet, although you can manually adjust them with M665 ex: M665 L260.1:260.2:260.0. If you see how individual tower arm lengths affect your map by +/- .1 to an arm length and compare your map results if you really want to check that (I haven't figured out a good setup to do this measurement manually to that precision). If you find the offending tower you can just leave it compensated for software or shim it for a mechanical fix. Luckily tower angle issues though should be corrected by a 6 factor calibration.

edit: correction (the thought came in soon as I quit thinking about it) arm length differences can be handled in software, tower position from center needs to shimmed, still the process to determine the offending tower should be possible with small adjustments the individual arm lengths.

-

So far, I've had no luck fixing this. I'm still not even 100% sure that the backlash is on the "Y" tower. (The only thing I'm sure of is that there's more backlash the closer the effector is to that specific tower.)

I've reprinted and replaced the carriage adapters, and changed the bearings in the carriage, but no significant change.

Is it possible that a stepper has something wrong with it that might cause backlash? (I'm wondering if it would be worthwhile to try and swap out the stepper on that tower.) If it matters, they are 1.6amp 0.9 degree steppers that I run at 1.3 amps.

-

@garyd9

I had mixed results with Haydns ball studs a few years ago when I ordered 5 sets of mags and balls to build my own arms.

He mentioned, they might be not 100% round. He sent me 50 balls extra to sort out the best.Just my two cent.

-

When I think about it, I think the last time I cleared up the ripple as you see in the height map was actually solved by swapping my magball arms around. Accumulated errors between carriage + arms+ effector made measuring arms with magballs in them unattached to the actual build a trap, I had to measure from the rail to the ball end, then from ball end to ball end, then put the arms in the right position to get most uniform pairs on a tower as well as best average length. For my magball arms (360mm haydn huntley magball arms), what threw me off was the effective pivot point. For my set at least, If I measure the arm with a 9.5mm ball stud on each end from the edge of a ball to the other edge of the ball, the firmware measurement is that distance minus 7 (plus corrections for effector/carriage errors). Why 7? Because (once again for mine at least) the 9.5mm ball is inset about 3mm into the arm, and the effective pivot is 3mm further in from the edge of the arm, leaving 3.5mm from each ball end to subtract on each side. My desire for things to work neatly kept driving me to think it'd pivot in the center of the ball stud which is not the case. Figuring that out was so frustrating I think I want to forget it again.