Piezo board with 4 sensors?

-

Okay anyone with the universal board, do you know if it is possible to tune a piezo such that it is in a compressed state normally (Voltage is high) and then when I probe the bed the piezo is uncompressed (voltage is low) to trigger the endstop? or is it purely voltage spike that the universal board can register?

-

First you have to understand what a piezzo does. Let me try to explain. It produced "voltage" when you bend it. It doesn't matter in which direction, this only affect the polarity. Next thing is, it doesn't store the voltage when bended. In common the universal board mesured the voltage which emerge when you bend it, bend it more or in the other direction.

-

The voltage generated is proportional to how much & how fast you bend it. The Universal board processes that voltage and produces a cleaned-up active low digital o/p.

-

Noted, so it generates voltage just on the motion of compression or bending. I suppose I just need to get a few to play with. So technically having a piezo in compression, then relaxing it will still generate a voltage correct?

-

Yes. What do you have in mind?

-

@Fickert said in Piezo board with 4 sensors?:

So technically having a piezo in compression, then relaxing it will still generate a voltage correct?

Exactly, it reacts to a change not to pressure. For e.g. my andromeda's were tensioned when bed is normally sitting on them and when you press on the bed it actually releases the tension on the andromeda, that works exactly the same as the andromeda's were relaxed and I added tension... the disk itself produce voltage on change. You can try it yourself, get a piezo speaker from a toy, postcard, old watch/calculator, hook a simple voltmeter to the leads and play with it, press it then release it, you will see a voltage spike when you press, then while you keep the pressure voltage is gone, then you release and voltage spike is back there :). It is important if you use multiple sensors in parallel you match polarity 'cause they will cancel each other out if you reverse it.

-

@arhi This is awesome news, that means with my scenario it should work great. I thought I had a piezo buzzer from my days of ardupilot / pi building of drones but doesn't look like it. Will order some they're cheap enough.

-

@Fickert when I first saw the post by precise piezo about their system on reprap.org I was astonished how no one thought of this before

and had to try immediately. I could not find a piezo disk around me so I ordered myself immediately one "music telegram" via phone. It arrived in few hours

and had to try immediately. I could not find a piezo disk around me so I ordered myself immediately one "music telegram" via phone. It arrived in few hours  so for ~1eur I got piece of paper with some image and text + some noise generator (they call that a song) and a piezo speaker

so for ~1eur I got piece of paper with some image and text + some noise generator (they call that a song) and a piezo speaker  ... 10 or 100x more expensive than the price of the disk alone in a proper shop but got delivered in few hours, on my doorstep

... 10 or 100x more expensive than the price of the disk alone in a proper shop but got delivered in few hours, on my doorstep

I have a plan for one new machine (design ready in my head, should start building in summer) and I plan to use switches + piezo sensors for homing to have repeatability on power failure and "complicated tool changes", but that's some other story for some other time.

Try the piezo sensors, you will love them. When they are properly set they work awesome. The simple disks in holders like the old version work great, the new thing precise pieze guy's made (andromeda and orion) are AWESOME

-

@arhi Even if this thread is quite old now: thanks for the information you provided! I found this thread since I just bought some of the Andromeda piezo sensors and wanted to know if it is okay to mount them under constant strain - which you obviously did.

-

@arhi Maybe as a remark to the setup with the missing fourth screw that did not work for you: if I am not mistaken, these sensors produce a negative signal if they are pulled instead of pushed. That might have been the case in your setup - when you press onto the fourth corner without the screw, you have quite exactly a 1:1 lever arm with its bearing axis running diagonally over the print bed. Thus and assuming the electronics senses both positive and negative signals, in theory the two sensors located on the diagonal axis each see the force +F, while the third one located on the opposite side sees force -F - which means the signals of two of the three sensors cancel out each other. If you can provide that sensor with an additional circuitry that short-circuits the sensor for negative signals, this might well work as well..

(edited to remove stupid logic error..)

-

@NeoDue said in Piezo board with 4 sensors?:

in theory the two sensors located on the diagonal axis each see the force +F, while the third one located on the opposite side sees force -F - which means the signals of two of the three sensors cancel out each other

In theory that would be possible. In practice, my 4 channel 1GHz scope say that they are all polarized properly and that signal amplitude in that corner is "pathetic"

I moved to the sensor in the head as the sensor in the table was just not repeatable enough and on the printer that I'm using most these days, I'll be removing piezo completely next time I'm changing the nozzle. Orion in analog mode works decent but it is PITA to setup. Every time I do anything with my hotend it takes me hours to set Orion to work, I had it, next time I'm changing the nozzle I'm removing the Orion from the head and mounting back the bltouch. On other printers, it works nice, but here it's just too pita

...

...Don't get me wrong, I still love piezo style but something on this printer just don't sit properly, orion either does not trigger at all (probably everything is too stiff) or it triggers ok but print quality is 5#$^@$#%@ because the hotend wobbles

-

@arhi Hm. I guess the Orion Sensor is a bit of a pain depending on the geometry of the print head, yes, but I am puzzled about what you say about the Andromeda's... sounds to me like the bed screws maybe got stuck in their guidance due to the off-centered push or something. Force needs to go somewhere

Let's see how the Andromeda sensors will work for my printer and if the "constant spring load/unload if touched" setup I chose really does what it should long-term. The only other chance to fit a decent z sensor onto my Neo without losing precious X-Y motion range would be to mount a BLTouch above the whole printhead unit and then somehow make the touching pin about 12cm longer and guide it through the whole print head... somehow I doubt that would work reliably...

-

@NeoDue said in Piezo board with 4 sensors?:

@arhi sounds to me like the bed screws maybe got stuck in their guidance due to the off-centered push or something. Force needs to go somewhere

for the piezo to work you need to have a "hard contact", soft contact won't work. when you remove 4. screw in the region of the 4. screw you have soft contact and piezo does not trigger ( or trigger after moving bed 2-3mm down making it 2-3mm late and useless ) .. the force is there but the way it acts on the 3 piezo sensors is not shaped in the way that it will trigger the andromeda.

Let's see how the Andromeda sensors will work for my printer and if the "constant spring load/unload if touched" setup I chose really does what it should long-term.

I think it should work without a problem. The issues I have with piezo are "instant", once I make them work, they work awesome till next time I remove something, then again they instantly don't work and I need to spend time to make them...

second part of the problem is probing speed with duet where duet is (was, this is changed now in latest beta according to release notes, did not try yet) slowing probing down in analog mode thinking that head is close to the bed and this does not play well with piezo as it creates "soft contact" .. latest beta moves at appropriate speeds so this should be fixed now..

-

btw, one additional piece of info, when I replaced the regular wire going from piezo analog output to duet with coax cable (I used some balanced microphone cable) the quality of the signal improved 10000000000x and it was much much much easier to setup and use

-

@arhi Thanks a lot for the hint with the cable! I will keep that in mind.

To the other problem: okay, this means the higher the gradient of the load change (not the absolute value), the better the signal. Now I understand, thanks a lot.

This tells me I should probably play safe and try to remove the dampening of the impulse caused by the spring being mounted in parallel to the sensor - even if the sensor does not care a lot about static load. The slower I can go i the end, the less I fear for my precious glass plate...

My printer has a rather stiff bed (glass plate plus 5mm thick milled aluminum plate) - so if anything gives, it is the metal frame between z axis and bed which is actually the flimsiest part of the whole printer.I'll search for some pictures how other printers have their bed mounted, maybe that lets me find an idea on how get the springs out of the way.

-

@NeoDue said in Piezo board with 4 sensors?:

rather stiff bed

My bed surface is very stiff (alu+glass+printbite) but is sitting on springs

so link hotend-print surface is not very stiff due to springs ... stiffening springs helps but not enough in my case (this is not a very good printer really it's based on ender5 .. improved but still ..)

so link hotend-print surface is not very stiff due to springs ... stiffening springs helps but not enough in my case (this is not a very good printer really it's based on ender5 .. improved but still ..)speed with piezo is counterintuitive

.. if you approach it fast it will react quickly but if you approach it slow it will react late so you will actually have much more force "bending your hotend" ... latest beta firmware should allow you to properly setup speed. before latest beta the speed you set would not be used but some lower speed (assuming you are using analog trigger) would be used.... that's a problem as you could not properly set the speed, especially if you have slow Z as I do... with latest beta the set speed should be used for actual probing (we'll see when I test, my printer is currently dead, I have to rewire it)

.. if you approach it fast it will react quickly but if you approach it slow it will react late so you will actually have much more force "bending your hotend" ... latest beta firmware should allow you to properly setup speed. before latest beta the speed you set would not be used but some lower speed (assuming you are using analog trigger) would be used.... that's a problem as you could not properly set the speed, especially if you have slow Z as I do... with latest beta the set speed should be used for actual probing (we'll see when I test, my printer is currently dead, I have to rewire it) -

I guess, it's not speed but acceleration one has to think about - then It is clearer, at least for me

Yesterday, I tried how a piezo speaker I had lying around might react by gluing one onto the frame holding my printbed, roughly where the Andromeda would be mounted if I followed my initial idea. It turned out my spings are too stiff: the bed spring would rather bend the frame if I pressed onto the bed instead of giving in - and the piezo would barely detect anything.

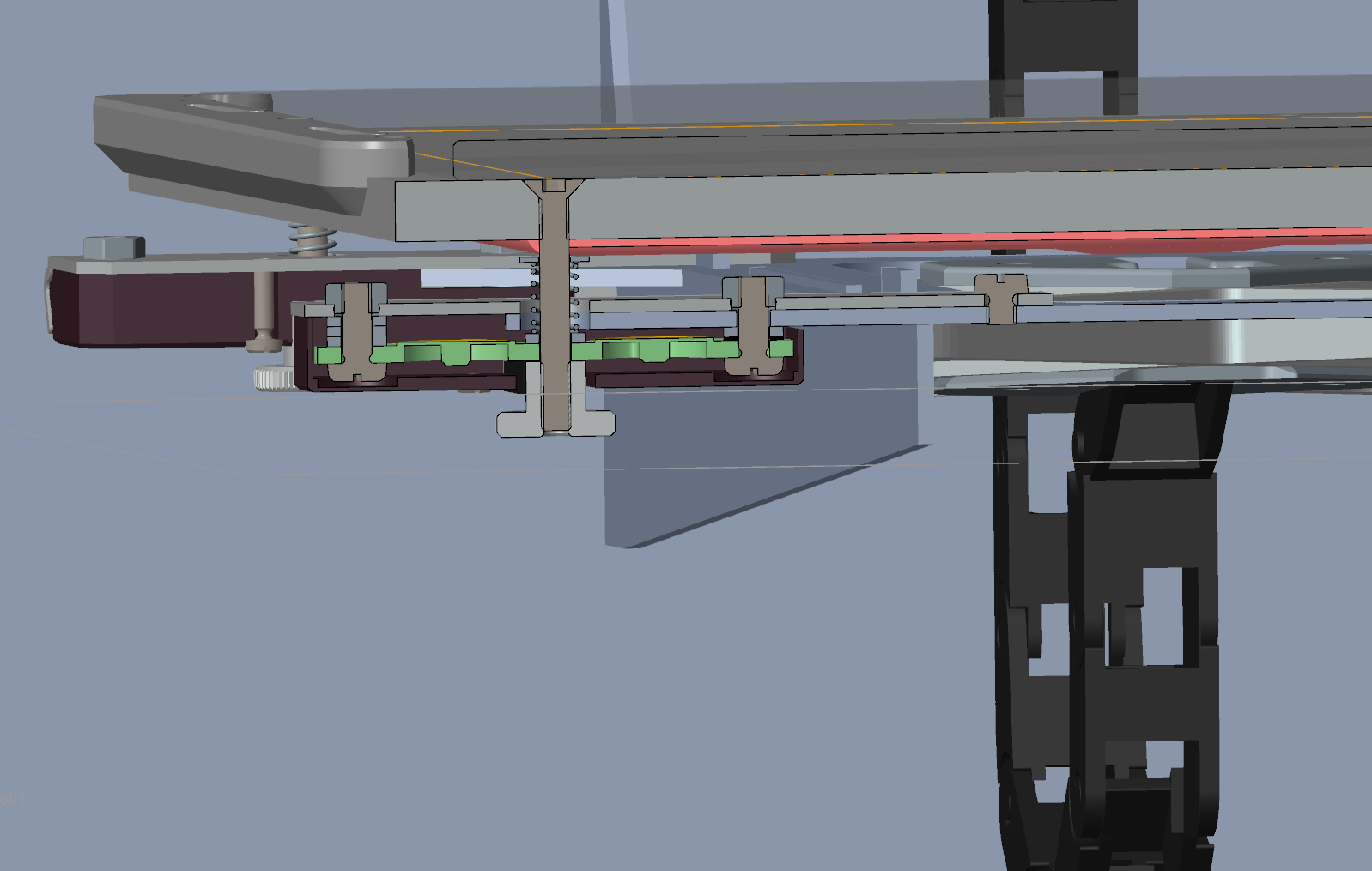

After some attempts on how to fit everything into the available space (my printer has just 32mm beneath the printing surface with the z-axis being at its lower limit and the printer housing, meaning 13mm for the Andromeda and the adjustment screw), as far away as possible from the heating element and still keeping the adjustment screws accessible, the whole design - with the piezos nicely covered with a housing - looks like this now:

(the thin aluminum plate is L-shaped to give it more stiffness; that is cut away in the view. So it not quite as flimsy as it might look)While this means I will have to drill some more holes into the z-axis frame, I definitely will see a signal now whenever I tap onto the bed with something. Now It's up to finding the correct settings for sensitivity - as soon as the sensors have arrived and I have assembled all this. Some miniature coaxial cable is also ordered

When this is running, I want to find a way if I can use the Piezos as "second" z-endstop (i.e. z-endstop controlled by the piezo elements - but in case these fail for some reason, the exisiting less precise endstop detection should kick a bit above that and force the Duet to retry...) but I will open a new thread for that topic unless I find something here in the forum.