Endstops not working during homeing but light up on board

-

X and Y now home correctly. Need to gather myself before I have the guts to try Z.

-

-

@Veti My Z is on dual steppers with lead screws. I can send a +5 and it moves the bed downwards. I believe this is correct? I have a CNC and I think it's opposite of that.

-

+ is away from the nozzle - is towards the nozzle -

I'm on to the BLTouch for Z. I'm trying to do a little homework before 100 questions on here. This is from the setup page.

"Ensure in your config-override.g file (in the /sys folder of the SD card) does not contain an M307 H3 command that overrides the above configuration"

I don't see the config.overrrid.g via DWC. Is this something I need to add? Also, Can I not add folders etc.. directly to the SD via DWC? There are other instructions in this that call for /sys folder in SD card.

-

thats fine. its for the case that you have one.

the sys folder already exists and that is where the config.g for example is located.

-

I got it to home all, BLTouch deploys and touches and all is good. Slight issue with where it probes, or thinks it probes, but I'll research before I post more. Thanks again for all the help.

-

@resh Probably should make another thread for this, if so let me know. As mentioned, my home all is working now but the XY coordinates are slightly off during Z probe. The code calls for the nozzle to go to X15 and Y15. The X15 is almost spot on but the Y is off by about 10mm. I have set the G31 offset for BLTouch. It seems like the discrepancies in the G1 X15 Y15 line are related to the placement of my endstops. My X is closer to the bed than my Y. Probably just coincidence.

called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Fri Feb 26 2021 10:46:02 GMT-0500 (Eastern Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X315 Y315 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X-5 Y-5 F6000 ; go back a few mm

G1 H1 X315 Y315 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X15 Y15 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed -

For the G31 measure the distance between the probe and nozzle tip.

For the endstop position, if the endstop triggers when the nozzle is slightly off the bed you can use a negative minima value in M208 to move the 0,0 position back to the corner of the bed. That might correct the x15 y15.

Also it's probably a good idea to probe the center of the bed rather than a corner.

-

@Phaedrux I've measured the zprobe to nozzle X,Y offset and input that for G31. I have Z probe trigger height set at 2.5 but if I look closely when it triggers the nozzle doesn't touch the bed when it's triggered, it's maybe 1mm above. Is that what you're referring to in that second sentence? Is the nozzle supposed to contact the bed during Z probe?

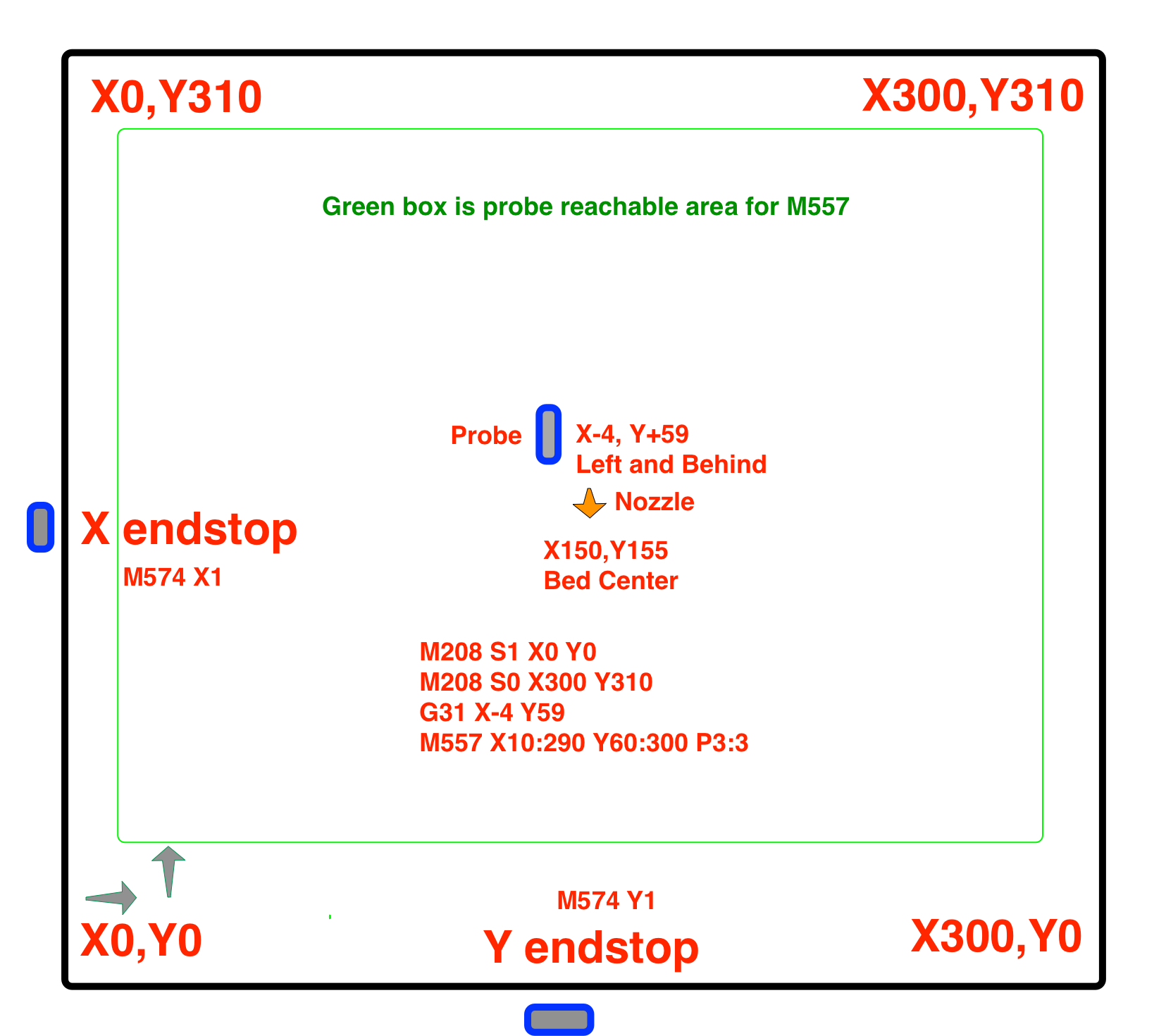

I guess what I'm asking is how does the machine know where the endstops are vs. the location of the actual bed? I could have my endstops 3ft away from where the bed is but I don't believe I've entered any values to accommodate for this. I've entered the size of my bed here: M208 X310 Y310 Z180 S0 ; set axis maxima. but I'm not sure what that's done. I agree I should probe the center of the bed but that brings me to my question. Thanks for the help.

-

@resh said in Endstops not working during homeing but light up on board:

Is the nozzle supposed to contact the bed during Z probe?

No. The probe should trigger when the nozzle is still above the bed. You don't want a crash after all. See here about setting your probe offsets: https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

@resh said in Endstops not working during homeing but light up on board:

I guess what I'm asking is how does the machine know where the endstops are vs. the location of the actual bed?

That's defined by M208. That command tells the firmware what position the nozzle is at when the endstop triggers.

@resh said in Endstops not working during homeing but light up on board:

I've entered the size of my bed here: M208 X310 Y310 Z180 S0 ; set axis maxima.

That's the maxima, but what is the minima. Start with the nozzle at the front left corner of the bed as 0,0. Then the distance to the travel extents will be your M208 minima and maxima. The minima can be negative in cases where the endstop is farther from the edge of the bed and the nozzle is no longer over the bed when the endstop is hit.

Try creating a diagram like this to help you visualize.

-

@Phaedrux This is great, thank you!

-

@Phaedrux I've got the 208's figured out. I'm little confused on the M557 for probe reachable area vs. M557 for define mesh grid. This my current config: M557 X15:215 Y15:195 S20 - Are there two separate M557 or is it just one and the M557 is the probe points? Thank you

-

M557 defines the area of the bed used when probing for the creation of the G29 mesh. You should only choose points that are reachable by the probe. If you choose points that the probe can't reach they will be skipped.

-

@Phaedrux Can I come back to the mesh grid after I've completed test calibration prints? I've done initial leveling with the paper in the corner method. I also followed your link above and fine tuned the Z probe trigger height, without baby stepping or printing. I think my next steps are thermistor setup and then maybe melting something. I've butchered this thread enough.

-

Yes you can add mesh compensation whenever or if you want. It's useful to at least create a map just to visualize the surface of the bed. If it's flat enough you need not use it.