G0 move seizes when G29 S1 active, fine when G29 S2

-

@jackstack said in G0 move seizes when G29 S1 active, fine when G29 S2:

Not sure if M122 has to be after i replicate the failure.

ideally, but I mostly just wanted to see if there were hiccups being reported. But you're using x16 microstepping so I think that is unlikely.

As Veti notes, your Z accel is quite low. Is it that low for a mechanical reason? Raising it to ~100 should be a bit better for mesh compensation adjustments.

You're also trying to use 2800ma on the Y motor. That will be capped at 2400ma which is the max for the Duet2. Do be sure your board as active cooling.

-

Important to preface that the bed is massive, unheated and fixed, and I'm not using ABL sensor. It's manually generated mesh map with a Z end stop below the bed about 3mm. I couldn't find any recommendation for resetting Z0 datum manually, but single axis moves have been fine with G29 S1 eg. moving from X min to x max Z has responded and maintained consistent height above bed and in the slicer it compensates down to initial layer reference to the mesh bed.

-

@Phaedrux Huh, I thought Duet 2 wifi was listed as 3A max for stepper. Is it current limiting to 2400 or do I need to set it to 2400. Based on the stepper motor sizing forum page, the only "not ideal" setting of the nema 23 I'm using is its 5.4 mH.

-

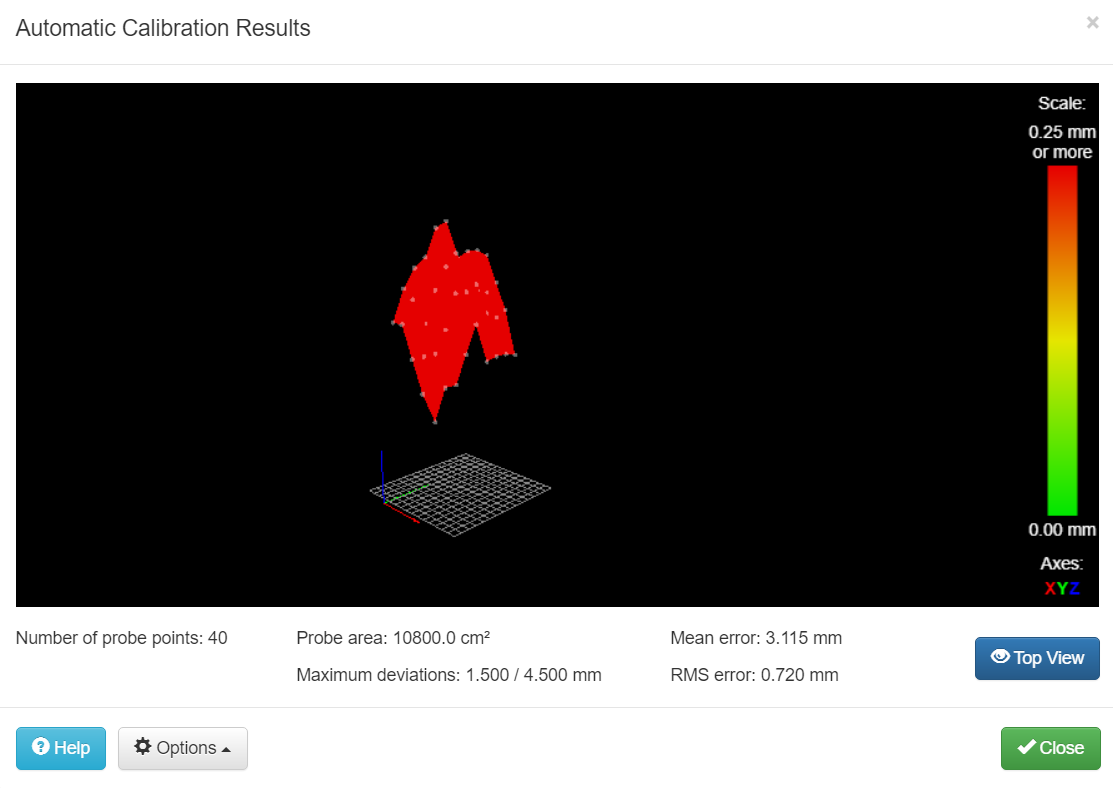

all i can think of when i see that heighmap is. no

-

The deviation on that heightmap isn't too bad given the size. But there shouldn't be such an extreme offset from Z0.

Can you post your homing files? bed.g if used?

And can you give a better explanation of how you're using the "probe"?

Given the large amount of adjustment being requested you may need to reduce the initial layer speeds quite a bit. Plus you're saying that it's the Y axis that is stalling on that first rapid move. The high steps per mm of the Y axis may require reduced max speeds and lower acceleration.

-

@jackstack said in G0 move seizes when G29 S1 active, fine when G29 S2:

I'm not using ABL sensor

is it planned? it would make it a lot easier

-

Yes, not using a ABL was planned. I have some adjustment for the Z end stop so I can decrease that ~3mm offset and do a more consistent job of generating the mesh bed. The scale of the display does make it seem horrible but I'm using a large nozzle so theres margin here compared to a .4mm nozzle.homeall.g

In terms of Y stepper, i was actually having worse performance running a lower acceleration for Y, speed is reasonable due to diminished torque at higher RPM but the G0 also failed at F1200 mm/minbed.g

As for "probe" I don't have one. I have a Z end stop that sets min axis point. M558 P0 H5 F120 T1200 "P0" sets it to no probe and it prompts you to manually job the z down to touch the bed.

-

you can use something like this. (i use it on my delta)

https://de.aliexpress.com/item/32838312776.html

cheap and works well.

just probe the bed once and remove it.

-

G1 H2 Y5 F1000 ; go back a few mm

G1 H1 Y-1923 F360 ; move slowly to Y axis endstops once more (second pass)

G1 H1 X-915 F1800 ; move quickly to X axis endstops and stop there (first pass)

G1 H2 X5 F1800 ; go back a few mmDon't use H2 on the XY moves to back away from the endstops. otherwise the homeall looks ok.

-

@Phaedrux Should it just be omitted then? H0 explicit but also default.

Thanks!

-

yes, H0 is the default if no H parameter is supplied.

-

@Veti Imma have to check those out! way easier than manually measuring lol Mechanically my printers designed as a set and forget for at least several prints.