stepper precision

-

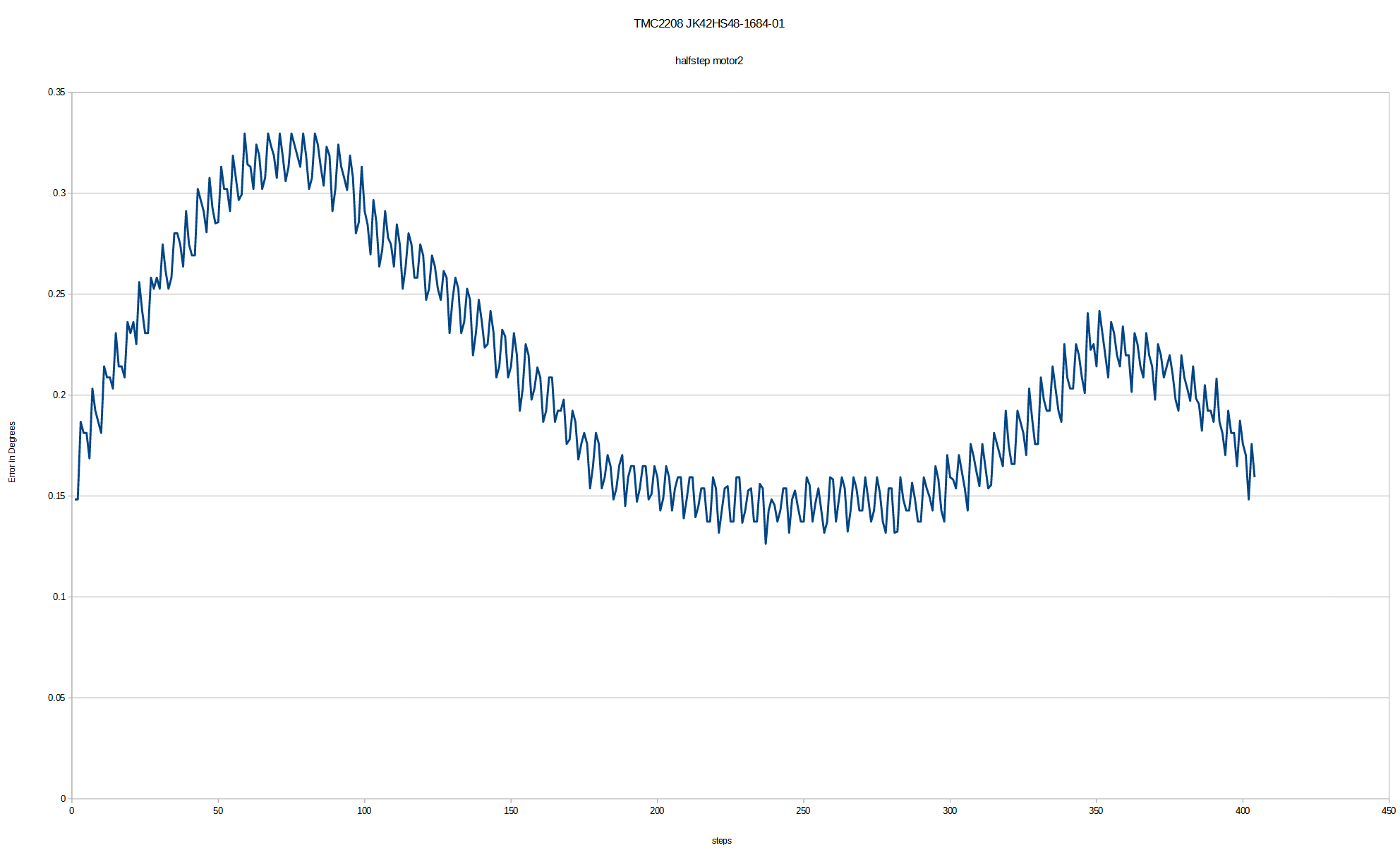

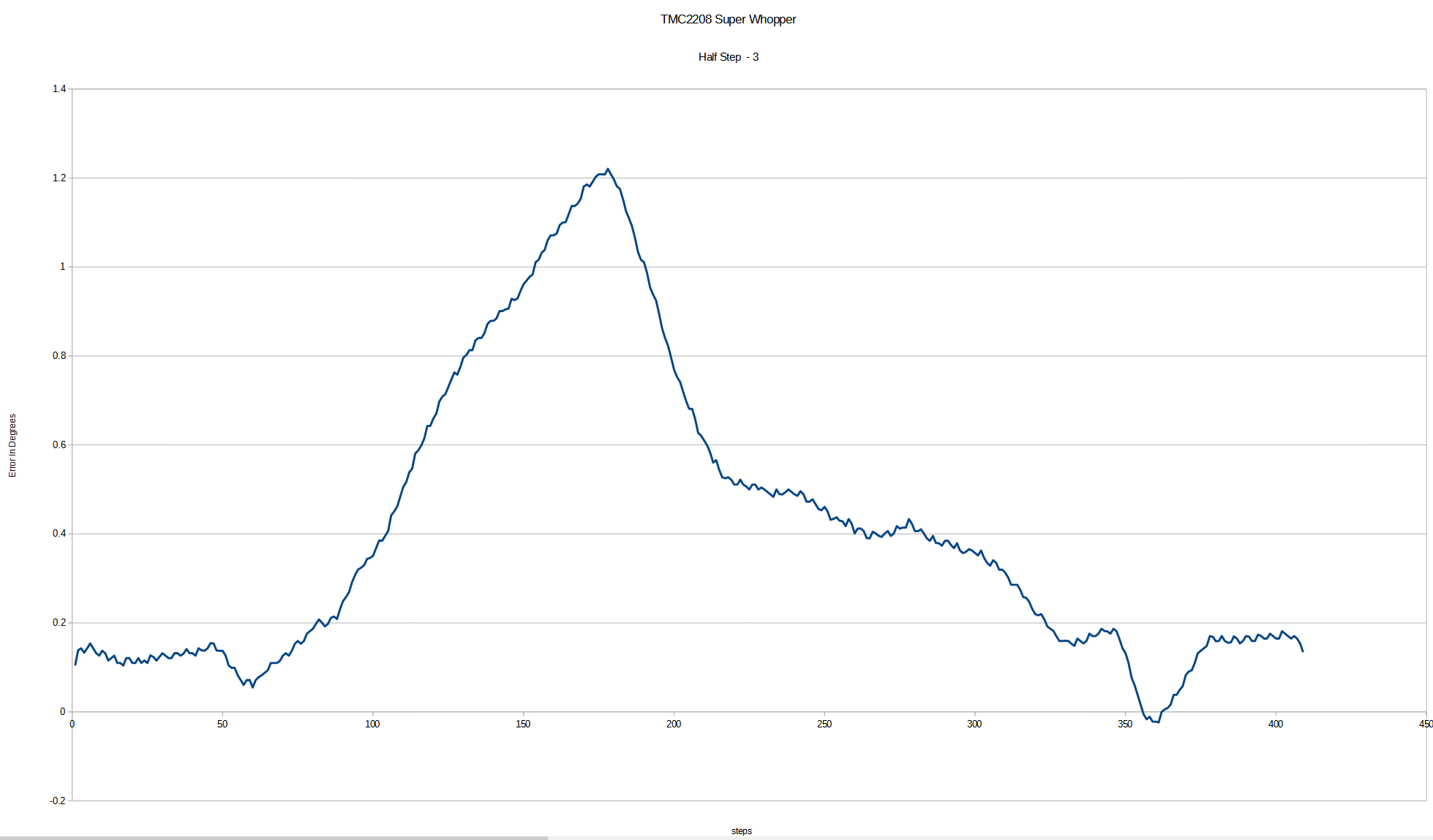

third super whapper motor

-

So, basically, at 180 steps or so the actual vs demanded position deviation of the last motor is more than half a step with the others close to that, with zero load?

That is way worse than what I would have expected...

-

@arhi said in stepper precision:

Haven't got to it yet, can't find where I put my vallder stepper with encoder and driver combo. Also I wanna finish with few nema17 before I have to use another mount to test the bigger motor

That's funny.

A while back I purchased such a system for testing but the project got put on hold as other more important things needed to be done.

And now I cannot find it.

Frederick

-

-

@DaBit said in stepper precision:

That is way worse than what I would have expected...

will have to spend more time looking at all this data, so far I'm running the tests and just showing the error of going forward than backwards. The other data I'm interested is spread of steps going in one direction only, how much off each step is from ideal position but I will do those graphs after I finish all the tests as I need to return this encoder in few days

-

@fcwilt said in stepper precision:

And now I cannot find it.

so you understand my frustration

I'm not used to everything being "in order" and everything "having it's place" but I hate working from "storage", can't find anything, $@^%#^ is getting on my nerves and breaks my concentration too .. and I don't see the end, I doubt my house will be ready before summer

-

second DPM motor

-

I found the box with the stepper/encoder and controller!

Now I just need to find the time - still looking for that.

Frederick

-

-

@arhi Are you sure you're calibrating the controller every time?

It looks like going forward, you get 0.5-degree of error, but going backwards, you get MUCH LESS error. Under 0.1 degree

Maybe try going three turns forward and then three turns backwards just in case it take one-turn to calibrate or something.

-

@alankilian said in stepper precision:

@arhi Are you sure you're calibrating the controller every time?

For S42B - yes, I am sure, I calibrated every time when running closed loop. I don't see a point as nothing physically changed in the setup between runs but I still run the calibration every time before I run the test as calibration is rather quick (it goes full circle one direction and then full circle other direction) ... anyhow notice these lasts graphs are with TMC2208, nothing to calibrate there

-

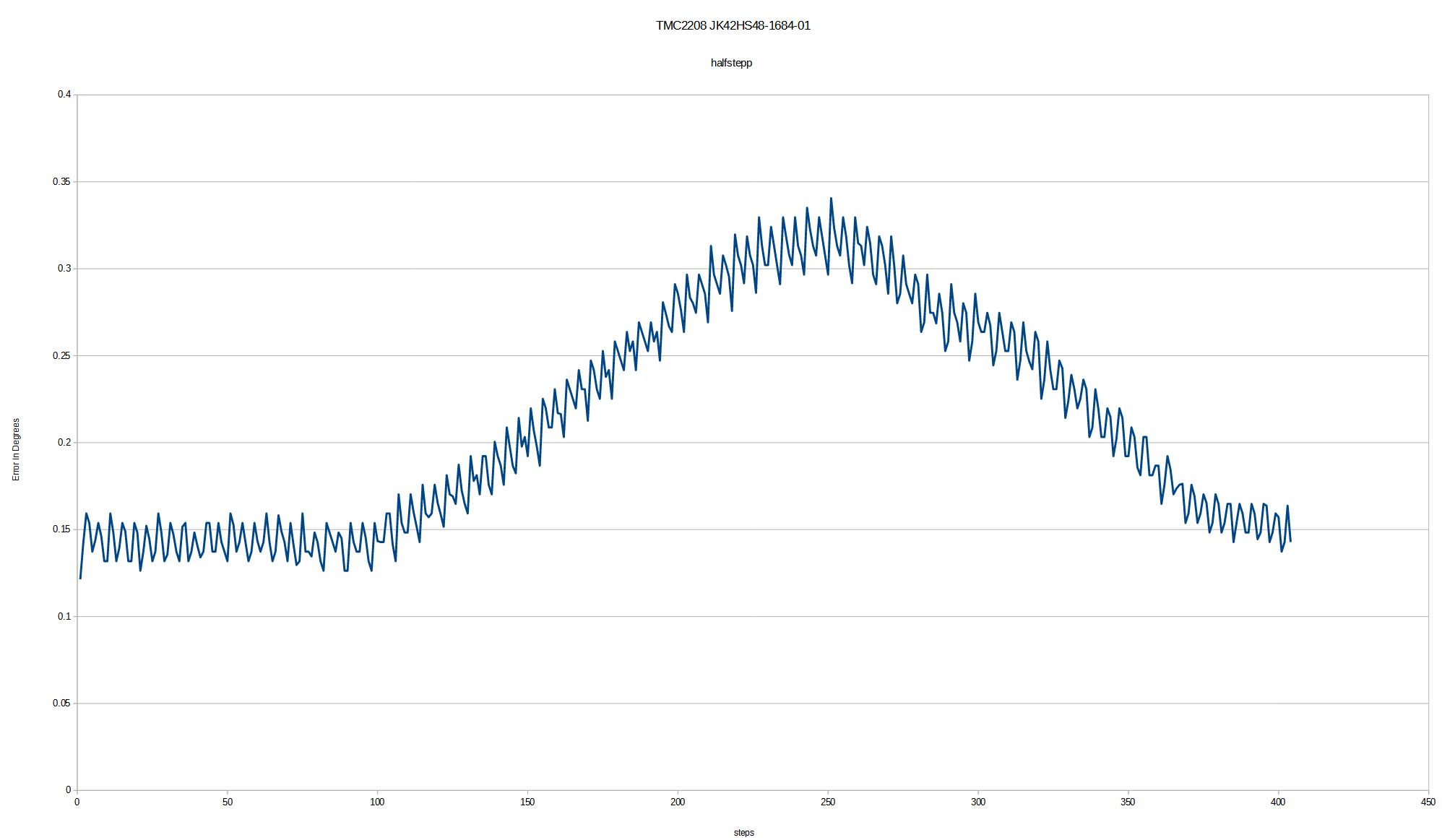

same motor as earlier only run again to see how "repeatable" this is (not very)

-

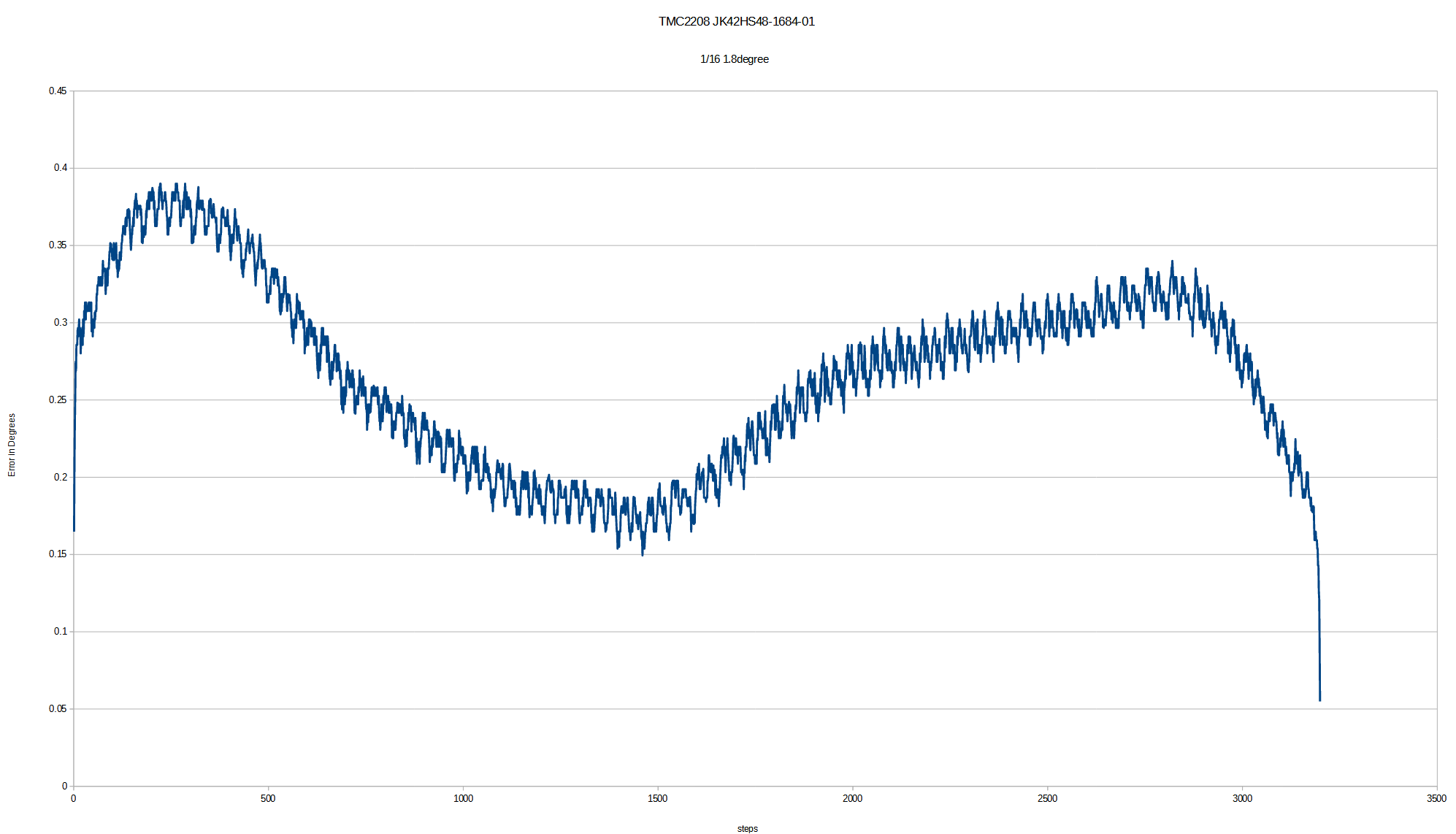

JK42HS48-1684-01

-

-

This looks interesting!

do you also think, that comparing one and the same motor once in Fullstep and once in 1/16microsteps, one session with one without microplying to 256 would also tell a bit of how much those features within the driver do contribute to the error?

Great work! Keep it up!

-

@LB said in stepper precision:

This looks interesting!

do you also think, that comparing one and the same motor once in Fullstep and once in 1/16microsteps, one session with one without microplying to 256 would also tell a bit of how much those features within the driver do contribute to the error?

Well I only have 2208 and there I cannot turn on/off the 256 interpolation, I can only play with MS0 and MS1 .. so change 1/2, 1/8, 1/16 ... since I was looking at testing motors and not drivers the idea is to use single driver on all motors, introducing new driver and spi control would require a new hat with spi interface too and that all requires time

... I just managed to find the stepper with encoder but the driver is still missing for that test .. I'm now going to run this last JK42HS48-1684-01 with few more microstepping options on the 2208 before I turn this place upside down finding that driver

... I just managed to find the stepper with encoder but the driver is still missing for that test .. I'm now going to run this last JK42HS48-1684-01 with few more microstepping options on the 2208 before I turn this place upside down finding that driver -

the graphs (and data behind them) so far:

encoder-readings.odsWhat's presented in these graphs so far and in this ods is

move full circle forward

move then full circle backwards

record both positions in the array

display difference of position readout as error -

-

These graphs are all very interesting (as if I understand what you are doing) but what is the real world application for this information?

Thanks.

Frederick

-