Mesh Bed Compensation above Z =0 limit

-

Hey! I have a self built hypercube 400^3 with a Duet 2 wifi board. Running RRF3 3.1.1.

My headbed is an aluminum plate which I got locally from a friend and I've installed a silicone heater underneath. I have a BLTouch installed as well and use Mesh bed compensation during printing.

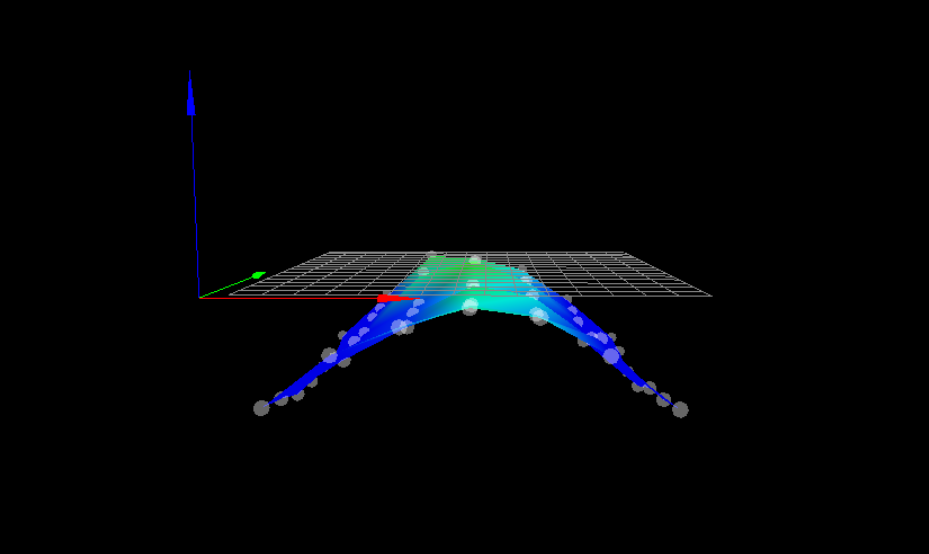

The plate as installed is in an upside "u" shape with the highpoint almost exactly at the x=200 mark. So when I home using the center of the plate the edges are well below the z=0 datum. When printing the mesh bed compensation works well until the printhead gets to either limit in the x direction. I get a prefect layer and squish in the middle half of my plate, but the end quarters it's clear the nozzle is too far away from my build plate.

My question is....can the Duet allow the mesh bed compensation to raise the bed above the z=0 datum? It doesn't appear so, but I'm wondering if I'm missing something.

I've tried setting my home Z position to one of the edges and tricking the duet into thinking the middle of the bed is above the datum lowering the bed to compensate, but it only resulted in the "substantial z offset" error, and the same results (perfect middle half, no squish on end 1/4's).

Clearly the best way forward is to get a flatter headbed, but it's time and money I don't have at the moment. Was hoping there was a software way to fix my problems.

Thanks!

-

at 400 you will most likely have the axis sagging under their own weight.

this will result in twisting of the carriage and means the z offset will be different based on the position of the carriage.

-

Fair point, and is something I'll look into changing....but in the meantime it still leaves me with the same question.

I've been considering going to MGN rails for the x axis.....maybe this will speed up my decision process.

-

i went a similar route. (though i dont have a 400x400 bed)

i started with a hypercube, then went to a hypercube fusion and then changed the x and y setup to a blv and now have a full metal blv.

-

What's the max deviation for that mesh? Can you include the numerical details?

You can try changing the M208 Z minima to a slightly negative number to allow the print head to go below 0, though I'm not sure that will help in this case.

At any rate, as you've discovered, it's likely your X axis sagging rather than the bed itself. Which is why I asked for the numerical value. If it's rather large you should be able to see a gap with a straight edge laid flat on the bed.

-

Probe area: 1089.0 cm²

Maximum deviations: -0.720 / 0.010 mm

Mean error: -0.341 mm

RMS error: 0.227 mmI just ran a straight edge over the bed, and I can see a gap on one side if I push down on the other.....so it appears it may be the bed more so than the gantry.

I'll try your suggestion and see if that helps. thanks!

-

Could try a 90 degree rotation on the bed if possible so that the saddle effects of the bed and the gantry don't combine.

-

If I end up taking the bed off, it'll likely go a fab shop to get milled.....

but I do appreciate your suggestion.Im going to try the axis minima route and let you now how it goes.

thanks!