My new large scale 3D printer Hydra

-

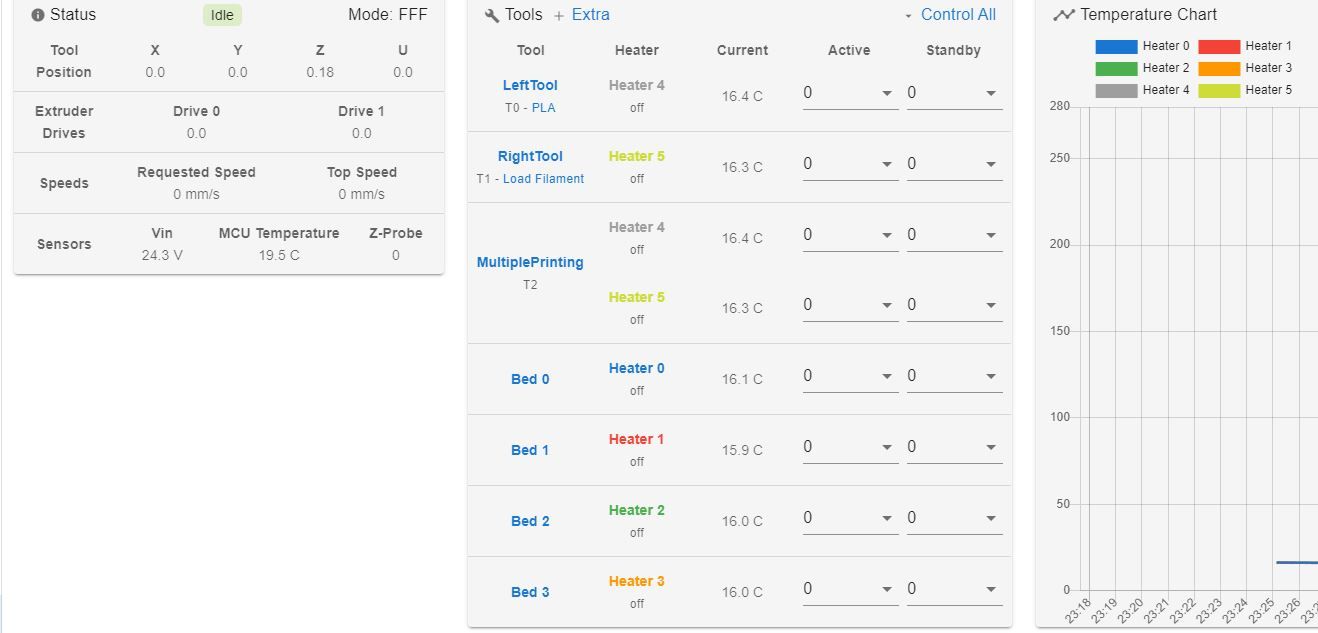

I'm running the rrf 3.2beta3 on the duet WiFi and the 3.20 on panel due.

This is shown on the panel. The web interface shows all heaters correctly. -

Can you post your config for the heaters?

What heaters currently show up in Paneldue?

-

this is my heater config:

; Heaters ;BedHeaters ;Layout: ; 1 2 ; 3 4 ;Bed0 M308 S0 P"duex.e2temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin duex.e2temp M950 H0 C"duex.gp1" T0 ; create bed heater output on duex.gp1 and map it to sensor 0 M140 P0 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit ;Bed1 M308 S1 P"duex.e3temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin duex.e3temp M950 H1 C"duex.gp2" T1 ; create bed heater output on duex.gp2 and map it to sensor 1 M140 P1 H1 ; map heated bed to heater 1 M143 H1 S120 ; set temperature limit for heater 1 to 120C M307 H1 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit ;Bed2 M308 S2 P"duex.e4temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin duex.e4temp M950 H2 C"duex.gp3" T2 ; create bed heater output on duex.gp3 and map it to sensor 2 M140 P2 H2 ; map heated bed to heater 2 M143 H2 S120 ; set temperature limit for heater 2 to 120C M307 H2 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit ;Bed3 M308 S3 P"duex.e5temp" Y"thermistor" T100000 B4138 ; configure sensor 3 as thermistor on pin duex.e5temp M950 H3 C"duex.gp4" T3 ; create bed heater output on duex.gp4 and map it to sensor 3 M140 P3 H3 ; map heated bed to heater 3 M143 H3 S120 ; set temperature limit for heater 3 to 120C M307 H3 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit ;HotendHeaters ;LeftHotend M308 S4 P"spi.cs5" Y"rtd-max31865" ; configure sensor 4 as thermocouple via CS pin spi.cs1 M950 H4 C"!exp.heater3" T4 ; create nozzle heater output on e0heat and map it to sensor 4 M143 H4 S280 ; set temperature limit for heater 4 to 280C M307 H4 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;RightHotend M308 S5 P"spi.cs6" Y"rtd-max31865" ; configure sensor 5 as thermocouple via CS pin spi.cs2 M950 H5 C"!exp.heater4" T5 ; create nozzle heater output on e1heat and map it to sensor 5 M143 H5 S280 ; set temperature limit for heater 5 to 280C M307 H5 B0 S1.00 ; disable bang-bang mode for heater and set PWM limitand a screenshot of the webcontrol:

-

Thanks. Will see if @wilriker has any comment

-

@Phaedrux Technically it's not problem to show all bed heaters, chamber heaters and all tools - in practice though we run out of screen estate quickly. On 5" and 7" we have 7 slots and on the 4.3" it's even less with just 5 slots.

I think about how to use the screen estate better for the next version. IMHO tools should have preference so they and at least one heated bed should always be displayed. But I could fill the remaining slots (if any) with whatever is not displayed otherwise.

-

Meanwhile the one color prints look pretty decent. Unfortunately I have ugly red blobs if I print with dual color.

The reason for this is that the second head restore the position of the first tool after toolchange.

I´m wondering if it´s possible to not restore the position of the first tool and move the second head directly to the next position? -

that looks exactly like one on the street. the defect make it look more real

-

@rabbit said in My new large scale 3D printer Hydra:

The reason for this is that the second head restore the position of the first tool after toolchange.

I´m wondering if it´s possible to not restore the position of the first tool and move the second head directly to the next position?Take a look at this thread: https://forum.duet3d.com/topic/19201/wrong-return-point-after-tool-change

-

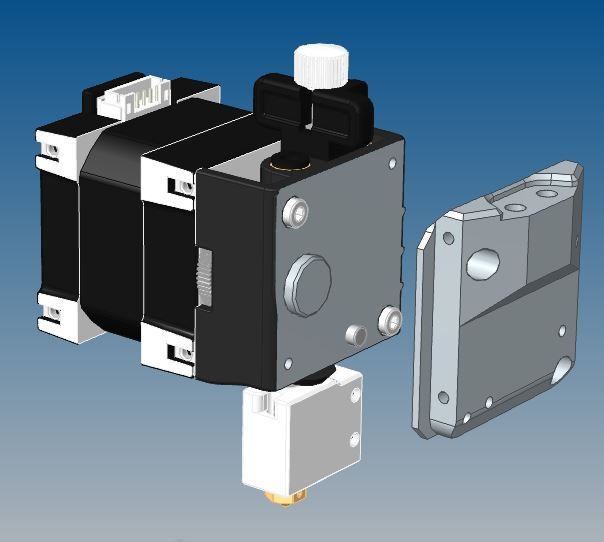

Here are the step files of my hemera aqua mod:

waterCoolingBlock.stp

waterCoolingLid.stpthe seal is a lassercut from 1mm silicone.

-

thats not printed is it? picture in the other thread looked more metally

-

no, that was milled from 7075 aluminum.