More Blobbing

-

post your config

-

Forgot to mention E3D V6 hot end @ 195C on PLA with calibrated extrude.

The blobs are definitely at the end of extrude. Aand now I suddenly noticed that the exact blob form is shown at the random corner seams. Probably more PA as you mention.

Thanks for the help.

config(1).g

; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; physical driv e 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X320.00 Y320.00 Z1600.00 E410.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E6000.00 ; set maximum instantaneous speed changes (mm/min)

M203 X8000.00 Y8000.00 Z600.00 E1800.00 ; set maximum speeds (mm/min)

M566 P1 ;Mimic Marlin jerk

M572 D0 S0.015 : PA

201 X1000.00 Y1000.00 Z200.00 E600.00 ; set accelerations (mm/s^2) ----was250

M906 X2800 Y1800 Z800 E800 I20 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout;M915 X Y S5 F0 H200 R0 ; X / Y Axes Stall Detection

-

B4138

your thermistor is not correct for e3d. you are printing at the wrong temperature.please select semitec in the duet configurator for your thermistor.

-

@tommyb said in More Blobbing:

201 X1000.00 Y1000.00 Z200.00 E600.00 ; set accelerations (mm/s^2) ----was250

that line is broken

-

M92 X320.00 Y320.00

what kind of setup are you running. thats an unusual number

-

The cut and paste of text deleted M in Accel line, the config.g file has it...sorry for not checking.

I am running Core XY with with Z on X axis & 200mm bed size. I am using surplus KR ball screw rails that are way oversized in length, hence home switches are far off from bed edge. I do have to admit getting the home switches set up was far more complicated then it should have been so while this works, I am sure it could have been done better.

-

@tommyb said in More Blobbing:

I am running Core XY with with Z on X axis & 200mm bed size. I am using surplus KR ball screw rails that are way oversized in length, h

nice. would you post a picture?

-

Well, it is quite the monster; everything but hot end, probe and Duet are surplus $0.

-

@tommyb

you have to wait a bit after the upload reaches 100% -

Thanks for the tip.

-

did you change the thermistor stettings? did it improve the print?

looking at the printer (or cnc machine), i am wondering if the long metal holding the extruder introduces wobble

-

@Veti said in More Blobbing:

semitec in the duet configurato

I missed the B factor comment above. The configurator still produced a B=4138 value. I look around and saw Duet requires B=4388, tried that and way under temp on print. I will let it cool down and execute a calibration. The stability looked ok.

I may have an odd thermistor, is there a way to tell? It came with the Hot End.

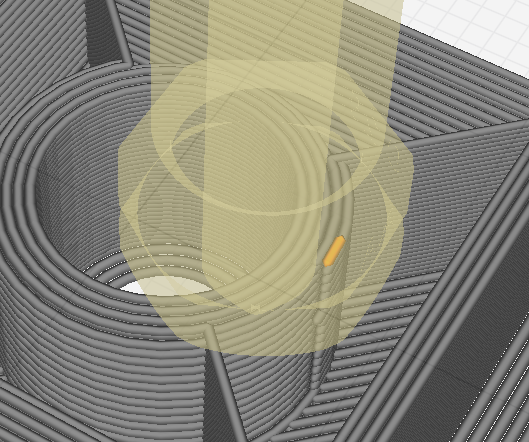

Also dug a little deeper on circumferential blob and turns out Cura places a small extrusion path at the start of the layer right at the end of the path. And then follows up with at the end of the layer to join with the initial small path. This image show the HE after rotating clockwise past the initial extrude.

-

@tommyb said in More Blobbing:

201 X1000.00 Y1000.00 Z200.00 E600.00 ; set accelerations (mm/s^2) ----was250

Did you add the missing M to the start of that line?

-

@tommyb said in More Blobbing:

I may have an odd thermistor, is there a way to tell? It came with the Hot End.

What hotend exactly do you have?

-

The M was only missing in the cut and paste, not the actual Config.g. Thanks for checking.

I have a V6 Light HE...if anybody has experience to move on from this, let me know. I need a reason to convince the wife to spend any more $ on this sport. The Heat break is SST and not easily damaged...and cheap! So far PETG and PLA seem to work fine, but I am happy to be convinced of other models (Humera)?.

So after have a sudden bed thermistor open error (did not touch any wiring) and some more time troubleshooting and fixing, I looked hru various references with conflicting info and confirmed B=4275 for the Simtec 104 GT thermistor. HE and Bed have been Auto recalibrated.

PA so far seems about the same from 0.05, 0.10, 0.15, 0.20 and no change vs first picture.

No for twhe real problem all along. With a pretty decent print in progress, the part fails each and every time at layer 26/88 at the exact same spot in the print and with sound of skipping stepper . The part shifts the exact same 10mm of the 20mm block wall distance and prints a wall in the very middle of the part. All motors are cool and there is nothing unique in the print at this point.

I started to look at the G code to see if it is somehow corrupted at that point, but is getting late. Ill also try a slower print to see if motor just needs a different input that instant. More to come.

-

@tommyb said in More Blobbing:

B=4275 for the Simtec 104 GT thermistor

that is only valid if you specify the c value as well.

-

Thank you Veti, yes I added a C and here is my HE config.

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; RR3define E0 temperature sensor was B4138

M950 H1 C"e0heat" T1 ; heater 1 uses the e0heat pin and sensor 1

M570 H1 P90 T15 ; Heater@1 temp@15 out of range alarm >@90sec

M143 H1 S245 ; set temperature limit for heater 1 to 250C