Tips to mitigate vertical artifacting Duet 2 Wifi

-

@Phaedrux The max speed test is interesting. Started at lower speeds. As it got faster the ringing increased, the artifact stayed the same.

-

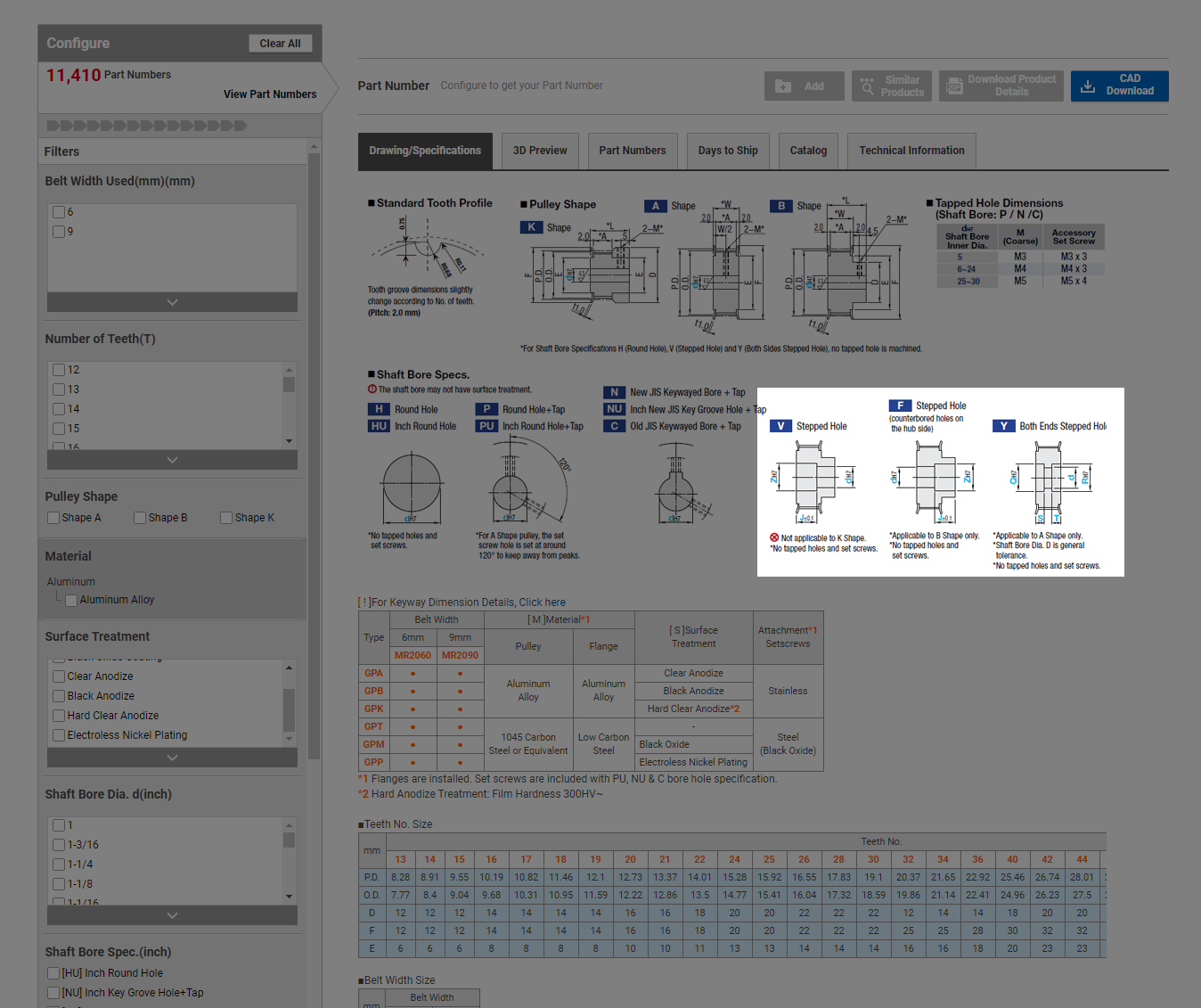

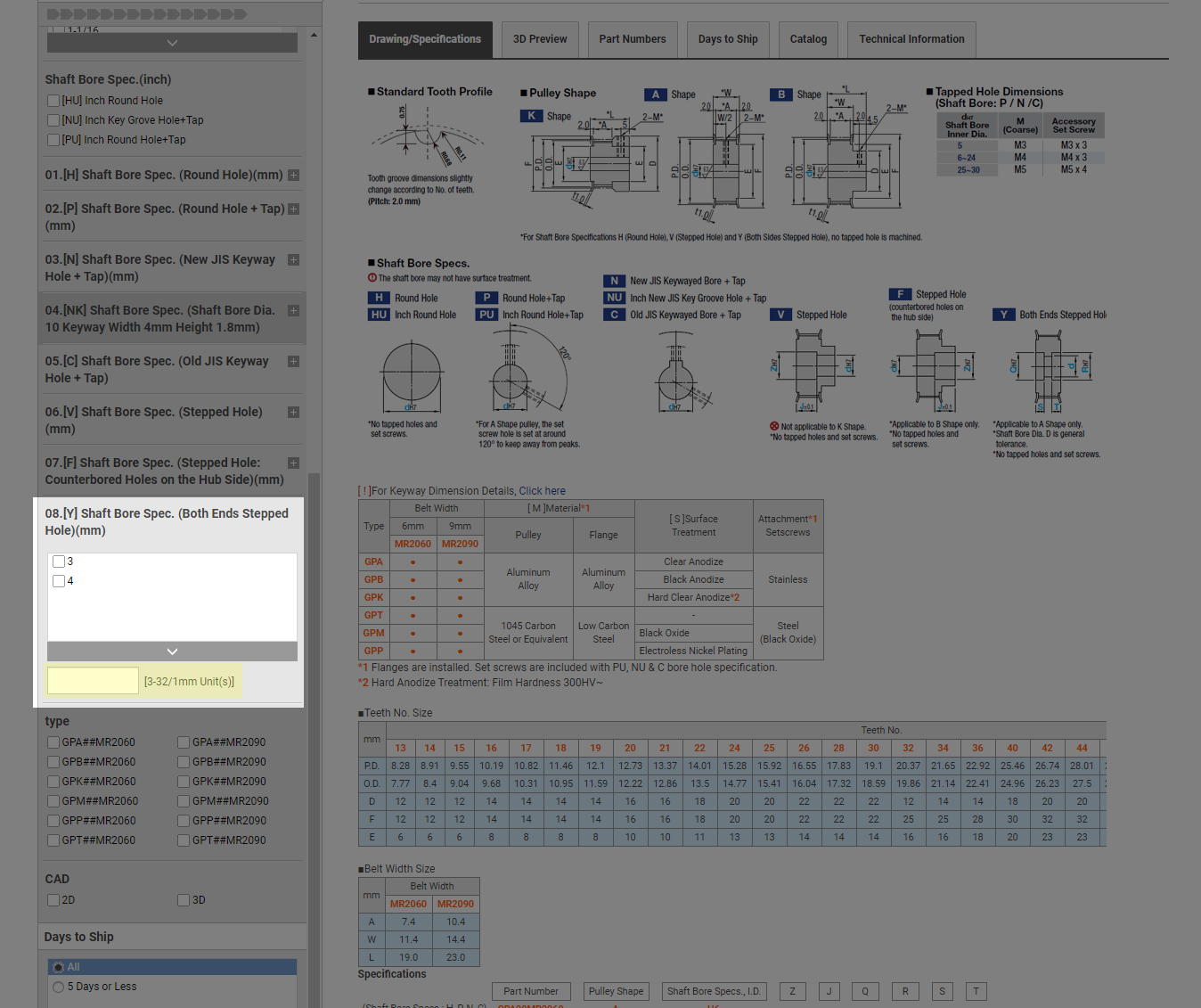

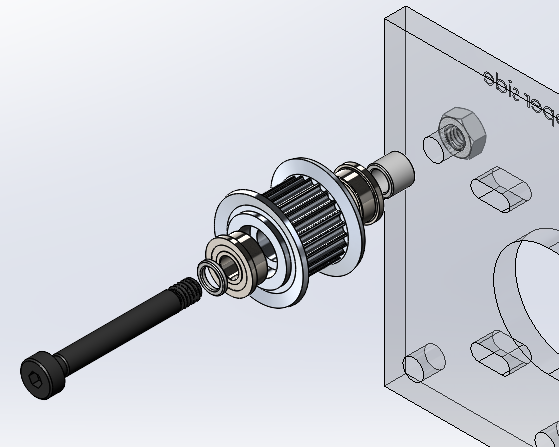

Well, I wasn't able to find any ready-to-go off-the-shelf idlers from Misumi (that are more than 5 or 6 mm), but I've always wanted to try using one of their customizable pulleys for idlers: See info here.

You can choose a wide range of sizes of pulley there, and you can get stepped holes made which should allow for easy placement of bearings. They have a variety of options and you can have the stepped hole sized how you wish. See:

[Edit: this photo is slightly misleading, there are more options to configure to get a full part number. Still playing around with it

]

] -

@bot said in Tips to mitigate vertical artifacting Duet 2 Wifi:

Well, I wasn't able to find any ready-to-go off-the-shelf idlers from Misumi (that are more than 5 or 6 mm), but I've always wanted to try using one of their customizable pulleys for idlers: See info here.

You can choose a wide range of sizes of pulley there, and you can get stepped holes made which should allow for easy placement of bearings. They have a variety of options and you can have the stepped hole sized how you wish. See:

snip

[Edit: this photo is slightly misleading, there are more options to configure to get a full part number. Still playing around with it

]

]I've done that on my machine, and it works quite well (albeit the assembly stackup can get pricy quick!). Must carefully select parts based on all the appropriate parameters.

Something to look out for is there is an issue on Misumi's site it seems, where you cannot select all the options on the left side (for example, with the Gates MR2 page, the "T" parameter does not show up. As an example, filling out all the available options can give you "GPA30MR2090-A-Y4-Q6-R6-S3", so copying and pasting that P/N with the addition of "-T3" into the search pulls up a real part.

For this case, do we want GT2/GT3 (Gates MR) or the 2GT series?

Looking at 2GT

Looks like something like 26teeth would match the 16mm OD (16.04mm OD, 16.55 PD). However the max 'shaft' hole for this size is 6mm, and the max counterbore is 8mm. However, it looks like the site gets stuck at GPA26GT2060-A-Y6, and we cannot configure past that. -

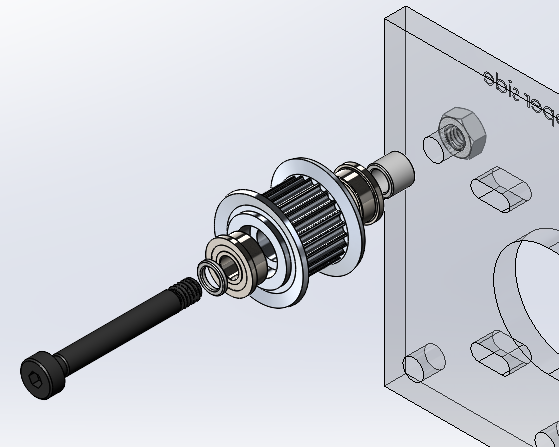

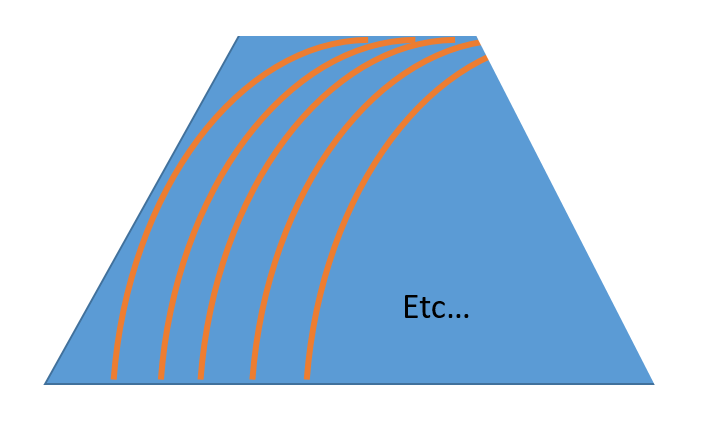

@brotherchris this happens with thin wall (one or two wall/perimeter only) prints correct (I'm sure the answer is yes, but I want to ask). What you could do, to see if it is an extruder issue, is print a hollow square pyramid (maybe with the top cut off) or cone. Probably should keep the print speed consistent throughout the print. What this should, I think, test, is if the "candy stripes" will maintain the same pattern (straight diagonals) or change style, by varying the layer cross section as height increases. I think that, if it is an extruder issue, the diagonal artifacts will turn into curves.

Horrible PowerPoint diagram - what is happening now

What I would expect to happen (not exactly haha)

-

@sebkritikel Yes, it seems to happen on all prints. I will print a pyramid and see what it does.

-

@mwolter Hey I ran these tests and the flow rate definitely impacts the 45 degree lines. This is a .4 and a .47, huge difference. No luck on the verticals.

-

Disassemble and reassemble the Hemera?

-

@Phaedrux Never a bad idea.

-

@sebkritikel said in Tips to mitigate vertical artifacting Duet 2 Wifi:

For this case, do we want GT2/GT3 (Gates MR) or the 2GT series?

Looking at 2GTThose are essentially all the same thing. Gates powergrip. GT is the early version, GT2 being a newer stronger belt design, GT3 being the newest (2GT being either GT in 2mm pitch, or GT2 written oddly). They come in anything from 1 to 14mm pitch (with 2mm being the most common in 3D printing).

The tooth profile and the pulleys are all same for a given pitch. Its only the belt construction that changed as far as I know. -

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@mwolter Hey I ran these tests and the flow rate definitely impacts the 45 degree lines. This is a .4 and a .47, huge difference. No luck on the verticals.

.47 what? Extrusion width? What's the nozzle diameter?

I'd be curious to see if anyone has tried using flat faced extruder drive gears... if what you are seeing changes with flow rate, then it could be a product of variations in effective pitch diameter with the teeth on the drive gears. Might have trouble pushing the filament.

Or if you are running a 0.4 nozzle and were printing at 0.4, then yes, going up to 0.47 will make a huge difference. -

@theruttmeister I misspoke, I meant extrusion width. It's a .4 nozzle, it was just a test to see the impact.

-

@brotherchris

Ah, yes... I've had people disagree with me, but I (and stratasys of all people) believe that your extrusion width should always be greater than your nozzle diameter. Otherwise the extrusion is not controlled and can shift about. All the testing I have seen over the years supports this.

As a general rule of thumb I aim for nozzle diameter plus 1/2 the layer height (which is based on the math of the form the extrusion actually takes). With the ratio of layer height to extrusion width of 2:1 or more.

You can totally go down below the nozzle width, but you are going to get artifacts as a result.Try increasing it even more, see the results you get.

-

@brotherchris Interesting results with the extrusion width test and it might indicate an issue with the extruder gears. Would be easier to see the diagonal artifacts change if you can try multiple extrusion widths in a single, single-walled print. Simplify3d can do this easily, not sure if the others can. I find it particularly useful to isolate an extrusion issue by printing a cylinder with no top or bottom since there are no retractions or start-stop points.

-

@sebkritikel said in Tips to mitigate vertical artifacting Duet 2 Wifi:

[...]

I've done that on my machine, and it works quite well (albeit the assembly stackup can get pricy quick!). Must carefully select parts based on all the appropriate parameters.

That is awesome! I'm glad to hear. How did the bearings fit into the stepped holes? Not much of a press fit, but an "aligned fit?" Where they won't go in unless they're straight, but they aren't firmly held in place?

Something to look out for is there is an issue on Misumi's site it seems, where you cannot select all the options on the left side (for example, with the Gates MR2 page, the "T" parameter does not show up. As an example, filling out all the available options can give you "GPA30MR2090-A-Y4-Q6-R6-S3", so copying and pasting that P/N with the addition of "-T3" into the search pulls up a real part.

I encountered exactly that issue but was too lazy to re-figure out how to get around those problems. With how shiny they made their website lately, the user experience hasn't improved much lol.

For this case, do we want GT2/GT3 (Gates MR) or the 2GT series?

Looking at 2GT

Looks like something like 26teeth would match the 16mm OD (16.04mm OD, 16.55 PD). However the max 'shaft' hole for this size is 6mm, and the max counterbore is 8mm. However, it looks like the site gets stuck at GPA26GT2060-A-Y6, and we cannot configure past that.I forgot about the 16 mm OD specification. That indeed will limit the geometry. I was also looking at 9 mm width, which perhaps could also change available specifications. With A shape and 9 mm belt, I was able to select Y in the range of up to 21 mm or so. The Y is confusing, though -- it's the shaft bore diameter. The stepped bore is greater.

Oh, and yeah we want the "MR2" listing. Misumi does have some other type listed under 2GT or some such, and they are said to be compatible by Misumi reps. Dunno. The MR2 has more options, IIRC.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@Phaedrux The max speed test is interesting. Started at lower speeds. As it got faster the ringing increased, the artifact stayed the same.

Since you've still got a lot of ringing I'd try to find a print speed you want to use (based on the layer height and width you want to use) to maximize the flow rate of the hotend, and then find a jerk and accel combo that eliminates the ringing. Then any remaining artifacts will be a lot easier to see and isolate.

Finding max flow rate: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s177

-

@theruttmeister said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@sebkritikel said in Tips to mitigate vertical artifacting Duet 2 Wifi:

For this case, do we want GT2/GT3 (Gates MR) or the 2GT series?

Looking at 2GTThose are essentially all the same thing. Gates powergrip. GT is the early version, GT2 being a newer stronger belt design, GT3 being the newest (2GT being either GT in 2mm pitch, or GT2 written oddly). They come in anything from 1 to 14mm pitch (with 2mm being the most common in 3D printing).

The tooth profile and the pulleys are all same for a given pitch. Its only the belt construction that changed as far as I know.For Gates GT2 VS GT3, you are correct - tooth profile is identical, GT2 pulleys and GT3 pulleys are identical. The GT3 belt is somewhat thicker on the backside.

GT2 is not 2GT, and GT3 is not 3GT - Gates GT3 belts used in Stratasys printers (Dimension series, etc) is not the same tooth profile when discussing Gates Unitta 2GT (sold by e3d for example), nor the 2GT (or 3GT) series sold by Misumi. GT2 vs GT3 does not correlate to 2mm or 3mm pitch, like you said - MR2, MR3, does correlate to pitch however. Gates GT2/GT3, be it MR2, MR3, MR5, etc, is not directly compatible with 2GT, 3GT, etc. What "Gates" you get from SDP/SI, Misumi, is not what you get from e3d.

Hilariously Misumi put out a blog post to talk about some of the differences, but frankly they did a bad job at it: https://blog.misumiusa.com/youve-got-the-power-mr-vs-gt/

Many people (including lovely Amazon and Aliexpress sellers) use 2GT and GT2 interchangeably (and often will throw MXL and whatnot in there as well).

-

@bot said in Tips to mitigate vertical artifacting Duet 2 Wifi:

That is awesome! I'm glad to hear. How did the bearings fit into the stepped holes? Not much of a press fit, but an "aligned fit?" Where they won't go in unless they're straight, but they aren't firmly held in place?

Exactly as you say! With the h7 hole, more of an aligned fit vs a press fit.

I encountered exactly that issue but was too lazy to re-figure out how to get around those problems. With how shiny they made their website lately, the user experience hasn't improved much lol.

I forgot about the 16 mm OD specification. That indeed will limit the geometry. I was also looking at 9 mm width, which perhaps could also change available specifications. With A shape and 9 mm belt, I was able to select Y in the range of up to 21 mm or so. The Y is confusing, though -- it's the shaft bore diameter. The stepped bore is greater.

Oh, and yeah we want the "MR2" listing. Misumi does have some other type listed under 2GT or some such, and they are said to be compatible by Misumi reps. Dunno. The MR2 has more options, IIRC.

Reading this stuff really bugs me out haha, I need to reach out to one of their reps re: 2GT, 3GT VS Gates MR. I'm pretty sure that, if Chris is using anything from e3d (2GT), Chris will need to stick with 2GT, vs Gates MR (even though MR has more options!).

-

@sebkritikel Dude... yeah I just read your reply and saw that blog post -- WTF. It's so confusing. I've got MR2 drive pulleys and 2GT idlers because a Misumi rep told me that this combination would work. And it seems to work pretty damn well but I almost want to try converting the idlers to MR2 to see how it is. My belts are also MR2.

I wasn't aware that the Unitta/E3D stuff is much different, but thankfully I have no desire to mix and match anyway.

-

@sebkritikel Here are the results of the pyramid. It breaks the strait lines into more of a gradient.

-

@sebkritikel said

Hilariously Misumi put out a blog post to talk about some of the differences, but frankly they did a bad job at it: https://blog.misumiusa.com/youve-got-the-power-mr-vs-gt/

They are different! [proceed to not explain the differences at all]

Thanks Misumi!