Magnetic sensor report low filament movement but isn't true.

-

Hi ,

I have a filament monitor that sometimes report no filament movment with apparently no reason.

It happens in cluster, sometimes it go well for days and sometimes I can't finish a print.This is my config

M591 D0 P3 C3 S1 R60:140 L24.8 E3.0and this is console during a print that stopped after a while

M591 D0 Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 3, mag 126 agc 128, measured sensitivity 24.78mm/rev, min 97% max 102% over 109.0mm 4/9/2020, 19:27:21 M591 D0 Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 3, mag 126 agc 128, measured sensitivity 24.79mm/rev, min 97% max 102% over 96.9mm 4/9/2020, 19:27:11 M591 D0 Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 3, mag 126 agc 128, measured sensitivity 24.78mm/rev, min 97% max 102% over 84.8mm 4/9/2020, 19:27:04 M591 D0 Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 3, mag 126 agc 128, measured sensitivity 24.77mm/rev, min 97% max 102% over 75.7mm 4/9/2020, 19:26:57 M591 D0 Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 3, mag 126 agc 128, measured sensitivity 24.77mm/rev, min 97% max 102% over 69.6mmAny idea?

-

@claustro said in Magnetic sensor report low filament movement but isn't true.:

mag 126 agc 128

Your agc value is very high. The agc value measures how close the magnet is to the sensor. If the magnet is too far from the sensor, it may miss some movement. From this post https://forum.duet3d.com/topic/15079/correct-acg-value-for-magnetic-filament-sensor/, @dc42 recommends:

Up to 110 is OK, however normal values are below 100. It looks as though the distance between the magnet and the sensor is a little too high (target is 0.25mm). Check that the screws holding the PCB down are not loose (caution: they are screwed into the plastic, so don't over-tighten them). If they are already tight, you could remove the 2 long screws to separate the two plastic parts and very slightly sand down the bottom surface of the top one (the one with the PCB attached).

How is the filament monitor mounted? Are there other wires that may cause interference running near it? Are you using shielded wiring? What Duet are you using, firmware version, and where is the sensor connected?

Ian

-

@droftarts

Thank you very much for taking the time of answering me.

I really start becoming frustrated with this sensor but at least with your input, I have something to try for fixing itThe magnet is very very close to the sensor I can see some minor scratch on the sensor itself Could be a weak magnet?

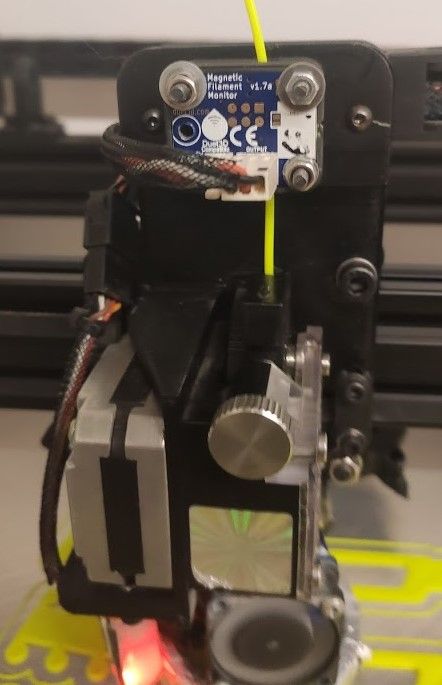

I am attaching a photo of my mount

The wires of the sensor run with all the other wires coming from the hot end.

Should I change the wires with a shielded one?Firmware version

Board: Duet WiFi 1.0 or 1.01

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 2.05.1 (2020-02-09b1)

The sensor is wired to E0 StopI tried to widen the tolerance to 50% - 150% but even with this it suddenly reports stopped filament even if 5 seconds before it report min 95% max 102%

My AGC is 105/104 but the problem is still here

Thank you

Andrea

-

@claustro Apologies for the delayed reply, I didn't see that you had replied, but found your thread again as I have recently updated the Magnetic sensor troubleshooting page: https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_RotatingMagnetVersion?revisionid=HEAD#Section_Errors_during_operation

Have you made any progress? There is a possibility of demagnetisation, but I think the agc would stay high. Minor scratches on the sensor don't sound great, but show the magnet is definitely close! The other possibility is a faulty sensor; could you post pictures of both sides of the sensor board, so we can visually check manufacturing quality? When and where did you buy the sensor, assuming it is a genuine Duet3D one?

Ian

-

@claustro in that picture you do not have PTFE Tu e between the extruder and the filament monitor. You need that to constrain the filament path otherwise retractions especially will not be registered properly

The reactions need to push the filament back past the sensor consistently.