Robotic kinematics

-

@tony73 no, I meant the G92:

G92 X0 Y70 Z-70 U0 V0

looks ok. G92 X390 is a too high angle.As my prototype takes too much time (orders missing), I'll make a very simple version at the weekend with R0 mode and take it to explain it.

-

ok! it seems like a great idea!

-

@tony73 I'll build it with the same properties like your parameters, so we can discuss all.

-

Hello! how is the construction of the robot going?

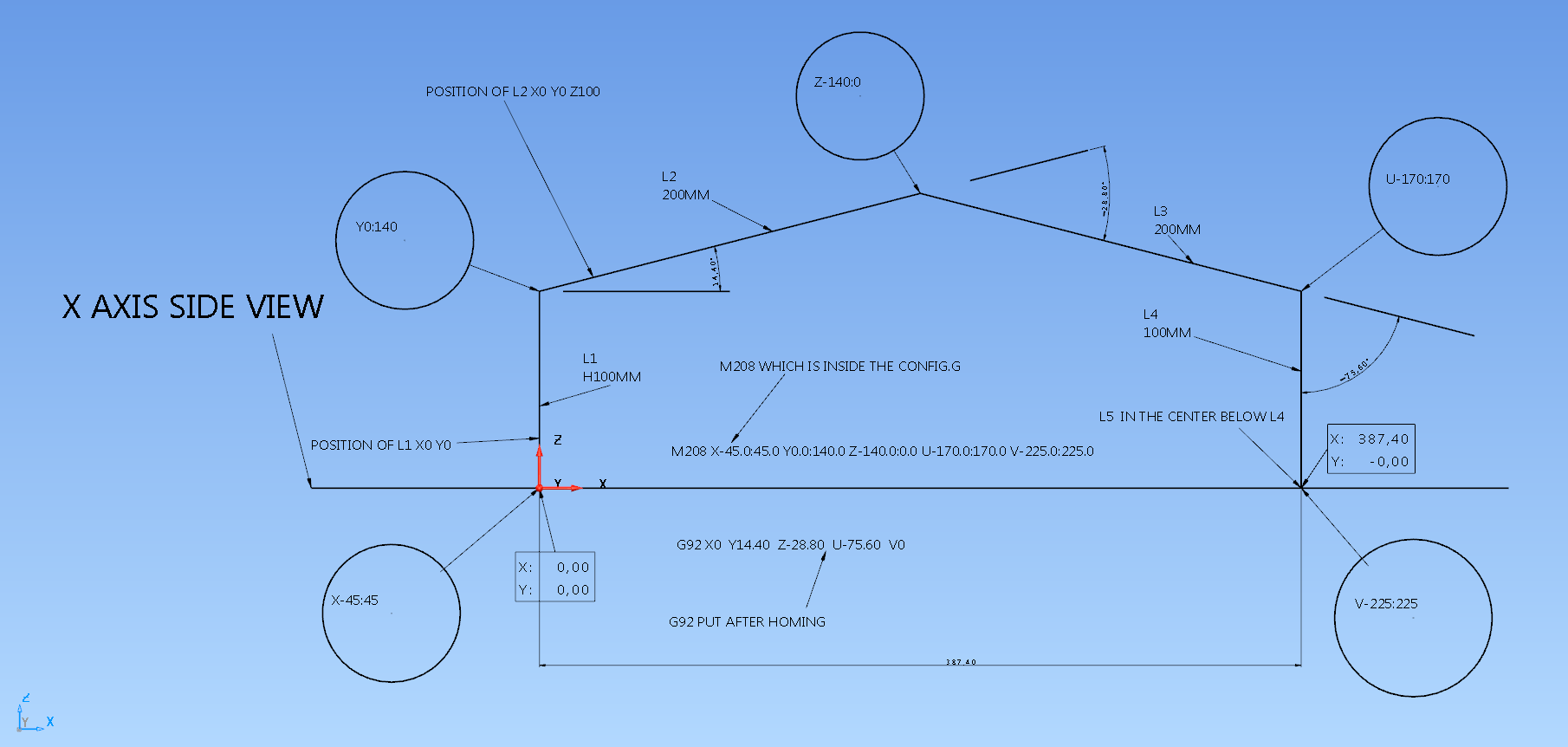

i tried to graph a situation with G92 to position the arm after homing, hope it is clear enough. calculated the degrees of a position X 387.4 Y0 Z0 on M669 of my config.g but I don't understand, if G92 are degrees and the calculation is right, if you can understand tell me if it's right or wrong, the motors should move, but instead simplify 3d answers me like this, Error: G1 / G2 / G3: intermediate position outside machine limits.

the G92 I put after homing and G92 X0 Y14.4 Z-28.8 U-75.6 V0

it looks like a little house!

the degrees of the graph are L2 14.40 L3 -28.80 L4 -75.60

-

@tony73 I am proceeding with boring my 1000 holes into aluminium, but not finished. I expect Tuesday. (boring holes without cnc is a penalty)

The graphic looks fine, the angles look all ok. Which G1 command do you want to execute? If it's G1 X300, then are you in absolute coordination mode or relative? Because if relative, it wants to move to 687,40, which is out of reach.

To exclude that it's a Simplify3D problem, can you execute it in the Duet Web Control (DWC)?Absolute mode is set with G90

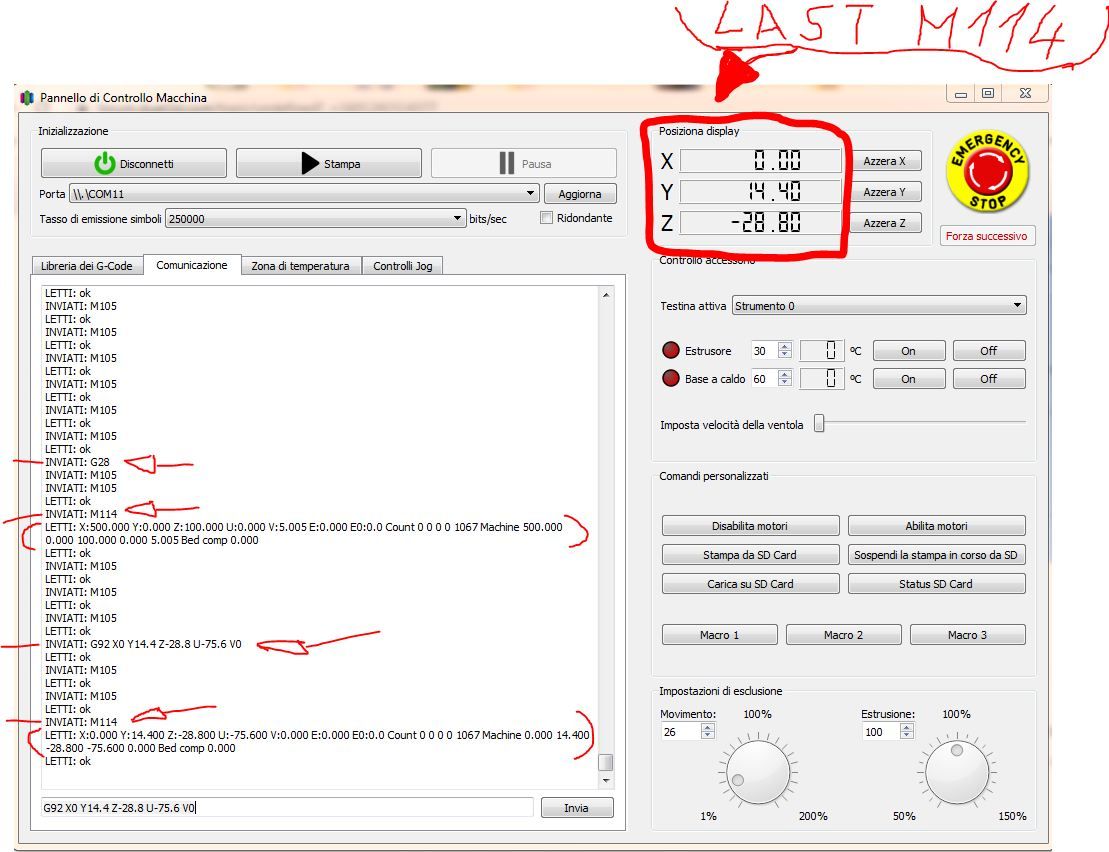

Can you please check M114 after homing and G92?

-

@JoergS5

purtroppo non avevo mai considerato il G90 G91 , se ho capito provando a mandare esempio: G1 X200 in modalita relativa G91 , tenterebbe di andare a X 587.40 ( X 387.40 + 200 ) , devo ricordarmi di G90 e G91 !

ho provato a inviare G90 prima di un comando G1 ma i motori purtroppo non si muovono.questo nella foto e G28 seguito da M114 che dice X500 Y0 Z100 U0 V5.005 dopo inviato

G92 X0 Y14.4 Z-28.8 U-75.6 V0 rifatto M114 risposta X0 Y14.40 Z-28.80 U-75.60 V0.0

LA COSA STRANA e che in alto a destra lindicatore degli assi di simplify 3d da come posizione del piano cartesiano X0 Y14.40 Z-28.80 che e uguale ai gradi di G92no ho ancora mai usato DWC , ma mi documento e provo !!

-

Sorry for barging in. But...

If you were to describe the robot as a number of transformation matrices (https://en.wikipedia.org/wiki/Denavit–Hartenberg_parameters) you could describe any serial robot with any number of axis. Even a serial scara could fit in this (except the bed).

Matrices are very nice to work with.

Combine this with the matrix defined cartesian and you can describe any combination of linear cartesian and serial rotary kinematics. What a dream

-

@bondus I know the matrix calculations, but I wanted to develop the algorithms from scratch and to have additional parameters like bending.

-

@tony73 you seem to have set G90 at the end of your homing file.

I'll check your procedure with my prototype tomorrow.

-

good morning ! I wait until you are done with the test robot, I stop asking you questions because I only make you confused!

-

Hello! did you manage to do the tests with the robot?

-

@tony73 I'm not finished building. I'm sorry, but I cannot plan how long building a prototype takes. I had design faults, which show up when building.

-

ok! I try to contact you on the weekend, see you soon!

-

@tony73 thanks for your patience!

-

Hello ! how is the construction of the robot going? did you manage to finish it and test with the firmware?

-

@tony73 I had other tasks during the week. But I have solutions for my design problems now and proceed at the weekend.

-

@JoergS5

ok! I wait to see, I'm glad to know that you have overcome the problems of building the robot! -

This post is deleted! -

how's the work going? I had read the post you deleted, I am waiting to see your robot, you say that it is very stable I could take it slow and build it if you release the construction schemes and reduction ratios. I have not tried to build anything even if I would like to try to see how the firmware behaves, I prefer to wait for your answers!

-

@tony73 I did delete the post, because I didn't want to tell you what to do. You should decide yourself. (and as I said, you'll get all the information I have. I learned a lot about manufacturing the last days also)

I have new design problems, the arms were too heavy for the steppers. But I have solved it with counterweights, so it's proceeding. The printer is in fact very stiff, I expect good print results. Current status is, I have to redesign actuator 2 (it was in the way of the arm 2 movement ;-( ).