help to setup M557 Mesh size

-

-

my config right now:

config.g:

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"Ender 5" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Physical drive 0 goes forwards M569 P1 S1 ; Physical drive 1 goes forwards M569 P2 S0 ; Physical drive 2 goes backwards M569 P3 S0 ; Physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z800 E411.53 ; Set steps per mm M566 X600.00 Y600.00 Z60.00 E300.00 ; Set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z500.00 E6000.00 ; Set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; Set accelerations (mm/s^2) M906 X500.00 Y600.00 Z500.00 E600.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X220 Y220 Z300 S0 ; Set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop ;M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop M574 Z0 ; configure Z-probe endstop for low end on Z M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch G31 P25 X-41.2 Y4.5 Z1.051 M557 X3:215 Y15:195 S20 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled ; Custom settings are not configured M501 M575 P1 S1 B57600homeall.g

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Jul 28 2020 08:52:12 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-225 Y-225 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-225 Y-225 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X110 Y110 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioninghomex.g

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) G91 ; relative positioning G1 Z5 F6000 H2 ; lift Z relative to current position G1 H1 X-225 F1800 ; move quickly to X axis endstop and stop there (first pass) G1 X5 F6000 ; go back a few mm G1 H1 X-225 F360 ; move slowly to X axis endstop once more (second pass) G1 Z-5 F6000 H2 ; lower Z again G90 ; absolute positioninghomey.g

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) G91 ; relative positioning G1 Z5 F6000 H2 ; lift Z relative to current position G1 H1 Y-225 F1800 ; move quickly to Y axis endstop and stop there (first pass) G1 Y5 F6000 ; go back a few mm G1 H1 Y-225 F360 ; move slowly to Y axis endstop once more (second pass) G1 Z-5 F6000 H2 ; lower Z again G90 ; absolute positioninghomez.g

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Jul 28 2020 08:52:37 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X110 Y110 F6000 ; go to first probe point G30 ; home Z by probing the bed G90 ; Make sure we are in absolute mode G1 Z10 F6000 ; Rapidly move the Z axis to Z=10. ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning -

G31 P25 X-41.2 Y4.5 Z1.051 M557 X23:215 Y15:195 S20after homing can you jog to X0 Y0 and make a photo

Best

-

after homing my printer go to middle

G1 X110 Y110 F6000 ; go to first bed probe point and home Z

0,0 is back right ( Ender 5 )

-

ok at 0/0 you are in the right back corner?

edit: should have read your first post

-

yes

-

@jay_s_uk said in help to setup M557 Mesh size:

G31 P25 X-41.2 Y4.5 Z1.051

G31 P25 X-41.2 Y4.5 Z1.051 M557 X41.5:219 Y15:195 P4 -

it will start G29 near the middle

i make a video

first i make homeall and then G29

video is uploading:

-

Since the 0,0 point is the rear right point maybe it would help to simply rotate the printer 180 degrees which would place the 0,0 point at the front left. (alternatively stand behind it). Then look at your nozzle and probe positioning. Which side is the probe on? is it towards the 0, or 200 side of the nozzle front/back left/right.

Another easy way to measure it is to use this method:

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Measuring_Probe_X_Y_OffsetOnce you're sure you have the probe offsets correctly set you can then find your grid spacing by moving the nozzle such that the probe is where you want it to be. The nozzle coordinates at each axis extent will be your grid limits.

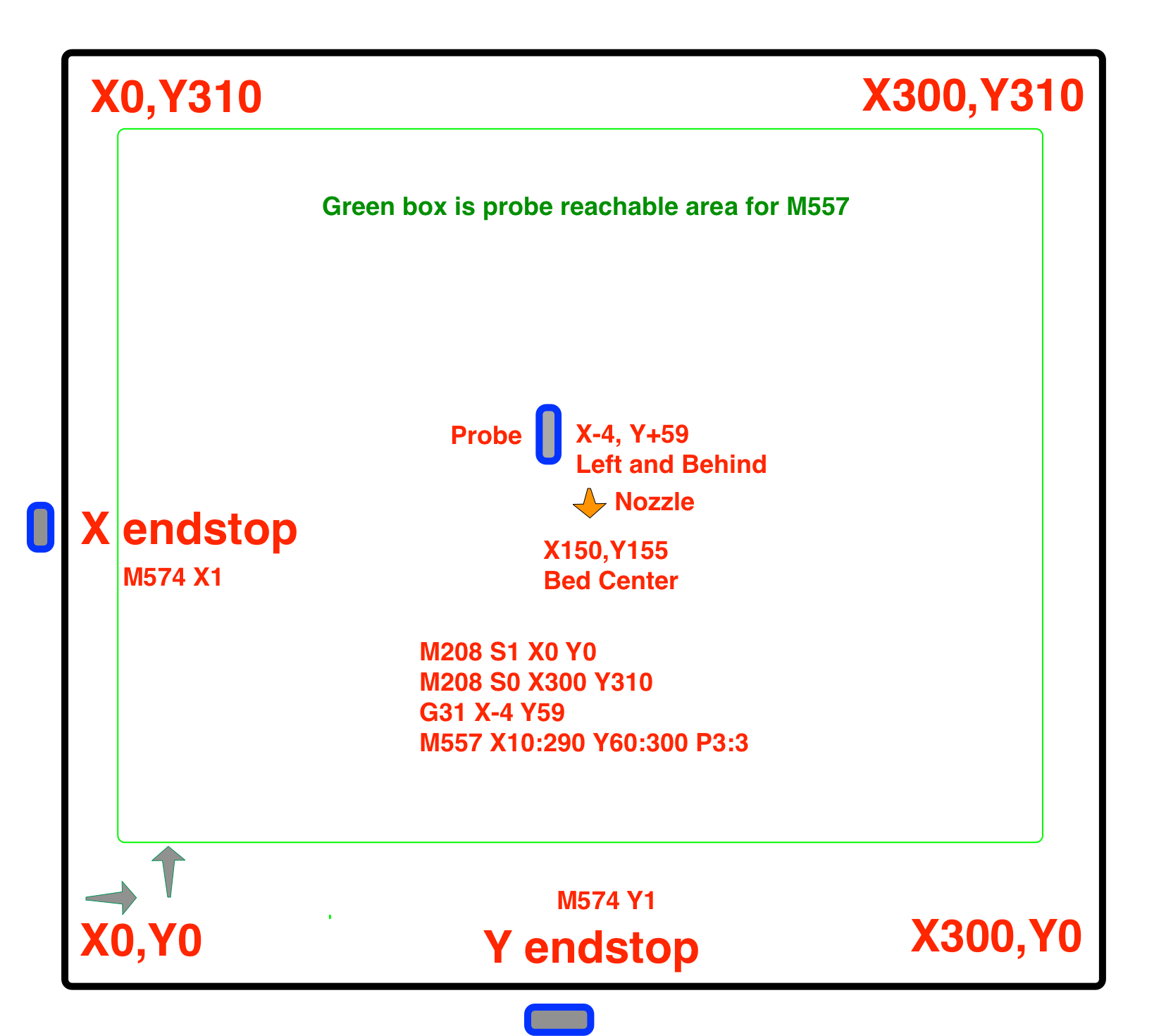

Perhaps create an image like this to help you visuallise.

-

so now i have sorted out !

probe is in the middle.but i have problems with the Z-offset:

my procdure to set z-offset with duet wifi and BLtouch:-

G28 XY

G1 X68.8 Y105.5 F4000 ; Move probe to middle of bed -

G30

-

jog Z axis untill the nozzle is touching the bed

-

G92 Z0

-

up with G1 Z10

-

G30 S-1

-

i get the z-offset :

G31 P25 X41.2 Y4.5 Z0.716

if i start a print the nozle its to close to the bed

is my procedure correctly ?

-

-

@lui2004 said in help to setup M557 Mesh size:

G31 P25 X41.2 Y4.5 Z0.716

Your procedure sounds fine, but your probe is a bit far out in X, if there is some tilt in the bed or gantry the height difference between the nozzle and probe may start to matter.

To try and correct for this it might help if you move the probe over so that it's right above where the nozzle was when you set Z0 before sending G30 S-1.

-

so today i have made my first print X and Y Tensioner for my Ender 5 but it dont looks good the quality is not perfect !

I have convert to DD with Bondtech Extruder and Micro Swiss all metal hotend.

Filament is and Extruder are Calibrated.

config.g

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"Ender 5" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Physical drive 0 goes forwards M569 P1 S1 ; Physical drive 1 goes forwards M569 P2 S0 ; Physical drive 2 goes backwards M569 P3 S0 ; Physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z800 E497.82 ; Set steps per mm M566 X600.00 Y600.00 Z60.00 E300.00 ; Set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z500.00 E6000.00 ; Set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; Set accelerations (mm/s^2) M906 X500.00 Y600.00 Z500.00 E600.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X220 Y220 Z300 S0 ; Set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop ;M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop M574 Z0 ; configure Z-probe endstop for low end on Z M558 P9 C"^zprobe.in" H5 F100 T4000 ; set Z probe type to bltouch and the dive height + speeds M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch ;G31 P500 X41.2 Y-4.5 Z0.685 ; set Z probe trigger value, offset and trigger height ;M557 X15:215 Y15:195 S20 ; define mesh grid G31 P25 X41.2 Y4.5 Z0.716 ; set Z probe trigger value, offset and trigger height M557 X41.2:221.2 Y4.5:219.5 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled ; Custom settings are not configured M501 M575 P1 S1 B57600Pictures from the printed Tensioner:

Simplify3D Config:

-

-

What material?

Have you redone PID tuning since changing the nozzle?

Have you recalibrated the extruder steps after changing it? Your extrusion multiplier says 0.75 that would be oddly low if your extruder steps per mm is correct.

Have you tuned pressure advance?

Are you printing the gcode over USB using S3D or are you uploading the gcode file to the duet via the web interface?

I would increase the extruder jerk from M566 E300 to E3000

Tune pressure advance. With a direct drive start with 0.04For retraction tuning I would increase retraction speed from 40 to 60 and uncheck only retract when crossing open spaces, check force retraction between layers, enable minimum travel for retraction, 3mm is fine, and uncheck wipe extruder for outer-most perimeters.

I'd probably also turn on relative extrusion distances (but that's neither here nor there)

-

-

material is Petg

-

Yes i have done the pid tuning nozzle and bed

-

yes i have recalibrated the Esteps.

EM is calibrated by this method:

https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257

is this method ok or i must use an other method to calibrate the EM ?

no, i dont use pressure advance,i have read the thread that is for Bowden

i upload the gcode via webinterface

-

-

Give this one a try

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

Pressure advance is for direct drive as well. Bowden users have more to gain from it, but it does help with direct as well.

-

now i have calibrated my printer with this method:

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165the layers looks smoother with pressure advance: 0.04

Esteps is perfect with 415 Stepsit will extrude 100mm

Petg EM is 93 no gaps and the 2 walls are perfect,no gaps betweens the wallsbut printing the cube the z-seam is broken take a look at the photo

-

@lui2004 said in help to setup M557 Mesh size:

but printing the cube the z-seam is broken take a look at the photo

Did you make any of the other retraction changes I suggested?

A broken wall like that on a 2 wall print with a stacked z seam isn't surprising. If there is a gap on the first layers it will continue to migrate upwards because there is nothing below it to build upon. You can't print in mid air.

Try a more complex test print like your original part. Set your seam position to nearest for petg to try to reduce stringing.

-

yes i have changed the retraction now i have :

Retraction Distance: 1.00 mm

Restraction Speed : 60 mm/si will reprint the Tensioner for my printer

i will post the result after the print

-

@Phaedrux said in help to setup M557 Mesh size:

uncheck only retract when crossing open spaces, check force retraction between layers, enable minimum travel for retraction, 3mm is fine, and uncheck wipe extruder for outer-most perimeters.

I meant these specifically.