Enclosure heater on Duet 3

-

To be clear - I mean mounted on the case of the enclosure (just in case that was not obvious) and forcing hot air into the enclosure.

-

I would think that having it inside would help it get and stay warmer, rather than constantly heating ambient temperature air.

Having something like that might be good for PLA and lower temp filaments though

-

@cdthomas9

I agree that it would be easier to heat with the heater inside the enclosure. But there was a question as to whether the lower cost heater itself could withstand operating at 80C (or thereabouts).If, on the other hand, the heater does have the capacity to raise ambient to 80+C AND maintain the interior - then my thought was that it would alleviate the issue of overheating the heater (pub intended).

Given the 10x cost difference between the two heaters mentioned, maybe some experimentation (or math) would tell the tale.

I'm a month or so away from building an enclosure - hence my interest (and musings). Will have to do some googling ....

-

Something I should have mentioned but not yet tested (it's on my list) are these Keenovo enclosure heating elements, which supposedly are rated up to 250°C for operating temperature.

I use their build plate heaters with great success..

-

I was going to stay out of this discussion but I can't keep it inside any more.

A bit of background - I have a 300 * 300 printer with I think a 600W bed heater and a 500*500 printer with a 1200W bed heater.

The small printer is enclosed, mostly with Lexan. With the 600W heater, the internal temperature is about 25C higher than the external temperature.My comments:

Unless your enclosure is very well insulated, you will not achieve the temperature you are hoping for.

Unless you have some sort of way to circulate the hot air in the enclosure, you will have temperature stratified air which is not what you want. My plans are to install fans underneath the heated bed to induce a slow circulation in the chamber.

The heater, if installed on the side of the enclosure, may or may not induce enough circulation - I have not done any tests of this yet but that was one of my thoughts on what to try.

In order to make the enclosure temperature reasonably responsive, you need to provide excess heating capacity and thermostatically control the heater. The Duet is ideal for that sort of control situation. If you don't have that extra heating capacity, it will take forever to heat up the enclosure.

I am concerned about the fan/heater combination if mounted on the enclosure side wall. There is a considerable chance of getting stray air currents into the build area which could cause differential expansion/contraction.

Install a thermal fuse to cover your butt.

The Keenovo heat pad will need a largish aluminum plate to be mounted on so that the heat can dissipate.

One cubic meter would be 1000mm1000mm1000mm and a 250W heater will do virtually nothing to heat that monster even if it is well insulated. Maybe if you have 4 to 6 of theses heaters and have a well insulated enclosure.

Finally, I'd like to point out that I have very limited experience so the above is just my thinking and may or may not reflect what you will actually see in real life.

Good luck! -

@jens55 - I agree that lightweight enclosures are going to struggle- at best they are to keep the temps stable and raising them much higher than ambient is going to require a lot of power. However, heating an enclosure is not difficult, but care does need to be taken to minimize risks.

Our enclosures are much more robust but do not have additional insulation added within them. A 24v 300w build plate heater, by itself, will raise the temperature to around 45-50ºc. The Stego 120v 200w heaters we currently use raise the temperature to 75-80ºc without issue in short order. A fan is used above the convection heater to stir the air throughout the enclosure.

The idea of using a fan under the build plate heater is intriguing, but it's job is to keep the build plate's temperature stable. Only by adding a second heater with it's own thermostat can you accurately control the enclosure's temperature.

I'm going to disagree with you on the fact that a 250w heater will do virtually nothing in a one cubic meter box as this is roughly the size of our enclosures. A simple experiment would be to simply put a 100w incandescent lightbulb inside, turn it on, and monitor the temps. A better experiment would be to do the same with an added fan to stir the air. We did similar experiments at the beginning of this journey..

Finally, this all reminds me of something in my past where I accidentally left a 60w incandescent shop light on overnight inside a very large kegerator. I could have cooked an egg inside that thing the next morning when it was discovered..

-

Thats what i use for my chamber, it runs on 110 with a 24v fan. they also have larger units available.

-

@oozeBot, I decided to run some tests today. My small printer has an enclosure that is roughly 1/3 of one cubic meter in volume. It has 4 sides of 3/8 (I think) Lexan, a wooden bottom and a Lexan top that has a 3/4" sheet of styrofoam over top.

While it is not 'air tight', it is reasonably closed with no big gaping holes. It is not 'insulated'.

I installed a single 100W light bulb inside and measured temperature vs time.

Over a 30 minute time frame, the temperature went from ambient to ambient plus 5.5C. The higher the temperature is over ambient, the slower is the overall enclosure temperature rise. At one hour, the temperature had risen to 6.6C over ambient.I leave it up to you to decide how much of a difference 250W would make in an enclosure of three times the volume of what I was running compared to 100W.

Again, if your enclosure is well insulated then yes, it will heat up although 250W would still be too low for me because of the amount of time wasted to get to operating temperature.You misunderstood the fan under the build plate I mentioned - the fan does not blow onto the build plate but horizontally along the underside of the build plate so as to induce a gentle air current to help thermal convection to circulate air.

From what I see, your stepper motors are in the same environment as the print. Unless you have water cooling set up for the stepper motors, you are running them well beyond their specifications if you run the temperature in the enclosure to 80C. Most (but not all) steppers are rated up to 80C. Beyond that, the magnets get affected and you are in danger of reducing the magnetic field they generate which in turn leads to a permanent reduction in torque output. The motors do a certain amount of self heating based on the amount of current going through them but at minimum they will heat up about 30C over ambient. If your chamber is 80C then your motors will run at around 110C which is well above specs and will result in motor damage over time.

My maximum enclosure temperature is 60C and I am already pushing things.

You might want to consider a separation between the build volume and the motors to keep the motors at a more reasonable temperature. -

@jens55 - I'm sorry if this wasted your time. To be honest, the printers we are using to build our new prototypes are not of the same design - they are older DIY that we are rapidly trying to replace with our new designs (and aren't talking about much).. but threads like this add confusion. My apologies. You are right that with the steppers inside the enclosure, our new design should not be heated to 80ºc.

About the fan under the build plate - I did understand and like the idea.. my thought was that since the thermostat is basically built into the build plate heater, it won't get above ~100ºc. The Stego we are currently using has a max surface temperature of 200ºc.

We are working on building our first purpose built enclosure for our new design as we speak. I'll be doing similar tests after it is complete and report back.

-

Not at all a waste of time. I have been wanting to test this for some time but kept stalling on it. This discussion gave me the extra incentive to set up the test ... so thank you!

-

I do use this type of heater - https://szxinruite.en.made-in-china.com/product/vykEjoYlrwhx/China-Rhw-032-Industrial-PTC-Fan-Heater-for-Electric-Cabinet-with-UL-Thermostat-Heater-Temperature-Control-Heater.html

At first, I've been using a 300W version which gives me 55C in 15 minutes with a heated bed set to 75. Now I do have installed 800W + 300W and together they are reaching 70C in 15 mins without a heated bed.

However, during heating, they turn off then the surface area of the radiator reaching specific temp. I am planning to mount the fan directly on the wall and make a-holes in the sidewall to suck cold air from outside and heat it through the radiator. Which I hope will keep the them on for a longer period and will heat even faster.

https://forum.duet3d.com/topic/13873/wip-corexy-with-heated-chamber/67?_=1598174589336

-

Digging up this older thread to report in.. we've recently tested multiple chamber heaters and have settled on a target temp of 70c for our enclosures. What we've picked as our recommendation is the Stego 028119-01. It is a 250w PTC with built in fan. Along with the build plate at 110c, it can heat our chamber to 70c in less than 30 minutes.

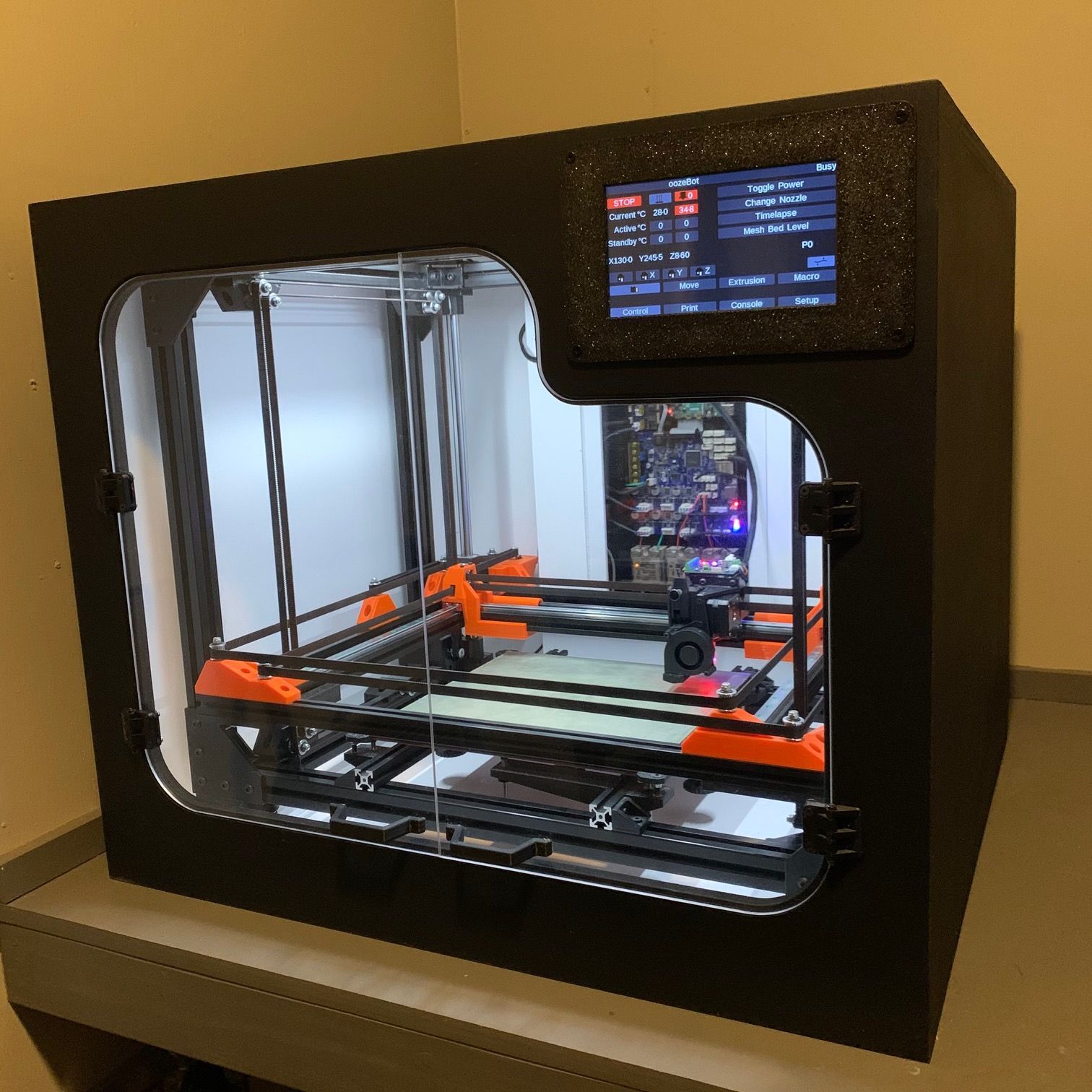

First, here is a photo of our enclosure:

And the Stego heater:

And the PanelDue after the chamber temperature has stabilized:

-

Boy that machine is looking sweet! Well done!