Is there a change in esteps for 3.11?

-

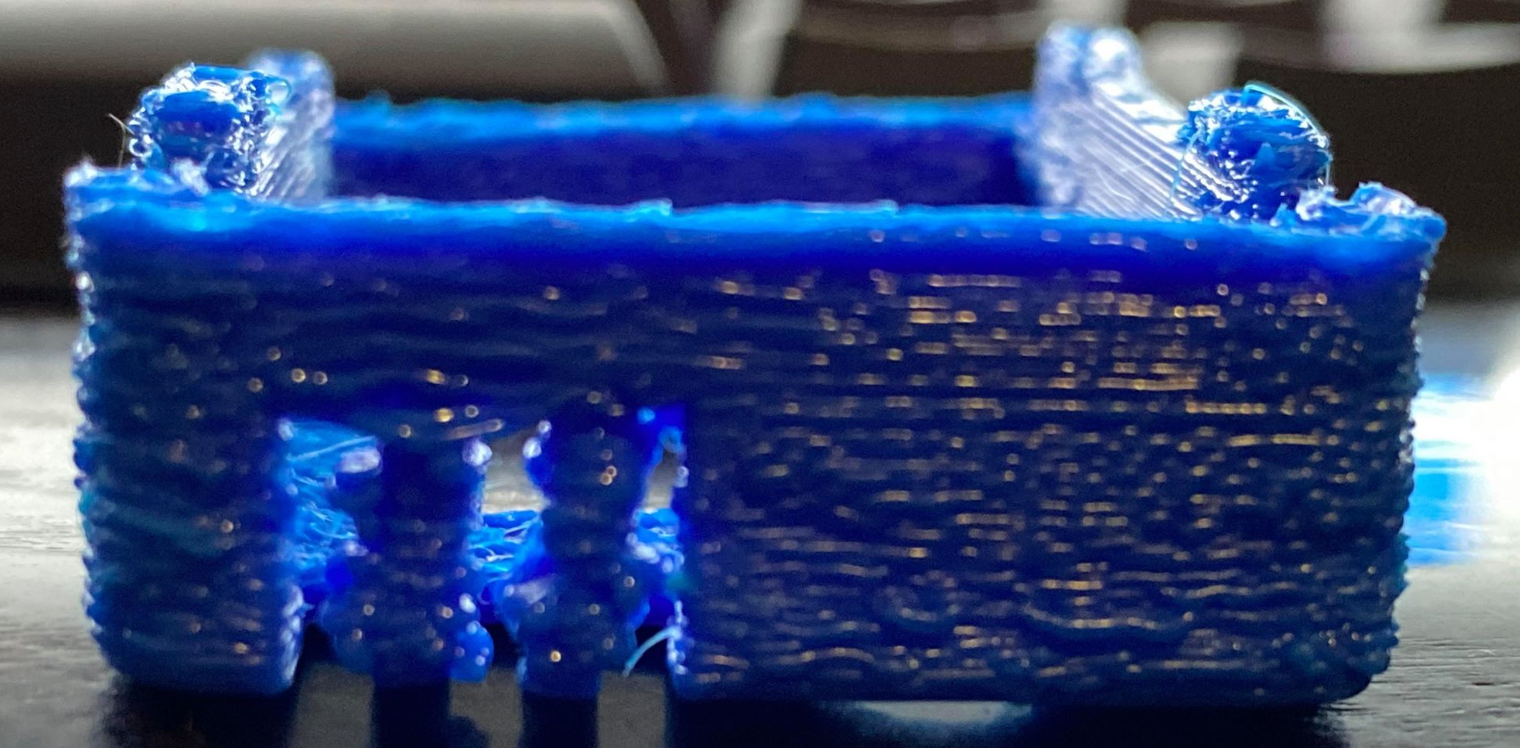

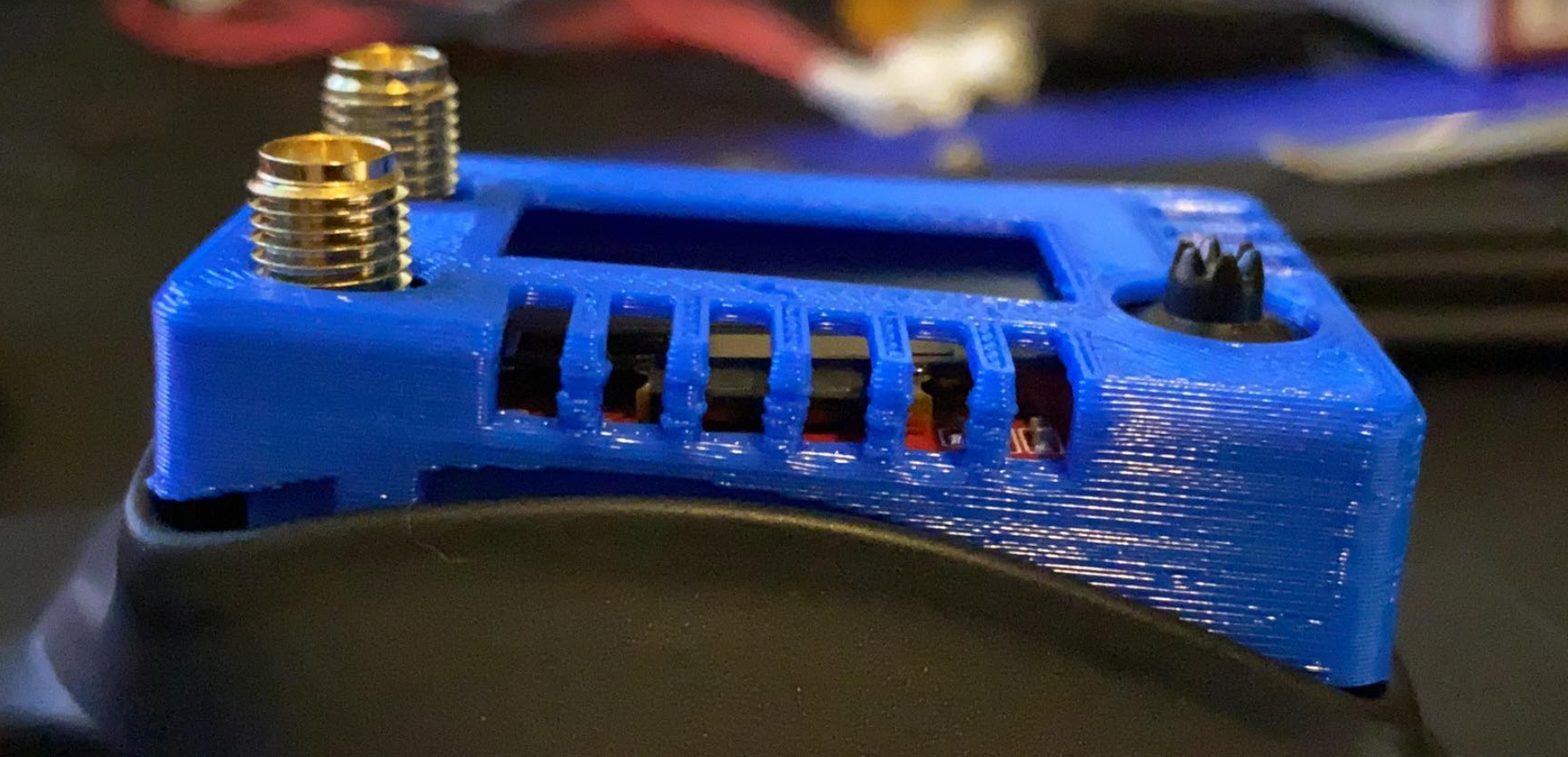

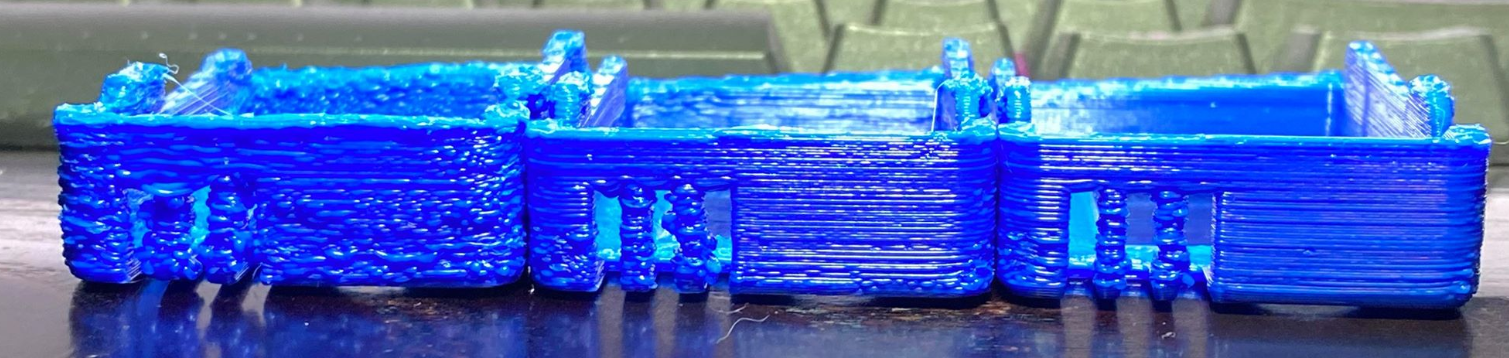

For example I had gcode I printed on 1.21rc3 and it printed perfectly fine, but since upgrading to 3.11 it printed like hot garbage. I don't know if its over extruding or what, but the prints are terrible.

This is on a D300vs Delta, it has an e3d titan on it and up until a few days ago it printed perfect.

That is with GCode that printed this same exact piece

Same GCode different results.

I was thinking it was a partial clogged nozzle, but I've done cold pulls and the end is coming out clean so I am at a complete loss.

Here is my Config.G

; Configuration file for UltiBots D300 V-Slot 3D Printer ; version 1.0 for firmware version 3.0 ; Communication and general M111 S0 ; Debug off M550 PVader ; Machine name and Netbios name (can be anything you like) M551 XXXXX ; Machine password (used for FTP) ;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits ;*** Wifi Networking M552 S1 ; Enable WiFi ;M587 S"Epcot" I"192.168.1.102" M555 P2 ; Set output to look like Marlin M575 P1 S1 B57600 ; Communication parameters for the PanelDue G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Axis and motor configuration M569 P0 S0 ; Drive 0 goes forwards (X tower) M569 P1 S0 ; Drive 1 goes forwards (Y tower) M569 P2 S0 ; Drive 2 goes forwards (Z tower) M569 P3 S1 ; Drive 3 goes forwards (extruder 1) ;M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high) M574 X2 S1 P"xstop" ; X min active high endstop switch M574 Y2 S1 P"ystop" ; Y min active high endstop switch M574 Z2 S1 P"zstop" ; Z min active high endstop switch ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration M665 L376.890 R209.421 H437.21 B140.0 X 0.125, Y 0.281, Z 0.000 ; set delta radius, diagonal rod length L380.31, printable radius and homed height M666 X-0.44 Y-1.37 Z1.81 ; put your endstop adjustments here, or let auto calibration find them M584 X0 Y1 Z2 E3 ; Set drive mapping M350 X64 Y64 Z64 E16 I1 ; Set microstepping to 32 for X, Y and Z and 16 for extruder stepper with interpolation M92 X640 Y640 Z640 ; Set axis steps/mm M906 X1000 Y1000 Z1000 E500 ; Set motor currents (mA) M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2) M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min) M566 X1200 Y1200 Z1200 E300 ; Maximum instant speed changes mm/minute ; Axis Limits M208 Z-0.2 S1 ; Fans M950 F2 C"fan2" M950 F1 C"fan1" ; This fan is the Heatsink Fan M106 P1 T50 S255 H1 ; Set hotend heatsink FAN1 thermostatic control at 50°C ; Thermistors M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 ; Heater configuration M140 H0 ; Tool definitions M563 P0 D0 H1 ; Define tool 0, the extruder G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ;M92 E415 ; Bondtech BMG steps per mm M92 E822 ; Titan Aero steps per mm old: 837 ; Z probe and compensation definition ; Change "H25" to "H3" AFTER commissioning your printer M558 P5 C"!e0stop" X0 Y0 Z0 H5 F600 ; FSRs with JohnSL board Z probe behaves as a switch and is not used for homing any axes ;G31 X0 Y0 Z-0.15 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed G31 X0 Y0 Z-0.75 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed T0 ; Select tool 0, the hot end M501 ; Load config-override.gThank you.

-

@sLpFhaWK Have you tuned the heater since converting to RRF3? I don't see any M307 but if you saved the tuning result using M500, then the M307 result will be in config_override.g. - might be an idea if you post that too.

Also, can you confirm that the extruder is using a 0.9 degree motor? The steps per mm are roughly double what one would expect for a 1.8 degree motor so I assume that is the case.

-

@deckingman said in Is there a change in esteps for 3.11?:

@sLpFhaWK Have you tuned the heater since converting to RRF3? I don't see any M307 but if you saved the tuning result using M500, then the M307 result will be in config_override.g. - might be an idea if you post that too.

Also, can you confirm that the extruder is using a 0.9 degree motor? The steps per mm are roughly double what one would expect for a 1.8 degree motor so I assume that is the case.

I haven't tuned the heater since upgrading to 3.11 but would that matter if it was tuned on 1.xx?

; This is a system-generated file - do not edit ; Delta parameters M665 L377.470 R206.427 H451.666 B140.0 X0.252 Y0.460 Z0.000 M666 X0.578 Y-1.992 Z1.414 A-1.07 B-0.18 ; Heater model parameters M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1 M307 H1 A512.9 C267.0 D9.0 S1.00 V0.0 B0 M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0This is my config-override.

As for the 0.9 deg stepper motor I honestly do not remember. If I had to guess I would say no as I didn't get the stepper through e3d when I had gotten the titan I already had a pancake but if it was configured before on 1.xx and working fine why would anything change in 3.xx?

Should I retune my hotend for the config changes you think?

-

So my issue is definitely over extrusion. I did 2 prints, one at .85 extrusion and then at .75 and the .75 is soo much better. Still not perfect but getting much closer.

I also need assistance with my 1st layer. I adjusted what I thought would fix the issue, but I still need to baby step up .5 mm to get a good first layer.

G31 X0 Y0 Z-0.75 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshedit was initially Z-0.25 but I changed it to Z-0.75, and I still had to baby-step up.

So now I need to find out the E-Steps for the Extruder motor. I'm so out of practice I don't remember anything.

-

I'm inclined to think heater temp issue as well.

When you updated to 3.1.1 did you create a fresh config set from the web configurator or did you manually update your config?

I assume you're using the E3D thermistor from the looks of your values?

Doing a new PID tune would be a good start.

For reference here's what the config tool generates for the heaters

; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limitStarting with that and then PID tuning the bed and hotend and saving the results with M500.

-

@Phaedrux said in Is there a change in esteps for 3.11?:

I'm inclined to think heater temp issue as well.

When you updated to 3.1.1 did you create a fresh config set from the web configurator or did you manually update your config?

I assume you're using the E3D thermistor from the looks of your values?

Doing a new PID tune would be a good start.

For reference here's what the config tool generates for the heaters

; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limitStarting with that and then PID tuning the bed and hotend and saving the results with M500.

I did not create a new config.g from the tool, I would really like to do that if I knew how to answer all the questions properly. Mine just seems to messy.

I am using the e3d thermistor.

I will tune it now, I figured out my steps value was doubled somehow. I checked my config.g backup I had saved before these changes and it was 415 before but for some reason it was 842. /shrug

-

M563 P0 D0 H1 ; Define tool 0, the extruder G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ;M92 E415 ; Bondtech BMG steps per mm M92 E822 ; Titan Aero steps per mm old: 837Well it's doubled there...

-

@Phaedrux said in Is there a change in esteps for 3.11?:

M563 P0 D0 H1 ; Define tool 0, the extruder G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ;M92 E415 ; Bondtech BMG steps per mm M92 E822 ; Titan Aero steps per mm old: 837Well it's doubled there...

Yep I Figured that out,l and have zero idea how that happened. I know MHackney was giving me a hand and had me cutting/pasting values from his to my config to get things working, maybe I over wrote that and commented out mine thinking it was a necessary change? I don't know.

Can you help me with my G1 Z0 issue I am having, I Can't remember what I need to change but when I type that it hits the plate and crashes, I'd like for it to be .2 or so mm off the bed but I can't seem to remember what to change. I thought it was the G31 command I used uptop but that didn't work, is it this M208 Z-0.2 S1?

-

@sLpFhaWK said in Is there a change in esteps for 3.11?:

Can you help me with my G1 Z0 issue I am having, I Can't remember what I need to change but when I type that it hits the plate and crashes, I'd like for it to be .2 or so mm off the bed but I can't seem to remember what to change. I thought it was the G31 command I used uptop but that didn't work, is it this M208 Z-0.2 S1?

Well it would depend on at what point you're sending the G1 Z0 command. When you do G28 (homedelta.g) it moves the carriages up to the endstops and sets the height based on whatever you have set as the homed height. If that value isn't quite right then it won't truly know where the bed is until you've done a G30 at the center of the bed. Usually that would be done after the G32 (bed.g) to do an auto calibration and then the last step there would be a G30 at the center. At that point, G1 Z0 should take you to touch the nozzle to the bed surface.