Thermal analysis of Duet Maestro

-

Hi Guys,

Having purchased a duet Maestro because i had previously been running my steppers at 800ma anyway i thought i'd take a little look into the thermals. I'm lucky enought to have a few thousand pound thermal imaging camera sat on my desk (trialling it for work purposes) and figured i'd use it!

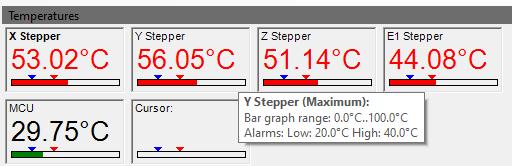

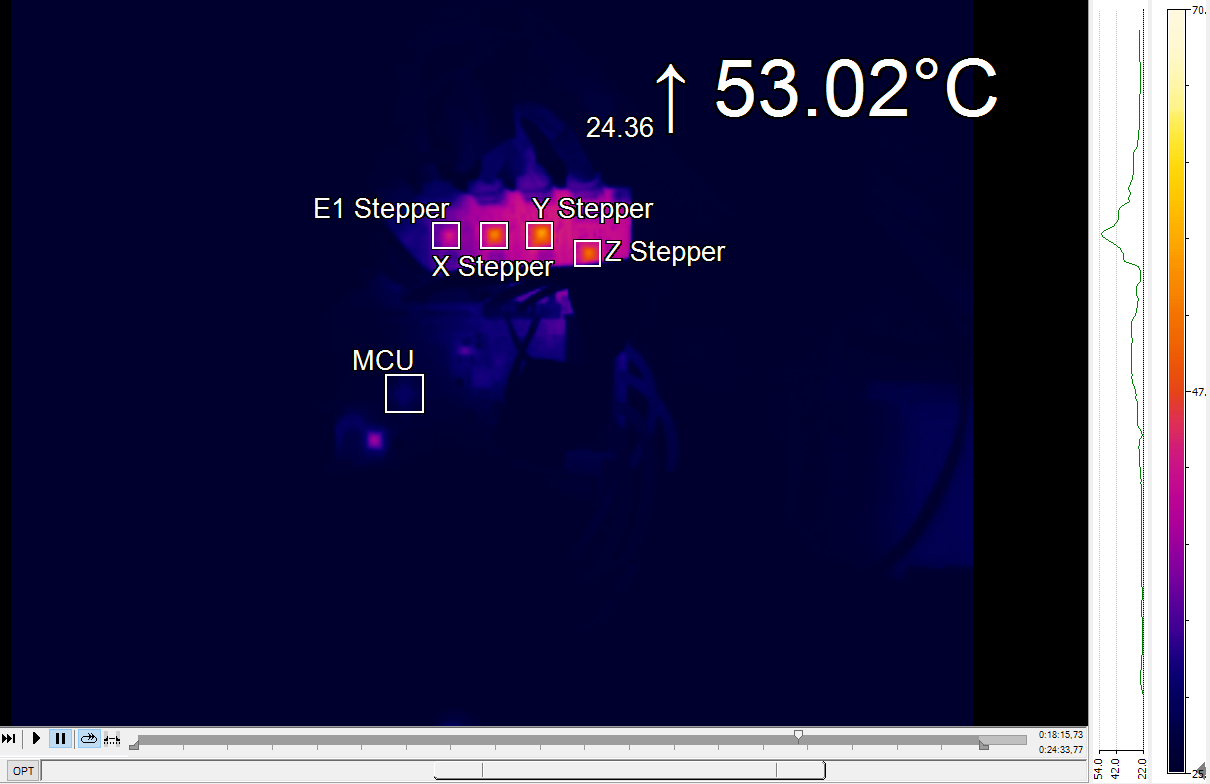

i haven't done too much digging into it yet other than a quick check that all is good. but here are some results - this is with a radial fan, a printed duct straightening the air out so it blows under the region of the board where the steppers are and motors running at 1000ma for the x,y and z and 800ma for the E1.

(this setup is partially calibrated - at room temp before the board is turned on, and after it has been unused overnight, i get almost identical readings to the hot end and heated bed. It is also pretty consistent between the displayed MCU temp and the one recorded using the thermal camera)

I read the alarm temps are over 100C so what is a good operating temp?

Also my MCU temp doesn't change much at all (it is closer to the cooling fan due to available room on machine) so is it really a good indicator for board cooling temps?

p.s. first duet board and i don't think i'll ever go back!

-

@Slzer said in Thermal analysis of Duet Maestro:

first duet board

don't take this the wrong way but the all green LEDs would suggest this may be a cloned board..

most coloned boards use 1oz copper thickness while the original uses 2oz for much improved thermal performance.

edit: maybe look to https://duet3d.dozuki.com/Wiki/Mounting_and_cooling_the_board and specifically the page it links to WRT using the CPU temp https://duet3d.dozuki.com/Wiki/Calibrating_the_CPU_temperature

-

@bearer said in Thermal analysis of Duet Maestro:

while the original uses 2oz for much improved thermal performance

Do you mean that 2oz doesn't just reduce voltage drop but also distributes the heat better? That's an interesting point.

Some boards use aluminum substrate. I wonder if the duet would benefit from it.

-

@zapta it does both, but the Duet probably benefits the most from the thermal properties as the currents are relatively small. (less the bed, but just for the bed wider traces in a short area would be so much cheaper solution to that even if the board got a little bigger)

-

Is anything under say 80C a safe running zone? With the fan turned off i see the heat distribute right across the board and the expected MCU temp rises. i think for better control i will need to find a way to reposition my fan cooling to avoid the MCU however this is challenging whilst keeping the board in the vertical orientation as suggested to enable regular convection cooling (which i want because it is quieter!)

-

What is safe anyway?

The drivers will protect themselves and shutdown if they are in danger of getting damaged (around 150C iirc).

But electronics will have a shorter lifespan at elevated temperatures, i.e. above 20-25C. Does it matter? maybe not, depends mostly on expectations.

-

You can play with the M106 command to set up the board cooling fan like setting a minimum speed and tying it to the MCU temp, so that if it's blowing across the drivers you get adequate cooling. A shroud over the board that forces the air to travel across the drivers on both sides of the board is best.

I used to try and get fancy with it but in the end just use a command in the start gcode to turn on the case fan at a set speed and then turn it off again at the end of the print. I got tired of the hysteresis ramping the fan speed up and down constantly during the print.