PA tuning

-

@deckingman did, without PA no holes

-

but PA is rather small and square looks great, only happens with cylinder and not every time and length is not consistent .. /me confused

-

@arhi I'd imagine that when using a 0.6mm nozzle that pressure would be low and hence also the need for PA to compensate. How bad are squares without PA? But yes, it's a bit odd that the length of the hole changes. It could be related to the position of each layer change.

I seem to remember from another post a long time ago that DC said that PA doesn't get applied to each small segment of an arc but is somehow accumulated and applied at some later point towards the end of the curve - kind of simulating one long move rather than lots of small individual segments. My memory is getting worse these days so I can't be sure, but there was certainly some discussion around the fact that tiny segments wouldn't build up pressure or if they did the extrusion amount would be too small to be able to do the necessary advance and retard. So some sort of accumulation was being applied. If that's the case, then I some variation in that accumulation between applications of PA would explain the varying hole size.

Or maybe the slicer is doing weird things with segment sizes. That's probably more likely. Do you have a different slicer that you can use?

-

@deckingman said in PA tuning:

@arhi I'd imagine that when using a 0.6mm nozzle that pressure would be low and hence also the need for PA to compensate. How bad are squares without PA?

Calibrated using those "lines" thingy, you can see images here on forum

https://forum.duet3d.com/topic/15717/pe-value-of-0-042-for-6mm-nozzle-direct-drive-makes-sense-orSquares are not too bad without PA but significantly better with.

But yes, it's a bit odd that the length of the hole changes. It could be related to the position of each layer change.

The starts are in same place for all the holes, nicely straight line trough Z (every second layer), the holes are end of layer last few moves before the stop and the filament stop flowing in different place for identical layers

I seem to remember from another post a long time ago that DC said that PA doesn't get applied to each small segment of an arc but is somehow accumulated and applied at some later point towards the end of the curve - kind of simulating one long move rather than lots of small individual segments.

Yes, I understood the same, can't remember where @dc42 wrote it, but looks like that algorithm is not ideal as obviously it aggregates too much

Up in the Z on the same part, where there's a bit different layer (some infill, not only perimeters) the PA looks ok and there are no holes, z-seam points are ok.

Or maybe the slicer is doing weird things with segment sizes. That's probably more likely. Do you have a different slicer that you can use?

Slicer is 100% doing all kind of shenenigans I can confirm that as

- simplify3d is rather stupid when it comes to small segments (and this STL was not made by me, I think it's using very high resolution for no real reason)

- playing g-code I see bunch of moves on each layer that are really unnecesary

but I did not notice anything strange on the outer perimeter where this hole is happening.

Good idea to try other slicer, I have here ideaMaker, CraftWare and PrusaSlicer set up together with (not really using any more) my own fork of Slic3r. I'm moving most of my work to ideaMaker anyhow, will try the same object.

-

Hit the same problem with different part and different slicer, reprinted without PA and problem did not go away (no changes visible) so looks like PA has nothing to do with this problem

-

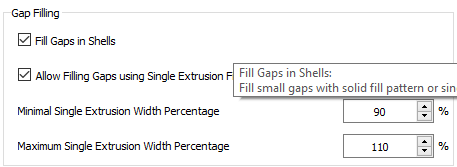

This is what's causing the problem

-

So what exactly is it doing?

-

@Phaedrux I'm not sure but if I turn off "fill gaps in shells" those holes are not there. The print is still not good as looks like the thickness of the cylinder is a problem. I have 1.5mm thickness and am printing 0.7mm extrusion width so 2 perimeters are 1.4mm .. without this parameter I can feel the hole between perimeters but with this parameter it looks like it tries to print 3 lines for this 1.7mm but underextruded and while it gets part to be solid somehow end of the line ends up not being there...

but first time it happened with s3d, now with idea maker, both times cylinder, both times "thin wall", both times .7mm extrusion width and s3d also tries to fill the gap, underextrude etc.. (not this STL, but the other one I had issues with S3D, this one works ok) I fear it has to maybe do with how my e3dv6 with .6 nozzle and bmg handle this under extrusion... will have to do some testing... as visualising the g-codes everything looks ok

-

I fear it has to maybe do with how my e3dv6 with .6 nozzle and bmg handle this under extrusion... will have to do some testing... as visualising the g-codes everything looks ok

Yes I think it looks like underrun. I seen it too on thin walled objects sometimes. Usually at the start of a line. Extra reprime can help in that case.

-

@Phaedrux need to inspect these IM gcode files, the s3d files I inspected it looked like problem is at the end of the line, not beginning.

-

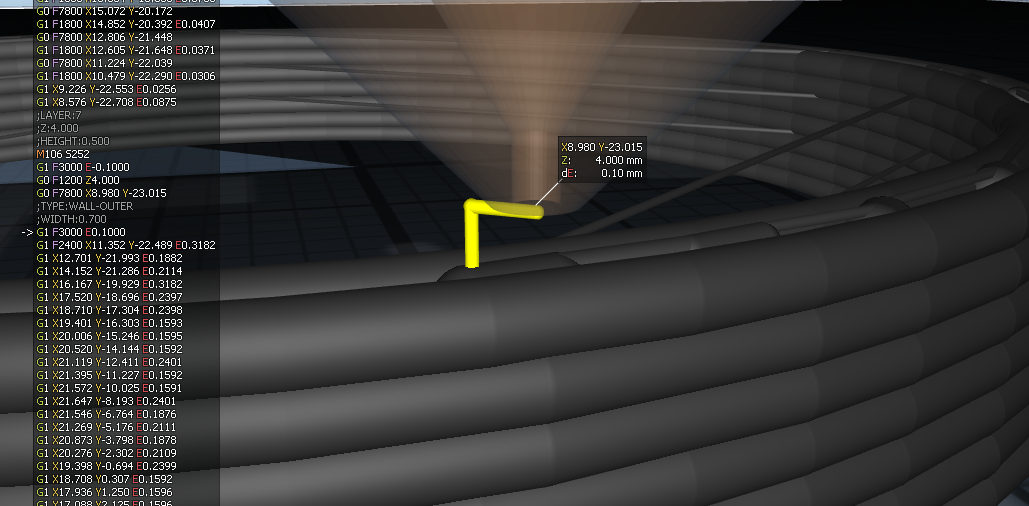

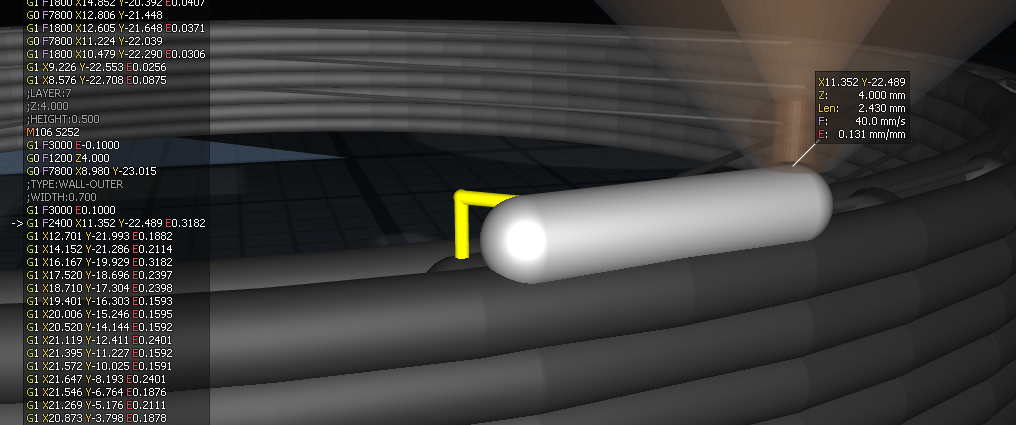

slowly moving forward on this problem... and it's making less and less sense

I decided to record the print to see if that will give me more data and I see that my idea that holes are at the end of the line, well, %$#_^@& they are not, they are at the BEGINING

..

..The G-Code is nothing special, the layer start by "go up, move to begining, start printing"

and first segment (that's turned in to hole) is printed with 0.131mm/min extrusion just like all the other segments in the line

but for some reason, nozzle is "empty" at this moment... and the "line" start forming somewhere at the middle of the first or begining of the second move.

so the prev layer finishes, with positive extrusion...

G1 F1800 X12.605 Y-21.648 E0.0371 G0 F7800 X11.224 Y-22.039 G1 F1800 X10.479 Y-22.290 E0.0306 G1 X9.226 Y-22.553 E0.0256 G1 X8.576 Y-22.708 E0.0875 ;LAYER:7 ;Z:4.000 ;HEIGHT:0.500 M106 S252there's a minimal 0.1mm retraction (that happens on the other prints as well where there are no holes)

G1 F3000 E-0.1000so then lift up move to start position

G0 F1200 Z4.000 G0 F7800 X8.980 Y-23.015prime 0.1mm and start printing

;TYPE:WALL-OUTER ;WIDTH:0.700 G1 F3000 E0.1000 G1 F2400 X11.352 Y-22.489 E0.3182 ; HERE IS THE HOLE!!!!! G1 X12.701 Y-21.993 E0.1882I don't get it

-

problematic g-code

link-prob.gcode@Phaedrux why is .7z or .zip not allowed extension? would make sense to 7z the .gcode files

-

May I ask what program you are using to examine the g-code? It looks interesting!

-

May I ask what program you are using to examine the g-code? It looks interesting!

That is CraftWare. It's a decent slicer, not feature-packed like other most popular ones (like for e.g. ideaMaker that generated the code I'm inspecting) but is IMO THE BEST g-code preview app out there. Try it out, lot of ppl use it as a slicer too and they are happy with it, it's "very visual", the devs are very responsive, development is very active and it's getting better and better every day..

-

Gaaaa ..... it tells me I am not a human when I sign up for the newsletter. I might have to fire up Chrome but this is SOOOO annoying!

Thanks for the info though, never heard of this program before!

Edit: Damn Captcha .....

-

@jens55 recaptcha is having some issues these days, I had to turn off ABP and uBLOCK on my firefox in order to get netfabb 2020 premium downloaded and installed

.. anyhow crafware is worth the hastle... I'm still not happy with it as a slicer (it's not bad, just idea maker is imo better) but it is very good, the support system is awesome, config system is also very very clear and easy to use... it's an eye candy .. and the gcode preview is the best there is... for e.g. if you ever tried velocity printing, craftware is the only g-code preview where you actually see the velocity print directly in the preview, it is that good

.. anyhow crafware is worth the hastle... I'm still not happy with it as a slicer (it's not bad, just idea maker is imo better) but it is very good, the support system is awesome, config system is also very very clear and easy to use... it's an eye candy .. and the gcode preview is the best there is... for e.g. if you ever tried velocity printing, craftware is the only g-code preview where you actually see the velocity print directly in the preview, it is that good

-

Yes, I did download it with chrome and agreed, eye candy factor is awesome

I only had limited time playing with it so far but it looks awesome. -

@jens55 yup, super nice, I have not tried it slicing for few months, should check it again these days, but ideaMaker was lot better last time I compared them. Anyhow, IMHO, it's better than both cura and prusa slicer

-

Hi, Im trying to repeat this test and trying to find solution.

@arhi did you found any solution for it or which way did you go with retraction/PA settings?

-

@petriheino said in PA tuning:

Hi, Im trying to repeat this test and trying to find solution.

@arhi did you found any solution for it or which way did you go with retraction/PA settings?

did not turn on any of my printers for almost a year.. too much work to be done, no time for hobbies

so nothing done about this

so nothing done about this