What do you think about Dragon Hotend

-

@oliof said in What do you think about Dragon Hotend:

Bigtreetech and trianglelabs both have their distribution agreements with phaetus it seems (phaetus historically has friendly interactions with either on Twitter). So neither are clones even if the dragon hotend comes from China.

Isn't Phaetus PRC company too ?

There is some IP / patent stuff about similarities between Mosquito and Dragon hat may or may not be relevant for you. I find it interesting that printing with PLA is an issue for some users on both designs

I noticed on Mellow CNF (clone of mosquito) that the copper heatsink on the surgical tube is moving up/down (did not notice that on original mosquito) and position of that heatsink might be important.

From the tests I made looks like if the steel tube gets hot PLA will stick and swell and block and no matter how strong your extruder is it will stop extruding, so the only way to make them work with PLA is some serious cooling of that tube.. so it is possible that

- copper heatsink is underdesigned

- copper heatsink is not at proper position (for e.g. I could easily slide it to touch the heater and that would not cool anything!!)

- copper heatsink do not have good contact with steel tube (I could move it up/down, it would not slide on it's own, but you could easily move it with your finger - tried the same on original mosquito - could not move it, so mosquito either have some of that fancy paste in there that solidified or the copper is machined to more tight tolerance)

-

@arhi said in What do you think about Dragon Hotend:

Isn't Phaetus PRC company too ?

Thats what I alluded to...

-

@arhi said in What do you think about Dragon Hotend:

.....................so it is possible that- copper heatsink is underdesigned

- copper heatsink is not at proper position (for e.g. I could easily slide it to touch the heater and that would not cool anything!!)

- copper heatsink do not have good contact with steel tube (I could move it up/down, it would not slide on it's own, but you could easily move it with your finger - tried the same on original mosquito - could not move it, so mosquito either have some of that fancy paste in there that solidified or the copper is machined to more tight tolerance)

It's also possible that the stainless steel tube isn't as thin walled as the original Mosquito. The cross sectional area of a Mosquito heat break tube is about 15% of a similar E3D style heat break, so very little heat gets conducted. For info, the guys at Slice engineering tell me that the original prototype Mosquitos did not have any copper heat sink at all - just the very thin walled tube. They also tell me that they have printed PLA for many hundreds of hours using that configuration providing the filament was always moving forward. The issue with all metal hot ends and PLA, is that no matter how efficient the heat break is, some heat will conduct through the filament itself. That is the reason why the copper heat sink was added to the tube.

-

@deckingman said in What do you think about Dragon Hotend:

It's also possible that the stainless steel tube isn't as thin walled as the original Mosquito.

That was my original idea, both 'cause that's what they show on the slice web site and 'cause I know that PRC have issues with producing super small things out of hard metals (e.g. till last year they had to import steel balls for ballpoint pens as they were not able to produce them themselves) so I assumed this type of tubing might be too expensive for them to make. So, I did what I normally do it this case and I tested it with microscope and .. well .. they are identical.

Also, dunno about price to make but for e.g. those 4 distancers that are also super thin walled tube are 5$ as spare part directly from slice ..

All in all, I can't say with certainty anything as I needed more time and I would like to do some destructive tests of the PRC versions (both dragon and crazy) with a bit better thermal camera than my seek's but none of that will happen, my time is too scarce these days, kid starting the school in september, the little bit of free time I had is just gone.. so all I can do is share those ideas I got after some short time of testing those. I'm expecting one original mosquito to arrive in next few weeks from 'murica so at least I'll have access to one original that works (omni has one on his printer and while it works awesomely some of the issues I seen on a clone exist there too!!! the black alu "frame" gets hot enough, even trough those 4 tiny tubes and 2 tiny screws, that 2 screws that attaches it to the PETG part melt the plastic and whole things falls out so omni had to add a steel plate between mosquito and petg and now it's awesome as mosquito is screwed in to steel plate and not in to the petg) and I'l have at home one original + one clone so I can mix & match parts to see what does and what does not influence quality of printing as for e.g. I'm pretty sure that the "heatblock" (60$ piece of coated copper ?!?!?!) is not a crucial part ... Anyhow, I'll do this mix & match maybe if I get time, 150$ for original is not "too much more expensive" than PRC stuff that makes all the research feasible .. if I'm doing it it would be 'cause I'm interested in how/why original works better than PRC stuff and sice I'm not really in the habit of helping PRC cloners probably I'll keep the results for myself... but we'll see, if I get to any results at all

They also tell me that they have printed PLA for many hundreds of hours using that configuration providing the filament was always moving forward.

Heard that story from them too (I think they wrote even on this forum but I seen it in other places) but that does not coincide with my experience with original device :(. It depends really on what do they consider "always moving forward"

.. even the mellow crazy PoS works if you are pushing filament non stop trough it, but you have to stop to move to another section of the print, or you have to slow down for a segment, or even retract... the second you slow down/stop the PLA gets stuck ... not in the first 20min of printing but.. and that's with original purchased directly from them, not even trough reseller (this one is now arriving from filastruder, I hope it's original

.. even the mellow crazy PoS works if you are pushing filament non stop trough it, but you have to stop to move to another section of the print, or you have to slow down for a segment, or even retract... the second you slow down/stop the PLA gets stuck ... not in the first 20min of printing but.. and that's with original purchased directly from them, not even trough reseller (this one is now arriving from filastruder, I hope it's original  )

)The issue with all metal hot ends and PLA, is that no matter how efficient the heat break is, some heat will conduct through the filament itself. That is the reason why the copper heat sink was added to the tube.

Dunno if you remember some 7-9 years ago a Hungarian guy Laszlo (nickname everywhere was "arcol") invested hefty sum in making a new & better hotend.. in first year some 20,000eur cache were spent on prototypes + all the time & energy ... I was close with him at the time landing a hand as much as I could (going to Budapest every month or two too). His first upgrade of existing hotends at the time (most common high end was makergear hotend, and "common" one was j-head e3d did not exist yet) was making a break between melt zone and the rest of the hotend out of PEEK. After bunch of "user error" mistakes where the heat chamber would just slide of a molten PEEK heatbreak he decided to use the steel heatbreak. The best his machinist could do was 0.1mm wall steel heatbreak (that you would have to be very carefull screwing on as you could easily crumlpe it even by hand).. That was the first hotend of that type using thin steel tube as a way to prevent heat creep. What he found next was that 2 major paths for the heat to creep up were

- trough filament

- trough heater wires

the wires thing he solved easily, but the filament thing was unsolvable, you just had to move the filament forward non stop and no problems would occur...

When E3D pushed their first hotend to me it looked like a ripoff of arcol's hotend modified for mass production.

This was the last version of his heatbreak (year 2012)

https://web.archive.org/web/20121107001851/http://shop.arcol.hu/item/arcol-hu-ss

Now, this is of course all working with 3mm filament that's waaaaaaaaaaaaay harder to deal with (both higher pressure required to extrude and more volume for heat to creep up) but 1.75 filament was not a thing in 2012

Back on the subject, if arcol's "neighbor machinist" could do .1mm wall on the 50yo manual lathe...

p.s. some interesting history on wayback machine - arcol's blog: https://web.archive.org/web/20180224170604/http://blog.arcol.hu/

-

Does the Dragon has a recommended fan mount as the E3D one does? In all the ads pictures I saw there was no fan.

BTW, it looks like a crossbreed between the E3D V6 and the Mosquito. For me, using a standard V6 block and nozzle is an advantage.

-

@arhi This is getting off topic I know, but I'm beginning to think that an all metal mixing hot end just isn't possible. My latest design iteration will confirm that (if I've managed to cure all the leaks). The reason why I'm beginning to believe that is because when one has multiple inputs, inevitably some of those filaments will not be moving forward at all for maybe hours. Regardless of how efficient the heat break is, it is inevitable that the filament itself will conduct some heat. Maybe a periodic purge of the "unused" filaments might help. Or maybe I restrict myself to never printing PLA. Or maybe I try and make my own custom heat breaks with PTFE liners and only print low temperature filaments. Dunno - we'll have to see.....

BTW, I hope you don't mind my pointing this out but I know that English isn't your first language. You are using the word "trough" when I think you mean "through". A "trough" is a long narrow open container, often for animals to eat or drink from. So "heat creep trough filament" doesn't make much sense, whereas "heat creep through filament" makes perfect sense.

Hope you don't mind me pointing that out but if you'd rather I didn't, just say so.

Hope you don't mind me pointing that out but if you'd rather I didn't, just say so. -

@deckingman said in What do you think about Dragon Hotend:

@arhi This is getting off topic I know

Maybe @Phaedrux can rip the off-topic part of our discussion into a new topic about all metal hotends - pros/cons/history/ideas... might be useful discussion

but I'm beginning to think that an all metal mixing hot end just isn't possible. My latest design iteration will confirm that (if I've managed to cure all the leaks). The reason why I'm beginning to believe that is because when one has multiple inputs, inevitably some of those filaments will not be moving forward at all for maybe hours.

That is the reason I never wanted to use all those "two nozzles single heater" nor "two input single nozzle" solutions popping up since day one. The major reason is that I'd be going either "main+support" or "hard+soft" combo of materials so 99% of the time only one will be printed while the other material will 99% of the time sit still and cook... not to mention when they require different temps (like TPU/PVA + ABS/PETG/HIPS/ASA combo). That is also why I never seriously looked at the diamond as the "color" aspect is fairly irrelevant for what I print (if it needs color it will be post-processed).

Regardless of how efficient the heat break is, it is inevitable that the filament itself will conduct some heat. Maybe a periodic purge of the "unused" filaments might help.

IMHO the "purge" should work. In theory, you could measure how much heat would creep up in set amount of time so you can know exactly how much you need to purge at what interval. Question is only how to actually do it as this is something a firmware would have to support as you have no idea in G-Code what amount of time passed. Some half-way solution, of course, would be to do it from g-code and purge "more than required" and "more often than required" but should work IMHO.

I think there are 2 problems there

- cooking of the filament

- heat creep leading to filament swelling and blocking of the filament path

I am confident that some fancy machining could solve the heat creep by introducing the water cooling of the cold side of the melt chamber. I did some tests with arcol back in the day and steel is pretty resilient to being cold and hot on a very short distance, the downside is a requirement of a more powerful heater and more energy waste keeping the few mm's of a steel tube at 200C temp differential. We were even trying to find a company willing to make us a Peltier element with a 3.2mm hole that we would cement the tube trough (as just drilling a Peltier plate just kills the darn thing, we tried

).

).The bigger issue is the cooking of the filament as a most filament (especially ABS in my experience) will change properties if it stay on the extrusion temperature long enough. Many will start to carbonize, others will decompose; ABS will for e.g. go dark, start to harden (maybe crystalize?) and some oily thing (super flammable) will start to separate.

The only thing I can see the "cooking" problem being solved on a "single heater" hotend would be to purge the filament from time to time, and since purging also solves the heat creep...

Or maybe I try and make my own custom heat breaks with PTFE liners and only print low-temperature filaments.

You still get the "cooking" issue. I don't have enough experience with PLA (I don't think PLA reached even 1% of the filament I printed), maybe it does not suffer from that too much but it's still a problem.

As for low temp vs high temp, looking through history, all the fancy all metal hotends have some kind of issue with low temp filaments, OTOH the hotends that play nice with those low temp materials will be terrible at the high temp ones. IMHO the only real solution is to have a "head per material" setup.

This is something I do since day one.. on my rapman I had 4 complete extruder assemblies one for PP and HDPE, one for ABS with .5mm nozzle and one for ABS with .25mm nozzle.. for e.g. for my I3 style printer I made a modular X carriage so I can easily swap the head (single screw)

https://www.thingiverse.com/thing:2039960

and there I have a PTFE lined hotend (some old design of mine) for PLA, again my design for 3mm filament with 1mm nozzle for PP/HDPE, some all metal 3mm with bmg, all metal 1.75mm with remote direct drive, dual hexagon full metal with dual remote direct drive etc etc..I have sitting in pieces the e3d's toolchanger (no time to assemble) that I hope will be the final solution... we'll see, in the meantime I'm looking to buy some el-cheapo UV printer so I can design and print a proper connector with pogo pins or something similar that I would like to use for the extruder assembly...

BTW, I hope you don't mind my pointing this out but I know that English isn't your first language.

After the political BS that happened here during 90's and creation of new nationalities and new languages English is now my 6th or 7th language

Real problem is that I never actually "learned" English, never took courses etc. I spent 8 years learning German in school (and apart of being able to read technical documentation I can't speak nor understand a word of it)... so while I do use it non stop I know I'm far from good at it (you should hear me speak, sounds like a comic exaggerating how a Russian criminal sounds like

but I manage to get point across so I don't care much

but I manage to get point across so I don't care much  )

)You are using the word "trough" when I think you mean "through".

Yeah, I am mixing those two often and spell checker does not catch it as "trough" is also a valid word :(. Thanks for the reminder I'll try to pay attention more :), I do appreciate any comment that helps me improve

-

@arhi PLA doesn't "cook" but what it does do is hydrolyse. That is to say, the longer it is held at print temperature, the less viscous (more "runny") it becomes. So if it's sat at print temperature for an hour or more, when you do try to extrude some, the entire contents of the melt chamber comes out of the nozzle in one single runny stream. Then you get nothing until fresh filament fills up the melt chamber again. At least, that is what happens with the Diamond. So I'm kind of used to purging "unused" filaments.

I've never had any problems with PET-G. Even after being held at print temperature for 8 hours or so.

The Diamond suffers from heat creep - the 5 colour is much worse than the 3 colour due to the lower heat sink fins being reduced in diameter. But, they use E3D "lite" style heat breaks which have the PTFE Bowden tube going right through the heat break. So although the filament swells due to heat creep, it doesn't block the heat break. Of course, the PTFE liner limits the temperatures and therefore filament types that can be used.

I haven't connected my RPI yet but I'm told that it would be possible to do "time based" purging using the SBC (something to do with a python program using the API).

-

@deckingman said in What do you think about Dragon Hotend:

@arhi PLA doesn't "cook" but what it does do is hydrolyse. That is to say, the longer it is held at print temperature, the less viscous (more "runny") it becomes.

Good to know, it's much easier to handle "empty" than "charred" nozzle :). I had nozzles that I had to redrill with a larger drill as it was impossible to clean up carbonised ABS.

I haven't connected my RPI yet but I'm told that it would be possible to do "time based" purging using the SBC (something to do with a python program using the API).

I'm waiting for that to become "a thing", especially the support for duet2+sbc before I invest some time to see what can be actually done with it. Slowly going trough Danal's work on the library and thinking about redoing (in go most probably, 'cause I need a reason to become more proficient in go) his library and porting the plugins I'm used to on octoprint to this new platform.. but for now I'm just patiently waiting to see where it all leads as for now I don't see a reason to go duet3 way and my bunch of duet2 boards so far don't know how to communicate with SBC.

-

@arhi said in What do you think about Dragon Hotend:

@deckingman said in What do you think about Dragon Hotend:

@arhi This is getting off topic I know

Maybe @Phaedrux can rip the off-topic part of our discussion into a new topic about all metal hotends - pros/cons/history/ideas... might be useful discussion

Yes. There's an awful lot of people who are still building things like that dragon hotend, and have clearly never seen the early dev work done by NopHead.

And the dragon hotend?

Will suck with PLA. Heatsink is waaaaay too small.

It actually looks like the hotend Prusa was waving around about 7 or 8 years ago that he never got to work.but I'm beginning to think that an all metal mixing hot end just isn't possible. My latest design iteration will confirm that (if I've managed to cure all the leaks). The reason why I'm beginning to believe that is because when one has multiple inputs, inevitably some of those filaments will not be moving forward at all for maybe hours.

That is the reason I never wanted to use all those "two nozzles single heater" nor "two input single nozzle" solutions popping up since day one. The major reason is that I'd be going either "main+support" or "hard+soft" combo of materials so 99% of the time only one will be printed while the other material will 99% of the time sit still and cook... not to mention when they require different temps (like TPU/PVA + ABS/PETG/HIPS/ASA combo). That is also why I never seriously looked at the diamond as the "color" aspect is fairly irrelevant for what I print (if it needs color it will be post-processed).

Regardless of how efficient the heat break is, it is inevitable that the filament itself will conduct some heat. Maybe a periodic purge of the "unused" filaments might help.

Based on the work I've done, thermal creep isn't the main issue. At least not if your heatsinks are large enough. But all the other things are problems.

IMHO the "purge" should work. In theory, you could measure how much heat would creep up in set amount of time so you can know exactly how much you need to purge at what interval. Question is only how to actually do it as this is something a firmware would have to support as you have no idea in G-Code what amount of time passed. Some half-way solution, of course, would be to do it from g-code and purge "more than required" and "more often than required" but should work IMHO.

Snip!

Or maybe I try and make my own custom heat breaks with PTFE liners and only print low-temperature filaments.

This is where I stopped my work. Basically, in all-metal hotends you need to have some clearance around the filament to allow for thermal expansion. PTFE is soft and slippery enough that you can have a tight seal. If you don't have that seal, molten material gets pushed up into the thermal break far enough it causes issues.

Add the fact that my design requirement was to be able to print TPU and PETG in the same part. The TPU compresses and gets pushed back into the thermal break. Not good. Gave up.

I did think about things like silicone seals at the base of the thermal break. But frankly I think mixing heads are just a bad solution and need far too much complexity to be worth it. So long as you can index the nozzles accurately between 2 or more extruders, there's no real advantage to mixing heads (unless you really are going to mix).

At the end of the day you have a printhead that requires two (or more) filaments to even function at all. I don't think mixing heads have a large enough market to be worth the trouble.Although now I'm nostalgic for a 'mixing' head I saw several years ago at the NY maker faire... he wanted to run about 12 filaments, and liquids and god knows what else. I'm fairly certain that never worked.

You still get the "cooking" issue. I don't have enough experience with PLA (I don't think PLA reached even 1% of the filament I printed), maybe it does not suffer from that too much but it's still a problem.

As for low temp vs high temp, looking through history, all the fancy all metal hotends have some kind of issue with low temp filaments, OTOH the hotends that play nice with those low temp materials will be terrible at the high temp ones. IMHO the only real solution is to have a "head per material" setup.

What do you consider a 'low temp' or 'high temp' material? There has been at least 1 extruder on the market that (if fitted with a better sensor) could print in ULTEM or PEEK, was also very good with PLA, maybe the best with TPU. It couldn't print wax to save its life...

This is something I do since day one.. on my rapman I had 4 complete extruder assemblies one for PP and HDPE, one for ABS with .5mm nozzle and one for ABS with .25mm nozzle.. for e.g. for my I3 style printer I made a modular X carriage so I can easily swap the head (single screw)

https://www.thingiverse.com/thing:2039960

and there I have a PTFE lined hotend (some old design of mine) for PLA, again my design for 3mm filament with 1mm nozzle for PP/HDPE, some all metal 3mm with bmg, all metal 1.75mm with remote direct drive, dual hexagon full metal with dual remote direct drive etc etc..I have sitting in pieces the e3d's toolchanger (no time to assemble) that I hope will be the final solution... we'll see,

I'm not convinced that the e3d design is the way to go (a magnet is all that stops the head from falling off? Really? So no high-speed printing then.) but its an early attempt and sold as an experiment.

But the concept, tool changers, is absolutely the way to go. We are lucky that RRF and duet 3 makes that a practical option now.

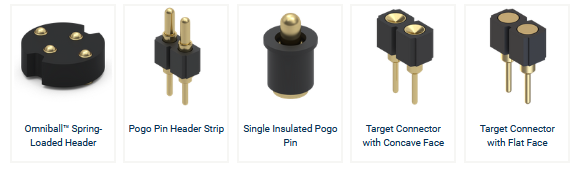

If you really want to go crazy, you can even add a Palette to such a machine. 4 colour head for PLA, plus more heads for other stuff.in the meantime I'm looking to buy some el-cheapo UV printer so I can design and print a proper connector with pogo pins or something similar that I would like to use for the extruder assembly...

Why print something that already exists?

(Yes, I get the irony of saying that here, of all places)

-

@arhi said in What do you think about Dragon Hotend:

..................Slowly going trough Danal's work .............................

You did it again...

I have an RPI - it's bolted to the printer but that's as far as I've got with it.

To clean carbonised or blocked nozzles and stainless steel heat breaks, I wouldn't for one minute suggest that you should try putting them in an oven which has a pyrolytic cleaning cycle. Because that cycle typically reaches about 500 to 600 deg C which will burn away any plastic and leave nothing more than some loose ash which is easily removed with soft brush. It won't damage stainless steel, brass, or copper but it's too close to the melting point of aluminium so don't try it with a complete hot end. Of course you should never try this in any case because burning off plastic could release toxic fumes. That's why I wouldn't ever suggest you try it. But hypothetically speaking, if you take precautions about ventilation and so forth, it does work.

-

@theruttmeister said in What do you think about Dragon Hotend:

Will suck with PLA. Heatsink is waaaaay too small.

The heat sink is similar in size to the Mosquito and the M works fine.

Why do you think the Dragon would be different?

Thanks.

Frederick

-

@theruttmeister said in What do you think about Dragon Hotend:

Yes. There's an awful lot of people who are still building things like that dragon hotend, and have clearly never seen the early dev work done by NopHead.

Yup, all the work NopHead and Arcol did shows many of this things are going in the wrong direction. Most of Nop's stuff is still available, Arcol killed his blog and the few forums he was active as are dead and non existing now. For some reason he was never accepted on reprap.org as his idea was always to make the commercial and not open design and the community really disliked that. Nop's work was also not that popular due to him keeping lot of details about his machine for himself (he was running combo of python on stronger computer with stepper on mcu 10+ years ago) as noone could reproduce his awesome results and while his posts were always super informative and full of real engineering and real math ppl kinda like YT flashy stuff and not something with substance

It actually looks like the hotend Prusa was waving around about 7 or 8 years ago that he never got to work.

I remember that one and was actually trying to find the video and pics but could not. It was before Prusa Research while he was still just a Czech student. If you find some links share

there's no real advantage to mixing heads (unless you really are going to mix).

That's the think @deckingman is trying to do, he's trying to make a new hotend that will actually mix the filament as diamond is not mixing them (you can read his text about "toothpaste effect")

What do you consider a 'low temp' or 'high temp' material? There has been at least 1 extruder on the market that (if fitted with a better sensor) could print in ULTEM or PEEK, was also very good with PLA, maybe the best with TPU. It couldn't print wax to save its life...

which one?

ATTM I tested mosquito and it prints both PEEK and PLA

E3DV6 I used to print wax filament made by Kai. Never tried anything hotter than nylon on E3DV6.

I'm not convinced that the e3d design is the way to go (a magnet is all that stops the head from falling off? Really? So no high-speed printing then.) but its an early attempt and sold as an experiment.

I did not make my toolchanger design in 10+ years I'm in 3D printing and I was thinking about it since day one. No clue if it was lack of time, knowledge, ideas... but I never did it. That's why I purchased this one to use for a while and learn from all the bad decisions they made (and acknowledge good ones), before I decide how to proceed.

Why print something that already exists?

I looked trough I think 500 different connectors and was not satisfied with what I found. I'll go trough this site too. I prefer to purchase a working solution than to invent hot water

but so far nothing I found was fitting my vision

but so far nothing I found was fitting my vision -

@deckingman said in What do you think about Dragon Hotend:

You did it again...

I have an RPI - it's bolted to the printer but that's as far as I've got with it.

I mostly use orangepi's as they were more powerful and cheaper/easier to get here but I have bunch of rpi's too. We (oracle-mysql) started supporting arm cpu recently so I have whole bunch of them for testing

.. I have them in raid, solo.. some I use with 3d printers with octoprint... I took one rpi4 on the side to try this RRF integration .. that's where I run duetlapse

.. I have them in raid, solo.. some I use with 3d printers with octoprint... I took one rpi4 on the side to try this RRF integration .. that's where I run duetlapseTo clean carbonised or blocked nozzles and stainless steel heat breaks, I wouldn't for one minute suggest that you should try putting them in an oven which has a pyrolytic cleaning cycle. Because that cycle typically reaches about 500 to 600 deg C which will burn away any plastic and leave nothing more than some loose ash which is easily removed with soft brush. It won't damage stainless steel, brass, or copper but it's too close to the melting point of aluminium so don't try it with a complete hot end. Of course you should never try this in any case because burning off plastic could release toxic fumes. That's why I wouldn't ever suggest you try it. But hypothetically speaking, if you take precautions about ventilation and so forth, it does work.

Interesting. I assumed that once carbonized exposing it to even more heat would not help but only worsen the situation so I always used mechanical way of cleaning. Normally I'd leave it in acetone for few days, then move the acetone container with nozzle to the ultrasonic cleaner than remove from acetone and put directly in to ultrasonic bath with some cleaning detergent heated to 70C and after that - mechanical cleaning.

-

@fcwilt said in What do you think about Dragon Hotend:

@theruttmeister said in What do you think about Dragon Hotend:

Will suck with PLA. Heatsink is waaaaay too small.

The heat sink is similar in size to the Mosquito and the M works fine.

Why do you think the Dragon would be different?

Thanks.

Frederick

I dunno, I've not done testing on either of them. But given the mass and surface area of the heatsink, plus the lack of any information on how the stainless tube is attached to the copper (if its not a press fit, that's a problem). I would expect it to be sub-optimal.

But then I disagree with the design choices made on the mosquito as well.Simply saying a hotend 'works' isn't much of a measure. If I actually got off my behind and made the testing rig I designed ages ago I would measure force required for a given extrusion rate, which is the type of metric that would allow us to actually measure if a given hotend design is better or worse than any other. But I haven't, so I shouldn't complain too much.

But my hypothesis is that both of those hotends would require less force to extrude if they were fitted with larger heatsinks. -

@deckingman said in What do you think about Dragon Hotend:

To clean carbonised or blocked nozzles and stainless steel heat breaks, I wouldn't for one minute suggest that you should try putting them in an oven which has a pyrolytic cleaning cycle. Because that cycle typically reaches about 500 to 600 deg C which will burn away any plastic and leave nothing more than some loose ash which is easily removed with soft brush. It won't damage stainless steel, brass, or copper but it's too close to the melting point of aluminium so don't try it with a complete hot end. Of course you should never try this in any case because burning off plastic could release toxic fumes. That's why I wouldn't ever suggest you try it. But hypothetically speaking, if you take precautions about ventilation and so forth, it does work.

Rather than heating up a big oven, a plumbers propane torch does wonders for cleaning nozzles... and it's very quick!

More importantly, it doesn't get SWMBO wound up. -

@arhi said in What do you think about Dragon Hotend:

That's the think @deckingman is trying to do, he's trying to make a new hotend that will actually mix the filament as diamond is not mixing them (you can read his text about "toothpaste effect")

Static mixing or active? Because sealing an active mixer is a challenge.

What do you consider a 'low temp' or 'high temp' material? There has been at least 1 extruder on the market that (if fitted with a better sensor) could print in ULTEM or PEEK, was also very good with PLA, maybe the best with TPU. It couldn't print wax to save its life...

which one?

Type A Machines G2. Not that you can do anything useful with ULTEM or PEEK without an oven to print inside... Plus you can't buy that extruder any more.

Why print something that already exists?

I looked trough I think 500 different connectors and was not satisfied with what I found. I'll go trough this site too. I prefer to purchase a working solution than to invent hot water

but so far nothing I found was fitting my vision

but so far nothing I found was fitting my visionI know the feeling. But just used some of the mill-max SLC components on a project. If I try and build a tool changer with electrical connections, I'll use something from them.

-

@theruttmeister said in What do you think about Dragon Hotend:

Static mixing or active? Because sealing an active mixer is a challenge.

static mixing using "weird paths" like those multi-component mixer attachments on the industry syringes ..

https://somei3deas.wordpress.com/2020/02/24/my-6-input-51-mixing-hot-end-version-2/

there are 9 parts of that, I find it super interesting

I know the feeling. But just used some of the mill-max SLC components on a project. If I try and build a tool changer with electrical connections, I'll use something from them.

I just went trough the site, they have the pogo pin modules I was planing to use but they don't have a "connectors" with guides, locks etc etc.. I did not plan to use just blank pins and house them in my case (if I don't have to :D) but to pack bunch of stuff like this into a mating pair:

-

I think the closest are these

https://www.mill-max.com/products/new/rugged-spring-loaded-wire-termination-connectorsBut no, not an actual connector. But if you are building a tool changer you don't need a connector, you need to design the electrical connections into the tool mount.

A simple PCB, that carries SLC's and breaks them out into maybe Molex KK connectors, and locates accurately on a machined aluminium mount that holds the printhead. With a matching PCB and mount on the printer...That's how I

didwould do it.

You could also just use the ones I linked to and bolt them in position.

Although if you are only going to use 2 tools, and don't need to be able to swap out the heads super fast, just regular connectors would work.

-

@theruttmeister said in What do you think about Dragon Hotend:

I dunno, I've not done testing on either of them.

Perhaps you should. I tried one M and was so impressed that I equipped my other printer with one.

I like everything about the M. If it has a downside I have not found it yet.

Time will tell.

Frederick