spoolholder some ooooold pictures

-

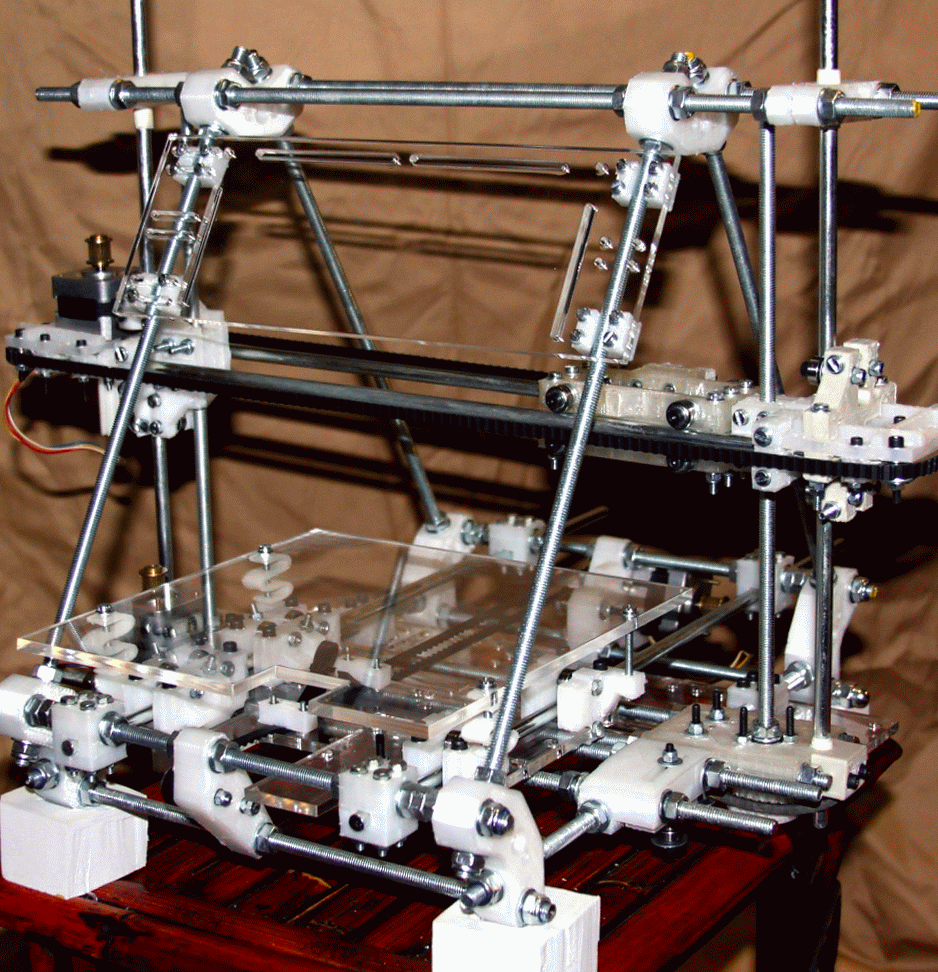

I mentioned some "2 degrees of freedom" spool holder I was using a while back with some snappy filament (natural PLA 3mm from BfB was brittle as glass) and I found some image of the thing so here it is

This allows for much more brittle filament to unspool properly and not snap that often compared to standard 1 degrees of freedom spools we all use nowadays. It is especially important with extruders that use drive gear that also rotates the filament. This will happen if you have drive gear cut with an M3/M4 thread so they are not straight but under slight angle, they will slowly rotate the filament and brittle ones will snap, this spool holder allow the whole spool to rotate and counter this rotation of the extruder.

This allows for much more brittle filament to unspool properly and not snap that often compared to standard 1 degrees of freedom spools we all use nowadays. It is especially important with extruders that use drive gear that also rotates the filament. This will happen if you have drive gear cut with an M3/M4 thread so they are not straight but under slight angle, they will slowly rotate the filament and brittle ones will snap, this spool holder allow the whole spool to rotate and counter this rotation of the extruder.https://elco.crsndoo.com/rapman/IMG_1379.jpg

top piece is designed by nophead for his sky hook filament holder:

https://www.thingiverse.com/thing:85Only instead of a plastic hook I'm using M8 stud. The 608 bearing inside the hook mount allows for the contraption to rotate around Z axis..

Not a very useful design nowadays as filaments are not as brittle any more and extruders use cnc-cut gears that are not rotating filament, but still, maybe interesting piece of history.

p.s.

bunch of these old pics there: https://elco.crsndoo.com/rapman/

e.g. who remembers these old BfB design nozzles https://elco.crsndoo.com/rapman/img_1141.jpg with silicone insulation

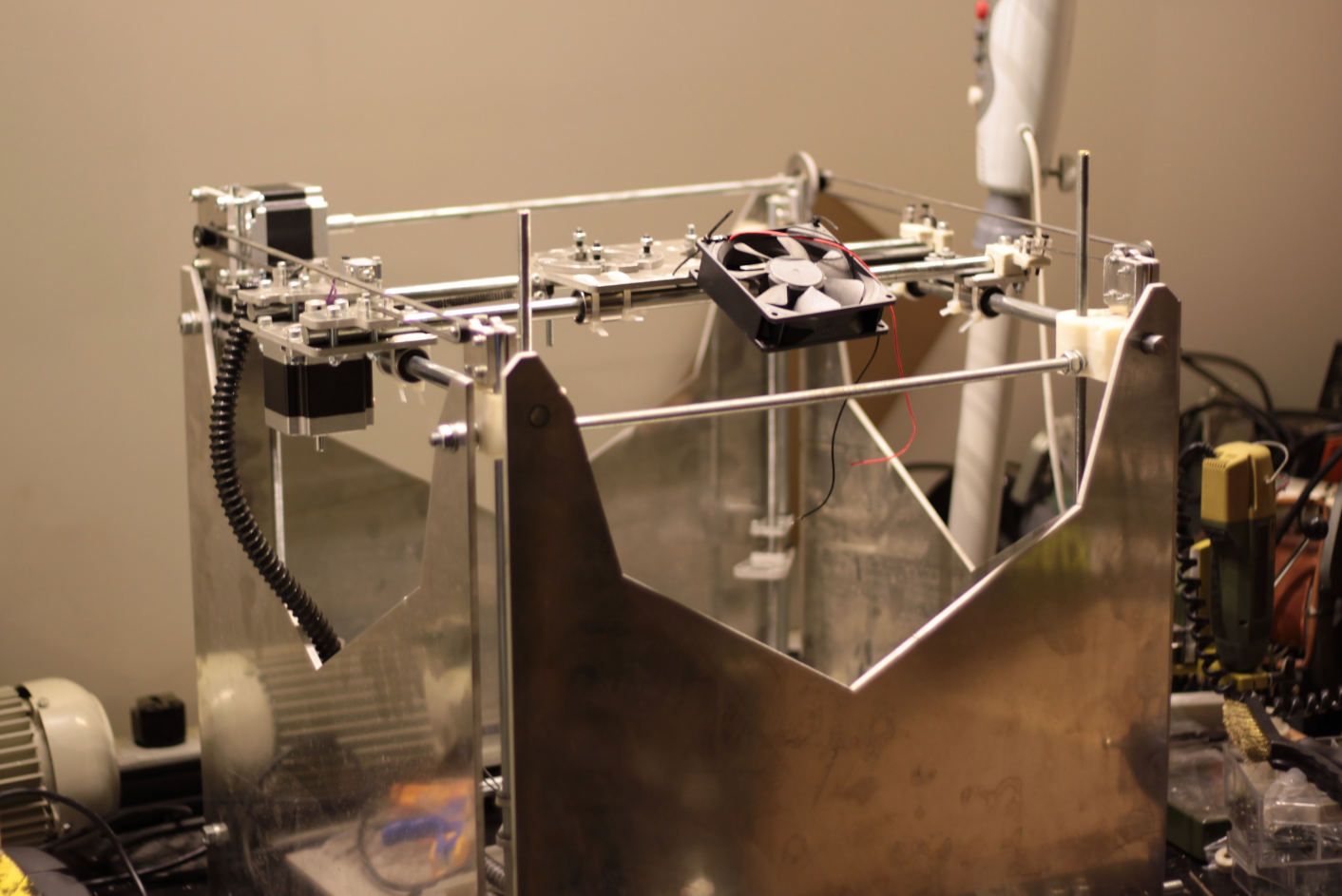

or original Edd's Mendel design before Prusa simplified it ... this one is running in Belgrade hacklab for nine years (actually, I gave it to them 9 years ago, it's running approx 8 years, it took them a year to gather all the electronics and to turn it on as I gave them belts and motors but not the stepper drivers and controller, expected hacklab to do part of the build themselves

(actually, I gave it to them 9 years ago, it's running approx 8 years, it took them a year to gather all the electronics and to turn it on as I gave them belts and motors but not the stepper drivers and controller, expected hacklab to do part of the build themselves  What's interesting for this Mendel is that except for X-carriage that was PLA, everything else was made out of polypropilene ) :

What's interesting for this Mendel is that except for X-carriage that was PLA, everything else was made out of polypropilene ) :

https://elco.crsndoo.com/rapman/img_1252-MOTION.gif -

Monkeys bashing rocks together. How far we've come.

-

@Phaedrux said in spoolholder some ooooold pictures:

Monkeys bashing rocks together. How far we've come.

Crazy, looking at these old photos, remembering old designs... craaaaazy!!!

I lost contact with Enrique (creator of Skeinforge) dunno what's he doing these days. I think most advances happened there, in the slicing software. Cura and that bfb gui for skeinforge was first to build upon Skeinforge and then others started the work from scratch arriving at a plethora of slicers these days. Second huge improvement I see is in the extruder setup, those old nozzles, hand drilled aluminium rods vs today state of the art vanadium crazyness with polyfobic coating :). Dunno if anyone remembers, the small holes were hard to drill (I used to waste 4-5 nozzles before I can get one .25mm drilled without broken drill left inside) so Vik came with a hammer idea, you drill a .5mm nozzle and then you wack a hotend with a hammer and close up the nozzle to a smaller diameter the hole would not be perfectly round nor you could make it exact to any dimensions but you would get .2 - .35mm easy that way

the hole would not be perfectly round nor you could make it exact to any dimensions but you would get .2 - .35mm easy that way  ... everything else is more less same stuff, only higher quality materials and cheaper parts ..

... everything else is more less same stuff, only higher quality materials and cheaper parts ..This is bringing memories

.. 2 big players today started with rapman 3.1

.. 2 big players today started with rapman 3.1  Josef Prusa started his jurney with rapman 3.1 that he used to print first Ed's Mendel and produced the "Prusa Mendel" that's grandfather of currently famous Prusa mk3. Erick also started with rapman, tried to rewrite firmware for that pic32mx, replaced the shoddy acrylic frame with plywood and the 4 screws with high quality leadscrew and pushed out the first ultimaker

Josef Prusa started his jurney with rapman 3.1 that he used to print first Ed's Mendel and produced the "Prusa Mendel" that's grandfather of currently famous Prusa mk3. Erick also started with rapman, tried to rewrite firmware for that pic32mx, replaced the shoddy acrylic frame with plywood and the 4 screws with high quality leadscrew and pushed out the first ultimaker  ..

.. -

Hard to believe that this was designed in the 21st century

/var/folders/dt/1t1sf6d574d3l023pknh_754000cbj/T/com.apple.Preview/com.apple.Preview.PasteboardItems/img_1252-MOTION-1 (dragged).tiff

/var/folders/dt/1t1sf6d574d3l023pknh_754000cbj/T/com.apple.Preview/com.apple.Preview.PasteboardItems/img_1252-MOTION-1 (dragged).tiff -

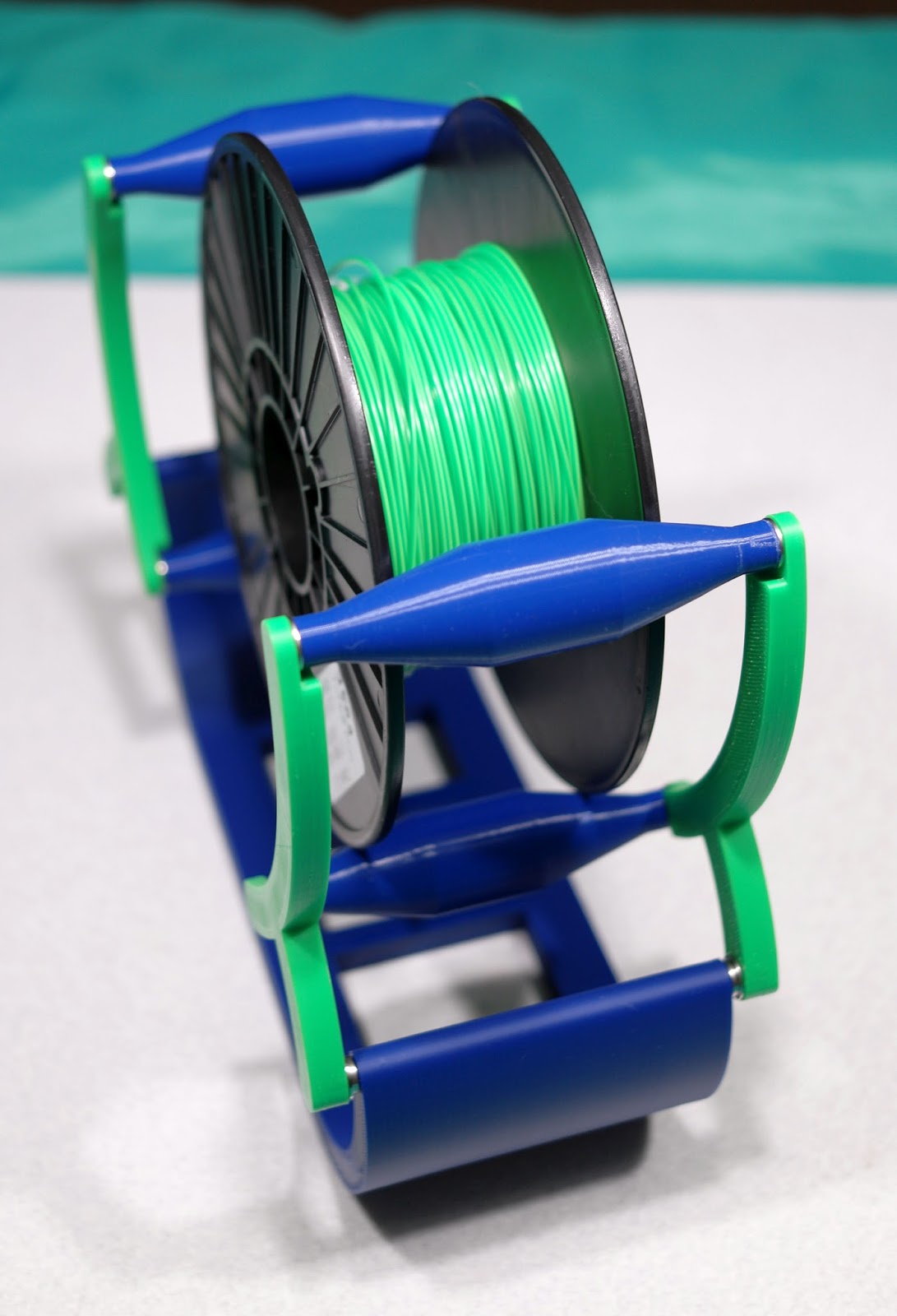

Here's two of mine- the first one has 12 bearings harvested from old HDDs. The weight of the spool keeps the rollers pressed against the spool flanges:

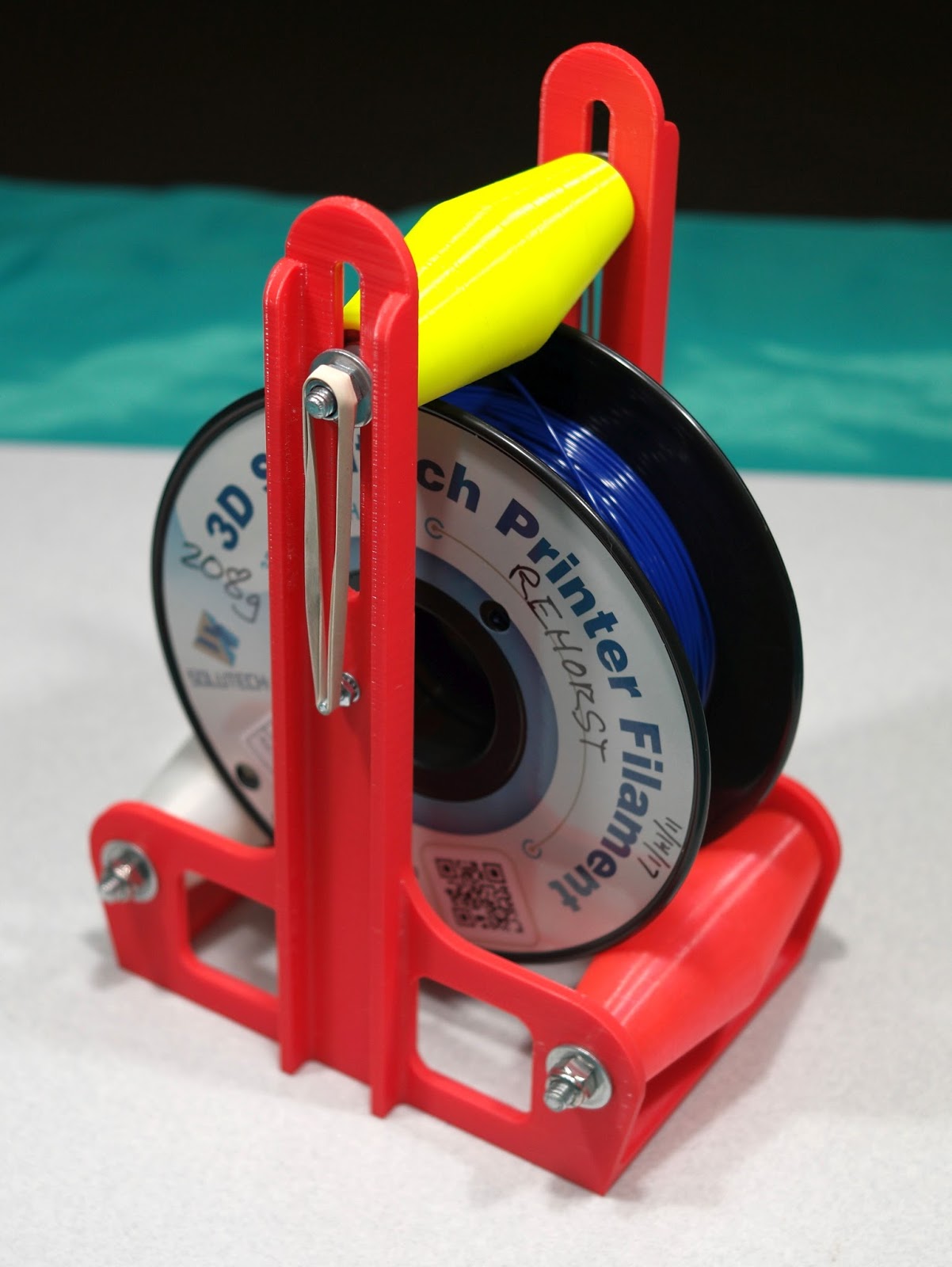

And another, this one using F608 bearings in the rollers. It works with any size spools up to 5 lb size:

We have another one of those on a printer at the makerspace. Someone turned the top roller from steel so no rubber bands are used to keep it pressed on the spool.

-

@zapta well it was easier to print and assemble than Darwin, had fewer issues than darwin, bit smaller print size but still was capable of printing 100% of its plastic parts. I printed 4 of them and all 4 are still working to this day. I only modified three of them to use belts with 5mm pitch (so larger pulleys as 5mm cannot bend that tight as 2mm can) as that was the only pitch I could buy locally decade ago, and also I modified them to use NEMA23 motors 'cause I had (still do) a whole bunch of salvaged NEMA23 motors.

The only real issue with enders is that we were using non-hardened smooth rods and those 3 bearings riding the rod would flatten it over time. You just tighten everything a bit when it happens and continue using it, it does not affect the print :). With modern hotends and modern slicers those printers produce output measurable to today's printers, they only hw thing you need to upgrade on them is to replace the M8 screws for Z with proper leadscrews :)... Ed Sells did a really god mechanical design there, it a beast of a machine. Mendel90 by NopHead, Prusa by Prusa and many other machines are direct descendants

-

@mrehorstdmd I love that design

-

@zapta this is my "upgrade" of rapman somewhere in 2012, I replaced all the acrylic pieces with HDPE and aluminium, machine was used for both milling and 3D printing. I never made the software that was properly handling printing+milling in the same time but as printer and as mill separately it worked great. It milled all the gears and small parts for itself

.. I was using proxxon rotary tool for milling. Image is from 2014 IIRC when I was taking it apart for cleaning.

.. I was using proxxon rotary tool for milling. Image is from 2014 IIRC when I was taking it apart for cleaning.https://elco.crsndoo.com/rapman/IMG_3555.jpg

p.s. I'm super stoked I found these images sorry if I'm booring anyone, but I tought all these were lost in fire 2014 so super happy I found them

-

I love history lessons!

-

@arhi said in spoolholder some ooooold pictures:

top piece is designed by nophead for his sky hook filament holder:

https://www.thingiverse.com/thing:85Those filament baskets seem to pull from the center of a spool-less filament and create a rotational tension. Reminds me of the various how-to-fold-a-cable videos on youtube. E.g. https://youtu.be/KHwPthJO5bo?t=55

As for the history aspects of home 3D printing, within a few years we progressed from that home made mendel design to this verity of off the shelf and affordable printers https://www.3dprintersonlinestore.com/3d-printers .

-

@zapta well don't forget original reprap project that dr Adrian started was all about self replication, so the idea was to have a printer that can reproduce his parts and with few vitamines you can get in any hardware shop you reproduce it.

The repstraps were always there, I used my cnc with more accuracy than most of today's 3d printers and EMC (linuxCNC these days) and Wade's extruder back in the day but the focus was on the self replication, not necesary quality nor price... dr Adrian was looking at reprap printers as "organism" that mutates and expands. In the meantime offshoots from that project made repstraps available to the public for peanuts, great development and something I was always more interested than the "Self replication" part of the project itself.

I always remember the talk dr Adrian gave about organisms and "success". What's the most successful organism on the Earth? It's CORN!!!