Unsure with Duet (RRF3) & Simplify3D

-

Does anyone with simplify3d have any ideas? How do you have simplify3d setup for heated bed?

My only options in simplify3d are:

Do I need to set G10 P1 in config.g > tools?

Is the output from simplify3d interpreted with my M190 S[bed2_temperature] and M109 S[extruder0_temperature] - so the printer will see the output from simplify3d and use it?

Thank you,

e_p

-

@en_passant said in Unsure with Duet (RRF3) & Simplify3D:

Is the output from simplify3d interpreted with my M190 S[bed2_temperature] and M109 S[extruder0_temperature] - so the printer will see the output from simplify3d and use it?

Yes?

I'm not sure I understand the problem. Is your printer not heating?

What does simplify actually produce for gcode? Those commands should evaluate to actual usable gcode commands and the firmware should respond to them.

What isn't working?

-

@en_passant said in Unsure with Duet (RRF3) & Simplify3D:

Is the output from simplify3d interpreted with my M190 S[bed2_temperature] and M109 S[extruder0_temperature] - so the printer will see the output from simplify3d and use it?

Save the generate gcode from S3D to a file, open the file with a text editor, and search for M190. This is what the duet will see.

(it's S3D job to replace those variables with the actual values before writing the .gcode file)

-

In S3D my heated bed is listed as T0.

In your start script, it should say bed0 temperature I believe, to match T0, but I'm unsure if the T0 actually applies to the bed.

Regardless, FYI, my setup has bed as T0 and start script uses bed0_temperaure.

-

@Phaedrux said in Unsure with Duet (RRF3) & Simplify3D:

@en_passant said in Unsure with Duet (RRF3) & Simplify3D:

Is the output from simplify3d interpreted with my M190 S[bed2_temperature] and M109 S[extruder0_temperature] - so the printer will see the output from simplify3d and use it?

Yes?

I'm not sure I understand the problem. Is your printer not heating?

What does simplify actually produce for gcode? Those commands should evaluate to actual usable gcode commands and the firmware should respond to them.

What isn't working?

I tried running a print of a test cube but I'm getting heater faults:

Warning: Tool 0 was not driven because its heater temperatures were not high enough or it has a heater fault

I have tried changing my starting script but I'm unsure what I should put in M190 and M109 so it correlates with simplify3d.

I have:

T0 ; select tool 0 (hot-end) M190 S[bed0_temperature] ; set bed temperature & wait M109 S[extruder0_temperature] ; set hot-end temp ; change M109 to M104 T0 S[extruder0_temperature]? M116 H1 S2 ; wait: hot-end = S[extruder0_temperature] +/- 2C G1 E10 F500 ; extrude 10mm @ 500mm/min (prime) G1 X5 F10000 ; x 5mm y 0mm [absolute] @ 10000mm/min (wipe start position: x 5 y 0) G1 Z0.10 F1000 ; z 0.10mm [absolute] @ 1000mm/min (bed up to begin wipe) G1 X177.5 E5 F15000 ; x 177.5mm [absolute] & extrude 5mm @ 15000mm/min (max) whilst z = 0.10mm [absolute] (nozzle wipe: extruding while moving) G92 E0 ; set extruder position to 0I changed the script above to M190 S[bed0_temperature] because my config has:

M140 H0 ; bed heater #0 = heater #0 [m950 h0] (implied due to no p (bed heater index) parameter invoked)@bot said in Unsure with Duet (RRF3) & Simplify3D:

In S3D my heated bed is listed as T0.

In your start script, it should say bed0 temperature I believe, to match T0, but I'm unsure if the T0 actually applies to the bed.

Regardless, FYI, my setup has bed as T0 and start script uses bed0_temperaure.

Thanks. Is your hot-end set up as T1? ...T2 etc? Do you have T0 setup as your bed and hot-end setup as T1 in config.g?

@zapta said in Unsure with Duet (RRF3) & Simplify3D:

@en_passant said in Unsure with Duet (RRF3) & Simplify3D:

Is the output from simplify3d interpreted with my M190 S[bed2_temperature] and M109 S[extruder0_temperature] - so the printer will see the output from simplify3d and use it?

Save the generate gcode from S3D to a file, open the file with a text editor, and search for M190. This is what the duet will see.

(it's S3D job to replace those variables with the actual values before writing the .gcode file)

Thanks! I'll try having a look now!

Thanks all!

e_p

-

My hotends are T0 and T1. There seems to be no conflict with the bed being "T" anything. I think this is just S3D being lazy and not making things make sense.

-

Thanks @bot - appreciated.

@bot said in Unsure with Duet (RRF3) & Simplify3D:

My hotends are T0 and T1. There seems to be no conflict with the bed being "T" anything. I think this is just S3D being lazy and not making things make sense.

I just changed my config M563 to P1for hot-end. Then changed the starting (and ending) scripts to use T1 opposed to T0.

I got this:

24/05/2020, 21:26:18 Warning: Tool 1 was not driven because its heater temperatures were not high enough or it has a heater fault 24/05/2020, 21:26:21 Error: Attempting to extrude with no tool selected.My hot-end temp on DWC didn't move from 140 it was at for the part prior in the script... but the bed did move to 55 which is what I set it to for testing so may be making slight progress!

So, in simplify3d you have heated bed = T0 and also have hot-ends as T0 and T1?

I'll move my tools configs back to T0 for hot-end in simplify3d, config and scripts...

Edit: can't change simplify3d to T0 (because heated bed currently T0)

*e_p

-

s3d uses

M140 S100 M190 S100to set bed temperature

T0/1/2/3... irrelevant

only thing important is to have

M140 H0 -

What version of simplify3d are you using?

Once you indicate that the heater controller is a heated bed, it shouldn't prevent you from choosing T0 for bed.

It seems like a starting script or something is selecting T1 for your print. Are you trying to print with a second extruder? It should choose T0 for the print if not.

-

@en_passant, as a side note, S3D is a stale product.

Once you will have this working, you may want to consider one of the free slicers such as PrusaSlicer or Cura which are actively maintained.

-

@zapta said in Unsure with Duet (RRF3) & Simplify3D:

@en_passant, as a side note, S3D is a stale product.

Once you will have this working, you may want to consider one of the free slicers such as PrusaSlicer or Cura which are actively maintained.

Yeah... I was on simplify3d's forums trying to find an answer for this and seen a lot of very unhappy customers! I got an email about a year ago saying there was version 5 being introduced at the end of 2019, that then moved to the beginning of 2020...

But, it's what I've got and would rather get the printer set up using something at least somewhat familiar before venturing off the beaten track...

@bot said in Unsure with Duet (RRF3) & Simplify3D:

What version of simplify3d are you using?

Once you indicate that the heater controller is a heated bed, it shouldn't prevent you from choosing T0 for bed.

It seems like a starting script or something is selecting T1 for your print. Are you trying to print with a second extruder? It should choose T0 for the print if not.

I'm on 4.1.2. I quit and restarted it and I can now select primary extruder = T0 AND heated bed = T0.

My config now has:

M563 P0 D0 H1 S"Nozzle" ; tool 0 [hot end] define G10 P0 S0 R0 ; tool 0 [hot end] operating & standby temps T0 ; select t1 (hot-end)my starting script is:

M104 S0 ; cancel s3d set temp G21 ; work in mm G92 E0 ; reset extruder count M220 S100 ; reset speed multiplier M104 T0 S140 ; set hot-end to 140C M190 R50 ; set bed temp to 50C & wait M104 T0 S175 ; set hot-end to 175C M116 H1 S1 ; wait: hot-end = 175 +/- 1C G1 E-20 F2500 ; e -20mm (retract) @ 2500mm/min M104 T0 S140 ; set hot-end to 140C M116 H1 S2 ; wait: hot-end = 140 +/- 2C G91 ; relative co-ords (from last position not origin) G1 Z5 F1000 H1 ; z 5mm @ 500mm/min (ensure it's below probe trigger height) G1 X-500 Y-500 F3000 H1 ; x & y -500mm [relative] (> max) @3000mm/min - until limit sw. detects G1 X-500 H1 ; x -500mm [relative] (> max) @ 3000mm/min - until limit sw. detects G1 Y-500 H1 ; y -500mm [relative] (> max) @ 3000mm/min - until limit sw. detects G1 X5 Y5 F500 ; x & y 5mm @ 500mm/min G1 X-10 H1 ; x -10mm @ 500mm/min - until limit sw. detects G1 Y-10 H1 ; y -10mm @ 500mm/min - until limit sw. detects G90 ; absolute co-ords (relative to origin) G1 X172.5 Y172.5 F15000 ; x & y 172.5mm [absolute] @ 15000mm/min G1 X177.5 Y177.5 F1000 ; x & y 177.5mm [absolute] (bed-centre) @ 1000mm/min G30 ; raise bed until probe triggered & set z to trigger height G1 Z5 F500 ; z 5mm [absolute] @ 500mm/min (max speed) G91 ; relative co-ords (from last position not origin) G1 X-172.5 Y-172.5 F15000 H1 ; x & y -172.5mm [relative] @ 15000mm/min G1 X-50 Y-50 F1000 H1 ; x & y -50mm [relative] (> max) @1000mm/min - until limit sw. detects G1 X-50 H1 ; x -50mm (> max) @ 1000mm/min - until limit sw. detects G1 Y-50 H1 ; y -50mm (> max) @ 1000mm/min - until limit sw. detects G1 X5 Y5 F500 ; x & y 5mm @ 500mm/min G1 X-10 H1 ; x -10mm @ 500mm/min - until limit sw. detects G1 Y-10 H1 ; y -10mm @ 500mm/min - until limit sw. detects G90 ; absolute co-ords (relative to origin) G1 E20 F2500 ; e 20mm (extrude) @ 2500mm/min (cancel previous retract) T0 ; select tool 0 (hot-end) M190 S[bed0_temperature] ; set bed temperature M109 S[extruder0_temperature] ; set hot-end temp G1 E10 F500 ; extrude 10mm @ 500mm/min (prime) G1 X5 F10000 ; x 5mm y 0mm [absolute] @ 10000mm/min (wipe start position: x 5 y 0) G1 Z0.10 F1000 ; z 0.10mm [absolute] @ 1000mm/min (bed up to begin wipe) G1 X177.5 E5 F15000 ; x 177.5mm [absolute] & extrude 5mm @ 15000mm/min (max) whilst z = 0.10mm [absolute] (nozzle wipe: extruding while moving) G92 E0 ; set extruder position to 0but when I ran a test cube generated with those I get:

24/05/2020, 21:52:59 Warning: Tool 0 was not driven because its heater temperatures were not high enough or it has a heater faultThe heated bed changed over from 50 to 55 just like I want but the hot-end is saying it's not hot enough.

I now think this may be because (as I noticed when I heat the hot-end manually) I cannot extrude until 160. The reason I have 140 is because I have precision piezo and it's advised (and I did notice when I tested) it gets a bit spurious above that when doing G30.

I did also have:

T0 ; select tool 0 (hot-end) M190 S[bed0_temperature] ; set bed temperature M109 S[extruder0_temperature] ; set hot-end temp M116 H1 S2 ; wait: hot-end = [extruder0_temperature] +/- 2Cbut it seems to ignore the wait command?

@arhi said in Unsure with Duet (RRF3) & Simplify3D:

s3d uses

M140 S100 M190 S100to set bed temperature

T0/1/2/3... irrelevant

only thing important is to have

M140 H0Thanks @arhi. And the hot-end? It doesn't seem to pick up my M109 S[extruder0_temperature]...?

e_p

-

For M116 try putting just the tool number with P0 instead of the heater number.

Maybe also try setting temps with G10 and then waiting with M116 instead of both M109 and waiting.

Other than that, I can't spot anything that seems amiss.

-

@bot said in Unsure with Duet (RRF3) & Simplify3D:

For M116 try putting just the tool number with P0 instead of the heater number.

Maybe also try setting temps with G10 and then waiting with M116 instead of both M109 and waiting.

Other than that, I can't spot anything that seems amiss.

Thanks @bot. I appreciate you taking the time to read my config & scripts.

I just tried:

T0 ; select tool 0 (hot-end) M190 S[bed0_temperature] ; set bed temperature M109 S[extruder0_temperature] ; set hot-end temp M116 P0 S2 ; wait: hot-end = [extruder0_temperature] +/- 2Cto no avail. It doesn't even change the active temperature on DWC (though my bed is changing to 55 as I set it to in s3d).

I suspect M109 S[extruder0_temperature] isn't correlating with s3d.

Not sure how to implement G10 - as it mentions that (and appears so) that s3d uses M109?

*e_p

-

Since you can configure the start script with whatever you want, and when you include a temperature variable in the script, S3D suppresses its own M109 command, you can use G10 in the start script with no issues.

-

@en_passant said in Unsure with Duet (RRF3) & Simplify3D:

And the hot-end? It doesn't seem to pick up my M109 S[extruder0_temperature]

s3d generates for me

M140 S100 M190 S100 M104 S255 T0 M109 S255 T0bed 100C, hotend 255C

works as expected -

my suggestion - forget about S3D

execute M-code manually trough DWC and see if it works

if everything works ok (M140, M190, M104 and M109) only then move forward to s3dfor me, I don't have much of code in s3d at all.

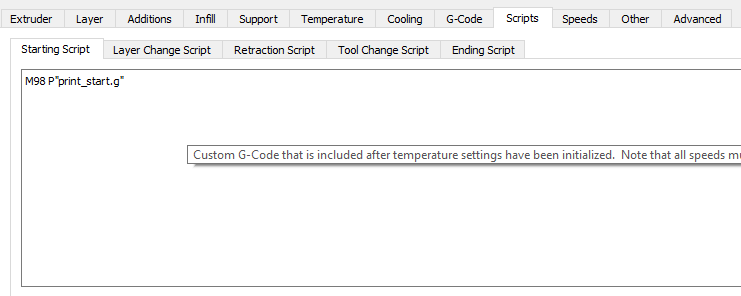

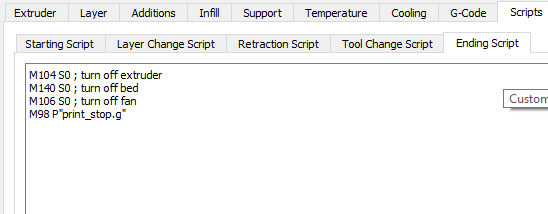

start code:

end code:

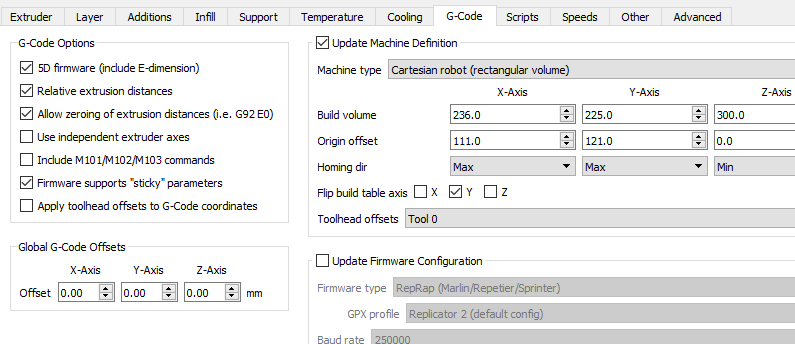

s3d relevant configuration:

print_start.g on the RRF:

; no volumetric extrusion M200 D0 ; relative extruder distance M83 ; do not home if already homed if !move.axes[0].homed || !move.axes[1].homed || !move.axes[2].homed G28 ; do the wipe M98 P"wipe.g" ; use MESH compensation G29S1 ; all currents to 100% M913 X100 Y100 Z100 ; load default jerk, speed and acceleration values M98 P"cfg_jerkspeedaccel.g" ; reset baby steps M290 R0 S0 ; reset speed overrides M221 S100 M220 S100 ; Dynamic Acceleration Adjustment ; M593 Fxxx ; Pressure Advance M572 D0 S0.042and print_stop.g

M104 S0 ; turn off extruder M140 S0 ; turn off bed M106 S0 ; turn off fan M913 X20 Y20 Z25 G91 G0Z10 G90 M913 X100 Y100 Z100 M98 P"wipe.g" -

head of the generated file that works

; G-Code generated by Simplify3D(R) Version 4.1.2 ;... ; configuration dump ;... G90 M83 M106 S0 M140 S85 M190 S85 M104 S240 T0 M109 S240 T0 M98 P"print_start.g" ; process Process1 ; layer 1, Z = 0.500 ;M118P0S"MESSAGE: TOOL CHANGE" T0 G1 E-0.1000 F3000 ;M118P0S"MESSAGE: LAYER CHANGE" ; feature skirt ; tool H0.500 W0.648 G1 Z0.500 F600 G1 X-4.272 Y11.571 F12000 G1 E0.1000 F3000 G1 X-4.278 Y-31.610 E5.1186 F360