Delta proper endstop upgrade - advice welcome

-

@jmshep I fully agree these not inexpensive, but I feel their ease of mounting and integrated physical stopper design go a fair way of making up for that. I glanced at what it would cost to have the endstop bracket that I have been using CNC machined. All of a sudden the €30 becomes quite cheap actually. While I admit that the bracket was not optimized for metal machining, for under 30 a piece you do not get much commercial machining done.

I am not sure whether I agree that they are over the top. To me it seems that a repeatable max height reference (which the endstops ofc provide) is a vital part to be able have an accurate coordinate system. The other vital part, especially for delta's, is the Z-probe. The 3D print community has gone to great lengths to improve Z-probe design and accuracy. It seems that this effort goes to waist if the endstops are not repeatable, as the total repeatability of the system is a function of both the endstops and Z-probe repeatability.

Now I do not say micro switches cannot be repeatable, not at all. The issue is, while the ones I currently have are of OMRON make, they are not specced for repeatability. Which leaves me with an unknown factor here.

-

@Nxt-1 Try other avenues first but if you get really stuck - PM me. I just went to Misumi site and picked a part number at more or less random and added it my shopping cart, then got as far as a "Place order" button. So it seems that my account is still valid.

But be aware of 2 things that Misumi are saying - copy and paste from their site ....

"Important notice: Due to COVID-19 our costs for importing products to Europe have increased tremendously. Therefore, an additional freight cost surcharge of 11.50 Euros per delivery will be invoiced from May 1st, 2020. Find further information here.

Since 29. January 2020 most of the production from China has been transferred to other manufacturing sites due to the corona virus. For this reason, the lead time of some transferred products had to be extended."

........and once I got as far as viewing the cart, I got this

"For this service, the consumption tax will be borne by customers."

I'm not sure what the latter means but suspect that one might get clobbered for import duty as well. That's happened to me a couple of times recently and I've ended up paying FedEx and DHL sums of money that I didn't expect.

So try other avenues first but if you get really stuck, PM me and we'll work out some way of me ordering them on your behalf and posting them on to you.

-

@Nxt-1 said in Delta proper endstop upgrade - advice welcome:

I am not sure whether I agree that they are over the top. To me it seems that a repeatable max height reference (which the endstops ofc provide) is a vital part to be able have an accurate coordinate system. The other vital part, especially for delta's, is the Z-probe. The 3D print community has gone to great lengths to improve Z-probe design and accuracy. It seems that this effort goes to waist if the endstops are not repeatable, as the total repeatability of the system is a function of both the endstops and Z-probe repeatability.

Assuming the delta uses a 'smart effector' or some other probe that is always available, such as a retracting probe... and assuming that a G32 is done at the start of every print job... When the Delta finishes its G32 Z probe sequence, and resets Z0, at that moment, the endstops drop completely out of the picture. They literally have zero effect on the resulting alignment/accuracy/repeatability, etc.

Therefore, they only need to be "good enough" to get the effector where it can probe. Which cheap mechanical switches fulfill that mission just fine.

So... Delta that does not or cannot probe before each job? Better endstops do contribute to overall accuracy. Delta that probes before each job? Endstops don't matter much at all.

One caveat: If you plan to power-fail restart, endstops matter again. Me, personally, I'd much rather have a small UPS.

-

@Danal said in Delta proper endstop upgrade - advice welcome:

Assuming the delta uses a 'smart effector' or some other probe that is always available, such as a retracting probe... and assuming that a G32 is done at the start of every print job... When the Delta finishes its G32 Z probe sequence, and resets Z0, at that moment, the endstops drop completely out of the picture. They literally have zero effect on the resulting alignment/accuracy/repeatability, etc.

Therefore, they only need to be "good enough" to get the effector where it can probe. Which cheap mechanical switches fulfill that mission just fine.

My delta indeed used a smart effector and a G32 is part of my normal pre-print routine. You are right that as soon as the probe routine is done, the endstops are no longer in use as long as you do not rehome. While I knew this, my brain seemed fine with ignoring the impact of this

, thank you pointing this out.

, thank you pointing this out.Yet I do want to argue that the G32 procedure constantly assumes it's XY position is acurate. Which in a delta is determined at the moment of homing. So indirectly, the repeatability of the endstops does influence the G32 procedure and its results. Though I must admit that head cannot really comprehend how much a tiny XY offset would influence the results. I assume it will not be huge.

Also I have sometimes saved a print from the bin after a layer shift by homing. This got by thinking about rehoming every N layers by default on very large prints.

-

Yep, any kind of restart, rehome, is obviously very dependent on the upper stops.

Also, those switches and mounts are really cool!

-

@Danal Yes, the switch/mount is pretty nice. You can tell it is a product designed for that specific purpose, which probably explains the price.

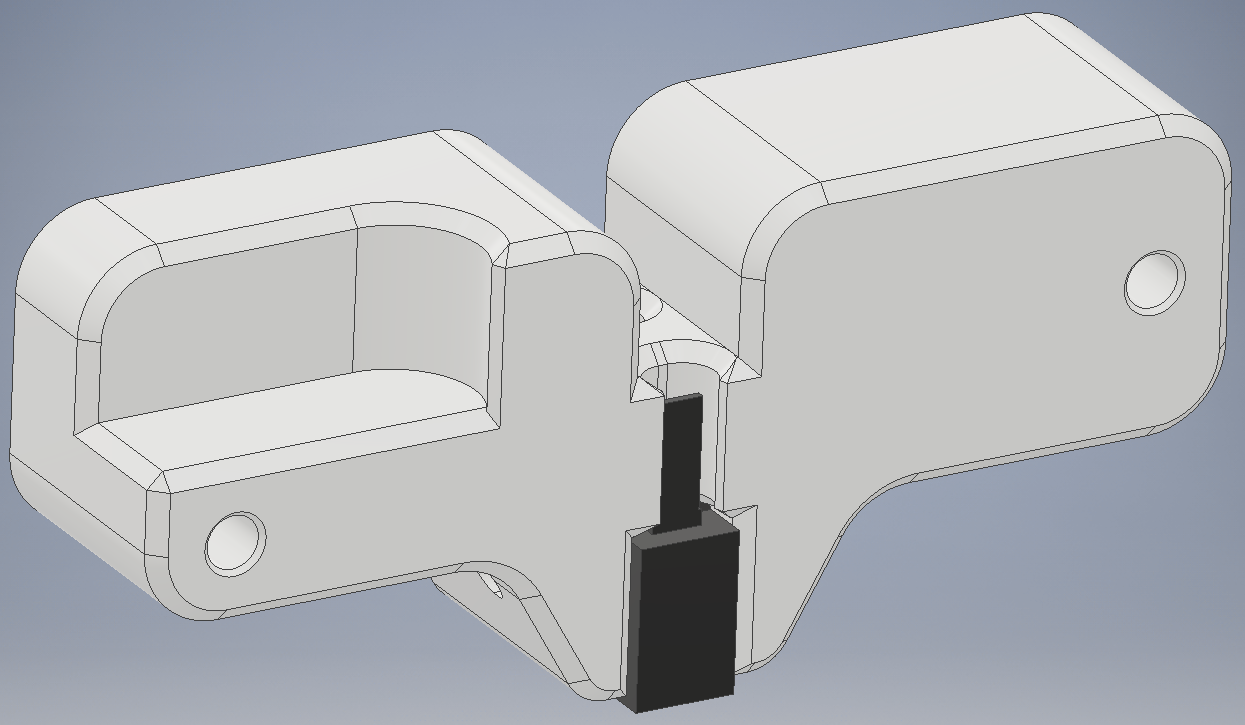

Currently I am using a 3D printed mount that embeds the micro switch and mounts to the aluminium extrusions like this:

fyi, yes those are rusty nails you see right there. I did not have small enough pins and the nails where spot on the right diameter to fit the holes in the switch

-

LOVE the custom pins, probably took you forever to get JUST enough iron oxide to act as a lubricant/traction interface without overwhelming the arc reactor. Microgram scale for weight/adjustment, no doubt.

-

@Danal said in Delta proper endstop upgrade - advice welcome:

LOVE the custom pins, probably took you forever to get JUST enough iron oxide to act as a lubricant/traction interface without overwhelming the arc reactor. Microgram scale for weight/adjustment, no doubt.

You are correct getting the oxide layer just the right thickness and purity took several attempts and is not recommend for the faint of hearth. I am not sure when I started the process, but it might be over 20 years ago

-

@deckingman said in Delta proper endstop upgrade - advice welcome:

Metrol precision switch

what will be the difference in between mechanical high precision switch and optical sensor?

would precision mechanics dramatically change the measurement? -

@c310 said in Delta proper endstop upgrade - advice welcome:

@deckingman said in Delta proper endstop upgrade - advice welcome:

Metrol precision switch

what will be the difference in between mechanical high precision switch and optical sensor?

would precision mechanics dramatically change the measurement?My two cents is that opticals can be more repeatable than mechanical and vice versa. I am not expect by any means though. The main reason I have not given them serious consideration is implementation difficulty.

To accurately trigger optical sensors you need to interrupt the optical path with some kind of a flag. I am no fan of implementing something tiny that stick out on top of the moving carriage. Especially not if it most likely will be printed and needs to be accurate across the three towers. Also as far as I know you always need an additional form of a physical stop in case an endstop fails to trigger for some reason.

Ambient light influences should be mentioned I guess when talking about optical sensors. But again, not an expert on the matter here.

-

@Nxt-1 said in Delta proper endstop upgrade - advice welcome:

Ambient light influences should be mentioned I guess when talking about optical sensors. But again, not an expert on the matter here.

Given the way the sensor is shrouded, it would be very difficult for ambient light to interfere with it I think.

The flag position should ideally be adjustable, so that exact positioning isn't needed. You can just turn the screw to adjust it. The LED on the endstop makes adjusting it quite easy.

so optical can be quite beneficial, especially if you need an endstop that you can physically travel through if needed.

-

Just for the sake of keeping this thread complete, I have placed an order with Cncsystems Ltd (UK) for some Metrol STE060PB's. They should be arriving by the end of May.