Having y axis ringing on coreXY

-

@Phaedrux one would think that going with 100 jerk and acceleration would over come that. I don’t think it even reached 5mm/s. On X axis having 700 jerk and 1200 acceleration I have 0 artifacts. Should I not have something there to if something is lose?

Only thing I could think of that has some sloppiness would be motor mounts. I will try and put a strap on them against the frame.Most reinforced parts have other issue that I have found. I tried 3 sets of idler mounts before I found one that lines up and don’t limit the travel. I can’t find y axis parts either that’s reinforced for my 10mm rods. Most are 10mm and 8mm or for mitsumi bearings which are smaller.

-

Your HEVO looks very nice.

Are you sure these are ringings? Ringing typically appear near corners, not along the entire surface. Are they at ~2mm pitch, similar to the belts?

-

If you print a cube with linger walls does the drop off become more apparent?

-

@zapta it is some sort of vibration for sure. I printed a cube at 60mm. First part is slow the middle part which is most smooth are 60mm/s and above part is 40mm/s. So going slower actually gave me more artifacts. The X axis is also best at 60mm/s. I tried a xyz calibration cube with 60mm/s on outer perimeter and it actually turned out pretty nice if you don’t take to account that pa was not used.

Forum seems to be very unstable when it comes to uploading pictures and files so here is a link instead

-

I've managed to reduce a similar artifact on my prints by re-checking all of my idlers. Specifically, I had to make sure each smooth and toothed idler would spin freely. I'm talking sustained fast spins, not just slow smooth spins. Think fidget spinner speeds for a second or two after flicking the idler. I managed to do this by placing 1mm precision shims between each pulley and the mounting plate underneath it to reduce the friction. Some form of lubrication might also help.

Your motion system has some drag somewhere, and you gotta reduce it. Pulleys wobbling slightly off-center will cause this too. I haven't eliminated it entirely, but it has been reduced significantly.

Also, check what the natural resonance frequency of your frame is using your phone with an accelerometer app and a hammer. I found that mine was in the 67Hz range, but was lower for vibrations running through the y-axis (cause there's no crossbar reinforcing that axis so its less rigid). Use this frequency as a starting point for DAA tuning.

-

@H2B said in Having y axis ringing on coreXY:

I've managed to reduce a similar artifact on my prints by re-checking all of my idlers

Same here. I switched to a good quality Gates belt and pulleys. The pulleys have 5mm bore (vs the standard 3mm) and use smooth 5mm axis rather than threaded bolts, so more stable and less wobble.

I think this is a corexy phenomena but don't know for sure.

-

The OP also mentions that X axis sides of prints are fine. Definitely a frame rigidity issue with coreXY designs, at least as far as my troubleshooting leads me to believe.

I'll try reinforcing my frame across the Y dimension to see what happens. Should be straightforward enough to try. Most coreXY designs usually have a couple of Z axis extrusions for rails or reinforcement, and I haven't seen many that incorporate an extra Y member somewhere midway the sides of the frame.

-

@H2B how do I find the natural resonance using a hammer? Just hit the frame with a hammer and use an app? Would Gates belt app work?

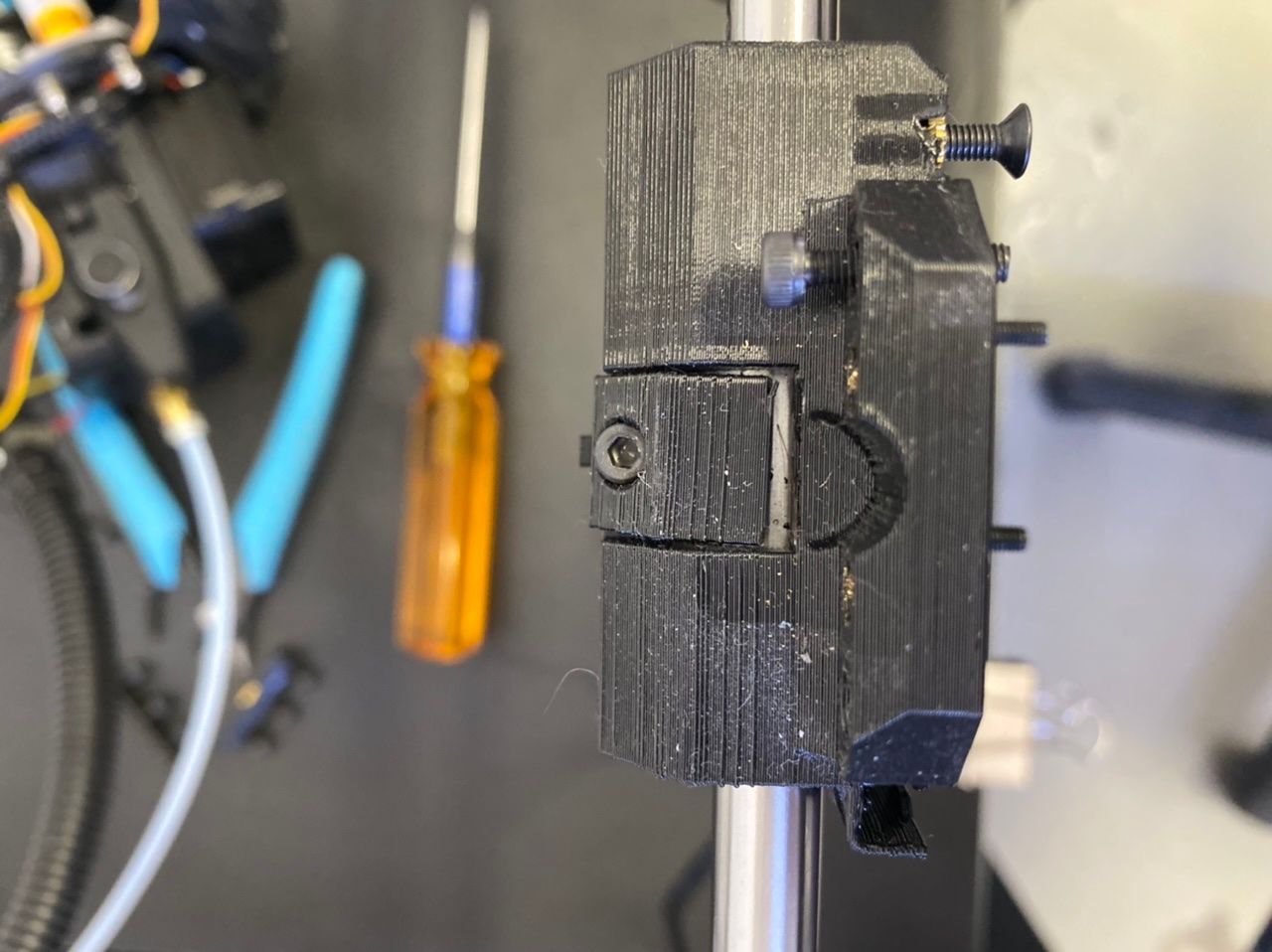

I went over everything today and the last part I have not checked was the extruder mount. It was completely cracked on the top bearing, so it was basically running on just the lower rod. So when doing y moves I believe it all to be flexing. I hope this to be the issue now.

-

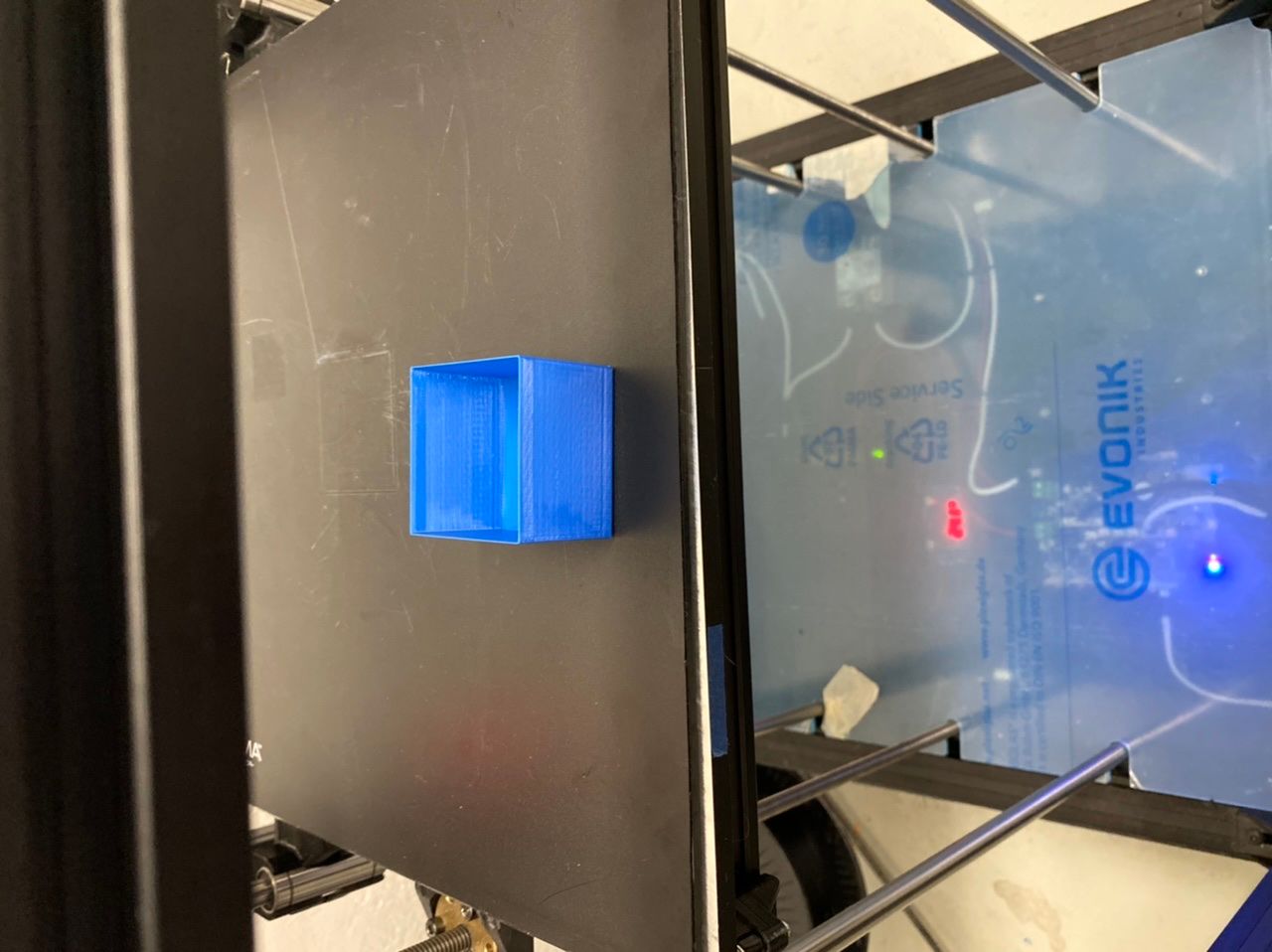

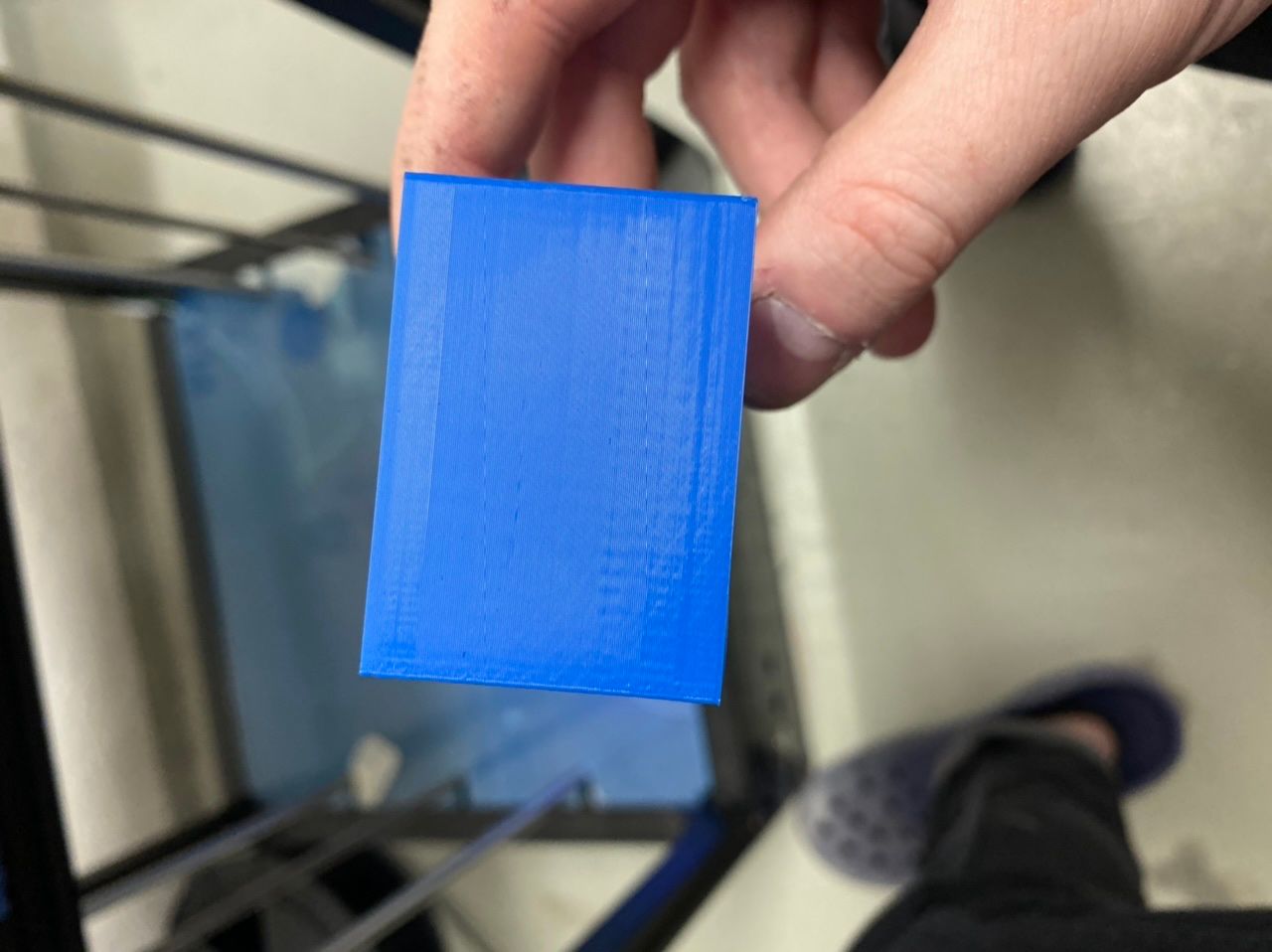

A little bit of update. I reprinted the broken part and reprinted the y axis parts. I wanted double clamping parts.

I did a test print tonight and results are hard to understand. The initial ringing I had is gone I believe but there is something else.

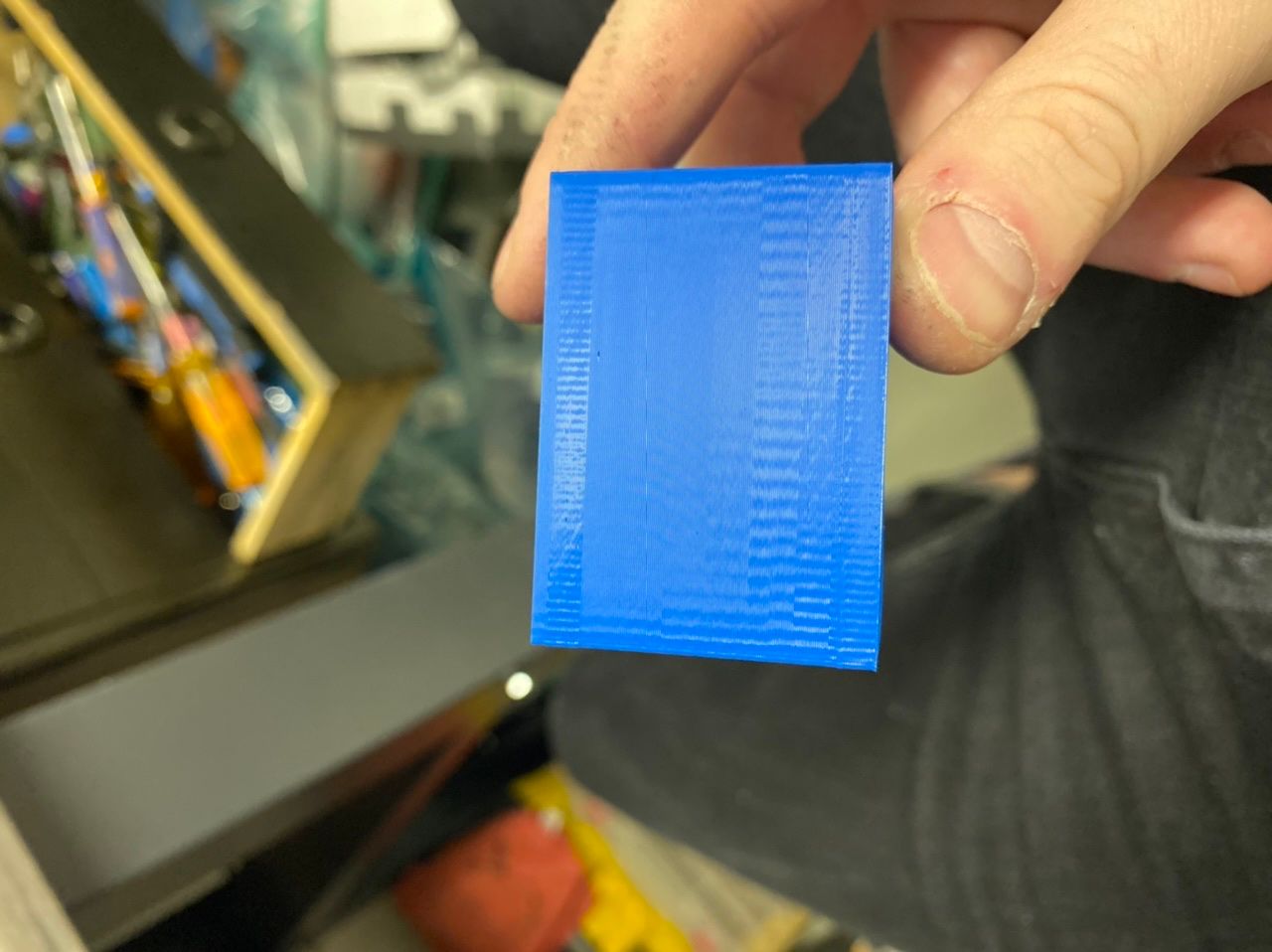

Looking at the cube left side is worse then the right side. Every 5mm or so I raise speed by 20. I start at 40/60/80/100/120/140. At 140 it’s looking great in the middle but start and slowdown not so much. I have the same on the x axis but much less and it goes away much around 80mm/s. I am not running pressure advance. What could it be?Orientation of the cube

Left side

Right side (picture make it look better then it is)

This is my x axis, basically same on booth sides

-

For a very crude "resonance" test, I downloaded an accelerometer app called Resonance on my phone.

I placed the phone in the middle of my build plate, set it to a 5 second record time, and then started recording and hit the frame with a hammer (lightly! just a tap is enough) across the axis I was measuring.

First time, I struck the hammer around the middle of the X-axis frame member at the front of the printer. I then repeated the same procedure for striking the hammer around the middle of the left Y-axis frame member.

The app spits out the results of what frequencies it measured. Its a crude method of model analysis, but it worked for me.

@Alucardi those ripples I've found are caused by friction in the idlers, causing the idler shafts to wobble slightly when moving. I reduced those artifacts a lot by placing .5mm precision washers between the bottom idler pulleys and the mount they sit in, and made sure that all my idlers spin freely when I rotate them by hand. Usually a combination of friction between the idler top and bottom surfaces, coupled with the tension of the belts, has caused this sort of artifact in my prints. By smoothing out the idler motion, I've reduced these ripples significantly.

Maybe do the same on your printer and see if it helps. The resonance stuff is very crude at best, but it is useful to compare if the frame has different ringing frequencies in the X vs Y direction. I've found that at slower printing speeds (60mm/s) I have a huge difference between the X (around 65-70Hz) and the Y (around 25 Hz). At higher speeds and accelerations, this tends to even out around 112Hz (which doesn't show up as much in the print's perimeters), probably to the steppers pulling harder on the belts to reach the higher speeds. These frequencies are measured by once again placing the phone on the build plate and starting the resonance app recording feature, but this time during an actual print.

-

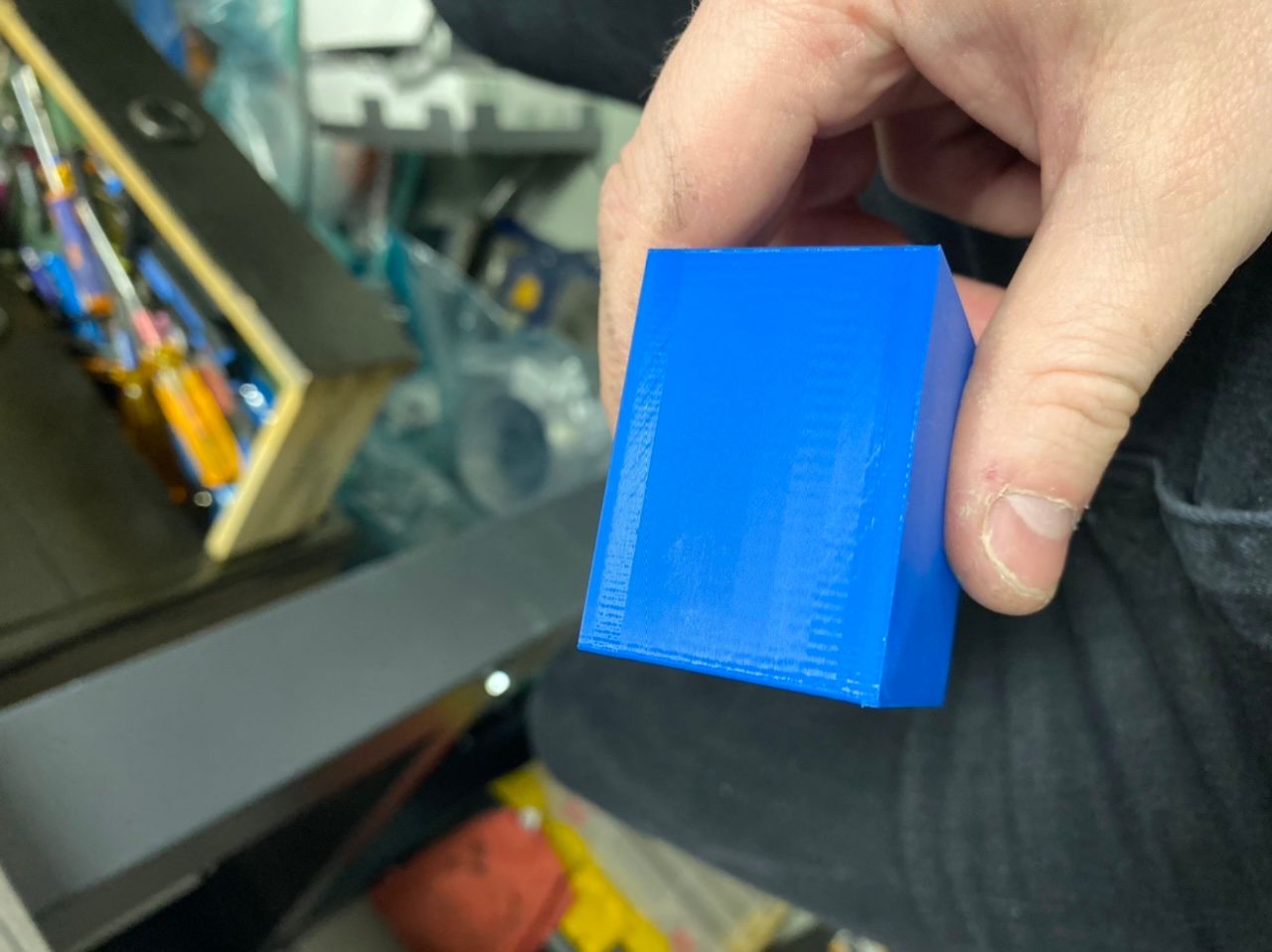

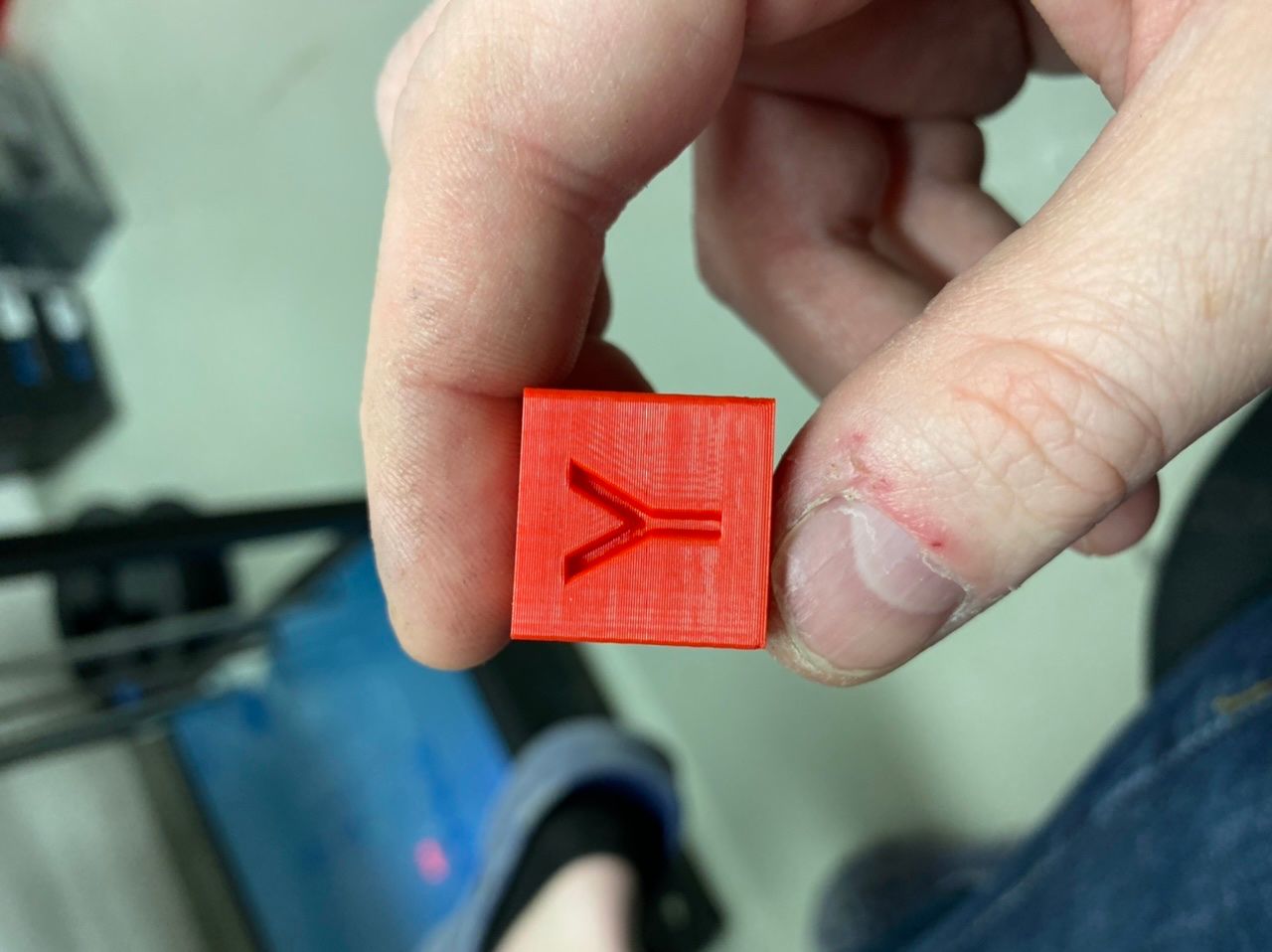

@H2B not sure what I did but it’s perfect now

I made 100% sure everything was aligned in the gantry. Changed back to original idler mount with no printed spacer between the idlers. This cube is printed with 2500acc and 500 jerk. I have made no tuning to any values or the profile. I have .05 pa and that’s it. Outer perimeter is 25mm/s rest is 80mm/s.

I made 100% sure everything was aligned in the gantry. Changed back to original idler mount with no printed spacer between the idlers. This cube is printed with 2500acc and 500 jerk. I have made no tuning to any values or the profile. I have .05 pa and that’s it. Outer perimeter is 25mm/s rest is 80mm/s.

-

Haha! You've probably ended up making the idlers smooth again. You could use that printed spacer you mention if you lap/sand the surfaces that come into contact with the pulleys so that they're nice and smooth. And a touch of grease wouldn't hurt either.

Congrats!

-

@H2B said in Having y axis ringing on coreXY:

And a touch of grease wouldn't hurt either.

Graphite powder might be better in this application. Greasy can get gummed up pretty easily. Rubbing it with a 2B pencil should do it.