Why can’t I tune pa correctly?

-

@dc42 so your saying that if I tune it for say 40mm/s I have to print at that speed always if I want pa to work?

Extruder is a bondtech dd extruder. I know about the ringing and I am working on dialing in my profile. What repeat print defect are you talking about. I can’t see it. Can you mark the picture?

Everyone says pa is the best feature ever but why does it not work as good as la? I have no problem using la adjusting speeds on the fly and still have good results. -

I'm also not sure why RRF doesn't implement LA as an alternative algorithm. They are both under the GPL..

I would love at least an experimental port of LA, just for the sake of comparing them..

-

@Alucardi In my experience, once the correct PA value has been found, it works well at all speeds from 40 to 300 mm/sec (yes, I did mean 300mm/sec print speed) as demonstrated here https://somei3deas.wordpress.com/2018/01/15/an-attempt-to-investigate-pressure-in-the-extrusion-system-with-a-diamond-hot-end/. But nobody takes much notice of my findings.............

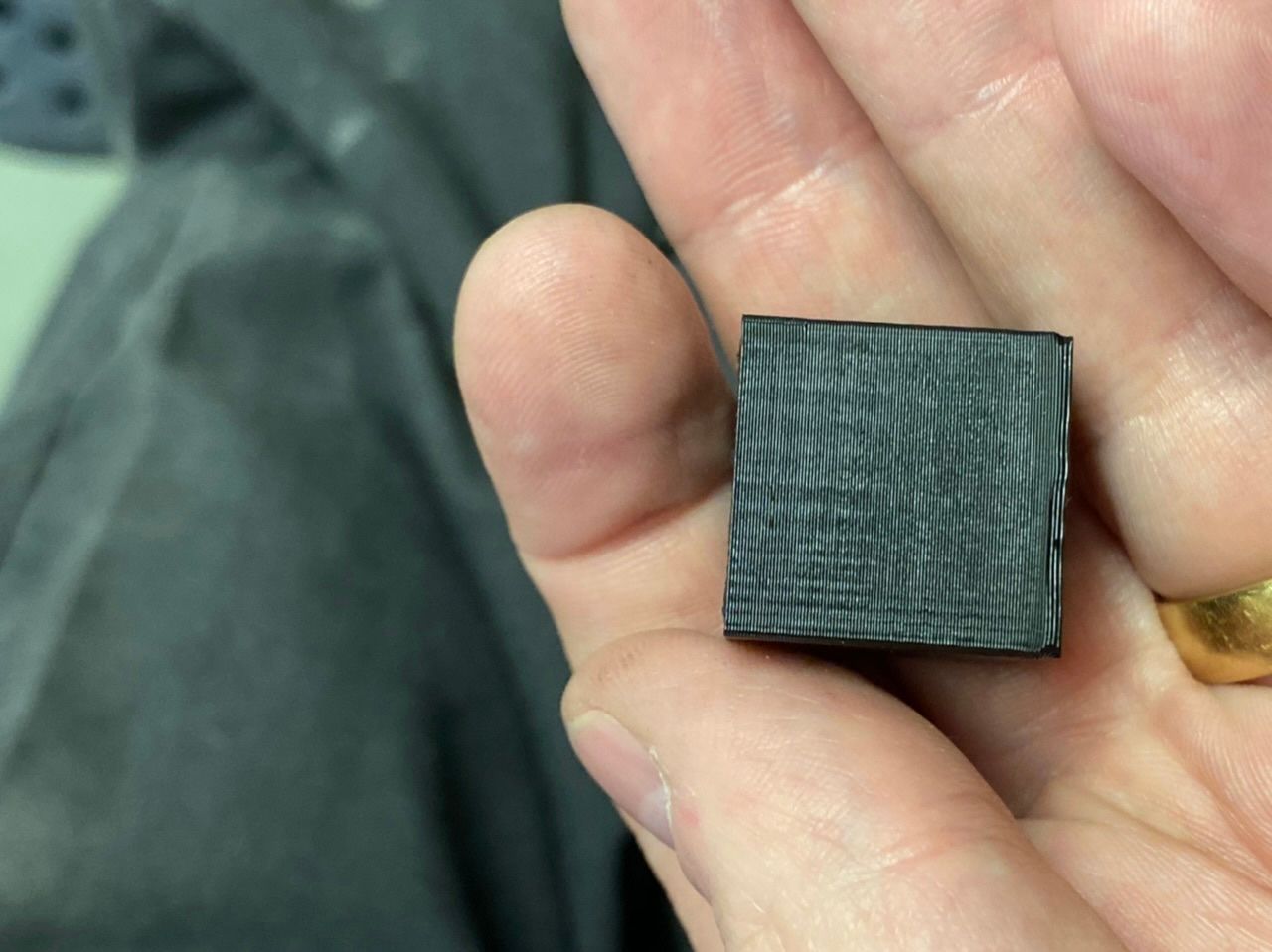

Ref your test cube, IMO it's too small and the moves are too short for there to be much of a pressure build up. A caveat to that is that you haven't stipulated what print speed or acceleration you used, nor the filament type or nozzle diameter so it's impossible to say for sure. If you were printing at high speed, with a high acceleration, and/or with a small nozzle, then you might be getting a build up of pressure which needs to be compensated for.

But in any case, PA isn't a universal "fix everything" solution. It's hard to make recommendations based on just one picture and not knowing what settings you used but it looks like your corners are over extruded and bulging. The tower on the left has rounded corners which might be why it looks better. Try increasing XY jerk. Or maybe drop the temperature if you can. Or both. You need to adjust everything else first and only when you can't make further improvements, try introducing PA (which you can do "on the fly").

-

@deckingman sadly I am stuck with the jerk I have, anymore and I will get more ringing. I have x 400 and y 380 for jerk, my acceleration is 1000. I use a .5mm nozzle and the cube is printed at 25mm/s on the outer layer. The one I used to test pa is printed at 50mm/s. I have no issue printing at this temp on my other printer that also have same extruder.

-

@Alucardi I'd say that having to slow down to around 6mm/sec before a direction change is a large part of the problem. Also IMO, a print speed of only 25mm/sec with a 0.5 mm nozzle is unlikely to build up much pressure, which is why PA isn't having much effect on the print quality. The fact that you get ringing at such low speeds indicates a mechanical problem, which again can't be fixed by pressure advance.

-

@deckingman I know the ringing as an issue but I replaced basically everything on the printer and I still have some. When I got the printer it was terrible but replacing all printed parts, use axles on idlers and smooth idlers all over it has improved it but I can’t get rid of the last ringing. I believe it to be vibrations or something.

So your saying it’s impossible to get rid of that gap of filament cause I have low jerk? -

@Alucardi said in Why can’t I tune pa correctly?:

So your saying it’s impossible to get rid of that gap of filament cause I have low jerk?

Not necessarily (but probably). You may be able to improve it - I really don't know enough about your machine to have an informed opinion. What I am saying is that no amount of changes to pressure advance setting will make the problem magically disappear.

-

@deckingman but the problem is not there when not using PA. Either i get bulging corners or gaps.

-

@Alucardi said in Why can’t I tune pa correctly?:

@deckingman but the problem is not there when not using PA.............

So don't use it.

-

@deckingman there is a reason I use pa. It’s cause I have bulging edges if I don’t. You have another suggestion on how to get rid of them?

-

Can you share some more of your configuration settings? Including your slicer print settings?

-

@Alucardi I've given you some suggestions already but for various reasons you say you can't implement them. The point about pressure advance or Marlin's linear advance is that they alow a good printer to print faster by compensating for the increased pressure which can happen as a result of the increased speed. But your printer has problems at low speed and with a largish nozzle. So you are trying to use pressure advance to improve print quality by compensating for pressure which doesn't exist. Which is not how it works and why I said do not use it.

It's a bit trying to start an engine which has run out of fuel by charging the battery - and then blaming the battery charger when it doesn't work. -

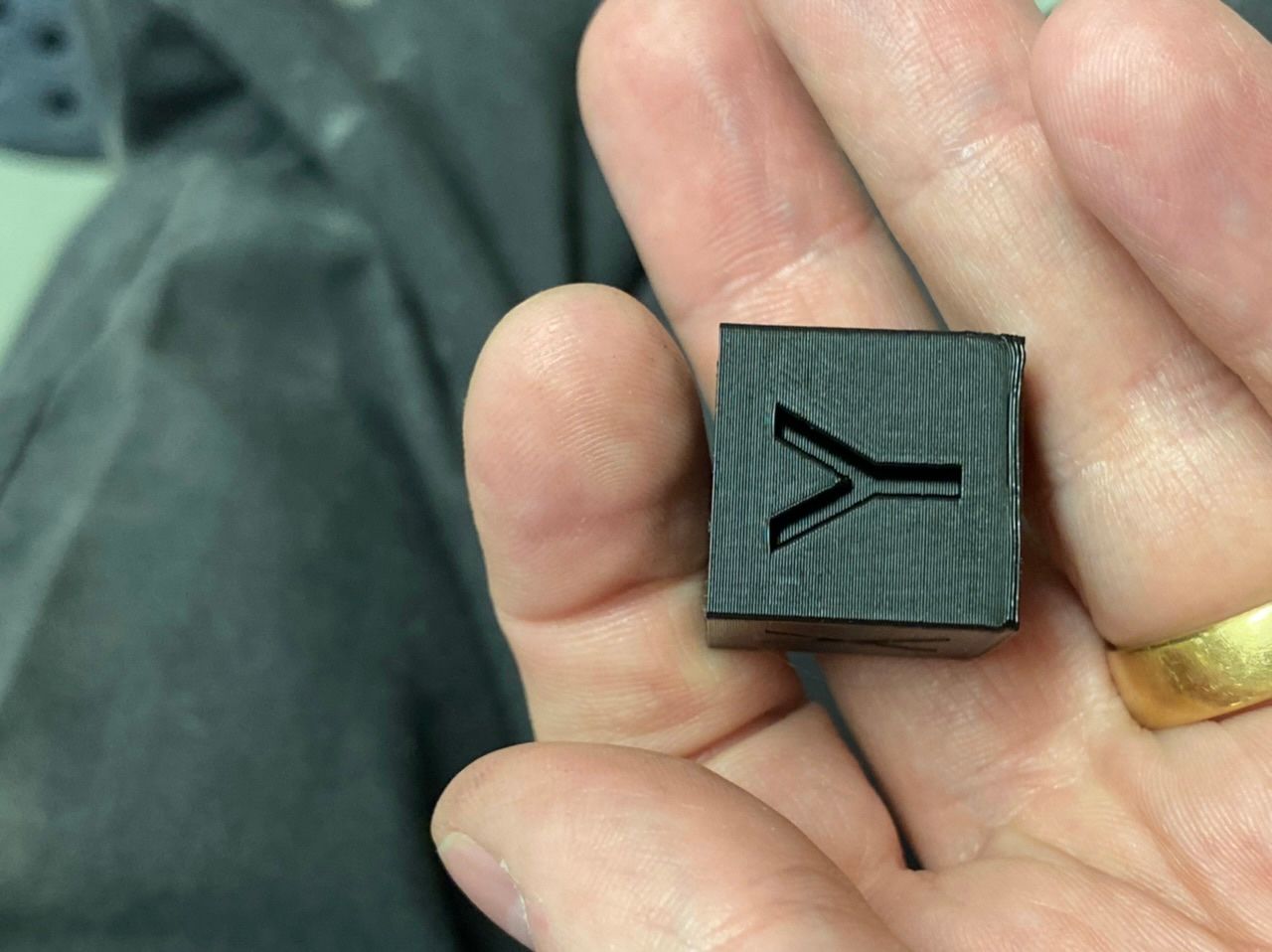

@deckingman but i do have bulging edges even if perimeters are printed at low speed, 25mm/s. Suggestion I got was increase jerk and that really can’t help me now since I get more ringing if I raise it. The ringing have bin present since I bought this half finished project and I have reduced it by a lot but that last part I don’t know how to get rid of. Filament also plays a big part. They grey cube shows how it was at first with same settings through all testing.

I won’t argue with you but even at the low speeds I get bulging edges on the x and y letters and by edges are not sharp, they don’t go away just cause someone say I can’t have bulging edges. That’s the reality no matter what you are saying and pa helped remove that.

-

@Alucardi It's because the filament oozes out of it's own volition or due to gravity. So when you slow the print head down the filament continues to ooze and you get over extrusion. Which is why a higher jerk speed might help because the print head won't slow down so much. But you say you can't do that.

So here is another suggestio that you could try. Use a 0.4mm nozzle instead of the 0.5 mm nozzle. A 0.5mm nozzle has a 50% bigger area than a 0.4mm nozzle and "ooze" gets worse as nozzle size increases. -

@deckingman i use a .5 nozzle out of convenient. I use that when I print tpu which I do a lot and was planing to do on this printer to. But I will definitely try it with a .4 nozzle and report back.

I read a lot that you can avoid using pa by tuning jerk and acceleration but I have ringing issues which I can’t track down. So pa is my option. I only plan on having dd on this printer for a while, extruder is going to another project I need to build. So hopefully going Bowden will clear my issue since my extruder setup is heavy (prusa mk3s bondtech extruder). -

@Alucardi If you are unable or unwilling to try anything other than PA, then I have no more suggestions. Filament will ooze out of a nozzle when it's heated, due to gravity and thermal expansion. At low speed and with a large nozzle, the pressure on the filament going in to the hot end will likely be immeasurably small. So what you are tying to do with PA is control that oozing (due to gravity and thermal expansion) by applying a negative pressure to the incoming filament. But PA isn't designed to do that - it's designed to compensate for pressure (which you don't have). As well as decreasing the extruder speed at the end of a move, PA will increase extruder speed at the start of a move to compensate for the lag between the carriage accelerating and the filament flow which accelerates at a slower rate. Which is why it won't compensate well for "natural" oozing due to gravity and thermal expansion. You may see some slight improvement but it's the wrong tool for the job. You need to get the printer working well at low speed without PA and only then introduce PA to help with the pressure that will encounter when you start printing at higher speeds.

-

@deckingman i just said I will try a smaller nozzle. I can’t work with jerk since I can’t go higher then 400, that’s all.

I am used to la which seem to work better in my case. Since the same extruder but running marlin fixes this issue. But like I said I will start with a smaller nozzle -

@Alucardi I would be curious to know the technical differences between the implementations of PA and LA. It's starting to sound like they give substantially different results, but it has been half a decade since I used anything other than RRF.

-

This post is deleted! -

@deckingman doing the change to a .4 nozzle I noticed the throat a bit lose on the hotend. So during disassembly I found that the extruder body was only mounted with 3 out of 4 bolt. The one missing being one of the clamping bolts for the hotend. I have honestly torn the entire printer apart since I got it but never thought about the extruder 🤬 New problem there is my z offset lol

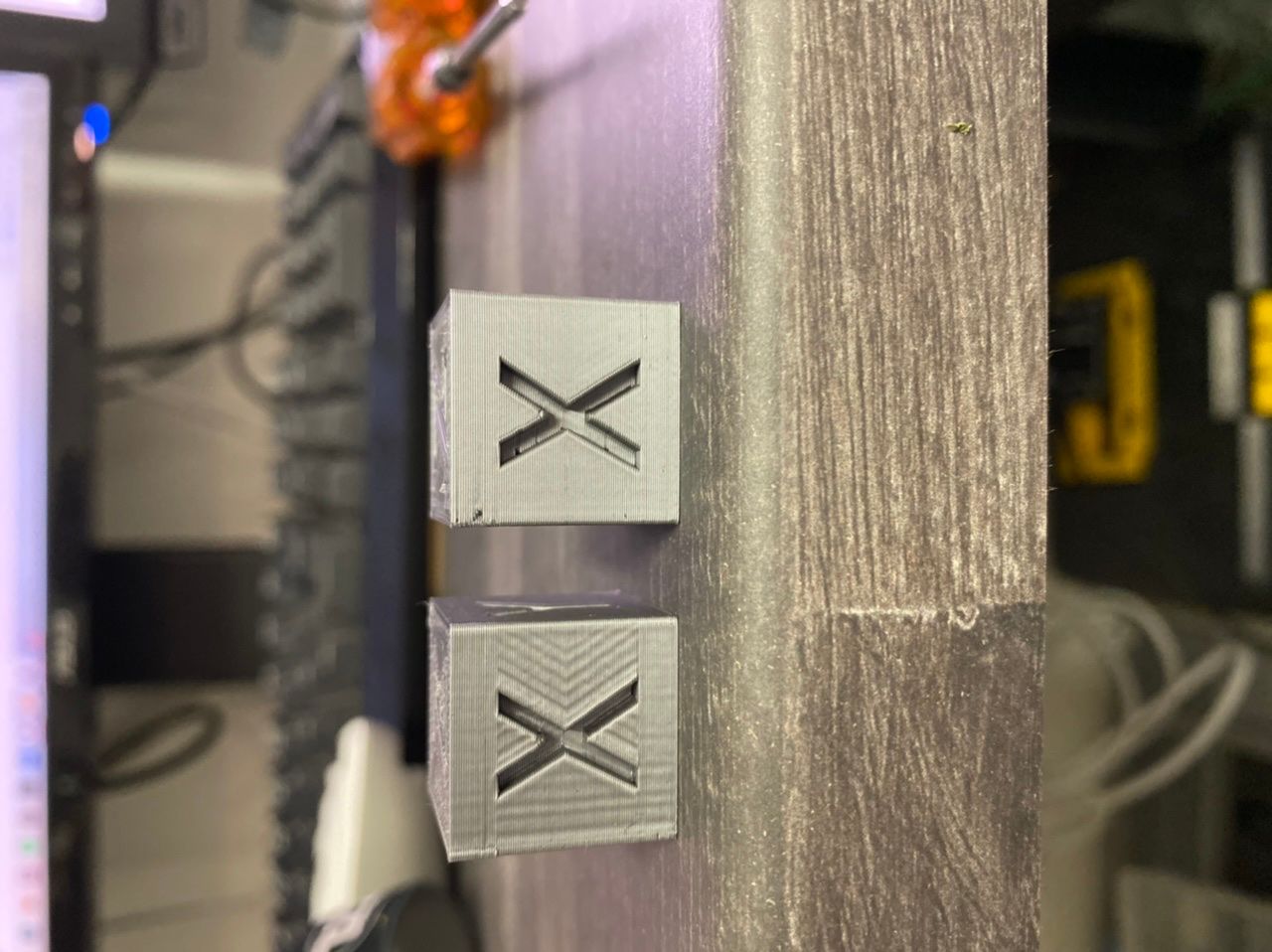

So after fixing that I seem to be able to get better results. Previous model was printed with 400 jerk, 1000 acceleration and 25mm/s outer perimeter. New cube is 600 jerk, 1200 acceleration and 30mm/s outer layer and the seam is not there anymore.