Layer shift detection?

-

@NitroFreak said in Layer shift detection?:

@Danal said in Layer shift detection?:

@NitroFreak said in Layer shift detection?:

I have long asked dc42 why he focuses so much on integrated stepper drivers.

He stated (in other threads) that expansion boards with no drivers, and outputs for external drivers, are on the roadmap for Duet 3. No dates, yet.

You got me wrong, i dont want to buy a duet 3 with 6 expensive drivers only to expand it with another board that adds additional cost.

Give me a Duet 3 without any stepper drivers that has the breakout pins right on the board, and I´d be so happy.

I get it. I'm just repeating what Dave said.

What do people use those huge stepper drivers for anyway?

Printers.

-

@Danal said in Layer shift detection?:

Printers.

I get it, but why? If you have to use nema 34´s, you are already more expensive than servos that have similar power output.

Servos have the advantage that they are very power dense, so they require less metal and copper to output the same power (factor 3)

They are only more expensive because they require the encoder and feedback loop, but those stay constant with size going up, so they amortize really quickly going up in size and stepper nema 23 setups with similar power output already cost more. -

@NitroFreak said in Layer shift detection?:

i dont want to buy a duet 3 with 6 expensive drivers

You are kidding, right? Duet 3 uses TMC5160A-TA. These are DigiKey Qty 2000, $3.11 each. I'm sure the board builders get them for under $3. Removing six of them cuts $18 or less from the internal cost. Maybe $18.50 if you count the passives.

Like any technology, that number will fall over the lifecycle of the D3.

I'd think the more important thing is the lack of pins for Step/Dir/Ena, or SPI equivalent, that are fully supported for external drivers. Expansions will provide that.

-

@NitroFreak said in Layer shift detection?:

If you have to use nema 34´s

Very, very, few of these in Hobbyist printers. TMC5160 may be a bit of overkill for Nema17 if one looks only at current; at the same time, it is the "latest and greatest" at things like interpolation, whatever.

And the points I made about price above, they get even less if you compare a prior generation to the 5160. In other words, the incremental cost of "latest greatest" is probably under $6 per board, even if "latest greatest" is not strictly speaking 'required' for most of D3 installations.

-

And, having said all of that, my second or third post in this thread was "Also, the 'real' way to do this is closed loop...".

So I am totally with you on servos (or equivalent). I'm just pointing out that the factual cost of those TMC drivers is only a few percent of the board cost.

I'd love to see more direct support for closed loop.

-

@Danal said in Layer shift detection?:

@NitroFreak said in Layer shift detection?:

i dont want to buy a duet 3 with 6 expensive drivers

You are kidding, right? Duet 3 uses TMC5160 DigiKey Qty 2000 they are $3.11 each. I'm sure the board builders get them for under $3.

Removing six of them cuts $18 from the internal cost. Maybe $18.50 if you count the passives.

Yes, i can see that you know how pricing works. If you consider that the components cost maybe 80$ ( the processor costs 8€, the rest is cents) cutting 25% of the internal costs is quite a bit. Now, hoping that they keep the profit margin % the same, those 18$ can easily amount to 50$ saved on the final product. And especially considering that one does not need to buy the separate 30€ expansion breakout board (why can the breakout pins not be on the board from the start?) That is a substantial chunk of change. Also the PCB itself shrinks, further reducing cost.

So no, i am not kidding. -

@NitroFreak Interesting. If the servo gets hung up, or misses steps, is there some means of feeding that information to the extruder so it won't keep trying to squirt plastic?

-

@mrehorstdmd said in Layer shift detection?:

@NitroFreak Interesting. If the servo gets hung up, or misses steps, is there some means of feeding that information to the extruder so it won't keep trying to squirt plastic?

Yes, the servo has an alarm output that switches from 0 to 5v where you can run (dont have to) a wire from the servo to the duet which treats it as an endstop. You can configure that endstop as an emergency stop.

https://duet3d.dozuki.com/Wiki/Connecting_an_Emergency_Stop -

@NitroFreak But it doesn't "recover" from lost steps, etc., merely shuts down the print?

I like the idea of silent operation- I have a sand table that could use some additional quieting down...

I'm looking at the NEMA-17 motor/driver you linked and the torque spec looks really low. 0.48 Nm can't be right for 52W motor, unless that's torque at maximum rpm. How do you select these things for a given application?

I found the manual here. Are there any special tricks required to interface these to a Duet board?

Do you notice any differences between steppers and servos in terms of things like ringing in prints?

-

@NitroFreak Parts cost is the only driver of price? Assembly labor? Firmware is not a contributor? Trade show marketing (well... not right now)? Support? A dozen things I forgot? Price and cost are only very loosely related, and neither of us really knows how Duet3D chooses to run internally. Therefore, let's turn the question around:

Retailers have posted prices of $230 USD or 250€ to 260€ today for a 6HC, what would you expect to pay for a driverless "base" board?

-

@mrehorstdmd said in Layer shift detection?:

@NitroFreak But it doesn't "recover" from lost steps, etc., merely shuts down the print?

I like the idea of silent operation- I have a sand table that could use some additional quieting down...

I'm looking at the NEMA-17 motor/driver you linked and the torque spec looks really low. 0.48 Nm can't be right for 52W motor, unless that's torque at maximum rpm. How do you select these things for a given application?

I found the manual here. Are there any special tricks required to interface these to a Duet board?

Do you notice any differences between steppers and servos in terms of things like ringing in prints?

It can, it depends how you configure it. If you set it to never put out an alarm, it will not throw out an alarm and will just try to reach the next commanded position.

I know, it´s perfect, it´s even so perfect that i already suggested that servo to you in the thread that you opened about that sand table

The 52W nema 17 servo has a continuous torque of 0.125 Nm right up until 4000 Rpm, the 78W version has 0.185 Nm. The 180W Nema 23 version has 0.57 Nm right up to 3000 Rpm.

Check page 45 and 47 of the manual posted for the "curves"

You shouldn´t forget that steppers have big torque at basically 0 Rpm, but then fall off really quickly.

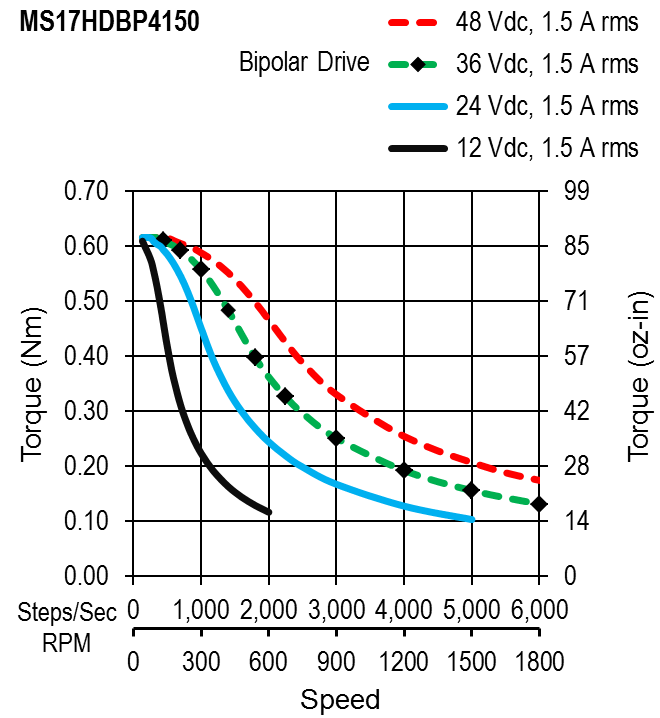

This is what a nema 17 torque curve looks like for a really beefy 63mm stepper (what e3d calls a super whopper)

For 24V, you can see that at around ~800 RPM the torque already falls below the value of the 78w nema 17 servo (0.185Nm)

What this means is that you can have a onstant acceleration at any speed without worry of the motors running out of torque. Basically, if your acceleration is fine at 10mm/s, then the same acceleration will be fine at 400mm/s.

The same acceleration at 400mm/s with steppers would result in lost steps, even though at 10mm/s it was fine. -

@Danal said in Layer shift detection?:

@NitroFreak Parts cost is the only driver of price? Assembly labor? Firmware is not a contributor? Trade show marketing (well... not right now)? Support? A dozen things I forgot? Price and cost are only very loosely related, and neither of us really knows how Duet3D chooses to run internally. Therefore, let's turn the question around:

Retailers have posted prices of $230 USD or 250€ to 260€ today for a 6HC, what would you expect to pay for a driverless "base" board?

You´re dragging retailer margins into this.

With your thinking, a thermocouple daughterboard must cost loosely the same as a duet 3 because of firmware, trade show marketing, support and a dozen other things.Let´s look at a real world comparison.

I´m choosing the duex5 expansion board and the expansion breakout board.

https://www.duet3d.com/Duex5

https://www.duet3d.com/DuetAddons/Expansion_Breakout

Both can house a theoretical 5 steppers. I know the Duex has heater mosfets, but let´s just subtract 10 pounds from the price for that.

That makes a price difference (82.50-10)-25 = 47.50 pounds. So roughly 50 pounds for 5 stepper drivers. (10 for one)

This is a real world price difference for the consumer that you can hopefully also comprehend.

So I don´t think its unrealistic expecting to slash 60 pounds off the price of the duet 3 for a version without 6 stepper drivers- especially considering they are the beefier cousins that cost more.

So, Price right now on Duet3d website for the Duet 3 is 185 Pounds. I´d expect a realistic price of around 125 Pounds for a Duet 3 without drivers.

Please let me know how wrong my assumptions and calculations are. -

@NitroFreak said in Layer shift detection?:

You shouldn´t forget that steppers have big torque at basically 0 Rpm, but then fall off really quickly.

This is what a nema 17 torque curve looks like for a really beefy 63mm stepper (what e3d calls a super whopper)That doesn't entirely apply to integrated stepper drivers like TMC used in the Duet. They get very close to constant torque because of what I said previously.

-

@NitroFreak said in Layer shift detection?:

Give me a Duet 3 without any stepper drivers that has the breakout pins right on the board, and I´d be so happy.

It's just a matter of market demand. If there is sufficient demand, Duet will be happy to come with such a product. One thing you can do is committing for large quantities for whatever product you want.

-

@NitroFreak said in Layer shift detection?:

So, Price right now on Duet3d website for the Duet 3 is 185 Pounds. I´d expect a realistic price of around 125 Pounds for a Duet 3 without drivers.

Sounds good to me. And, as I mentioned in a prior post, I'd actually like to see this as well. I support the move of the entire industry to closed loop.

Please let me know how wrong my assumptions and calculations are.

Perhaps my "Are you kidding?" kicked this off on the wrong foot. I apologize.

Seriously, tone is really hard to convey when communications are entirely written, and I used a phrase that might have worked in a face-face conversation, yet that clearly caused miscommunication on a forum.

I apologize.

-

@Danal said in Layer shift detection?:

Seriously, tone is really hard to convey when communications are entirely written, and I used a phrase that might have worked in a face-face conversation, yet that clearly caused miscommunication on a forum.

I apologize.

No hard feelings, i understand

@Edgars-Batna said in Layer shift detection?:

That doesn't entirely apply to integrated stepper drivers. They get very close to constant torque because of what I said previously.

What do you mean? Do you have a source for that claim?

Integrated just means they are soldered on the board instead of pushed in a socket or connected externally.

The torque drop off is largely due to the design of the stepper motor itself.

I´m not going into detail, there´s wikipedia or books for that, but in short Inductance and lack of time for the current to build in the windings is the leading cause for step motors losing torque at high speeds.

You can mitigate that by increasing the voltage which in turn builds current faster. -

@NitroFreak said in Layer shift detection?:

@Danal said in Layer shift detection?:

Seriously, tone is really hard to convey when communications are entirely written, and I used a phrase that might have worked in a face-face conversation, yet that clearly caused miscommunication on a forum.

I apologize.

No hard feelings, i understand

@Edgars-Batna said in Layer shift detection?:

That doesn't entirely apply to integrated stepper drivers. They get very close to constant torque because of what I said previously.

What do you mean? Do you have a source for that claim?

Integrated just means they are soldered on the board instead of pushed in a socket or connected externally.Fixed:

That doesn't entirely apply to integrated stepper drivers like TMC used in the Duet. -

@Edgars-Batna said in Layer shift detection?:

Fixed:

That doesn't entirely apply to integrated stepper drivers like TMC used in the Duet.I just looked through the 2660 datasheet (https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC2660_datasheet.pdf)

and couldn´t find any reference to a torque curve or generally a flat torque band thanks to the 2660.

Could you elaborate some more? -

@NitroFreak said in Layer shift detection?:

@Edgars-Batna said in Layer shift detection?:

Fixed:

That doesn't entirely apply to integrated stepper drivers like TMC used in the Duet.I just looked through the 2660 datasheet (https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC2660_datasheet.pdf)

and couldn´t find any reference to a torque curve or generally a flat torque band thanks to the 2660.

Could you elaborate some more?The torque curve is not flat, but it's "good enuf" and absolutely not falling rapidly. Obviously, you're better off with a servo for high speed applications, but within a 3d printer TMC manages really well. That's what I understand from reading the docs and from experience.

-

@NitroFreak Wait just a minute... a "super whopper" stepper has stall torque of 85 oz-in? That's a medium sized NEMA-17 stepper spec, not a "super whopper". I've seen NEMA-17 motors that go up to 110 oz-in.

A 52W servo has torque of 17 oz-in. That's like a pancake stepper. Can you drive a 3D printer mechanism with that?

I'm using 64 oz-in steppers to drive X and Y in my corexy machine, and they don't seem to have any trouble throwing the 1.5 kg moving mass around, but can 17 oz-in manage that? Maintaining torque up to 3000 rpm is nice, but there's no need for 3000 rpm in a printer, unless maybe you gear the motor down to get more torque at the more typical speeds.

What am I missing?