Is it normal for motors to vibrate and hiss at standstill?

-

As a result of the recent global development, I now have some time to try and resolve some issues that have been driving me crazy since autumn. In particular, I have been trying to resolve the horrible hissing/grinding noise my printer makes in Spreadcycle mode. The noise is higher pitched when using interpolation, but not dramatically so.

motor settings: M569 P0 S1 D2 F3 B2 Y5:1 for all

motors:

When I touch the motors, I can feel a slight vibration with no dicscernable pattern. I tried capturing the frequency with a guitar tuner but it appears to be all over the place.

I know that exact configuration should work because the motors I have come from a Prusa MK2 (and MK3 has the exact same motors) an the values are from a known working Klipper configuration for the machine (Raspberry Pi + EINSY RAMBO + the same motors). Is it possible I have some sort of high frequency noise in my system? How would I even test for that? I don't have an oscilloscope.

Massive thank you to everyone that decides to help, Matěj -

@Matej101 Can you post all your motor settings from config.g? Or your whole config.g. And M115 for firmware version and board type, so we know what stepper drivers you have. Lastly, what's the model number of the motors, because LDO has a bunch of different ones https://ldomotors.en.alibaba.com/productgrouplist-803887838/XYE_Stepper_Motor.html

Most information on stepper motors is here: https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors

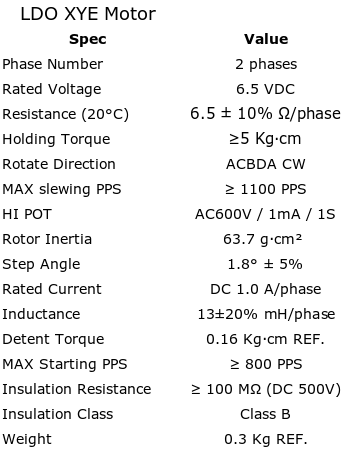

If the specification you posted above is correct, I see two problems with this motor. From https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_General_recommendations

Avoid motors with rated voltage (or product of rated current and phase resistance) > 4V or inductance > 4mH.

The specs above say "Rated voltage 6.5 VDC" and "Inductance 13±20% mH/phase". Which would make them rather unsuitable and noisy. Is this really the motor you have?

I have some no-name steppers with integrated leadscrews on my Z axis, and they are noisy as hell, despite having generally similar specs to other motors I have which are quiet. I think most noise is down to the quality of the stepper; the consistency of the coil windings, the quality of coil wire, the alignment with the magnets on the motor shaft etc. When they are not constructed to high standard, you get coil whine and the motor vibrates from one position to another, particularly at standstill.

Ian

-

As far as I can tell these really are the motors I have. Like I said, they come from a Prusa machine and Prusa has the motors custom painted and stenciled so the model number does not show. The motor settings are in the first post:

m569 p0 s1 d2 f3 b2 y5:1 for all motors

I tried currents from 400mA to about 900mA and the noise never really goes away. I also tried running just the motors from a new separate power supply in case the old psu was unstable, no difference. -

-

@Matej101 said in Is it normal for motors to vibrate and hiss at standstill?:

As far as I can tell this really are the motors I have.

Check the resistance per phase with a multimeter. Is it 6.5 ohms? If so, I don't know how they work with the Trinamic TMC2130, which is basically an inferior version of the TMC2660 on the Duet!

Why not use Stealthchop? Making motors quiet at standstill is what it's for. D3 in your M569 command. But then I don't know the effect of the other settings you have set (F, B and Y). I'd probably just set D3 and set V so it changes over at low speed. See https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M569_Set_motor_driver_direction_enable_polarity_and_step_pulse_timing

I'm guessing you've seen https://duet3d.dozuki.com/Wiki/Reducing_Stand-Still_Noise ? Though doesn't mention Stealthchop, may need to be updated.

Ian

-

I have a Maestro, so TMC2224. I read the wiki page you linked, and tried a whole bunch of other tuning routines I found around the forums. The reason I want to try Spreadcycle is to get better accelerations and accuracy out of the extruder, which is a 3.5:1 belted direct drive. The phase resistance measures 6.8 ohms.

-

I checked the schematics and the RAMBO appears to have twice as big filtering capacitors on the driver output pins as well as a 120 ohm resistor on each pin. I don't really know what the resistors are supposed to do but the caps could play a factor in reducing the noise, no?

-

@Matej101 Can you confirm that the issue you see happens always? What I mean by that is: have you tried various hardware combinations, i.e. other stepper of the same model with the driver you are connected to as well as with other drivers. I just want to make sure that this is not a rare case of driver+stepper=bad-luck-combo.

-

@wilriker I know the steppers work with TMC2130s (like i said before) and I found some pictures online from people using Duet 2 with a Prusa machine. I know for a fact some people use these with SKRs and 2208/9 drivers and they do notseem to have this issue. I have three of those motors (X,Y and E0) and tried two different Duet Maestro boards (first one had a broken reset pin so I sent it back), same issue every time. I also have two slightly different steppers on the Z axis, they have the same issue.

Before switching to Duet, I had a miniRAMBo 1.3 with A4988 drivers. The motors vere very loud and had audible high pitched whine at standstill, bute none of this grinding hiss nonsense. Stealthchop is capable of completely removing those standstill vibrations and whining, but I don't think it is ideal for the extruder.

Datasheets for all the motors:

https://github.com/PrusaOwners/prusa_docs/tree/master/mk3_parts

I have a 0.9 pancake stepper on the way, I'll see how that one performs. -

@Matej101 Have you tried to use stealthChop with a very low switch-over speed to spreadCycle? So you could get rid of any noise at standstill but could leverage the precision and reliability when moving.

-

Yes, it works quite well but again I would like to get rid of Stealthchop at least for the extruder. I can't imagine the sudden EMP when switching is good for print quality, and from my tests it reduces torque too.

-

The 0.9degree stepper has arrived and with it the hiss is (mostly) gone! There is still a faint grinding noise at standstill but it's almost as quiet as the old motor was in Stealthchop mode! I still plan to look around for MK3 owners to borrow motors from for testing, until than the conclusion seems to be one of the following:

- I got unlucky and received a bad batch of motors, or my motors simply wore out (the printer is three years old after all)

- Prusa and Ultimachine have managed to cook up some black magic stabiliser for the Einsy