Heater numbers incorrect in DWC 2.0.7

-

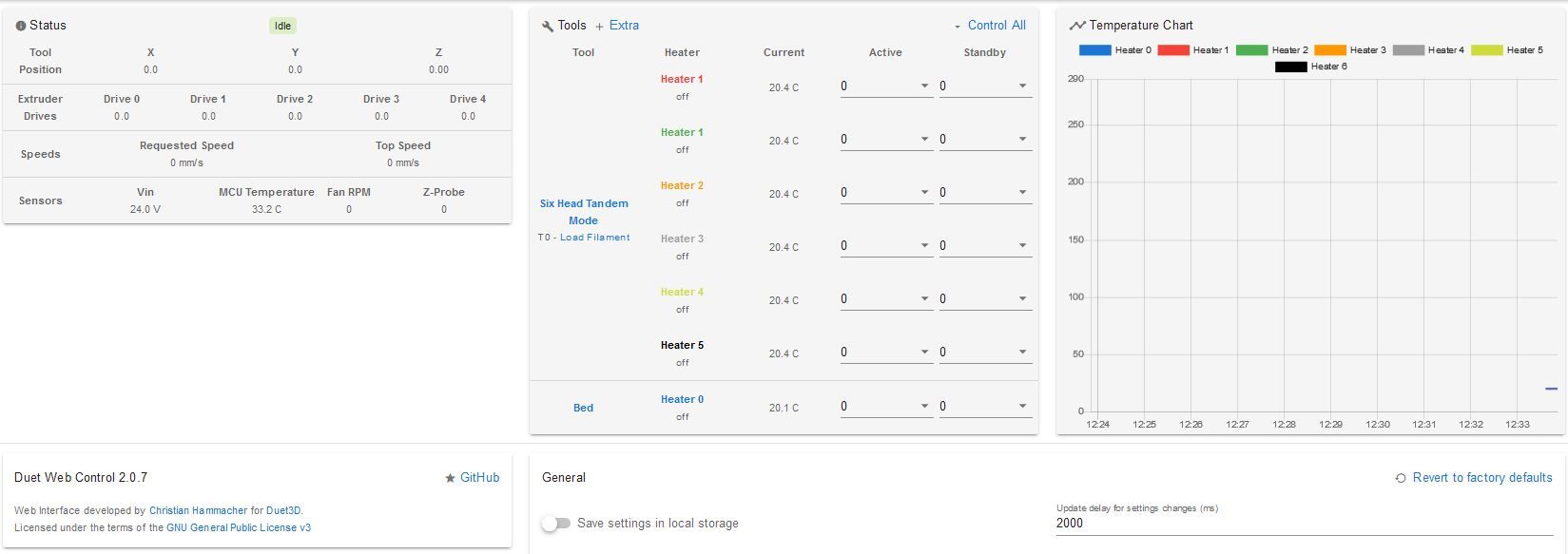

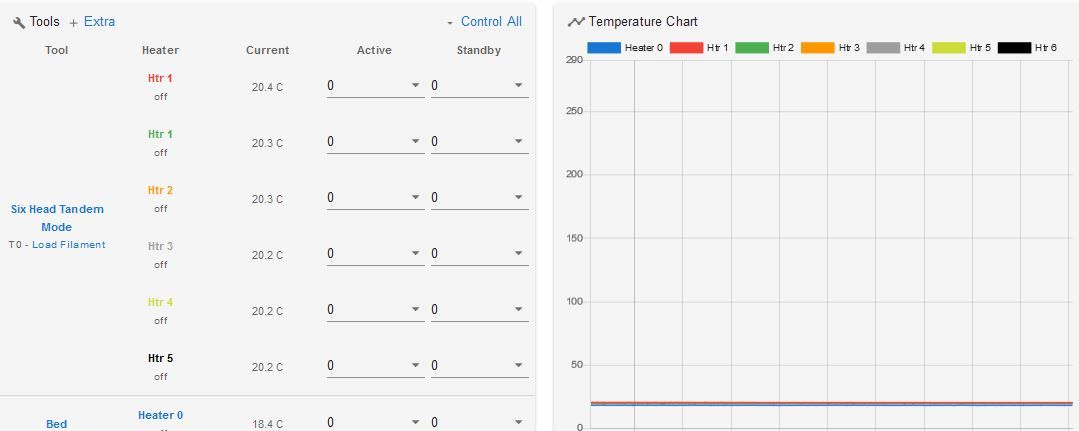

Still a problem in DWC 2.0.7 with heater numbers in the tool list.

Trend chart is correct, but tool list shows heater 1 twice, and omits the last heater regardless the number of heaters

I have another machine with 4 printheads that does the same thing at DWC rev 2.0.4

This problem only happens when combining multiple heaters/drives on one tool, but not when I configure them independently.

Board: Duet WiFi 1.02 or later + DueX5

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 2.05.1 (2020-02-09b1)

Config:

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; By Versatile 3D LLC 8/13/2019; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M200 D1.75 ; set all extruder filament diameters to 1.75mm

M667 S1 ; Select CoreXY mode; Z-Probe

M307 H6 A-1 C-1 D-1 ; Disable the 6th Heater to free up PWM channel 4 on the Duex board. (Special Parameters to chg PWM ch to discreet)

M307 H7 A-1 C-1 D-1 ; Disable the 7th Heater to free up PWM channel 5 on the Duex board. (Special Parameters to chg PWM ch to discreet)

M558 P5 H5 F50 T1500 X0 Y0 Z1 ; Set Z probe type/mode 5. H=Dive Height. F=Speed the bed moves T=Travel Speed(From https://betrue3d.dk/bltouch-on-duet-wifi-configuratio-and-usage/#wiring)

G31 P100 X0 Y30 Z1.50 ;(Z - larger number = smaller gap) Set Z probe trigger value, offset and trigger height

;G29 S1 ; Enable Mesh Bed Compensation (S1 = Load Prev Grid, S0 = New grid probe on pwr up))

M557 X60:600 Y10:425 S75 ; Define mesh grid for printing compensation

M376 H10 ; Set Mesh Bed Taper Height.; External IO

M581 E6 S0 T0 C0 ; Configure E-Stop as E5(E6) S0(NC) T0(Trigger EStop) C0 (Anytime); Network

M550 P"Printfarm-PRO Model 584 PH-1,2,3,4,5,6" ; Set machine name

M551 P"V3DLLC: ; Set password

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drive Directions

M569 P0 S0 ; XY Front / Drive 0 goes backwards

M569 P1 S1 ; XY Rear / Drive 1 goes forwards

M569 P2 S1 ; Z-Left Screw / Drive 2 goes forwards

M569 P3 S1 ; Extruder 0 / Drive 3 goes forwards

M569 P4 S1 ; Extruder 1 / Drive 4 goes forwards

M569 P5 S1 ; Extruder 2 / Drive 5 goes forwards

M569 P6 S1 ; Extruder 3 / Drive 6 goes forwards

M569 P7 S1 ; Extruder 4 / Drive 7 goes forwards

M569 P8 S1 ; Z-Right Rear Screw / Drive 8 goes forwards

M569 P9 S1 ; Z-Right Front Screw / Drive 9 goes forwards; Drive Scaling

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X160.00 Y160.00 Z2535.00 E2660 ; Set steps per mmM566 X15 Y15 Z.25 E20 ; Set maximum instantaneous speed changes (mm/min)

M201 X800.00 Y1000.00 Z25.00 E1500.00 ; Set accelerations (mm/s^2)

M203 X15000.00 Y15000.00 Z1200.00 E5000.00 ; Set maximum speeds (mm/min)

M204 R1000 ; Set Retract accelerations

M205 E3 ; Set Extruder Jerk (not sure where I found this)

M906 X1000.00 Y1000.00 Z800.00 E600.00 I30 ; Set motor currents(mA) and motor idle factor in percent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X450 Y600 Z370 S0 ; Set axis maxima; Drive/Axis Setup

M584 X1 Y0 Z2:8:9 E3:4:5:6:7 ; Drive Mapping (XY=drvs 0/1, Z screws=drvs 2/8/9, extruders=drvs 3/7)

M671 X1:610:610 S3 Y340:705:28 ; Set XY offsets for Z screws at; Endstops

M574 X1 Y1 S1 ; Set active high endstops for X and Y axis

M574 Z1 S2 ; Set endstops controlled by probe (disabled for commissioning W/O Z probe); Heaters

;BED HEATER

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for bed heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C;TOOL HEATERS

M305 P1 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 1

M307 H1 A35 C135 D3.75 B0 ; Set heater tuning parameters for heater 1 (E3D V6 XX Watt Htr Cartridge)

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

M305 P2 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 2

M307 H2 A35 C135 D3.75 B0 ; Set heater tuning parameters for heater 2 (E3D V6 XX Watt Htr Cartridge)

M143 H2 S280 ; Set temperature limit for heater 2 to 280C

M305 P3 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 3

M307 H3 A35 C135 D3.75 B0 ; Set heater tuning parameters for heater 3 (E3D V6 XX Watt Htr Cartridge)

M143 H3 S280 ; Set temperature limit for heater 3 to 280C

M305 P4 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 4

M307 H4 A35 C135 D3.75 B0 ; Set heater tuning parameters for heater 4 (E3D V6 XX Watt Htr Cartridge)

M143 H4 S280

M305 P5 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 5

M307 H5 A35 C135 D3.75 B0 ; Set heater tuning parameters for heater 5 (E3D V6 XX Watt Htr Cartridge)

M143 H5 S280

M305 P6 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 6

M307 H6 A35 C135 D3.75 B0 ; Set heater tuning parameters for heater 6 (E3D V6 XX Watt Htr Cartridge)

M143 H6 S280; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set Fan 0 P0 (Fan 0), S0.3 (30%), I0 (default), F500 (PWM 500hz), H1 (Disable Thermostatic Mode)

M106 P1 S0.3 I0 F500 H-1 ; Set Fan 1 P1 (Fan 1), S0.3 (30%), I0 (default), F500 (PWM 500hz), H1 (Disable Thermostatic Mode)

M106 P2 S1 I0 F500 H1 T45 C"Box_Fan" ; Duet Enclosure Cooling Fan; Tools

;Clone Mode*******

M563 P0 S"Six Head Tandem Mode" D0:1:2:3:4 H1:2:3:4:5:6 F0:0:1 ;Tool setup

G10 P0 S0 R0 X30 Y0 ; Set tool 0 temperatures and offsets (S0/R0=Standby/Active Temp.)

M567 P0 E1.0:1.0:1.0:1.0:1.0 ;Set Extruder Drive Ratios (all drives at 1.0 for ditto printing, add ":1.0" for each tool in use)

M568 P0 S1 ;enable mixing ratios;Single/Dual Extrusion Modes*******

;M563 P0 S"RT Tool" D1 H2 ; Std Printing - Define tool 0

;G10 P0 S0 R0 X30 Y0 ; Set tool 0 temperatures and offsets (S0/R0=Standby/Active Temp.)

;M563 P1 S"LT Tool" D0 H1 ; Std Printing - Define tool 1

;G10 P1 S0 R0 X-35 Y0 ; Set tool 1 temperatures and offsets;M572 D0 S0.05 ; Set Pressure Advance for Extruder 1

;M572 D1 S0.05 ; Set Pressure Advance for Extruder 2; Automatic power saving

;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings are not configured

; Simulated print time: 0

-

Try using the S parameter in M305 to give each heater a "name".

https://duet3d.dozuki.com/Wiki/Gcode#Section_M305_Set_temperature_sensor_parameters

-

@Phaedrux Gave that a try, but it just did the same thing with the new custom text.

-

@HenryDara said in Heater numbers incorrect in DWC 2.0.7:

; Heaters

;BED HEATER

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for bed heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

;TOOL HEATERS

M305 P1 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 1

M307 H1 A35 C135 D3.75 B0 ; Set heater tuning parameters for heater 1 (E3D V6 XX Watt Htr Cartridge)

M143 H1 S280 ; Set temperature limit for heater 1 to 280CThe other thing I notice is the order of your M307/M305 commands. Perhaps change your bed heater to match the order of your tool heaters.

-

@Phaedrux Tried that too, but still the same result. Thanks

-

@chrishamm Do you have any thoughts on this?

-

@dc42 Do you have any thoughts on this issue? Thanks...Henry

-

Looks like you have 6 heaters defined (+ bed heater), but heater 6 is disabled in zprobe section.

-

@aidar Good catch!

-

@aidar Ahhh yes, very good catch. Fixed it in the Config, but that didnt fix the number issue. Thanks for the heads up.

-

If I knew HTML I would dig to find out why it displays the wrong numbers. I dont see anything in the config that might cause a discrepancy on the main HTML page, it it makes no sense that the numbers would be correct in one pane, while different in the one right next to it. Everything functions correctly when I run all six nozzles, so its not the end of the world, but would like to figure it out someday.

-

Work on DWC 2 is still progressing. Thankfully it's just a cosmetic issue. I've moved this to the DWC forum for more visibility for @chrishamm

-

@Phaedrux Thanks for the update. Yes cosmetic, but causing us to make mistakes when setting individual nozzle temperatures. We adjust the numbers in our head for now, so I hope we can untrain when the numbers are correct on DWC2. Any idea how long before DWC2 gets released?

Thanks...HD

-

This post is deleted!