Printed bolt threads are wrong direction CoreXY

-

Can you post a photo of your printer from the front and indicate where the endstops are located?

-

Hi @Phaedrux

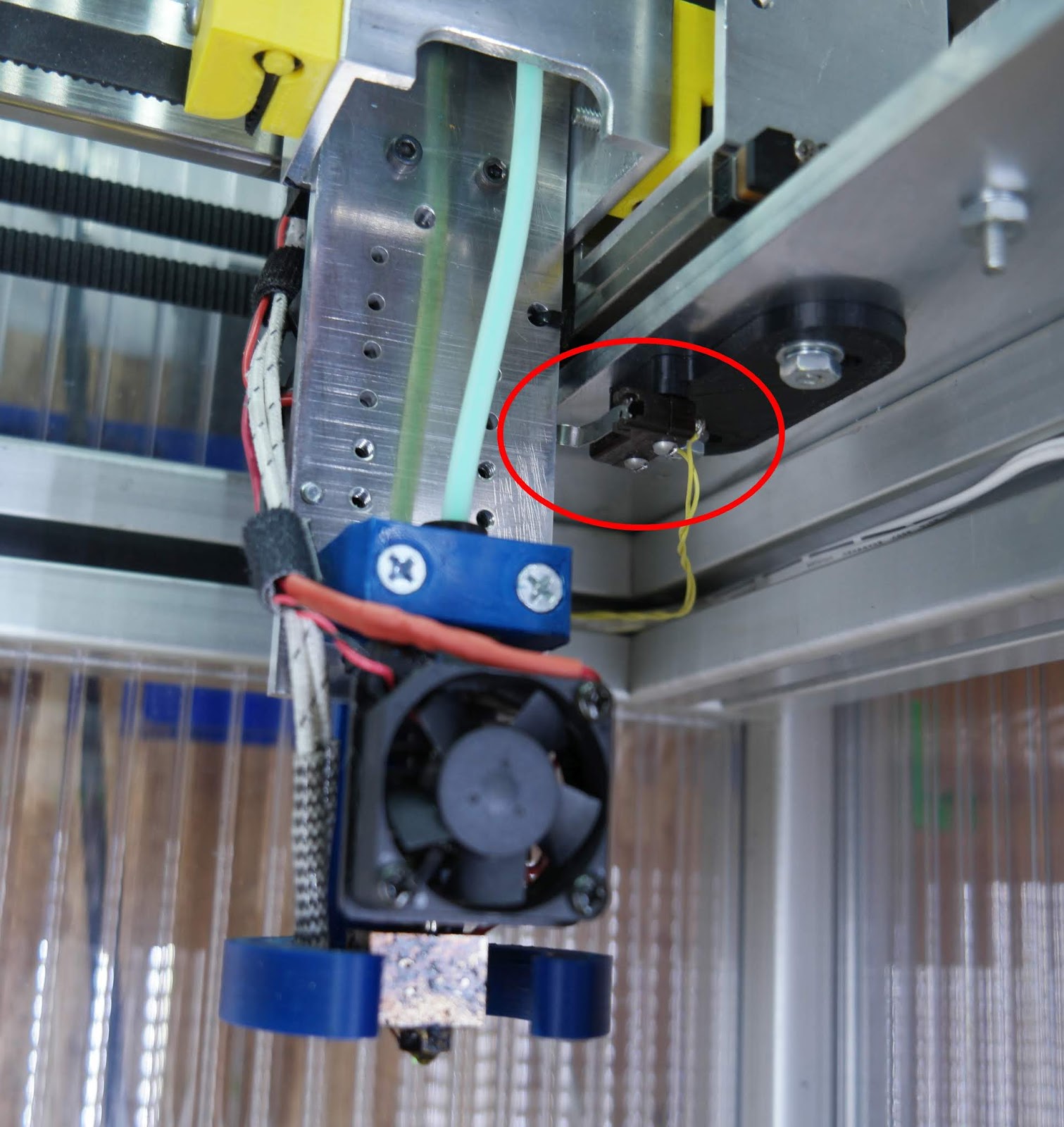

There is it, with X and Y switches visible

85-b760db5b-d95c-4482-9c5c-d45afe2a507f-resized.jpeg)

85-b760db5b-d95c-4482-9c5c-d45afe2a507f-resized.jpeg)

-

-

It looks to me like you have the homing switches in the right rear corner of the machine, and the motors at the front of the machine. The A motor is on the left (plugged into the X diver on the Duet board) and the B motor is on the right (plugged into the Y driver on the Duet board), the same way I set up my printer (except that I put the X switch on the printer's frame instead of on the extruder carriage). I have the origin set to the center of the bed. Here is the relevant section of my config.g file:

; Drives M569 P0 S1 ; motor A goes forwards M569 P1 S0 ; motor B goes backwards M569 P2 S1 ; Z motor goes forwards M569 P3 S1 ; extruder motor goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X160 Y160 Z800 E411 ; Set steps per mm M906 X1600 Y1600 Z1120 E500 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M205 X20 Y20 Z2 E50 ; Set maximum instantaneous speed changes (mm/sec) M203 X18000 Y18000 Z900 E3000 ; Set maximum speeds (mm/min) M201 X3000 Y3000 Z1000 E3000 ; Set maximum accelerations (mm/s^2) M204 P3000 T3000 ; Set print and travel acclerations (mm/s^2) ; Axis Limits M208 X-153:153 Y-178:150 Z0:687 ; Set axis minima:maxima ; Endstops M574 X2 Y2 Z1 S1 ; Set active high endstopsWhen homing, the extruder carriage should move toward the switches, regardless of their positions relative to minimum or maximum ends of the axes. M574 statement tells the machine that when the switches are activated, they are at Xmax and Ymax. The M208 statement tells the firmware what the ordinate values are at those positions.

-

Sorry, I got distracted by baby. Here's the post I started earlier in case @mrehorstdmd post didn't get you sorted.

Ok, so -X moves to the left, +X moves to the right, +Y moves to the back, -Y moves to the front. 0,0 is at the front left and 200,200 (for example) is back right.

You have the x endstop on the low end of travel (looks like its on the left side of the extruder carriage and the trigger bolt on the left side) and the Y endstop at the high end of travel at the back. The endstops look like makerbot style switches with an activation LED on the PCB, so active low.

M574 X1 S0

M574 Y2 S0Then in your homex you need to change from moving to X positive to X negative, like so:

; homex.g ; called to home the X axis G91 ; relative positioning M913 X50 ; set X motors to 50% of their normal current for homing G1 S1 X-321 F1000 ; move quickly to X axis endstop and stop there (first pass) G1 X3 F1000 ; go back a few mm G1 S1 X-321 F200 ; move slowly to X axis endstop once more (second pass) M913 X100 ; set X motors to 100% of their normal currentHome Y looks correct.

Homeall looks correct as well.

If the head isn't moving in the direction you expect (like -X going to the right) then one of the motors is either plugged into the wrong motor port, or needs to be reversed. Note your motor connections as described by mrehorst, and use the motor direction test from the corexy setup link to verify that the motors are turning in the right direction.

-

Damn! Thank you guys a million!

That was making me nuts... Eventually, I needed to swap motors indeed and reverse them:M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards@Phaedrux thanks a lot for a sketch and tweaking the homex.g - that solved it all.

Minus one issue - million to go :))

-

@felt342 Good! Now you can get to the fun stuff like calibrating the extruder...

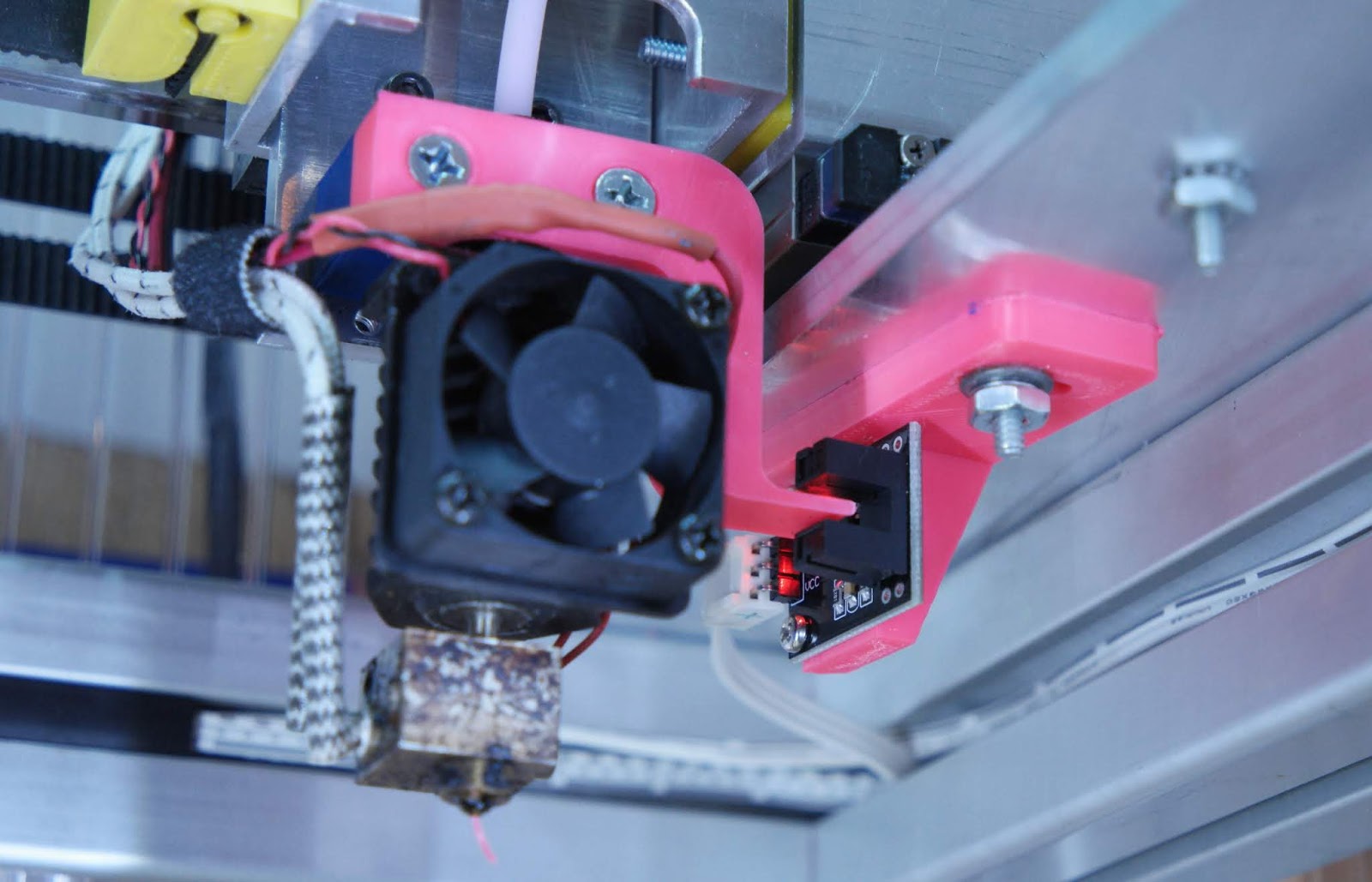

It isn't entirely necessary to have the X endstop on the X axis. Doing so requires an extra wire or two going to the extruder carriage. I prefer to minimize wires going to the extruder carriage. You can put the X axis endstop on the printer's frame instead, in which case you'll have to home Y before homing X. I've been doing that in my printer for over a year and it works fine. I just modified the homex.g file to home Y before it homes X.Older version of extruder carriage with X endstop mounted on printer frame:

Latest version:

-

It is a good point, I am thinking about to stick it to the frame. May I ask you that tunnel switch, is there any advantage compared to normal switch?

-

Well it is occasionally handy to be able to home the X axis without having to first home the Y axis to get it in position.

-

@Phaedrux said in Printed bolt threads are wrong direction CoreXY:

Well it is occasionally handy to be able to home the X axis without having to first home the Y axis to get it in position.

Before I put the switch on the frame I thought the same thing. In the year or so that it's been that way I haven't missed being able to home the X axis independent of Y.

-

@felt342 said in Printed bolt threads are wrong direction CoreXY:

It is a good point, I am thinking about to stick it to the frame. May I ask you that tunnel switch, is there any advantage compared to normal switch?

I assume you're referring to the optical switch. The ones I used have an LED on board that indicates when the light is blocked and that can be handy for making adjustments without having to check the display connected to the controller board. The type of snap action switches I was using always have some hysteresis that can make adjustments a little tricky, especially setting the Z=0 position in my sensorless printer. The optical switches have much less hysteresis. I'll be converting the Z axis endstop in my printer to optical next, now that I have figured out a way to make very fine adjustments.

I'm have mixed feelings about the optical endstops. The snap action switches I was using are extremely reliable. I don't know how well the optical switches will hold up at 50C. I haven't done any testing to see if the switches are affected by ambient light. These type of things are used in industrial machinery all the time so it's probably not an issue.

-

Thanks for sharing your experience!