bulge after z seam when printing outer layer first

-

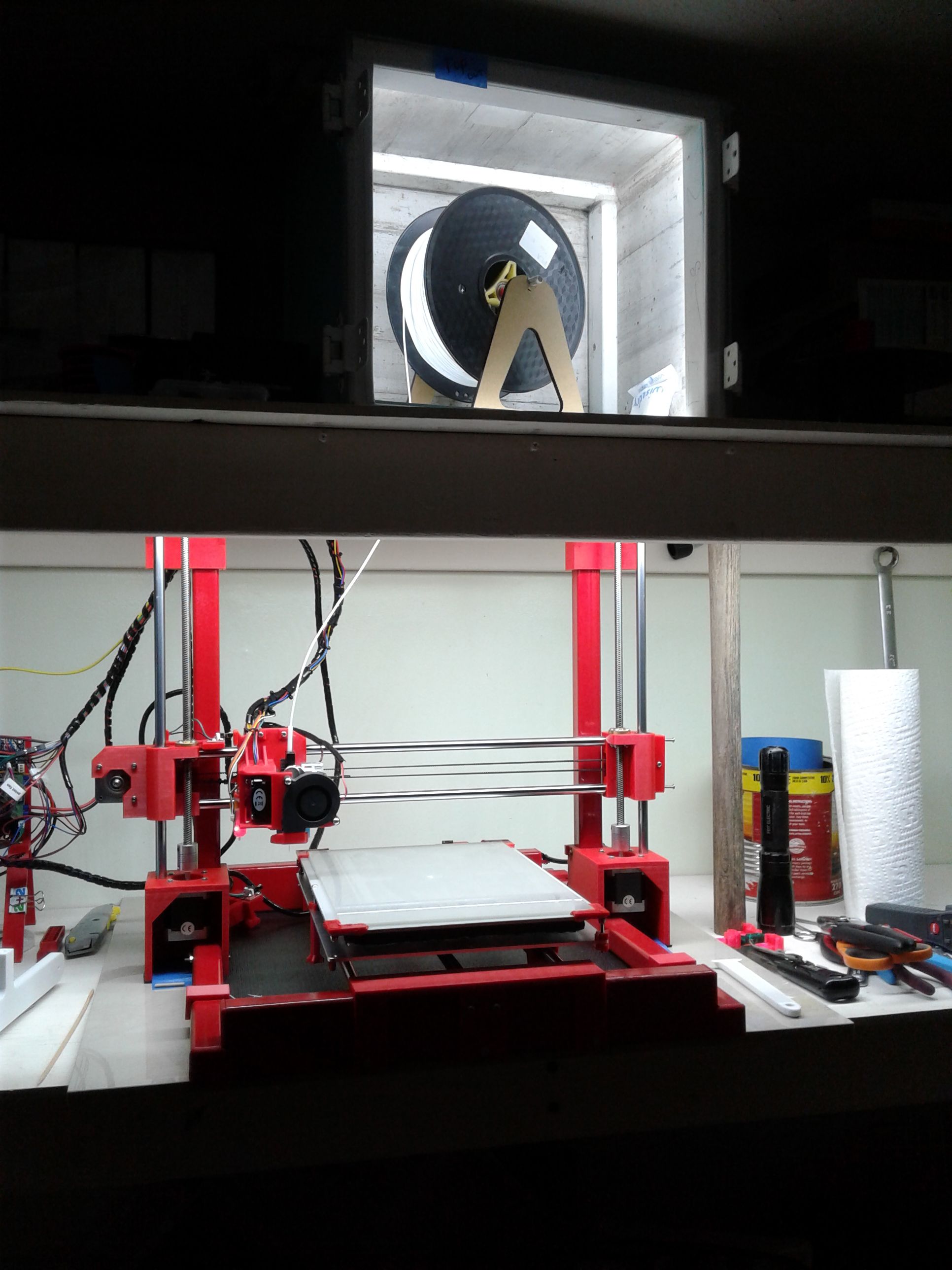

I finished building my first machine a couple weeks ago and I am still trying to dial it in. It uses a Titan Aero. I am having a problem I can't seem to shake.

When I print the outer walls first using cura on a round object printing with PLA, the start of the move at the seam bulges, which gradually tapers off and looks good after about an 1/8 of the way through the turn.

The problem starts shortly after the base is done.

I have tried changing temp down to 185, pressure advance from 0 to 0.100, retraction up to 1.5, outer wall speed down to 10 and up to 50, cooling from 40-80%, minimum layer time up to 15s.

I think it must be overextruding at the start.

I am running out of ideas, any input would be greatly apprecitated.

Thanks!!

-

@RedMachine

Have you tried adding a small negative value for unretract distance? If there's a bulge after an unretract that can sometimes help - especially with the more ooze-prone filaments like PLA and PETG.Keep the value small (5% -10% of your retract distance is a good place to start) or you might wind up starving your hotend for filament for models with frequent retractions.

-

@RedMachine

Witch kind of machine, CoreXY? -

I set "extra prime amount" to 0.5mm3 for a quick first test, and it definitely under-extruded the seam. This is the first thing that has effected it at all, so I will see if this can dial it in.

The setting is in mm3 and I am trying to retract 1.5mm printing with 1.75 filament, so I I will try 0.18mm3 which should be about 10% of the volume.

-

have you try to print a cylinder in vasemodus? if not please do it and post the result

-

It is a plane Cartesian that moves the gantry in the Z axis.

-

How was the orientation on the bed?

I would print a cube, setting the seam to the middle of one side.

That would it make easier to relate to the axis. For me it looks more like slack or lose parts. -

I actually did try changing belt tension some. It looked at first to me like it was overshooting with the Y axis.

It was oriented with the seam facing the front of the Y axis.

I will try a cube as you suggested.

-

-

@SIam What would this help disambiguate? Would it indicate if it is over-extruding in general or just at certain points?

-

As the spiralized without prime looks good for me, why are you using prime?

-

the cylinder looks good so far

your extruder runs smooth without any clicking noise? -

It does make a soft noise when it is retracting, but i wouldn't describe it as clicking. More like gears turning.

Since I haven't had a Titan before, i wasn't sure what to expect from it. I have it set at:

400 jerk mm/min

5000 speed mm/min

2000 accDIY, i was testing prime in the regular print also, so I thought I would just point out the conditions of the two different tests.

-

@RedMachine

Your jerk and acc is very low. On my BMG I use much higher values. -

@DIY-O-Sphere

What are your settings?

So I can know a range to start messing with. -

@RedMachine

Depends on the size of the motor.

In you case I would take the values of Phaedrux. They were pretty similar to mine (Pancake BMG direct) Currently I'm back on a bowden setup with a bigger motor.

https://forum.duet3d.com/topic/5982/typical-titan-extruder-settings/5?_=1578786524923

You also can increase your max. speed. The linked value is very high and only nessary for high speed printing. I would set that to 8000 mm/min -

@RedMachine

From that base you can try to increase jerk. But at some point your extruder will start skipping. -

it's 1.8, but I think they are similar. 17hs08-1004s.

Thanks for the link, I missed him saying that in that thread.