Delta experts: feedback appreciated

-

I see, there are 2 or 3 different calculators to check the min arm angle, but with your detailed model you can see right away what the angle is in any position. Just make the footprint smaller until you reach 20deg.

As for learning fusion, thats indeed the right way to go. I am still tweaking parts here and there^^

Mind sharing the link to the alu plates? when i look on ebay everything over 2mm thickness is super expensive

-

@sungod3k Yes, that was great. I only saw that today after creating ball joints. I moved the hotend to the edge of the bed opposite the tower and could just read the arm angle. Great stuff. I already modified the dimensions, but it messed up my effector assembly. Will redo that tomorrow.

Sorry, don't have a link to aluminum. A friend cut the parts for me, and charged 15€ including material. I guess for him they were small scrap parts.

-

I updated the design. Opposite the towers, the min arm angle is now 20.7deg. And towards the tower, at the edge of the bed I can barely fit a 4010 blower fan (1mm clearance to the belts). It all just barely works, and I really want to maximize the build volume.

I am thinking of another way to mount the carriages, like this: https://a360.co/2BhIiRJ

I would need to adjust the carriage, but I would provide some more room for cooling fans. Good idea or not worth the effort? -

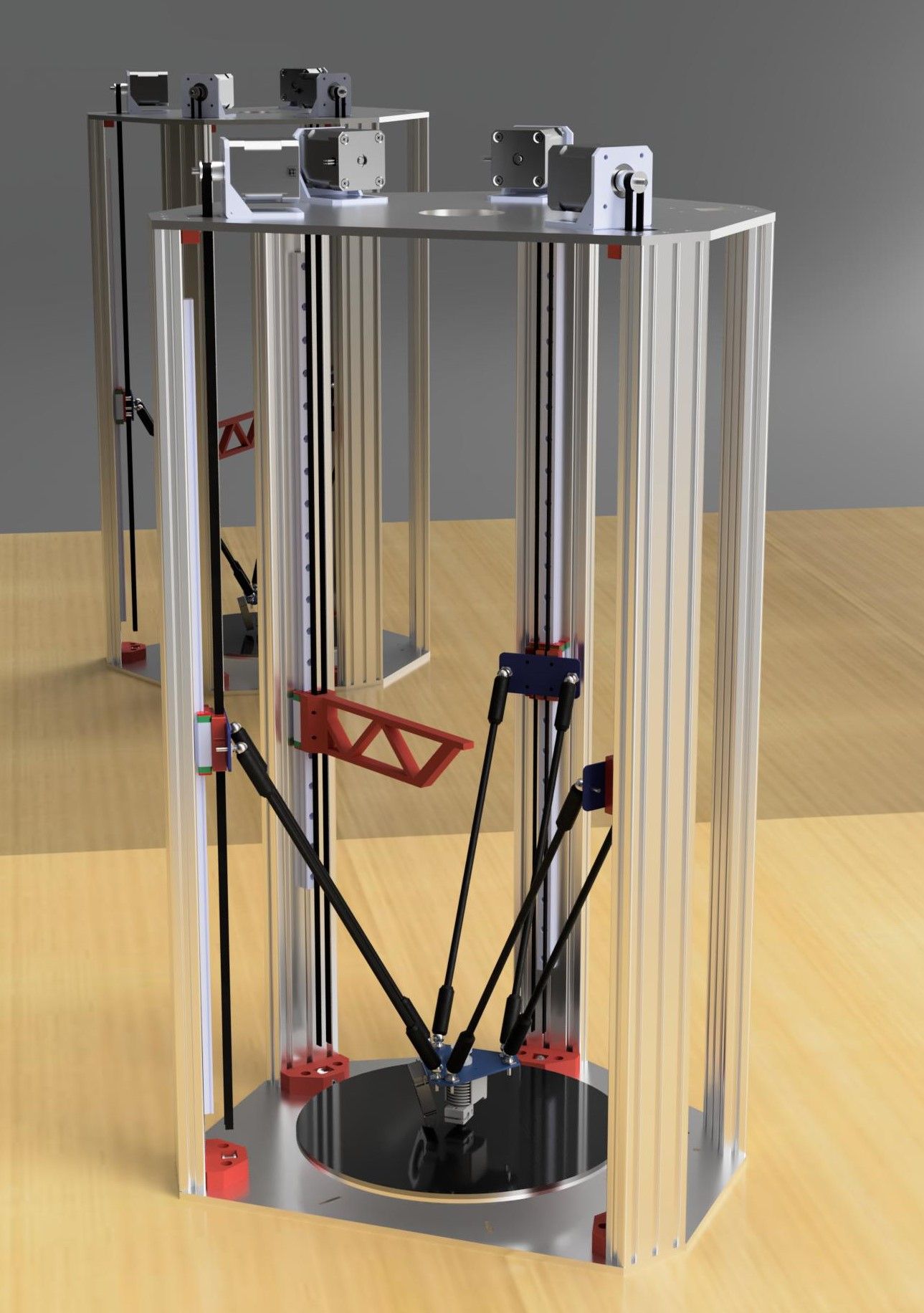

I am also thinking about a delta with alu top and bottom plate. I own a Rostock, and I cannot imagine anything being more rigid (unlike the rostock!) than screw-pulled direct alu to alu contact. Of course the cuts need to be very precise, but if they are there is really not a lot of room for play or mis-alignment. Even with just 3 verticals.

The motors at the top is a good idea. Like the rails it keeps the belts short as possible. I would however make the the plates round. That makes it VERY easy to bend-fit a plexi or acrylic sheet between the V grooves, in a way they follow the curve of the plate. Easy chamber, without the need for hinges and mounting materials!

-

Making the plates round would be fairly simple, although I have no plans on making a chamber.

Just updated again. Moved the carriage adapter in front of the belt. Now I have 23.6deg angle on the edge and more clearance near the towers: Minimum of 18mm between the edge of the smart effector and the belt.

-

I think I am almost done with th ebasic frame layout.

I just received an email about the Zesty Nimble V2. I did have a nimble before, but wasn't 100% satisfied.

Now I am in doubt about the extruder setup:- Fying extruder

- Nimble V2

- Or 4th axis extruder?

-

Drew up a first concept for the 4th axis extruder mount:

-

So, I would like some feedback/ verification:

With a 240mm bed, I now have:

- 25deg at the edge of the bed, opposite a tower

- 85deg, at the edge of the bed, nearest a tower

- 61deg in the middle of the bed.

Are these numbers ok?

-

Yes, the "rule of thumb" limit on low angle is 20 degrees (and that always occurs opposite a tower). You are comfortably away from that. None of the other angles really matter.

-

@Danal Thanks, I thought I saw DC42 mention somewhere that the center or high angles can have an affect on resolution. But it's hard to find any info on that. Thats why I asked for verification.

I can still put a 260mm bed in this setup, and the low angle then is about 22deg.

-

@bartolomeus said in Delta experts: feedback appreciated:

I think I am almost done with th ebasic frame layout.

I just received an email about the Zesty Nimble V2. I did have a nimble before, but wasn't 100% satisfied.

Now I am in doubt about the extruder setup:- Fying extruder

- Nimble V2

- Or 4th axis extruder?

I have used Nimbles on all my printers and they have worked well for me.

What problems did you have?

It would be much simpler than a flying extruder.

Frederick

-

I would go big. 22 is fine.

-

@fcwilt said in Delta experts: feedback appreciated:

@bartolomeus said in Delta experts: feedback appreciated:

I think I am almost done with th ebasic frame layout.

I just received an email about the Zesty Nimble V2. I did have a nimble before, but wasn't 100% satisfied.

Now I am in doubt about the extruder setup:- Fying extruder

- Nimble V2

- Or 4th axis extruder?

I have used Nimbles on all my printers and they have worked well for me.

What problems did you have?

It would be much simpler than a flying extruder.

Frederick

I never totally got rid of the wave pattern on the surfaces, even after I used the specified grease and also after they sent me a new worm gear.

-

Hi,

Just another thought.

Even if you don't go with a flying extruder you might want to keep the two additional "towers" and design some diagonal bracing between them and the rear tower.

Keeping things square with no bracing can be a challenge.

Frederick

-

@Danal Maybe in the future, I have a new 240mm bed ready to be installed. I'd like to have a 260mm one made out of tooling plate, but my funds have vanished....

-

@bartolomeus said in Delta experts: feedback appreciated:

@fcwilt said in Delta experts: feedback appreciated:

@bartolomeus said in Delta experts: feedback appreciated:

I think I am almost done with th ebasic frame layout.

I just received an email about the Zesty Nimble V2. I did have a nimble before, but wasn't 100% satisfied.

Now I am in doubt about the extruder setup:- Fying extruder

- Nimble V2

- Or 4th axis extruder?

I have used Nimbles on all my printers and they have worked well for me.

What problems did you have?

It would be much simpler than a flying extruder.

Frederick

I never totally got rid of the wave pattern on the surfaces, even after I used the specified grease and also after they sent me a new worm gear.

Hmm...

I had problems with my deltas but that wasn't one of them. What was the supposed cause?

Frederick

-

-

@fcwilt said in Delta experts: feedback appreciated:

@bartolomeus said in Delta experts: feedback appreciated:

@fcwilt said in Delta experts: feedback appreciated:

@bartolomeus said in Delta experts: feedback appreciated:

I think I am almost done with th ebasic frame layout.

I just received an email about the Zesty Nimble V2. I did have a nimble before, but wasn't 100% satisfied.

Now I am in doubt about the extruder setup:- Fying extruder

- Nimble V2

- Or 4th axis extruder?

I have used Nimbles on all my printers and they have worked well for me.

What problems did you have?

It would be much simpler than a flying extruder.

Frederick

I never totally got rid of the wave pattern on the surfaces, even after I used the specified grease and also after they sent me a new worm gear.

Hmm...

I had problems with my deltas but that wasn't one of them. What was the supposed cause?

Frederick

In the beginning many people had wave patterns on the surface of their prints with a Nimble. Most of these patterns disappeared by replacing the supplied lubricant with some silicone grease. The Nimbles are now supplied as standard with the silicone grease I believe. But somehow I couldn't get rid of it.

-

@bartolomeus said in Delta experts: feedback appreciated:

In the beginning many people had wave patterns on the surface of their prints with a Nimble. Most of these patterns disappeared by replacing the supplied lubricant with some silicone grease. The Nimbles are now supplied as standard with the silicone grease I believe. But somehow I couldn't get rid of it.

Thanks for that info.

I guess I got lucky.

Frederick

-

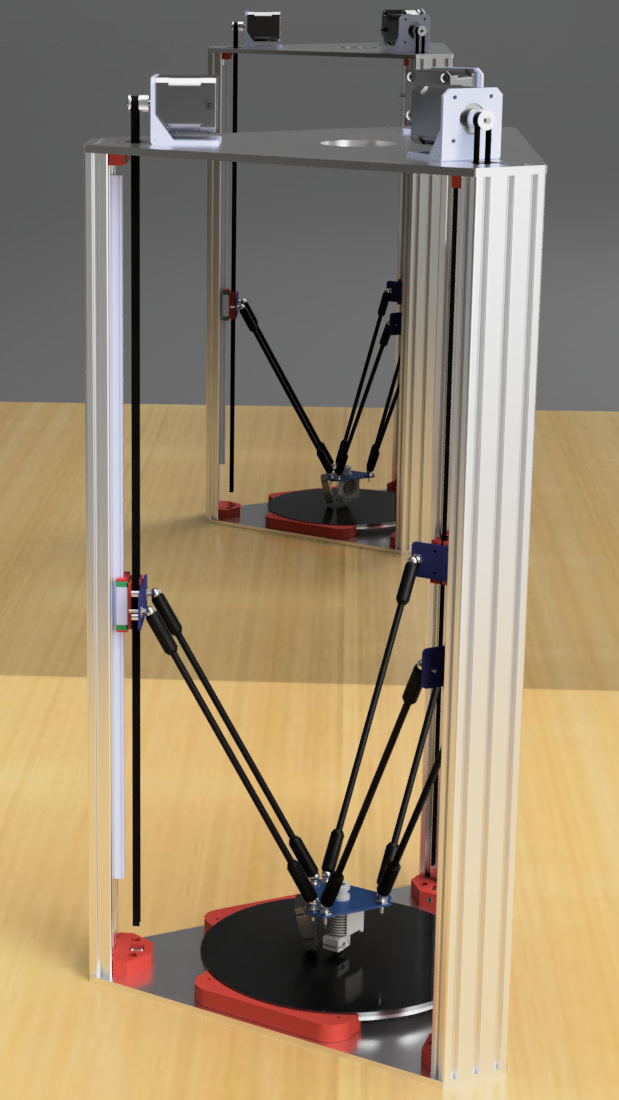

Whilst waiting for parts to arrive, I modified the design to a standard 3 tower delta. As a result the footprint is alot smaller.