Mesh bed leveling (3/4 of the bed works flawlessly)

-

I'm having an issue where the left side of my bed is constantly too close to the nozzle. The front, back and right side (even the middle) works perfectly, but if I print anything on the left side, the bed is always too close to the nozzle. I have an anet style printer, and my bl touch is located behind the x axis bearings. could this be the issue? It can't reach the front of the bed, so I would understand if that side wasn't meshed properly, but it is. Could the software mistakenly rotate my mesh compensation by 90 degrees? maybe its my bed gcode file... I'm not sure. Here are my config files:

Config.g:

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Wed Jul 31 2019 19:43:14 GMT-0600 (Mountain Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 P"Tatara" ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Physical drive 0 goes forwards

M569 P1 S1 ; Physical drive 1 goes forwards

M569 P2 S0 ; Physical drive 2 goes backwards

M569 P3 S0 ; Physical drive 3 goes backwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E837.00 ; Set steps per mm

M566 X600.00 Y600.00 Z18.00 E300.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z180.00 E6000.00 ; Set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z100.00 E10000.00 ; Set accelerations (mm/s^2)

M906 X500.00 Y500.00 Z500.00 E950.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-30 Y-43 Z0 S1 ; Set axis minima

M208 X215 Y200 Z240 S0 ; Set axis maxima; Endstops

M574 X1 Y1 S0 ; Set active low and disabled endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H5 F120 T6000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P500 X14 Y80 Z0.75 ; Set Z probe trigger value, offset and trigger height

M557 X30:200 Y-30:200 S40 ; Define mesh grid; Heaters

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S130 ; Set temperature limit for heater 0 to 130C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S275 ; Set temperature limit for heater 1 to 275C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings

M569 P4 S0 ; Physical drive 4 goes backwards

M584 X0 Y1 Z2:4 E3 ; Set Z motors on drives 2 and 4

M671 X-43.0:309.0 Y137.5:137.5 S4 ; Set the Z motor relative locationsM307 H1 A350.6 C148.4 D5.6 V11.8 B0

; Miscellaneous

T0 ; Select first toolBed.g:

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v2 on Wed Jul 31 2019 19:43:13 GMT-0600 (Mountain Daylight Time)

M561 ; clear any bed transform

G29 ; probe the bed and enable compensationalso, here are the errors I get:

Warning: Skipping grid point (30.0, -30.0) because Z probe cannot reach it

Warning: Skipping grid point (70.0, -30.0) because Z probe cannot reach it

Warning: Skipping grid point (110.0, -30.0) because Z probe cannot reach it

Warning: Skipping grid point (150.0, -30.0) because Z probe cannot reach it

Warning: Skipping grid point (190.0, -30.0) because Z probe cannot reach it

Warning: Skipping grid point (190.0, 10.0) because Z probe cannot reach it

Warning: Skipping grid point (150.0, 10.0) because Z probe cannot reach it

Warning: Skipping grid point (110.0, 10.0) because Z probe cannot reach it

Warning: Skipping grid point (70.0, 10.0) because Z probe cannot reach it

Warning: Skipping grid point (30.0, 10.0) because Z probe cannot reach it -

I would work to get all of your mesh points probable just to eliminate the obvious errors first.

; Axis Limits

M208 X-30 Y-43 Z0 S1 ; Set axis minima

M208 X215 Y200 Z240 S0 ; Set axis maxima...(clip)...

G31 P500 X14 Y80 Z0.75 ; Set Z probe trigger value, offset and trigger height

M557 X30:200 Y-30:200 S40 ; Define mesh gridFrom your config values the minium co-ordinate your nozzle can reach is (-30,-43), and the maximum (215, 200). If you moved your nozzle to (0,0) your probe would be over (14, 80).

The area of the bed plane the probe can reach is (-16, 37) to (229, 280). You wouldn't want to probe right upto the the limits of your motion or bed, perhaps leave 5mm spare. Assuming (0,0) and (215,200) places your nozzle over opposing corners of your bed this leaves the area you can probe as (5,42) to (210, 195).

First step for me would therefore be change:

M557 X30:200 Y-30:200 S40 ; Define mesh grid

To:

M557 X5:210 Y42:192 S43:30 ; Define mesh grid

But, this is all assuming your printable area is (0,0) to (215,200) and the probe offset is set correct.

-

I would be tempted to take it back a few steps just to ensure all is fine with your limits and probe offset. I find it easier working with (0,0) being the centre of the bed, but that's personal preference. If you do this M208 has been tidied up so you can do maximum and minimum on one line like:

M208 X[min]:[max] Y[min]:[max] Z[min]:[max]

-

Alright, I fixed the mesh grid, and will retry with the print that's giving me trouble. I measured the distance from 0,0 to the probe, and it was as you said. I also preferred it when the printer homed in the middle, but was unsure of how to do that. I'm guessing its a tick box I missed somewhere, I'll take a look. Although, I wasn't too sure how the mesh leveling worked on my other board, I just knew it worked and all was well lol.

Alright, The test print started, but the results are pretty much identical. I'm starting to think its the location of the sensor, but I have no evidence to support that theory. I might have to design a different mount, that would be closer to the nozzle.

-

looks like my bed is horribly out of level, I'll fix that now, but it shouldn't matter? my Anet board never really cared lol

-

Twist may give you a bit of an issue because of the large y offset. I'll reply later this evening about (0,0) in the centre.

-

Alright. Looks like I need some anti-backlash for my Z-axis, as it was a good centimeter off. I'm re-leveling now and will try again.

Edit: Alright, after levelling my bed, everything seems to be working better. Probem is, I just snapped off my bl touch holder. I'll have to super glue it and print a new one. I'm still interested in the centre homing spot though

Thanks for all the help!

Thanks for all the help! -

Morning!

Later (or earlier, depending on perspective!) than I had anticipated. Glad you're making progress. I'm having bed levelling issues myself and am part way through a thorough test on an inductive probe.

- Measure the size of your printable area in x and y axis. If new to the machine double check which is x and y by nudging the axis on duet web control. You want to measure parrallel (in the same direction as) the motion of the axis. I always assume the x axis is left to right as you are looking at a machine and came unstuck many times with my cantilever Ormerods in the simplest view the designers took a leg of the z axis and rotated the whole machine -90 degrees about z!

For my machines with MK3 alloy beds this is about 214mm. From your config file I'm assuming your bed is 215 in x and 200 in y.

- Measure the travel from the home positions to the the x and y axis to the closest part of the bed.

Again assuming (0,0) places the nozzle directly over the minimum corner of the printable area then you machine needs to travel 30mm in x, and 43 in y.

- Adjust M208 to suit the numbers you have recorded.

You had the following in your config:

M208 X-30 Y-43 Z0 S1 ; Set axis minima

M208 X215 Y200 Z240 S0 ; Set axis maximaThis is the same as:

M208 X-30:215 Y-43:200 Z0:240; Set axis limits

The distance from the central point of the printable area to the X limit switch is:

-(215/2) - 30 = -107.5 - 30 = -137.5

The distance from the central point of the printable area to the edge of the printable area furthest from the X limit switch is:

215/2 = 107.5

The distance from the central point of the printable area to the Y limit switch is:

-(200/2) - 43 = -100 - 43 = -143

The distance from the central point of the printable area to the edge of the printable area furthest from the Y limit switch is:

200/2 = 100.00

This would make your M208 look like:

M208 X-137.5:107.5 Y-143:100 Z0:240; Set axis limits

- Just as a sanity check, check the distance between the minimum and maximum positions in each axis to ensure they haven't changed:

X Axis:

Old == New

215 - -30 == 107.5 - -137.5

245 == 245Y Axis:

Old == New

200 - -43 == 100 - -143

243 == 243That should sort you out. I'll add a bit more about fiddling these settings to make it more accurate another time. Make sure you change your slicer too!

- Measure the size of your printable area in x and y axis. If new to the machine double check which is x and y by nudging the axis on duet web control. You want to measure parrallel (in the same direction as) the motion of the axis. I always assume the x axis is left to right as you are looking at a machine and came unstuck many times with my cantilever Ormerods in the simplest view the designers took a leg of the z axis and rotated the whole machine -90 degrees about z!

-

Morning! Albeit a little early as it's 2:00 am here haha.

I plugged the new M208 numbers in, and when instructed the nozzle finds (0,0) in the middle of the bed which is awesome! My bed is technically 220x220, but I'm having issues with the X-carriage and my Y-axis decreased in size when I upgraded my frame sadly. when I fix my x-carriage issues, I'll follow your math to get the true center (which is only 2.5mm away anyways).

I do see an issue with where my BL touch is probing. it doesnt really probe in the centre. More like towards the front right. Then when I try to level it its starts very far back, and eventually runs off the bed.

I'm still using the mesh grid from earlier, I'm guessing that's the issue?

I'm trying to figure it out now.

-

Yes you would need to do a new mesh. Out and about now but if I've signal while the little one is asleep I'll have a look at the mesh.

Regards the BL touch some people have reported that they needed to disable the heater for the duration of the probing and they have also reported issues with probing directly over magnets in a magnetic bed.

-

Sounds good

I've got lots of time. I designed a new BL touch holder. Ill try to print it quickly, and see if it works. If it does, it would allow me to probe my whole bed, aswell as more z height and maybe even a bit on the X axis. I'll update in a bit. (If I don't pass out again, but I should be good for another while here lol.)

I've got lots of time. I designed a new BL touch holder. Ill try to print it quickly, and see if it works. If it does, it would allow me to probe my whole bed, aswell as more z height and maybe even a bit on the X axis. I'll update in a bit. (If I don't pass out again, but I should be good for another while here lol.) -

Okay, So i made my BL touch mount, and it came out perfect the first time! even the quality was top notch due to the leveling lol. I measured the distance from the nozzle, and it is 3mm to the left on the x-axis, and 33mm behind it. I'm pretty happy with how it turned out as the carriage is much cleaner looking. I think I might be done for the day though as it's 4:35am now. Time for a cigarette, and to head off to bed. I'll have to figure out the z offset tomorrow as well for what feels like the thousandth time. Oh well. Its all worth it when it all works reliably in the end. After that, you take it apart again and make it better lol.

Have a good day!

-

Working on the other side of my day here! It was about that for my first post but no sign of my son falling asleep yet!

-

@doctrucker Hehe fair enough

Yeah, I'm all the way in Canada, how about you?

Yeah, I'm all the way in Canada, how about you?I think I was successful in gaining an extra 5mm on my X gantry, which means it's working area can be set to it's original 220mm. I'll have to change the axis limits first, and then I'll try working on the mesh grid, which should now be 220X210.

I like how you can put these codes into the custom section of the configurator. It makes editing the other code much easier.

-

I'm in the UK.

So from your comments earlier if you moved your nozzle to (0,0) over a piece of paper and marked the location of the probe you would have to move the nozzle to (-3,33) to be over that point? If so that would make your G31 line in your config (although you're liekly to need to fiddle the z trigger point):

G31 P500 X-3 Y33 Z0.75

This would mean based on:

M208 X-137.5:107.5 Y-143:100 Z0:240; Set axis limits

You can probe the following points area:

X Axis -140.5 to 104.5

Y Axis -110 to 133As discussed earlier the printable area is:

X Axis -107.5 to 107.5

Y Axis -100 to 100So the area we can probe (with 5mm 'spare') is:

X Axis -102.5 to 99.5

Y Axis -95 to 95Your mesh config line becomes:

M557 X-102.5:99.5 Y-95:95 S40.4:38 ; Define mesh grid

The S part of the above sets the grid size, and the above creates an array of 25 probe points.

Use the gcode reference as a guide when learning about the config file. I've added links to the config lines above to help explain them. Test my suggested config lines carefully and hover over the emergency stop on Duet Web control the first time you use it as I'm not always right myself on these things first stab!

-

You'll need to work on the above a little. Your config maximum limits should be set to avoid physical collisions on the machine rather than making sure the nozzle doesn't go outside the printable area. carefully move the axis to the software limit, making sure it doesn't his a physical limit first. If it hits a physical limit fist you need to reduce the respective axis travel to ensure it doesn't hit that physical limit. If it doesn't hit a physical limit and there is room to spare then increase the limit and carefully try again until you have the software limit ~2mm before the physical.

With the maximum limits of travel properly set up you should be able to adjust the mesh config and get a little more bed area probed.

-

Here are the new limits I just found, and the mesh I was working on, but was not totally correct. I'll try to fix my code now.

M208 X-140:113 Y-143:100 Z0:240; Set axis limits

M557 X-105:105 Y-100:100 S52.5:50 ; Define mesh gridThanks

I'll update once I know more.

Update: Alright, everything seems to be working pretty well with the grid you sent over

I'll have to fiddle around with it a tiny bit to get the Y axis probed a tiny bit farther back, but otherwise it's probably the best bed leveling I've ever seen on my printer. Thank you!

I'll have to fiddle around with it a tiny bit to get the Y axis probed a tiny bit farther back, but otherwise it's probably the best bed leveling I've ever seen on my printer. Thank you!  I'll take a look at the links above, and as an electronics student I mostly understand the coding aspect, Its just the math that gets me (And maybe some of the coding without realizing it haha).

I'll take a look at the links above, and as an electronics student I mostly understand the coding aspect, Its just the math that gets me (And maybe some of the coding without realizing it haha).Thanks again

-

I guess I have another question, why is the probe homing at some place to the right/front of the bed? is there another command to set the probe home position?

I also realized why the probe doesn't probe all the way to the back. It's because the nozzle itself can't reach all the way back there, so its out of the axis limits. At least that's what I think.

Everything is working pretty well now, Just gotta adjust some things in my slicer. Thank you!!!

-

@gtaman said in Mesh bed leveling (3/4 of the bed works flawlessly):

I guess I have another question, why is the probe homing at some place to the right/front of the bed? is there another command to set the probe home position?

Homing of the z axis is controlled by two things, homeall.g and homez.g. You can home the z axis individually or have it home as a set in home all. With my cartesian machines I tend to set the contents of homeall.g to refer to the other homing macros rather than write the detail out in two places. Yes there are some tricks to save a little time (particually with core XY) but to be honest I find it begging for mistakes having the two scripts do different things. My home all looks like:

; homeall.g

; called to home all axes

;

m98 Phomey.g

m98 Phomex.g

m98 Phomez.g@gtaman said in Mesh bed leveling (3/4 of the bed works flawlessly):

Everything is working pretty well now, Just gotta adjust some things in my slicer. Thank you!!!

Good to hear, no problem. Spent many an hour chasing an extra few mm on the probed bed area myself! Currently wrestling a large offset needed to put an 18mm body inductive sensor between the smooth rods and nozzle on a P3Steel machine!

-

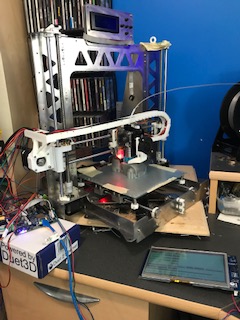

Hey! That looks pretty similar to my printer. Mine is the Tatara Hayabusa from thingiverse. I had protocase make it for me since I had a discount for being a student

I had to relocate my BL touch to the same location you're talking about. I originally started off with the Anet A8, and slowly upgraded everything. the only things left are the stepper motors, rods, and endstops.

I had to relocate my BL touch to the same location you're talking about. I originally started off with the Anet A8, and slowly upgraded everything. the only things left are the stepper motors, rods, and endstops.I was thinking of getting these, but I'm not sure if they'll work with the duet as I think you'll need removable stepper drivers.

https://spool3d.ca/mks-base-servo42-closed-loop-stepper-motor/

Maybe the duet has it built in? or maybe I just need stronger motors. I'll probably just start a new thread about it

Thanks one last time, I wouldn't have got it done over the weekend if it wasn't for your help lol